文章编号: 1004-0609(2006)09-1615-06

前驱体制备对三维通孔不锈钢泡沫性能的影响

周向阳, 龙波, 李劼, 刘宏专

(中南大学 冶金科学与工程学院, 长沙 410083)

摘 要: 研究前驱体中浆料浸入量与不锈钢粉末粒径对具有三维通孔网状结构不锈钢泡沫制品的开孔率和抗弯强度的影响。 研究发现: 随前驱体中浆料浸入量的增加, 泡沫制品的抗弯强度逐渐提高, 开孔率有所降低; 而随着粉末粒径的减小, 泡沫制品的抗弯强度显著增大, 其开孔率呈轻微降低的趋势。 当将44μm的316L不锈钢粉末与添加剂配成料浆浸入20ppi的聚氨酯海绵中, 制成浸入量0.5g/cm3的前驱体, 然后在(1260±2)℃时烧结30min, 可制得孔径大小为1mm左右、 具有良好三维通孔结构的不锈钢泡沫, 该泡沫的开孔率为81.2%, 抗弯强度为51.72MPa。

关键词: 不锈钢泡沫; 三维通孔; 开孔孔隙度; 抗弯强度 中图分类号: TG142.71

文献标识码: A

Effects of precursor preparation on performances of stainless steel foam with 3-D open cells network structure

ZHOU Xiang-yang, LONG Bo, LI Jie, LIU Hong-zhuan

(School of Metallurgical Science and Engineering, Central South University,Changsha 410083, China)

Abstract: The effects of the slurry loading and particle size of the stainless steel powder in the precursor on the open porosity and bending strength of stainless steel foams (SSFs) with 3-D open cells networks structure were investigated. The results show that the SSFs bending strength gradually increases and the open porosity falls with increasing the slurry loading in precursor; the bending strength remarkably improves and the open porosity reduces little by little with the particle size of stainless steel powder minishing. The 316L stainless steel powder and the additive sol are mixed to make slurry, subsequently the slurry is immerged into the sponge to obtain the precursor, in which the slurry loading is 0.5g/cm3, and then the precursor is sintered at the temperature of (1260±2)℃ for 30min, a stainless steel foam can be obtained, which has good 3-D open cells network structure, aperture of about 1mm, open porosity of 81.2% and bending strength of 51.72MPa.

Key words: stainless steel foam; 3-D open cells structure; open porosity; bending strength

多孔泡沫金属本身所固有的轻质、 高比强度的特点, 以及其所具有的过滤、 减振、 阻尼、 吸音、 隔音、 散热、 吸收冲击能和电磁屏蔽等多种物理性能, 使得其既可以用作结构材料, 又可以作为功能材料使用。 多孔泡沫金属在汽车和建筑等领域得到了越来越广泛的应用[1-4]。

现阶段研究得最多的是铝、 镁轻金属泡沫, 通常所用的制备方法有熔体直接发泡法、 渗流铸造法及粉末冶金法等[5-10]。 近几年来, 人们也开展了能抗腐蚀、 耐高温的钛及不锈钢等多孔金属材料的研究[11-13]。 多孔不锈钢大都采用加造孔剂的粉末冶金方法制备, 也有的使用纤维烧结的方法[14-19], 这两种方法所制备的主要是微孔或闭孔的泡沫不锈钢。 对具有三维通孔结构的高熔点、 高强度泡沫金属的制备研究, 国内外还罕见报道。

本研究小组在具有三维通孔结构的高熔点金属基泡沫方面进行了大量研究, 摸索出了多个制备该材料的工艺[20], 所研制的泡沫材料具有优异的粉尘或微粒捕集性能(即过滤性能)、 优异的抗高温腐蚀性能。 因而, 该材料可以用来过滤汽车尾气, 并可用作催化分解汽车尾气催化剂的载体; 当然, 该材料还可以对火电厂或冶金炉窑排放出来的含颗粒粉尘的烟气起过滤作用, 并可负载废气分解催化剂; 另外, 该泡沫材料还可用来对含微粒的溶液及高温熔体(如: 铝合金熔体、 粗四氯化钛溶液等)进行过滤。

