DOI: 10.11817/j.ysxb.1004.0609.2021-39793

上引连铸-连续挤压技术制备Cu-Cr-Zr合金的组织与性能

张文婧1, 2, 3,解浩峰1,彭丽军1,黄国杰1,杨 振1,米绪军1,黄 略1, 2,汪礼敏3

(1. 有研工程技术研究院有限公司 有色金属材料制备加工国家重点实验室,北京 101400;

2. 北京有色金属研究总院,北京 100088;

3. 有研粉末新材料(北京)有限公司,北京 101400 )

摘 要:采用上引连铸-连续挤压技术制备Cu-0.88Cr-0.14Zr(质量分数)合金,并对挤压后的棒材进行不同制度的时效处理。利用扫描电子显微镜(SEM)、透射电子显微镜(TEM)、电子背散射技术(EBSD)等分析测试手段研究合金经不同工艺/制度处理后的组织与性能的变化。结果表明:上引连铸Cu-Cr-Zr合金棒坯在连续挤压过程中发生了剧烈的剪切变形和动态时效,晶粒明显细化,析出尺寸为15~20 nm的Cr相,与铸态相比,挤压态合金的导电率与硬度分别增加了28.6%IACS、49.6 HV。确定了挤压态合金杆材经(925 ℃,12 h)均匀化退火和(1000 ℃,1 h)固溶处理后的峰时效制度是(475 ℃, 3 h),此时基体中析出了平均晶粒尺寸为2.6 nm的Cr相,合金的导电率和硬度分别可达73%IACS、155 HV。

关键词:Cu-0.88Cr-0.14Zr合金;上引连铸-连续挤压;时效处理;导电率;硬度

文章编号:1004-0609(2021)-05-1168-08 中图分类号:TG146.1 文献标志码:A

引文格式:张文婧, 解浩峰, 彭丽军, 等. 上引连铸-连续挤压技术制备Cu-Cr-Zr合金的组织与性能[J]. 中国有色金属学报, 2021, 31(5): 1168-1175. DOI: 10.11817/j.ysxb.1004.0609.2021-39793

ZHANG Wen-jing, XIE Hao-feng, PENG Li-jun, et al. Microstructure and properties of Cu-Cr-Zr alloy fabricated by up-drawn casting-continuous extrusion[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(5): 1168-1175. DOI: 10.11817/j.ysxb.1004.0609.2021-39793

Cu-Cr-Zr合金具有良好的力学、导电、抗高温软化等综合性能,在电气化轨道交通、电子工业、国防工业等领域得到了广泛应用[1-3]。科研工作者们对高强高导Cu-Cr-Zr系合金中合金元素、制备加工工艺以及显微组织优化等方面对合金性能的影响规律开展了系统研究,并取得了一定的进展[4-8]。由于Cr、Zr元素在大气环境下易氧化,目前国内主要采用真空熔炼-热加工方式进行高强高导铜铬系材料制备[9-11],该常规制备加工技术存在生产效率低、能耗高等缺点,无法实现大长度、性能均匀的线材、带材等产品产业化生产,降低了我国基本铜加工产品在国际市场上的竞争力[12]。

上引连续铸造制备-连续挤压工艺是金属熔体在熔体压力的作用下被压入小尺寸的真空结晶器中不断快速凝固,获得表面光洁的铜合金杆坯的一种铸造工艺;连续挤压时,铜杆坯在摩擦轮的作用力下在模孔中发生强塑性变形,变形过程中产生的摩擦力成为加热金属的热源,可实现金属的动态再结晶[13-14]。上引连续铸造和连续挤压组合工艺可有效缩短铜合金杆坯的制备流程,降低能源消耗,现已广泛地应用于紫铜、黄铜等合金的工业化生产[15-19]。徐高磊等[12, 14]研究了上引-连铸挤压法制备铜铬银合金的组织与性能,确定了铜铬银合金的上引连铸工艺参数。铜铬锆合金作为一种析出强化型合金,其连续挤压过程比较复杂,会发生晶粒细化和第二相析出。目前,对于铜铬锆合金在连续挤压过程中的组织演变及性能变化的研究较少,因此,本文以Cu-0.88Cr-0.14Zr合金为研究对象,采用上引连铸、连续挤压技术制备Cu-Cr-Zr合金,系统研究该合金在短流程制备加工、时效处理过程中的微观组织、力学/电学性能演变规律,为实现Cu-Cr-Zr合金的短流程制备提供数据支持和理论依据。

