J. Cent. South Univ. (2021) 28: 445-453

DOI: https://doi.org/10.1007/s11771-021-4614-0

Experimental investigation on fatigue of blade specimen subjected to resonance and effect of a damping hard coating treatment

CHEN Yu-gang(陈玉刚), ZHU Qing-yu(朱清玉), ZHAI Jing-yu(翟敬宇)

School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: Failures due to high-cycle fatigue have led to a high cost in aerospace engineering over the past few decades. In this paper, the experimental results of the fatigue behavior of compressor blade specimen subjected to resonance and the effects of a damping hard coating on relieving the fatigue progress are presented. The crack initiation and propagation processes were observed under resonance of the first bending mode by using the resonant frequencies as the indicator. Significant nonlinear features were observed in the spectrum of the blade with a fatigue crack. The finite element model considering the breathing crack was established with nonlinear contact based on the crack localization and size, which was obtained by ultrasonic phased array technology. The simulation results of the vibration behavior of the cracked blade were obtained and consistent with the experimental results. A NiCrAlY coating was deposited on the blade, and increases in the fatigue life were observed under the same condition. The results of this paper can help to better understand the fatigue of a compressor blade subjected to resonance and provide a preference for the application of a damping hard coating on compressor blades.

Key words: blade vibration; high-cycle fatigue; fatigue test; damping hard coating

Cite this article as: CHEN Yu-gang, ZHU Qing-yu, ZHAI Jing-yu. Experimental investigation on fatigue of blade specimen subjected to resonance and effect of a damping hard coating treatment [J]. Journal of Central South University, 2021, 28(2): 445-453. DOI: https://doi.org/10.1007/s11771-021-4614-0.

1 Introduction

High-cycle fatigue (HCF) failure, which is mainly caused by vibration, has plagued compressor blades in aero-engines and led to a high cost for the past few decades [1]. Failures of high-speed rotating compressor blades are very dangerous because broken blades can puncture the engine casing and directly affect flight safety. Failure analysis of the blades due to HCF has received attention from many investigations. Experimental studies and numerical estimations of the fatigue life have been presented in some works. Using analytical derivation and finite element analysis, AHMED et al [2] predicted the life of a compressor blade subjected to dynamic loadings and investigated the allowable crack size in the blade to avoid sudden failure. WITEK [3, 4] studied the crack growth characteristics of compressor blades subjected to a resonant vibration by simulation and experimentation, and obtained a crack length change curve with the number of load cycles. DHAR et al [5] estimated the fatigue life of a turbine blade considering the combined effects of vibratory, centrifugal, and thermo-elastic stresses.

For the fatigue of notched specimens, some worthy researches were carried out by researchers.

The influence of notches on the fatigue life of metallic structural components was analyzed, and notches with different shapes were examined in the case of both double-curvature shells and round bars [6]. The fracture behavior of a Francis hydraulic turbine runner blade with a semi-elliptical crack subjected to bending loading was analyzed, by simplifying the blade and its welded connection by a T-joint [7]. The strain-based multiaxial fatigue criterion previously proposed for smooth specimens was extended to notched specimens [8], which is a reformulation of the stress-based multiaxial HCF criterion. Modelling and analyses of the vibration characteristics of a beam/plate (which can be considered a simplified blade) with a crack are also a hot topic for fatigue analysis. CHONDROS et al [9] theoretically analyzed the vibration characteristics of simply supported beams with breathing cracks and found that the eigenvalue change caused by the cracks was related to the bilinear characteristics of the crack system. ORHAN [10] analyzed the free vibration and forced vibration of cracked beams based on the finite element method and suggested that the response of the forced vibration better described the changes in the crack depth and location than the free vibration. WAHEED et al [11] studied the nonlinear vibration response characteristics of a blade with a breathing crack and found that the larger crack length corresponded to more nonlinear disturbances in the dynamic response behavior. ZENG et al [12] performed researches on the cracked compressor blade with varying-section and twisted shape considering the rotational effects and comparatively accurate crack propagation paths. ZHAO et al [13] established a model of pre-twisted rotating blade with a breathing crack by proposing a new breathing model that considered the rotating and pre-twisted effects of the blade.