本文作者主要研究了前驱体中料浆浸入量及其中不锈钢粉末粒径对具有三维通孔结构不锈钢泡沫的孔洞形貌、 孔隙率和力学性能的影响。

1 实验

1.1 多孔不锈钢制备过程

研究所用的主要原料有316L不锈钢粉末(其主要成分见表1, 平均粉末粒径分别为37、 44、 52和61μm), 20ppi、 径粗0.3mm的聚氨脂海绵, 添加剂及高纯氩气(99.999%)。

不锈钢泡沫样品的制备过程为: 将不锈钢粉末与适量添加剂配成具有一定固含的料浆, 随即将料浆浸入聚氨脂海绵中制成具有一定浸入量的前驱体, 然后在高纯氩气保护下, 于(1260±2)℃下烧结30min[20]。

表1 316L不锈钢粉末化学成分

Table 1 Chemical composition of 316Lstainless steel (mass fraction, %)

1.2 性能检测与表征

1) 前驱体中浆料浸入量的表征 利用单位体积(cm3)海绵泡沫中所浸浆料干质量(g)来进行表征。

2) 试样形貌的表征 利用高像素数码相机来观察所测试样的宏观形貌, 利用SEM(日本电子公司(JEOL)JSM5600型扫描仪)观察所测试样的截面形貌, 利用金相显微镜(XJP-6A)观察孔壁的形貌组织及微孔特征。

3) 表观密度与开孔率的计算 先在空气中称试样的质量m, 再将试样浸到熔融的石蜡中, 冷却后除去表面的蜡, 再次称其在空气中的质量m1,然后用铜丝吊住试样称其在水中的质量, 该质量除去铜丝的质量后即得到试样在水中的质量m2。 表观密度(da)和开孔率(θo)的计算公式为

4) 力学性能测试 采用CSS-44100型电子万能试验机测定试样的抗弯强度。 实验跨距30mm, 位移加荷速度为0.5mm/min, 所用试样尺寸为35mm×12mm×6mm。

2 结果与讨论

2.1 浆料浸入量对不锈钢泡沫表观密度、 开孔率与抗弯强度的影响

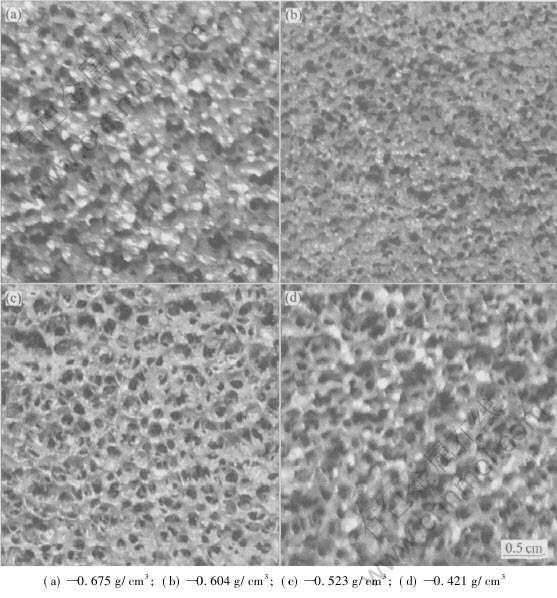

研究所用不锈钢粉末的平均粒径为44μm, 浆料浸入量控制在0.4~0.7g/cm3之间。 图1所示分别为采用0.675、 0.604、 0.523、 0.421g/cm3浸入量前驱体所制备的泡沫不锈钢的表观形貌。 可以看出, 浆料浸入量为0.675g/cm3时, 烧结制品的表面堵孔现象严重, 这势必会影响泡沫材料的三维通孔性; 而当浸入量为0.421g/cm3时, 烧结制品表面的闭孔较少, 但孔壁太薄, 这势必将影响材料的力学性能; 当浸入量为0.523g/cm3时, 烧结制品具有良好的表观孔洞形貌和三维通孔结构。 这表明, 前驱体中浆料浸入量对烧结制品的通孔性有一定的影响。