1 实验

1.1 实验材料

本研究中使用的合金材料实测成分为:0.88Cr,0.14Zr,余量为Cu(质量分数,%)。采用上引连铸技术制备出d 20 mm的Cu-Cr-Zr合金棒材后直接在TJ400 Conform连续挤压机上进行连续挤压,获得 d 13.5 mm的杆材。为了改善合金组织和性能,对杆材进行(925 ℃,12 h)均匀化退火和(1000 ℃,1 h)固溶处理后,进行时效处理,时效温度分别为425、450、475、500 ℃,时效时间分别为1、2、2.5、3.5、3、4、12 h。

1.2 实验方法

分别在WILSON VH1150型维氏硬度计和Sigma 2008型电导仪上对不同状态的Cu-Cr-Zr合金样品进行硬度和导电率测试。采用JEOL JSM- 7001F型场发射扫描电镜对铸态和挤压态的样品进行微观组织的观察。在JEM 2010型透射电镜下对不同状态的样品进行微观组织TEM分析,透射样品的制备步骤为:先采用线切割的方法切取厚度为0.5 mm的薄片;将薄片在砂纸上机械减薄至60 μm左右;用铳孔器从薄片上冲出d 3 mm的圆片;在Struers TenuPol-5型双喷电解减薄仪上对圆片进行减薄和穿孔,双喷电解液采用体积比为1:4的硝酸和甲醇混合液,工作电流为35~40 mA,液氮控制温度为-35~-40 ℃。

2 结果与讨论

2.1 上引连铸-连续挤压Cu-Cr-Zr合金的组织与性能分析

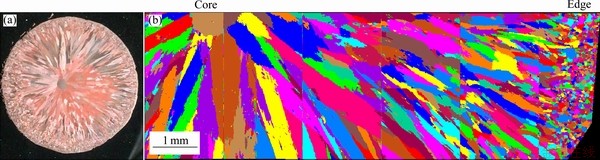

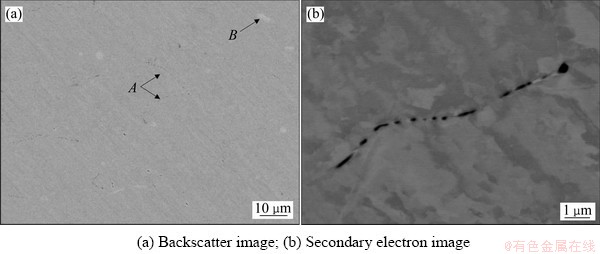

图1所示为上引连铸Cu-0.88Cr-0.14Zr合金棒坯的宏观组织照片。由图1可见,合金的宏观组织呈现出典型的铸造组织特征,即芯部和边部均为等轴晶,尺寸分别约为1mm和100μm,两者中间为粗大的柱状晶。图2所示为Cu-Cr-Zr合金棒坯微观组织的SEM像。从图2(a)背散射照片可以看出,棒坯铸态组织由灰色的富Cr相枝晶组织(A处)(见图2(b)为枝晶处析出富Cr相的放大图)、白色的富Zr相(B处)和Cu基体三部分组成。其中,白色的富Zr相呈棒状和块状。表1所列为各部位的能谱结果,同样证明了A处的灰色枝晶组织为富Cr相,B处的白色相为富Zr相。