The published studies show that most investigations concentrate on seeking the cause of blade fatigue by combining crack detection, a Campbell diagram and stress analysis or attempting to estimate the failure life according to damage accumulation and fracture mechanics theories. For analysis of the vibration characteristics of a cracked blade, cracks are mostly pre-established on the structure instead of resulting from a practical vibration fatigue process.

Hard coating is generally used as a surface treatment to allow the composite structure to have a special and superior performance, such as thermal barrier coatings and anti-corrosive coatings [14-16]. In recent years, hard coatings have been used as damping treatments for vibration reduction in titanium plates as a simplification of the blade [17] because of its better stability than the viscoelastic damping layer or constrained damping layer in severe environments. The damping mechanism was assumed and experimentally supported to be friction among particles [18] and the friction among internal micro-cracks [19, 20]. Some studies [21-23] have also applied a damping hard coating on bladed disks and obtained positive results.

In this paper, the fatigue behavior of compressor blade specimen subjected to resonance and the effects of a damping hard coating were investigated. The fatigue crack initiation and propagation processes were observed under resonance of the first bending mode. Nonlinear features were observed for a blade with a fatigue crack in both experimentally and via simulation. The effects of the damping hard coating on the fatigue life of the blade specimen were observed under the same conditions after depositing a NiCrAlY coating. The results of this paper can help to better understand the fatigue of compressor blades subjected to resonance and provide a preference for the application of damping hard coatings on compressor blades.

2 Experimental setup

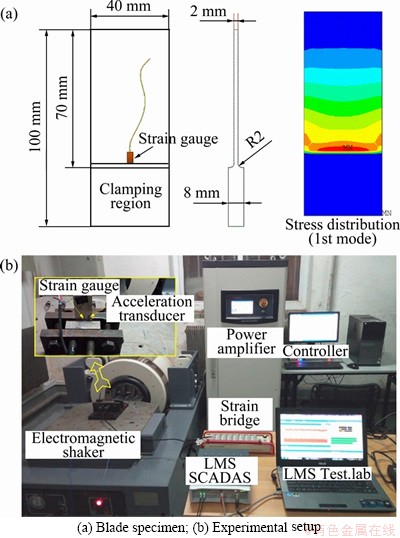

The blade specimen was designed considering the features of a compressor blade, as shown in Figure 1(a). The length, width and thickness of the blade specimen were 70 mm, 40 mm and 2 mm, respectively. A clamping region with a 30 mm height and 8 mm thickness was designed for convenient clamping. The rounded corner was designed to avoid stress concentration. To observe the fatigue behaviour under different stress levels, 6 blade specimens were manufactured with identical geometry using 45 steel (the elastic modulus is 220 GPa) and treated by thermal refining, and the yield stress was achieved to be higher than 600 MPa.

The layout of the fatigue test system is shown in Figure 1(b). The equipment and software used in the fatigue test system are listed as follows. The shaker and its power amplifier and controller were used to subject the blade to resonance. Strain gauges with the signal conditioner were used to measure the strain (ε) of the blade specimen and then the stress (σ) was obtained by σ=Eε, where  is the elastic modulus of specimen. The strain gauge was attached on the surface at the root of the blade specimen, which is the largest stress zone on the blade surface under the first mode resonance, as shown in Figure 1(a). Considering the fragility of the strain gauge, an accelerometer was simultaneously used to monitor the vibration amplitudes of the blade specimen. LMS Test. lab and LMS SCADAS III were used to gather and display the dynamic vibration signals in real time.

is the elastic modulus of specimen. The strain gauge was attached on the surface at the root of the blade specimen, which is the largest stress zone on the blade surface under the first mode resonance, as shown in Figure 1(a). Considering the fragility of the strain gauge, an accelerometer was simultaneously used to monitor the vibration amplitudes of the blade specimen. LMS Test. lab and LMS SCADAS III were used to gather and display the dynamic vibration signals in real time.

