文章编号:1004-0609(2010)07-1321-07

GH625镍基合金的高温压缩变形行为及组织演变

吾志岗,李德富

(北京有色金属研究总院, 北京 100088)

摘 要:在Gleeble-1500D热模拟机上采用等温压缩实验研究GH625合金的高温压缩变形行为,获得合金在温度为1 000~1 200 ℃、应变速率为10-2~10 s-1的条件下的真应力—应变曲线,并在考虑摩擦和变形热效应的基础上对真应力—应变曲线进行修正。对修正后的峰值应力进行线性回归,得到合金的高温材料常数:Q=635.38 kJ/mol, α=0.008 404 MPa-1, n=3.52。通过非线性回归建立GH625合金包含应变量的高温变形本构模型。在应变速率为0.1 s-1时,随着热变形温度的升高,合金发生动态再结晶的体积分数随之增加,在1 000~1 100 ℃发生部分动态再结晶,当温度达到1 200 ℃时,发生完全动态再结晶,此时平均晶粒尺寸约为22.21 μm。

关键词:GH625合金; 流变行为; 变形热; 本构模型; 动态再结晶

中图分类号:TG146.1; TG111.7 文献标志码:A

Hot compression deformation behaviors and

microstructure evolution of GH625 Ni-based alloy

WU Zhi-gang, LI De-fu

(Beijing General Research Institute for Non-ferrous Metals, Beijing 100088, China)

Abstract: The hot deformation behaviors of GH625 nickel-based alloy were investigated by hot compression tests with Gleeble-1500D simulated machine. The true stress—true strain curves in the temperature range of 1 000-1 200 ℃ and strain rate of 10-2-10 s-1 were obtained. The true stain—stress curves were corrected in consideration of the friction and deformation. The material constants, the activation energy (Q) of 635.38 kJ/mol, α of 0.008 404 MPa-1, and n of 3.52, of high-temperature deformation for GH625 were obtained by the linear regression of peak stress. The constitutive equation of GH625 alloy containing the strain was established through non-linear regression. When the strain rate is 0.1 s-1, the volume fraction of dynamic recrystallization increases with increasing the temperature. The results show that partial dynamic recrystallization can be received when the temperature ranges from 1 000 ℃ to 1 100 ℃, and fully dynamic recrystallized structure can be received when the temperature reaches 1 200 ℃. And the average dynamically recrystallized grain size is about 22.21 μm.

Key words: GH625 alloy; flow behavior; deformation heat; constitutive equation; dynamic recrystallization

GH625镍基高温合金是以钼和铌为主要强化元素的固溶强化型镍基变形高温合金,具有优良的耐腐蚀、抗氧化性能及良好的力学性能,现主要应用于燃气涡轮发动机、核动力设备和宇航发动机等领域。材料加工过程数值模拟技术已广泛应用于优化热加工工艺进而实现对微观组织的控制,这对于探索合理的加工工艺,降低合金管材和零件的生产成本以及加速合金产业化具有深远意义,而建立准确的高温变形本构模型是采用数值模拟的基本前提。目前,对GH625合金研究的报道主要集中于合金加工工艺、组织和机械性能方面: SHANKAR等[1]研究了Inconel625合金时效处理后的组织演变规律; DONG等[2]研究了Inconel625合金表面“黑斑”的相变;赵宇新[3]研究了在冷变形条件下GH625合金的力学性能变化规律;毛信孚等[4]研究了该合金的摩擦焊接工艺;周大勇等[5]研究了合金表面激光合金化组织,而对GH625合金的热变形行为特征及微观组织演变规律缺乏深入系统的研究和全面的认识。

本研究在Gleeble1500-D上进行GH625合金的高温压缩实验,并在考虑摩擦和温度的基础上对Gleeble压缩实验数据进行修正[6],利用Arrhenius方程[7-8]并引入Zener-Hollomon 参数[9]计算不同应变量下的材料变形常数,建立考虑应变量的本构模型,研究变形温度对材料变形组织的影响。

1 实验

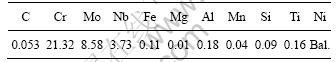

本实验用GH625镍基合金为d 200 mm的锻态棒材,其化学成分(质量分数,%)如表1所示。

表1 GH625镍基合金的化学成分

Table 1 Chemical composition of GH625 Ni-based alloy (mass fraction, %)

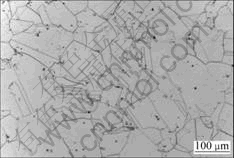

试样经1 200 ℃,保温30 min固溶处理后车削加工成d 8mm×12 mm的圆柱形试样,金相组织如图1所示。在Gleeble-1500D热模拟试验机上进行热压缩实验,试样两端放置钽片作为润滑,实验温度分别为 1 000、1 050、1 100、1 150、1 200 ℃,应变速率分

图1 固溶处理后GH625镍基合金的显微组织

Fig.1 Microstructure of GH625 Ni-based alloy after homo- genization

别为10-2、10-1、1、10 s-1,真应变量为0.7(实际变形程度为50.34%)。以10 ℃/s的速度将试样加热到预设温度并保温3 min后进行压缩实验,利用热模拟机自动采集的应力、应变和温度等数据,绘制真应力—应变曲线。热压缩完成后立即水冷到室温,以保留变形组织。采用线切割方法将变形试样沿轴向中心剖开,采用10 mL H2SO4+100 mL HCl+10 g无水CuSO4粉末配制成的混合溶液进行腐蚀,在Axiovert 200MAT光学金相显微镜上观测合金的金相组织。