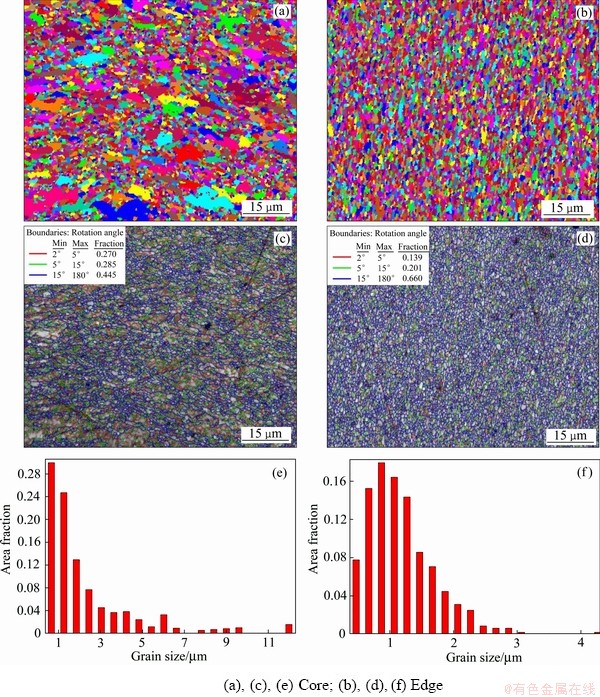

图3所示为上引连铸Cu-0.88Cr-0.14Zr合金铸坯经单道次连续挤压后的显微组织及晶粒尺寸统计图。观察发现,上引连铸Cu-0.88Cr-0.14Zr合金铸坯在连续挤压过程中发生了剧烈的剪切变形,晶粒明显细化,平均晶粒尺寸为1~2 μm,且边部晶粒细化更明显。观察图3(e)和(f)发现,破碎的晶粒主要由大量的大角度再结晶晶粒和小角度亚晶组成。且与芯部相比,边部晶粒大角度晶界所占比例更高(占比为66%),表明Cu-0.88Cr-0.14Zr合金经单道次连续挤压后,边部变形更充足,促进了再结晶过程。

图1 Cu-0.88Cr-0.14Zr合金上引连铸棒坯的显微组织

Fig. 1 Microstructures of Cu-0.88Cr-0.14Zr alloy up-drawing continuous casting billet

图2 Cu-0.88Cr-0.14Zr合金棒坯铸态组织SEM像

Fig. 2 SEM images of as-cast Cu-0.88Cr-0.14Zr alloy

图3 Cu-0.88Cr-0.14Zr合金铸坯经单道次连续挤压后的显微组织及晶粒尺寸统计图

Fig. 3 Microstructures and grain size statistics of continuously extruded Cu-0.88Cr-0.14Zr alloy