Figure 1 Blade specimen and experimental setup of fatigue test system:

During the fatigue test, the blade specimen was clamped by the customized holder, which was similar to the cantilevered boundary condition. At set intervals, the resonant frequency of the blade specimen was accurately recognized by a waterfall plot under sine sweep excitation. Then, the obtained resonant frequency was used as the excitation frequency, which subjected the blade specimen to resonance.

3 Results and analyses

3.1 Decrease of resonant frequency

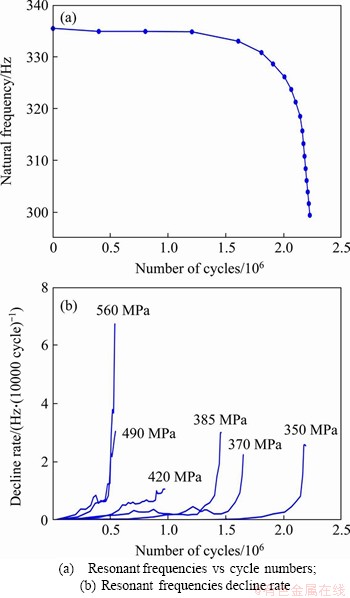

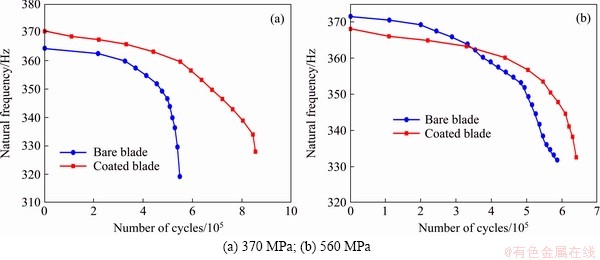

Different stress levels were applied to each blade specimen by providing different acceleration magnitudes of the base excitation using a shaker: 350 MPa, 370 MPa, 385 MPa, 420 MPa, 490 MPa and 560 MPa. The resonant frequencies of the blade specimen after different cycles were recorded as shown in Figure 2.

Figure 2 Change in the resonant frequencies of blade specimen with number of cycles:

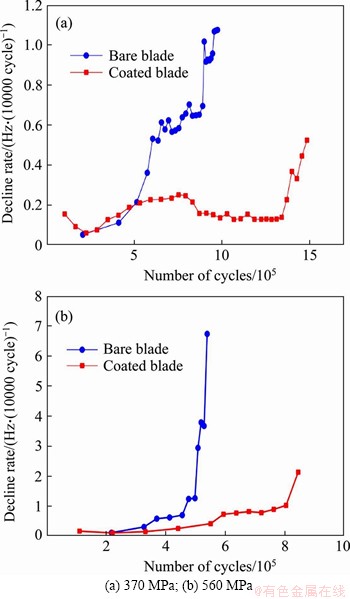

Figure 2(a) shows that the resonant frequency slightly changes at the early stage and rapidly decreases after a number of cycles. The early stage, where the resonant frequencies slightly change, can be considered the stage of fatigue crack initiation, and the following stage, where the frequencies rapidly decline, is the crack propagation process. The decline rates of the resonant frequencies under different stress levels are calculated and shown in Figure 2(b), which shows that the rates of decrease of the resonant frequency increase with the number of cycles and stress levels. Crack initiation and propagation tend to be faster under higher stress levels.