图2所示为浆料浸入量对烧结制品表观密度的影响规律。 显然, 随浆料浸入量的增加, 泡沫金属的表观密度增大, 浸入量从0.421g/cm3增加到0.675g/cm3, 表观密度从0.87g/cm3上升到1.37g/cm3。

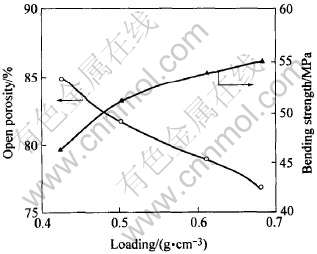

图3所示为料浆浸入量和烧结体开孔率与抗[CM(22]弯强度之间的关系。 不难发现, 浆料浸入量对不锈钢泡沫孔隙率与抗弯强度的影响较大。 浆料浸入量过少, 烧结后制品的抗弯强度太低; 浸入量过多, 将会使许多的孔洞堵塞, 影响多孔材料开孔率, 从而影响到材料的三维通孔性。

图1 不同浆料浸入量下金属泡沫的表观形貌

Fig.1 Apparent appearance of metal foams with different loadings

图2 浆料浸入量对表观密度的影响

Fig.2 Effects of loading on apparent density

图3 浆料浸入量对开孔孔隙率和抗弯强度的影响

Fig.3 Effects of loading on open porosity and bending strength

2.2 粉末粒度对多孔不锈钢开孔率与力学性能的影响

本次实验分别选用平均粒径为37、 44、 52和61μm的不锈钢粉末来制备泡沫不锈钢制品。 不锈钢粉末粒径同烧结体的开孔率与抗弯强度的关系分别列在图4和5中(浆料浸入量约为0.5g/cm3)。

从图4可以看出, 样品的开孔率随粉末粒径的减小而减小, 这主要是由于细粉末的比表面积大, 表面能高, 烧结驱动力大, 粉末间烧结更容易, 从而形成了较多闭孔所导致; 另外, 细粉末所得烧结制品的收缩较大, 也是导致开孔率降低的一个原因。 从图4还可以发现, 当粒径在37到52μm之间变化时, 泡沫制品的开孔率变化不明显, 此时开孔率的变化范围为(82±1)%。

图4 颗粒尺寸对开孔率的影响

Fig.4 Effects of particle size on open porosity

图5 颗粒尺寸对抗弯强度的影响

Fig.5 Effects of particle size on bending strength

不锈钢粉末粒径对烧结制品的抗弯强度影响明显, 细粒径粉末制得的制品的抗弯强度明显大于粗粒径粉末的。 当不锈钢粉末的平均粒径为61μm时, 抗弯强度仅为16.33MPa; 当使用44μm的金属粉末时, 烧结体的抗弯强度约为61μm时的3倍, 达到了51.76MPa。 出现这种现象的主要原因是: 粗粒径粉末所制备浆料的流动性能较差, 使得海绵中料浆的浸入量分布不均匀, 导致烧结出来的样品孔壁厚度不一致, 产生应力集中, 从而影响了样品的力学性能; 另外, 粗粒径粉末烧结样品具有孔隙球化程度不高、 在晶界上出现较大的孔洞及晶粒尺寸粗大等缺陷, 这些缺陷都将使得烧结制品的烧结致密化程度不高, 从而导致粗颗粒粉末所制备泡沫的抗弯强度较低。 粗粒径粉末烧结样品所具有的缺陷, 从图6中可以明显看出。

图6所示为采用粒径分别为61和44μm粉末制备的泡沫金属的孔壁金相照片。 显然, 粗粒径粉末(61μm)烧结样在晶界上出现的孔洞较大, 孔隙球化程度也不高, 其晶粒尺寸是细粒径(44μm)粉末烧结样的2~4倍; 细粒径粉末烧结样的粉末晶粒成近似球形, 晶界平滑, 晶界被较细小的闭孔隔开。 出现这些现象的主要原因是, 粗颗粒的表面能较细粉末的低, 烧结活性小。