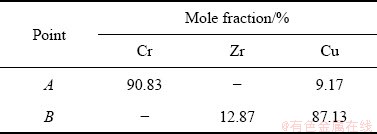

表1 Cu-0.88Cr-0.14Zr合金铸态组织中的第二相化学成分

Table 1 EDS analysis results of as-cast Cu-0.88Cr-0.14Zr alloy

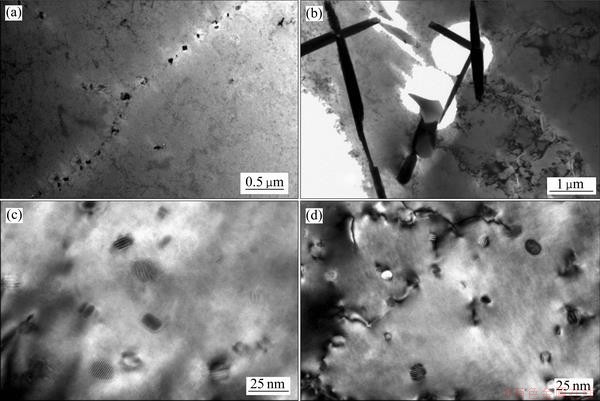

图4(a)~(b)所示为上引连铸的Cu-0.88Cr-0.14Zr合金棒坯组织的TEM像,观察发现,铸态组织枝晶处析出了尺寸为100 nm左右的富Cr相,如图4(a)所示。在图4(b)中还观察到了尺寸较大的块状与长条状的第二相,对其进行EDS分析发现其为富Zr相(该相中Zr的摩尔分数约为20%),与SEM观察的结果相同。图4(c)~(d)所示为铸坯经单道次连续挤压后的显微组织TEM形貌,从图中可以看出,Cu-0.88Cr-0.14Zr合金经连续挤压后,在基体中发现了大量尺寸为15~20 nm的条纹状析出相,根据前人的研究结果可知,该析出相为BCC结构的Cr相[20]。基体中大量Cr相的析出是因为合金在连续挤压前已对挤压模具腔体进行预热,模具的初始温度为450 ℃,挤压过程中材料会发生剪切变形,在轮槽摩擦力的作用下,材料的温度升高,随着变形程度的不断加剧,Cu-0.88Cr-0.14Zr合金的变形温度可以达到700 ℃以上,比其时效温度高出了200 ℃以上,材料此时发生了动态时效,促进了第二相在高温短时间内的析出。并且合金在连续挤压过程中发生了大量的塑性变形,产生大量的位错,这些位错也为第二相的形核提供了有利的位置。从图4(d)中可以看出,Cr相与位错存在明显的交互作用,在析出相附近观察到位错线。

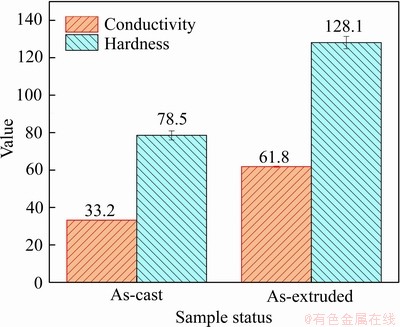

图5所示为Cu-0.88Cr-0.14Zr合金铸态与挤压态的性能对比图。观察发现,与铸态棒坯相比,连续挤压后的合金杆材性能明显改善,导电率和硬度分别提升了86%、63%。这是因为一方面合金经连续挤压后,发生了剧烈的剪切变形,晶粒显著细化,起到了细晶强化的作用;另一方面,挤压过程中合金发生了短时动态时效,析出了尺寸在15~20 nm的Cr相,起到了第二相强化的作用,同时Cr相的析出降低了固溶在Cu基体中Cr原子的含量,有利于提高合金的导电率。

图4 Cu-0.88Cr-0.14Zr合金棒坯铸态及挤压态组织TEM像

Fig. 4 TEM images of as-cast((a), (b)) and continuously extruded((c), (d)) Cu-0.88Cr-0.14Zr alloy