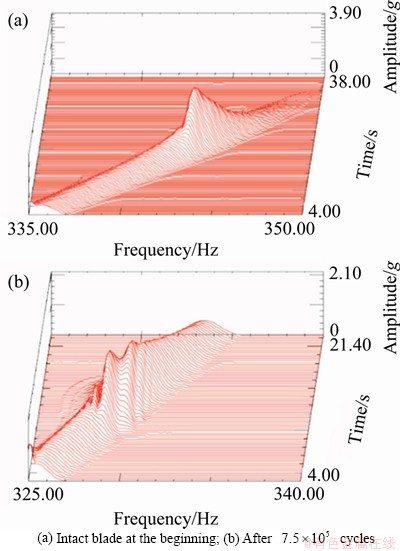

3.2 Features in 3D spectrogram and fatigue crack detection

A special “double peak” phenomenon was observed during the fatigue test, as shown in Figure 3. Figure 3(a) shows a waterfall plot of the intact blade, where a single peak appears when the excitation frequency encounters the resonant frequency. Figure 3(b) shows a waterfall plot after 7.5×105 cycles under a resonance stress of 420 MPa, where two adjacent peaks appear and the lower frequency has higher peak amplitude than the other one.

Figure 3 Waterfall plots during the sine sweep test:

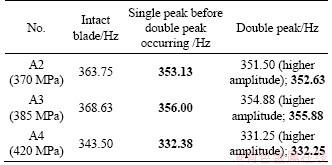

The frequencies of the double peaks, the single frequency before the double peaks occur and the frequency of the intact blade, are listed in Table 1. The higher frequency of the double peaks is close to the frequency before the double peaks occur. The resonant frequencies of the blade specimen decrease by 3.37%, 3.73% and 3.57% when the double-peak phenomenon occurs. This phenomenon can be used as an indicator for the appearance of a fatigue crack. Ultrasonic phased array inspection technology was used to detect the crack size and location to visually observe the fatigue crack state.

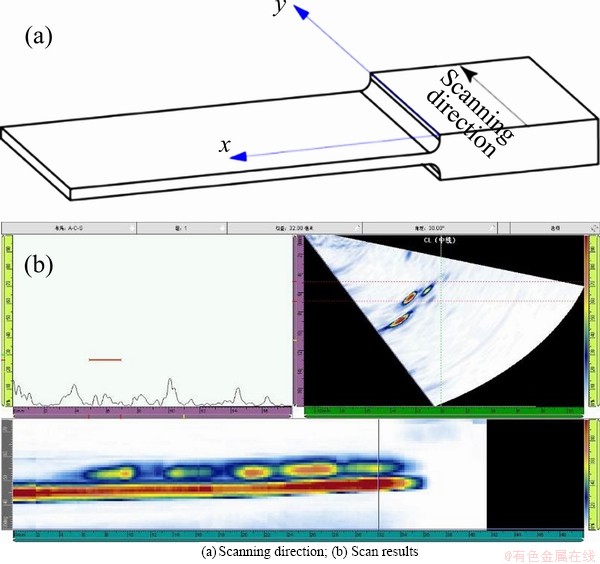

Figure 4 shows the scanning results of the ultrasonic phased array inspection when the double peak phenomenon occurs. The crack can be seen at one side of the blade root. The size and location of the crack can be determined and are listed in Table 2. In some published papers [24, 25], vibration fatigue failure is defined as a fundamental resonant frequency decrease of 5%. In this paper, fatigue failure occurs when the 1st-order resonant frequency decreases by 4% according to the results of the double-peak features and crack detection.

Table 1 Peak frequencies of “double peaks” and “single peak” curves

Figure 4 Ultrasonic phased array inspection of cracks:

Table 2 Quantitative information of the blade crack

3.3 Nonlinear vibration characteristics

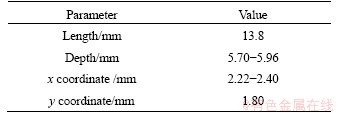

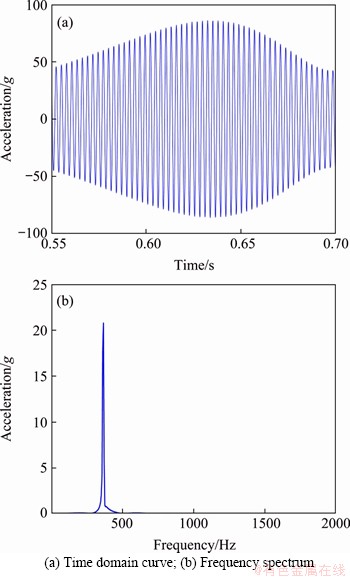

Figure 5 shows the response of the cracked blade under sine excitation at a fixed frequency. For the cracked blade, an obvious multi-harmonic vibration was observed, as shown in Figure 5, and the even harmonics had higher amplitudes than the odd harmonics.