图6 不同粒度粉末烧结样品的金相照片

Fig.6 Metallographic structures of sintered samples prepared from powders with different particle sizes

从图4和5中还可看出, 当不锈钢粉末粒径小于44μm后, 泡沫制品的开孔率与抗弯强度的变化不再明显。

2.3 优化条件下多孔不锈钢的外部形貌与内部结构

选用平均粒径为44μm不锈钢粉末作为原料, 前驱体中浆料浸入量在0.5g/cm2左右, (1260±2)℃温度下烧结30min后制备的三维通孔不锈钢泡沫的宏观形貌和截面SEM像如图7所示。 图7显示, 该泡沫不锈钢表面的孔洞分布比较均匀, 并且具有良好的网状结构, 其内部的孔洞分布也比较均匀, 孔径大小为1mm左右, 而且通孔性比较好;

图7 多孔不锈钢表面形貌与内部截面SEM像

Fig.7 Apparent appearance(a) and SEM image(b) of porous stainless steel

另外, 力学测试结果表明, 该多孔泡沫的抗弯强度达到50MPa以上。 这些表明, 本工艺所制备的不锈钢泡沫有作为汽车尾气分解催化剂载体的潜质。

3 结论

1) 多孔不锈钢的开孔率随浆料浸入量的增大而减小, 而抗弯强度有所提高。 综合考虑到多孔金属所需较高的孔隙率和较大的抗弯强度, 确定最佳的浸入量为0.5g/cm3左右。

2) 不锈钢粉末粒径对烧结制品的开孔率有一定的影响, 但影响并不显著; 粉末粒径对烧结制品的抗弯强度影响显著, 粉末越细, 烧结制品的抗弯强度越大。 当不锈钢粉末粒径小于44μm后, 泡沫制品的开孔率与抗弯强度的变化不再明显。

3) 选用粒径为44μm的不锈钢粉末作为原料, 前驱体浆料浸入量在0.5g/cm3左右, 1260℃温度下烧结30min后制备的三维通孔不锈钢泡沫具有较高的开孔率(81.2%)、 良好的三维通孔结构和较大的抗弯强度(51.72MPa), 该材料有作为汽车尾气分解催化剂载体的潜质。

REFERENCES

[1]汤慧萍, 张正德. 金属多孔材料发展现状[J]. 稀有金属材料与工程, 1997, 26(1): 1-6.

TANG Hui-ping, ZHANG Zheng-de. Development status of porous metal material[J]. Rare Metal Materials and Engineering, 1997, 26(1): 1-6.

[2]朱震刚. 金属泡沫材料的研究[J]. 物理, 1999, 28(2): 84-88.

ZHU Zheng-gang. Investigation of metal foam material[J]. Physics, 1999, 28(2): 84-88.

[3]徐光. 金属泡沫材料的性能[J]. 武汉冶金科技大学学报, 1998, 21(2): 154-160.

XU Guang. Performance of metal foam material[J]. Journal of Wuhan Metallurgy Science and Technology University, 1998, 21(2): 154-160.

[4]刘培生, 李铁潘, 傅超, 等. 多孔金属材料的应用[J]. 功能材料, 2001, 32(1): 12-15.

LIU Pei-sheng, LI Tie-fan, FU Chao, et al. Application of porous metal material[J]. Journal of Functional Material, 2001, 32(1): 12-15.

[5]Asholt P. Metallschaume[A]. Banhart J. Proc Symp Metallschaume[C]. Bremen: MIT Press-Verlag, 1997: 27.

[6]Wood J. Metal foams[A]. Banhart J, Eifert H. Proc Fraunhofer USA Symposium on Metal foams[C]. Bremen: MIT Press-Verlag,1998: 31.

[7]Asholt P. Metal foams and porous metal structures[A]. Banhart J, Ashby M F, Fleck N A. Int Conf[C]. Bremen: MIT Press-Verlag, 1999: 133.