图5 Cu-0.88Cr-0.14Zr合金铸态与挤压态性能对比

Fig. 5 Properties comparison of as-cast and extruded Cu- 0.88Cr-0.14Zr alloy

2.2 Cu-Cr-Zr合金连续挤压杆材时效析出行为 研究

2.2.1 时效对Cu-Cr-Zr合金连续挤压杆材性能的影响

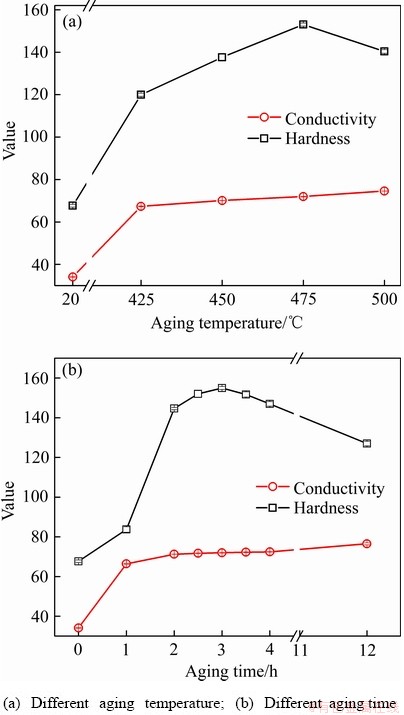

图6所示为连续挤压Cu-0.88Cr-0.14Zr合金杆材经(925 ℃,12 h)均匀化退火和(1000 ℃,1 h)固溶处理后不同时效制度下的硬度与导电率变化曲线。从图6(a)可以看出,合金在不同时效温度下保温3 h后,维氏硬度呈先升高后降低的趋势,当时效温度为475 ℃时,合金的硬度值达到最大值153 HV。合金的导电率随时效温度升高逐渐增大,当时效温度高于450 ℃时,导电率基本处于70%IACS~ 75%IACS之间。对比发现,当时效温度为475 ℃时,连续挤压Cu-0.88Cr-0.14Zr合金杆材的综合性能优异,确定475 ℃为其最佳时效温度。

图6(b)所示为连续挤压Cu-0.88Cr-0.14Zr合金杆材经(925 ℃,12 h)均匀化退火和(1000 ℃,1 h)固溶处理后在475 ℃时效不同时间的硬度与导电率变化曲线。观察发现,合金的硬度与时效时间呈先上升后降低的趋势,当时效时间为3 h时,合金的硬度最大为153 HV。继续延长时效时间至12 h,合金出现过时效现象,合金的硬度明显降低,仅为127 HV。合金的导电率与时效时间呈先快速上升后趋于稳定的趋势,当时效时间在2~12h时,合金的导电率差异不大,基本处于72%~75%IACS。对比发现,当时效温度为475 ℃,时间为3 h时,连续挤压Cu-0.88Cr-0.14Zr合金杆材的综合性能优异,确定其为峰时效制度。

图6 连续挤压Cu-0.88Cr-0.14Zr合金杆材在不同时效制度下的硬度与导电率变化曲线

Fig. 6 Hardness and conductivity curves of continuously extruded Cu-0.88Cr-0.14Zr alloy under different aging systems

2.2.2 时效处理对连续挤压Cu-Cr-Zr合金第二相析出行为的影响

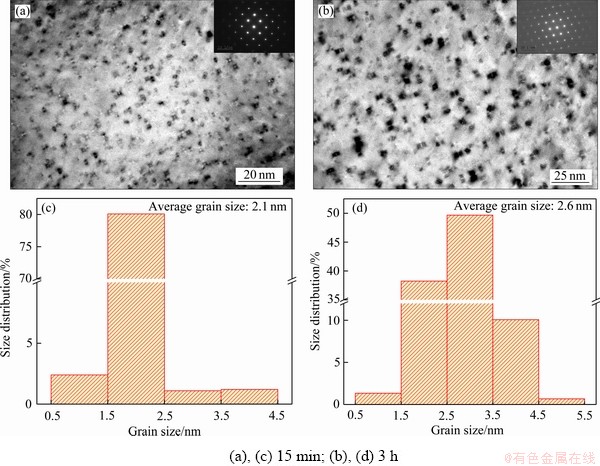

图7所示为连续挤压Cu-0.88Cr-0.14Zr合金杆材经(925 ℃,12 h)均匀化退火和(1000 ℃,1 h)固溶处理后在475 ℃下时效处理不同时间后的微观组织TEM像与第二相尺寸分布图。图7(a)所示为合金时效15 min后的TEM像,由该图可知,合金经短时间时效处理后,基体中出现大量弥散分布的豆瓣状第二相。对其进行衍射斑点标定发现,除了基体衍射斑点以外,没有第二相斑点的出现,表明该析出相与基体具有相同的晶体结构,KINGHTS等[21]的研究结果表明该豆瓣衬度的析出物为FCC结构的Cr相,且与Cu基体呈共格关系。对时效15 min的样品中Cr相尺寸进行统计,如图7(c)所示,尺寸在1.5~2.5 nm的第二相占比约81%,平均尺寸为 2.1 nm。