To account for this phenomenon, a finite element model of the cracked blade was established in ANSYS by using the geometry and material parameters as the same as the specimen, and a numerical simulation was conducted. The SOLID186 element was used to mesh the model of the blade specimen. The “surface to surface” contact element was used to simulate the breathing crack. Base excitation was applied on the finite element model, by applying the harmonic acceleration on the model. For the nonlinear characteristics, transient analysis under frequency sweeping was used by accelerating the base excitation instead of performing linear modal analysis.

Figure 5 Nonlinear vibration responses (test results):

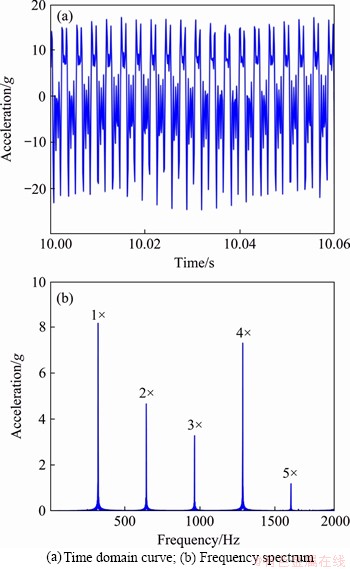

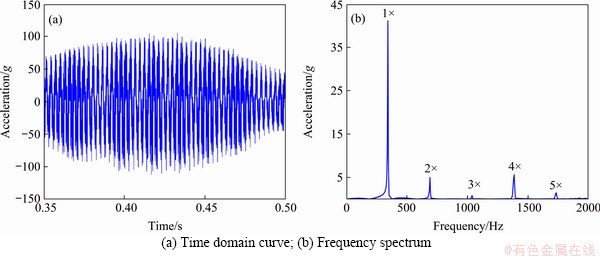

Figure 6 shows the time spectrum of the contact pressure and the corresponding contact status of the crack. A zero value of the contact pressure occurs in the crack open state, where the maximum stress is located at the crack tip. In the crack closed state, the maximum stress is located at the centre of the blade root on the intact side. The acceleration responses of the intact and cracked blades near the resonance were extracted, as shown in Figure 7 and Figure 8, respectively. A single frequency was observed in the frequency spectrum of the intact blade, while harmonic frequencies were observed in the frequency spectrum of the cracked blade.

Figure 6 Contact pressure and corresponding crack contact status

Figure 7 Vibration response of intact blade (simulation results):

4 Effect of damping hard coating treatment

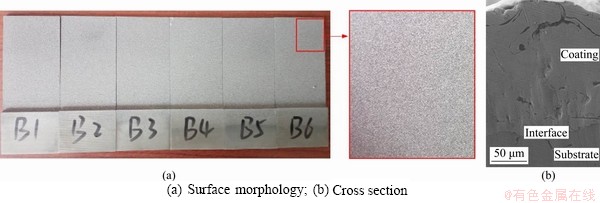

The NiCrAlY coating has been validated to have a good damping capacity, which can increase the loss factors and reduce the vibration of the blade and bladed disk [21-23]. In this study, a NiCrAlY coating with a thickness of 200 μm was deposited on the blade specimen by air plasma spraying (APS), as shown in Figure 9(a), to investigate its effect on fatigue on the blade subjected to resonance. The cross-section constitution diagram of NiCrAlY coating is shown in Figure 9(b). Material parameters of the NiCrAlY coating were obtained from the results of dynamic thermomechanical analysis (DMA) under room temperatures as listed below: elastic modulus is 56.6 GPa, density is 2840.7 kg/m3 and the loss factor is 0.0099.