[8]Renauld M L, Giamei A F, Thompson M S, et al. Porous and cellular materials for structural applications[A]. Schwartz D S, Shih D S, Evans A G, et al. MRS Symp Proc[C]. 1998, 521: 109.

[9]Neumann P. Metal foams and porous metal structures[A]. Banhart J, Ashby M F, Fleck N A. Int Conf[C]. Bremen: MIT Press-Verlag, 1999: 167.

[10]任建富, 王录才, 柴跃声. 泡沫铝合金材料的渗流法铸造方法初探[J].中国铸造设备与技术, 1994, 2: 42-45.

REN Jian-fu, WANG Lu-cai, CHAI Yue-sheng. Preliminary study on penetration casting process using foamed aluminum alloy material[J]. Foundry Equipment and Technology of China, 1994, 2: 42-45.

[11]贾英全, 曲凤泽, 史学娟, 等. 不锈钢纤维增强的不锈钢多孔材料的制备和力学性能[J]. 中国有色金属学报, 1998, 85(Suppl.2): 33-35.

JIA Ying-quan, QU Feng-ze, SHI Xue-juan, et al. Preparation and mechanics performance of stainless steel porous material enganced by stainless steel fibre[J]. The Chinese Journal of Nonferrous Metals, 1998, 85(Suppl.2): 33-35.

[12]张洪山. 海绵状不锈钢铸件的制造工艺[J]. 铸造, 1992, 4: 44.

ZHANG Hong-shan. Manufacture technology of sponginess stainless steel cast[J]. Foundry, 1992, 4: 44.

[13]林小芹, 贺跃辉, 江垚, 等. 不锈钢多孔材料过滤性能影响参数的实验研究[J].粉末冶金材料科学与工程, 2005, 10 (2): 128-132.

LIN Xiao-qin, HE Yue-hui, JIANG Yao, et al. Experimental study on effective parameters for filtration performances of stainless steel porous materials[J]. Materials Science and Engineering of Powder Metallurgy, 2005, 10 (2): 128-132.

[14]Park C, Nutt S R. PM synthesis and properties of steel foams[J]. Mater Sci Eng A, 2000, A288: 111-118.

[15]Park C, Nutt S R. Effects of process parameters on steel foam synthesis[J]. Mater Sci Eng A, 2001, A297: 62-68.

[16]方惠会, 黄朝强, 薛松. 金属纤维烧结滤毡孔隙结构的SEM分析[J]. 理化检验-物理分册, 2000, 36(6): 258-259.

FANG Hui-hui, HUANG Zhao-qiang, XUE Song. SEM analysis of hole structure of metal fibre sintered filtration felt[J]. Physics and Chemistry Test-Physics Fascicule, 2000, 36(6): 258-259.

[17]王同庆. 金属纤维烧结毡过滤材料过滤性能与科学应用[J]. 过滤与分离, 2003, 13(1): 26-28.

WANG Tong-qing. Filtration performance and science application of filtration material of metal fibre sintered felt[J]. Filtrating and Separating, 2003, 13(1): 26-28.

[18]Ambrozio F F, de Lima-Luis-Filipe C P, Jose M A, et al. Preparation and characterization of stainless steel filters[J]. Advances in Powder Metallurgy, 1992, 5: 439-444.

[19]Anon. Versatility and strength of sintered metal filters[J]. Power International, 1989, 35(406): 94.

[20]周向阳, 李劼, 龙波, 等. 三维通孔或部分孔洞彼此相连多孔金属泡沫及其制备方法[P]. 中国专利: 200510032174.7, 2005.

ZHOU Xiang-yang, LI Jie, LONG Bo, et al. The Preparation Means of the Porous Metal Foam with 3-D Open Cells or Portion Cells Connected with Each Other[P]. CN 200510032174.7, 2005.

基金项目: 湖南省科技计划重点资助项目

收稿日期: 2005-11-09; 修订日期: 2006-08-12

通讯作者: 周向阳, 副教授, 博士; 电话: 0731-8836329; E-mail: 13908482918@hnmcc.com

(编辑龙怀中)