图7 Cu-0.88Cr-0.14Zr合金在475 ℃时效不同时间后的TEM形貌和第二相尺寸分布图

Fig. 7 TEM images((a), (b)) and second phase size distribution((c), (d)) of Cu-0.88Cr-0.14Zr alloy aged at 475 ℃ for different time

图7(b)所示为合金经475 ℃时效3 h后(峰时效)的TEM像,观察发现,随着时效时间的延长,豆瓣状析出相的尺寸略微增大,尺寸主要分布在2.5~3.5 nm之间(占比约50%),平均尺寸为2.6 nm,并且同样没有发现第二相衍射斑点。与时效15 min的样品相比,随着时效时间的延长,第二相发生长大,但尺寸仍保留在较小的水平。文献[22-25]中的研究表明,Cu-Cr合金中加入少量的Zr元素后,Cr和Zr存在交互作用,Zr元素能占据一部分有效空位,阻碍Cr元素的扩散,进而起到抑制Cr相长大的作用,提高析出相的稳定性,改善合金综合性能。如图6(b)所示,当时效时间在0~3 h时,此时合金中析出细小的Cr相,并且随着时效时间的延长,Cr相发生轻微长大,起到第二相强化作用的同时也提高了合金的导电率。

3 结论

1) 上引连铸Cu-0.88Cr-0.14Zr合金棒坯经连续挤压后,晶粒明显细化,并且发生了动态时效,基体中析出了条纹状的Cr相,且Cr相易在位错线附近析出。与合金铸态棒坯相比,挤压态杆材的导电率和硬度分别提升了86%、63%。

2) 挤压态Cu-0.88Cr-0.14Zr合金杆材经均匀化退火和固溶处理后,在425、450、475、500 ℃下时效,其硬度与时效温度呈先升高后降低的趋势,导电率逐渐增大,确定其最佳时效温度为475 ℃。

3) 挤压态Cu-0.88Cr-0.14Zr合金杆材经均匀化退火和固溶处理后,在475 ℃下时效不同的时间,随时效时间的延长,其硬度先上升后降低,在3 h时达到峰值;导电率呈先快速上升后趋于稳定的趋势。确定挤压态Cu-0.88Cr-0.14Zr合金的峰时效制度为(475 ℃,3 h),此时,合金的硬度和导电率分别可达155 HV、73%IACS。

4) 挤压态Cu-0.88Cr-0.14Zr合金在475 ℃下时效,析出了尺寸较小的豆瓣状Cr相,随着时效时间的延长,第二相发生长大,但尺寸仍保留在较小的水平,Zr元素的加入可以有效抑制Cr相的长大,提高Cr相的稳定性。

REFERENCES

[1] LIU J B, HOU M L, YANG H Y, et al. In-situ TEM study of the dynamic interactions between dislocations and precipitates in a Cu-Cr-Zr alloy[J]. Journal of Alloys & Compounds, 2018, 765: 560-568.

[2] FENG H, JIANG H C, YAN D S, et al. Effect of continuous extrusion on the microstructure and mechanical properties of a CuCrZr alloy[J]. Materials Science and Engineering A, 2013, 582: 219-224.

[3] SUN L X, TAO N R, LU K. A high strength and high electrical conductivity bulk CuCrZr alloy with nanotwins[J]. Scripta Materialia, 2015, 99: 73-76.

[4] XIA C D, JIA Y L, ZHANG W, et al. Study of deformation and aging behaviors of a hot rolled-quenched Cu-Cr-Zr-Mg-Si alloy during thermomechanical treatments[J]. Materials & Design, 2012, 39: 404-409.

[5] ZHANG Y, VOLINSKY A A, TRAN H T, et al. Aging behavior and precipitates analysis of the Cu-Cr-Zr-Ce alloy[J]. Materials Science and Engineering A, 2016, 650: 248-253.

[6] PENG L J, XIE H F, HUANG G J, et al. Dynamic of phase transformation in Cu-Cr-Zr alloy[J]. Advance Materials Research, 2014, 887/888: 333-337.