Figure 8 Vibration response of cracked blade (simulation results):

Figure 9 Blade test piece with NiCrAlY coating of 200 μm thickness on a single side:

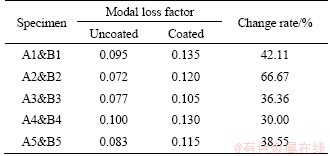

Before the fatigue test under resonance, the first order modal loss factors of the specimens were measured and compared with the uncoated specimens. Test results are shown in Table 3. It reveals that the modal loss factors increased more than 30% after the coating treatment by NiCrAlY. In the researches of cryogenic laser peening, HUANG et al [26] found that improving the damping ratio can increase the vibration fatigue life of TC6 titanium alloy.

The coated specimens were excited by the same stress level as the corresponding bare blade. A similar phenomenon was observed as “change little to decline rapidly”. However, obviously more cycles were required for the same decrease in percentage of the resonant frequency than for the bare blade, as shown in Figure 10.

Figure 11 compares the frequency reduction rates of the bare and coated blade specimens under identical excitation conditions. The coated blade specimen had a lower increasing speed of the rate of the decrease of the resonant frequency, which implies that the damping hard coating helps to decelerate the fatigue progress.

Table 3 Modal loss factors of coated and uncoated specimen

Figure 10 Resonant frequency changes of the coated blade specimen:

Figure 11 Frequency decline speed of blades with and without a hard coating:

5 Conclusions

In this paper, the fatigue behaviours of compressor blade specimens subjected to resonance and the effects of a damping hard coating were investigated. The fatigue crack initiation and propagation processes were observed under resonance of the first bending mode by using the resonant frequencies as the indicator. The effects of the damping hard coating on the fatigue life of the blade specimen were observed under the same condition after depositing a NiCrAlY coating. The following conclusions are drawn.

1) The decrease in the resonant frequencies can indicate the fatigue state. The state can be considered fatigue when the first-order resonant frequency decreases by 4% based on the results of the frequency sweep and crack detection. And the decrease rate of resonant frequency can reveal the fatigue crack growth of the specimen.

2) Some nonlinear vibration phenomena occur when the fatigue crack size increases to a certain extent, such as the double-peak phenomenon and multi-harmonic vibration, which can also be considered indicators of fatigue failure.

3) Damping hard coating treatments can increase damping coefficient of the specimen and then reduce fatigue failure by extending the cycles of the crack initiation and propagation process.

Contributors

The overarching research goals were developed by CHEN Yu-gang and ZHAI Jing-yu. CHEN Yu-gang and ZHU Qing-yu carried out the fatigue test and analyzed the experimental data. CHEN Yu-gang and ZHU Qing-yu established the finite element model and calculated the predicted vibration response. ZHAI Jing-yu and ZHU Qing-yu analyzed the calculated results. The initial draft of the manuscript was written by CHEN Yu-gang and ZHU Qing-yu. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

CHEN Yu-gang, ZHU Qing-yu, and ZHAI Jing-yu declare that they have no conflict of interest.

References

[1] YOUNOSSI O, ARENA M V, MOORE R M, LORELL M A, MASON J, GRASE J C. Military jet engine acquisition: Technology basics and cost-estimating methodology [R]. Santa Monica: Rand Corporation, 2002. https://www.rand. org/pubs/monograph_ reports/MR1596.html.

[2] AHMED M, ULLAH H, RAUF A. Fracture mechanics based fatigue life estimation of axial compressor blade [C]// 13th International Bhurban Conference on Applied Sciences and Technology IEEE. Islamabad, Pakistan, 2016: 69-74. DOI: 10.1109/IBCAST.2016.7429856.

[3] WITEK L. Experimental crack propagation and failure analysis of the first stage compressor blade subjected to vibration [J]. Engineering Failure Analysis, 2009, 16: 2163-2170. DOI: 10.1016/j.engfailanal.2009.02.014.

[4] WITEK L. Simulation of crack growth in the compressor blade subjected to resonant vibration using hybrid method [J]. Engineering Failure Analysis, 2015, 49: 57-66. DOI: 10.1016/j.engfailanal.2014.12.004.