[7] MISHNEV R, SHAKHOVA I, BELYAKOV A, et al. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy[J]. Materials Science and Engineering: A, 2015, 629: 29-40.

[8] FU H D, XU S, LI W, et al. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2017, 700: 107-115.

[9] 李华清, 谢水生, 吴鹏越, 等. Cu-Cr-Zr-Mg合金真空铸造工艺研究[J]. 特种铸造及有色金属, 2006, 26(7): 387-399.

LI Hua-qing, XIE Shui-sheng, WU Peng-yue, et al. Vacuum smelting casting process for Cu-Cr-Zr-Mg alloy[J]. Special Casting and Nonferrous Alloys, 2006, 26(7): 387-399.

[10] 翁远辉, 陈 钢, 吴 渊, 等. 非真空铸造铜铬锆合金中的烧损和缺陷研究[J]. 铸造技术, 2013, 34(8): 1021-1023.

WENG Yuan-hui, CHEN Gang, WU Yuan, et al. Melting loss and defects of Cu-Cr-Zr alloy prepared in non-vacuum condition[J]. Foundry Technology, 2013, 34(8): 1021-1023.

[11] 李华清, 谢水生, 米绪军, 等. Cu-Cr-Zr合金铸锭铸造缺陷产生原因与防止措施[J]. 铸造技术, 2006, 27(11): 1205-1209.

LI Hua-qing, XIE Shui-sheng, MI Xu-jun, et al. Defects analyzing and prevention of Cu-Cr-Zr alloy ingots[J]. Foundry Technology, 2006, 27(11): 1205-1209.

[12] 徐高磊. 铜铬银合金短流程制备关键技术的研究[D]. 北京: 北京有色金属研究总院, 2019: 4.

XU Gaolei. Study on key technologies of short process preparation of Cu-Cr-Ag alloy[D]. Beijing: Research Institute for Nonferrous Metals, 2019: 4.

[13] 李明亮, 刘 平, 刘新宽, 等. 铜合金连续挤压工艺及模具设计[J]. 锻压技术, 2014, 39(11): 39-42.

LI Ming-liang, LIU Ping, LIU Xin-kuan, et al. Continuous extrusion process and mould design for copper alloy[J]. Forging & Stamping Technology, 2014, 39(11): 39-42.

[14] 徐高磊, 彭丽军, 米绪军, 等. 上引-连续挤压法制备Cu-Cr-Ag合金的组织与性能[J]. 稀有金属材料与工程, 2019, 48(4): 1310-1316.

XU Gao-lei, PENG Li-jun, MI Xu-jun, et al. Microstructure and properties of Cu-Cr-Ag alloy fabricated by up-drawn continuous casting and continuous extrusion[J]. Rare Metal Materials and Engineering, 2019, 48(4): 1310-1316.

[15] YUAN Yuan, LI Zhou, XIAO Zhu, et al. Microstructure evolution and properties of Cu-Cr alloy during continuous extrusion process[J]. Journal of Alloys and Compounds, 2017, 703: 454-456.

[16] XU Gao-lei, PENG Li-jun, HUANG Guo-jie, et al. Microstructural evolution and properties of a Cu-Cr-Ag alloy during continuous manufacturing process[J]. Rare Metals, 2021, 40: 2213-2220.

[17] YUAN Yuan, LI Zhou, XIAO Zhu, et al. Investigations on voids formation in Cu-Mg alloy during continuous extrusion[J]. The Journal of Minerals, Metals & Materials Society, 2017, 69(9): 1696-1700.

[18] 孙 健, 刘 平, 刘新宽, 等. Cu-Ni-Si合金连续挤压过程中的组织演变及性能[J]. 中国有色金属学报, 2014, 24(4): 944-949.

SUN Jian, LIU Ping, LIU Xin-kuan, et al. Microstructure evolution and properties of Cu-Ni-Si alloy during continuous extrusion process[J]. The Chinese Journal of Nonferrous Metal, 2014, 24(4): 944-949.