[5] DHAR D, SHARAN A M, RAO J S. Transient stress analysis and fatigue life estimation of turbine blades [J]. Journal of Vibration and Acoustics, 2004, 126: 485-495. DOI: 10.1115/POWER2016-59336.

[6] CARPINTERI A, RONCHEI C, VANTADORI S. Stress intensity factors and fatigue growth of surface cracks in notched shells and round bars: two decades of research work [J]. Fatigue and Fracture of Engineering Materials and Structures, 2013, 36(11): 1164-1177. DOI: 10.1111/ffe. 12092.

[7] VANTADORI S, CARPINTERI A, SCORZA D. Simplified analysis of fracture behaviour of a Francis hydraulic turbine runner blade [J]. Fatigue and Fracture of Engineering Materials and Structures, 2013, 36(7): 679-688. DOI:10.1111/ffe.12036.

[8] CARPINTERI A, BERTO F, CAMPAGNOLO A, FORTESE G, RONCHEI C, SCORZA D, VANTADORI S. Fatigue assessment of notched specimens by means of a critical plane-based criterion and energy concepts [J]. Theoretical and Applied Fracture Mechanics, 2016, 84: 57-63. DOI: 10.1016/j.tafmec.2016. 03.003.

[9] CHONDROS T G, DIMAROGONAS A D, YAO J. Vibration of a beam with a breathing crack [J]. Journal of Sound and Vibration, 2001, 239: 57-67. DOI:10.1006/jsvi.2000.3156.

[10] ORHAN S. Analysis of free and forced vibration of a cracked cantilever beam [J]. NDT & E International, 2007, 40(6): 443-450. DOI:10.1016/j.ndteint.2007.01.010.

[11] WAHEED S O, MOSTAFA N H, JAWAD D H. Nonlinear dynamic characteristics of a simple blade with breathing crack using ansys software [J]. World Journal of Mechanics, 2011, 1: 21-30. DOI: 10.4236/wjm.2011.12004.

[12] ZENG J, CHEN K, MA H, DUAN T T, WEN B C. Vibration response analysis of a cracked rotating compressor blade during run-up process [J]. Mechanical Systems and Signal Processing, 2019, 118: 568-583. DOI: 10.1016/j.ymssp.2018. 09.008.

[13] ZHAO C, ZENG J, MA H, NI K, WEN B. Dynamic analysis of cracked rotating blade using cracked beam element [J]. Results in Physics, 2020, 19: 103360. DOI: 10.1016/j.rinp. 2020.103360.

[14] PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications [J]. Science, 2002, 296: 280-284. DOI: 10.1126/science.1068609.

[15] SHAO Fang, YANG Kai, ZHAO Hua-yu, LIU Chen-guang, WANG Liang, TAO Shu-yan. Effects of inorganic sealant and brief heat treatments on corrosion behavior of plasma sprayed Cr2O3–Al2O3 composite ceramic coatings [J]. Surface and Coatings Technology, 2015, 276: 8-15. DOI:10.1016/ j.surfcoat.2015.06.045.

[16] CARPINTERI A, DI COCCO V, FORTESE G, IACOVIELLO F, NATALI S, RONCHEI C, SCORZA D, VANTADORI S. Kinetics of intermetallic phases and mechanical behaviour of ZnSn3% hot-dip galvanization coatings [J]. Advanced Engineering Materials, 2016, 18(12): 2088-2094. DOI: 10.1002/adem.201600254.

[17] EASTERDAY O T. An experimental characterization of damping properties of thermal barrier coatings at elevated temperatures [D]. Ohio: Air Force Institute of Technology, 2011. https://www.proquest.com/docview/868175967.

[18] TORVIK P J, LANGLEY B. Material properties of hard coatings developed for high damping [C]// 51st AIAA/SAE/ASEE Joint Propulsion Conference. Orlando: Florida, 2015, 1-17. DOI: 10.2514/6.2015-4195.