[19] SUI X, SONG B Y, LI B, et al. Deformation characteristic and microstructure evolution of H62 brass copper during continuous extrusion[J]. Nonferrous Metals, 2011, 63(1): 11-18.

[20] FUJII T, NAKAZAWA H, KATA M, et al. Crystallography and morphology of nanosized Cr particles in a Cu-0.2% Cr alloy[J]. Acta Materiallia, 2000, 48: 1033-1045.

[21] KNIGHTS R W, WILKES P. Precipitation of chromium in copper and copper-nickel base alloys[J]. Metallurgica Transaction, 1973, 4(10): 2839-2393.

[22] ZENG K J, MAMALAINEN, LUKAS H L. A new thermodynamic description of the Cu-Zr system[J]. Journal of Phase Equilibria, 1994, 15(6): 577-586.

[23] GIERLOTKA W, ZHANG K C, CHANG Y P. Thermodynamic description of the binary Cu-Zr system[J]. Journal of Alloys and Compounds, 2011, 509: 8313-8318.

[24] CORREIA J B, DAVIES H A, SELLARS C M. Strengthening in rapidly solidified age hardened Cu-Cr and Cu-Cr-Zr alloys[J]. Acta Materialia, 1997, 45(1): 177-190.

[25] 彭丽军. Cu-Cr-Zr系合金微观组织演变规律及合金元素交互作用机理的研究[D]. 北京: 北京有色金属研究总院, 2014: 105.

Peng Li-jun. Study on microstructure evolution of Cu-Cr-Zr system alloys and interaction mechanism between alloying element[D]. Beijing: Research Institute for Nonferrous Metals, 2014: 105.

Microstructure and properties of Cu-Cr-Zr alloy fabricated by up-drawn casting-continuous extrusion

ZHANG Wen-jing1, 2, 3, XIE Hao-feng1, PENG Li-jun1, HUANG Guo-jie1, YANG Zhen1, MI Xu-jun1, HUANG Lue1, 2, WANG Li-min3

(1. State Key Laboratory of Nonferrous Metals & Processes, GRIMAT Engineering Institute Co., Ltd., Beijing 101400, China;

2. General Research Institute for Nonferrous Metals, Beijing 100088, China;

3. GRIPM Advanced Materials Co., Ltd., Beijing 101400, China)

Abstract: Cu-0.88Cr-0.14Zr (mass fraction) alloy was prepared by up-drawn casting and continuous extrusion technology, and then the extruded bar was aged at different temperature for different time. The evolution of microstructure and properties of the alloy treated by different processes were investigated by scanning electron microscopy (SEM), transmission electron microscopy (TEM), electron back-scattered diffraction technology (EBSD), and so on. The results show that the Cu-Cr-Zr alloy casting rod billet has severe shear deformation and dynamic aging happened during continuous extrusion process, the grains are refined obviously and the Cr phases with size of 15-20 nm are precipitated. Compared to as-cast alloys, the electrical conductivity and hardness of the as-extruded alloy increase by 28.6% IACS and 49.6 HV, respectively. The peak aging of the extruded alloy after homogenization annealing at (925 ℃, 12 h) and solution treatment at (1000 ℃, 1 h) is determined to be (475 ℃, 3 h). The Cr phase with average grain size of 2.68 nm is precipitated in the matrix after peak aging, and the electrical conductivity and hardness can reach 73% IACS and 155 HV, respectively.

Key words: Cu-0.88Cr-0.14Zr alloy; up-drawn casting-continuous extrusion; aging treatment; electrical conductivity; hardness

Foundation item: Project(2016YFB0301400) supported by the National Key Research and Development Program of China

Received date: 2020-07-10; Accepted date: 2020-11-06

Corresponding author: ZHANG Wen-jing; Tel: +86-18911970343; E-mail: zhangwenjing@grinm.com

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2016YFB0301400)

收稿日期:2020-07-10;修订日期:2020-11-06

通信作者:张文婧,高级工程师,博士;电话:18911970343;E-mail:zhangwenjing@grinm.com