[19] ZHAI Jing-yu, SONG Xin-yuan, YU Ying-dan, WU Hong-chun, PAN Xin-wei. Elastic modulus and damping of coatings based on microscopic defects [J]. Surface Engineering, 2019, 35: 512-519. DOI: 10.1080/02670844. 2018.1512234.

[20] ZHAI J, SONG X, XU A, CHEN Y G, HAN Q K. Dislocation damping and defect friction damping in magnesium: Molecular dynamics study [J]. Metals and Materials International, 2019. DOI: 10.1007/s12540-019- 00566-y.

[21] CHEN Yu-gang, ZHAI Jing-yu, HAN Qing-kai. Vibration and damping analysis of the bladed disk with damping hard coating on blades [J]. Aerospace Science and Technology, 2016, 58: 248-257. DOI:10.1016/j.ast.2016.08.016.

[22] CHEN Yu-gang, ZHAI Jing-yu, HAN Qing-kai. Multiobjective optimization of hard coating parameters designing for damping of the bladed disk [J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2018, 232: 1609-1619. DOI: 10.1177/ 0954410017703149.

[23] CHEN Yu-gang, WU Hong-chun, ZHAI Jing-yu, CHEN Hui, ZHU Qing-yu, HAN Qing-kai. Vibration reduction of the blisk by damping hard coating and its intentional mistuning design [J]. Aerospace Science and Technology, 2019, 84: 1049-1058. DOI: 10.1016/j.ast.2018.11.043.

[24] SPOTTSWOOD S M, WOLFE H F. Comparing fatigue life estimates using experimental and spectral density based probability distributions [J]. Journal of Aircraft, 2002, 39(3): 493-498. DOI: 10.2514/2.2955.

[25] HU Hai-tao, LI Yu-long, SUO Tao, ZHAO Feng, MIAO Ying-gang, XUE Pu, DENG Qiong. Fatigue behavior of aluminum stiffened plate subjected to random vibration loading [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1331-1336. DOI: 10.1016/S1003- 6326(14)63196-4.

[26] HUANG Y, ZHOU J, LI J, TIAN X, MENG X, HUANG S. Effects of cryogenic laser peening on damping characteristics and vibration fatigue life of TC6 Titanium alloy [J]. Chinese Journal of Lasers, 2020, 47: 149-156. DOI: 10.3788/ CJL202047.0402011. (in Chinese).

(Edited by HE Yun-bin)

中文导读

共振态下叶片试验件的疲劳试验研究及硬涂层阻尼的影响

摘要:高周疲劳导致的失效在过去几十年内对航空工程领域造成了巨大损失。本文给出了压气机叶片试验件在共振态下的疲劳试验结果,以及阻尼硬涂层对延缓振动疲劳的影响。以共振频率的变化为指标观测了一阶弯曲共振下的叶片试验件裂纹萌生和扩展过程;在出现疲劳裂纹叶片的振动时域图和频谱图中观察到了明显的非线性特征。利用超声相控阵技术辨识了疲劳裂纹的位置和尺寸,进而使用非线性接触的方法建立了考虑呼吸效应的裂纹叶片有限元模型,得到的裂纹叶片振动特性仿真结果与试验结果一致。在相同的试验条件下,通过在叶片试验件表面喷涂NiCrAlY涂层,研究发现试验件的阻尼性能明显提高、振动疲劳寿命延长。本文的研究结果有助于更好地理解压气机叶片的振动疲劳特性,为阻尼硬涂层在压气机叶片上的应用提供参考。

关键词:叶片振动; 高周疲劳; 疲劳测试; 阻尼硬涂层

Foundation item: Project(DUT20RC(3)014) supported by the Fundamental Research Funds for the Central Universities, China; Project (VCAME201801) supported by Key Laboratory of Vibration and Control of Aero-Propulsion System (Ministry of Education), China; Project(11472068) supported by the National Natural Science Foundation of China

Received date: 2020-05-30; Accepted date: 2020-10-22

Corresponding author: CHEN Yu-gang, PhD, Associate Professor; E-mail: cyg@dlut.edu.cn; ORCID: https://orcid.org/0000-0002- 1383-0391