2 结果与分析

2.1 摩擦和温度的修正

在压缩实验过程中虽有钽片做为试样与压头之间的润滑材料,但是两者之间的摩擦力是客观存在的。观察压缩后的试样可发现,样品均出现明显的鼓肚现象。这一现象可以解释为,由于摩擦的存在,限制了变形时材料的径向流动,改变了试样的单向压应力状态,而实验所得的应力—应变曲线是在均匀变形的假设条件下得到的,因此为获得更为精确的应力—应变曲线就必须进行摩擦修正。采用EBRAHIMI和NAJAFIZADEH [10]提出的热压缩试样与夹头间摩擦因子(m)的计算公式以及由变形功法推导的镦粗变形力计算公式[11]进行摩擦修正。

材料在塑性变形过程中产生的塑性变形功绝大部分转化为热能,当这部分热量来不及向外界扩散而积蓄于变形物体内部时,就会使变形体温度升高,引起变形热效应[12]。特别是在高应变速率条件下,变形过程可以近似认为是绝热过程[13],此时试样的温度随应变量的增大而急剧升高。

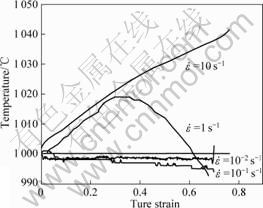

图2所示为实验测得试样在1 000 ℃时不同应变速率条件下的瞬时温度—真应变曲线。由图2可以看出,当 ≤10-1 s-1时,由于试样表面的热交换在低应变速率条件下起主要作用,导致试样表面温度略低于预设温度5%左右,这在实验允许的误差范围之内;当

≤10-1 s-1时,由于试样表面的热交换在低应变速率条件下起主要作用,导致试样表面温度略低于预设温度5%左右,这在实验允许的误差范围之内;当 =1 s-1时,温度变化呈抛物线型,此时最大温升为10 ℃左右,这相对于变形温度为1 000 ℃的材料可以忽略不计;而在

=1 s-1时,温度变化呈抛物线型,此时最大温升为10 ℃左右,这相对于变形温度为1 000 ℃的材料可以忽略不计;而在 =10 s-1时,试样温度随变形程度的增加急剧升高,在变形结束时,温度高达40 ℃,因此,为获得精确的应力—应变曲线,必须对高应变速率条件下(

=10 s-1时,试样温度随变形程度的增加急剧升高,在变形结束时,温度高达40 ℃,因此,为获得精确的应力—应变曲线,必须对高应变速率条件下( ≥10 s-1)的实验数据进行温度修正。采用插值法[14]并结合温升计算公式[15],对经过摩擦修正的应变速率为10 s-1的数据进行温度修正。

≥10 s-1)的实验数据进行温度修正。采用插值法[14]并结合温升计算公式[15],对经过摩擦修正的应变速率为10 s-1的数据进行温度修正。

图2 实验测得预设1 000 ℃时各应变速率下GH625镍基合金的瞬时温度

Fig.2 Instantaneous temperatures of GH625 Ni-based alloys under different strain rates at 1 000 ℃

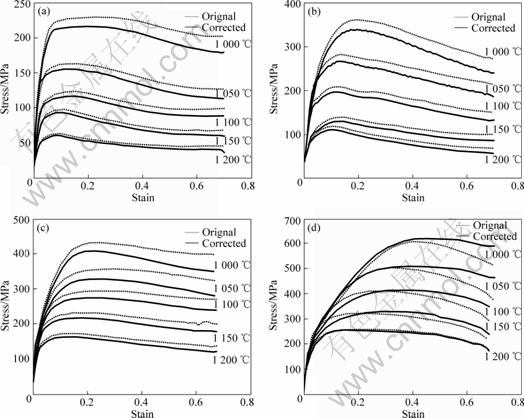

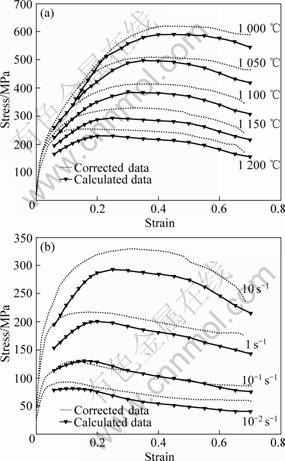

2.2 真应力—应变曲线分析

GH625镍基合金修正前、后的真应力—应变曲线如图3所示。从图3可以看出,GH625镍基合金的变形抗力相当大,在变形的初始阶段受加工硬化的影响应力值迅速上升至最高值,而后由于动态软化作用应力—应变曲线趋于稳态。在相同的应变速率和真应变量下,随变形温度的升高,合金变形所对应的流变应力值降低;当在相同的变形温度和真应变量下,随着应变速率的提高,合金变形所对应的流变应力值增加。

图3(a)~(c)所示的曲线只进行了摩擦修正,可以看出,在应变速率低于1 s-1时,修正曲线基本处于原始曲线的右下方,这是由于摩擦力的存在限制了材料的径向流动,使得变形抗力增大,且增加幅度随温度的升高而降低,但是并未改变材料变形的宏观规律和材料变形的峰值应力位置。在应变速率为10 s-1和温度不高于1 150 ℃的变形条件下,修正后的曲线处于原始曲线的上方(见图3(d)),这可能是由于此时变形热效应对材料的软化作用大于摩擦对材料变形的阻碍作用,即温升效应表现得更显著;而在1 200 ℃时,修正后的应力—应变曲线略低于原始应力—应变曲线,这表明1 200 ℃时摩擦对材料变形的阻碍作用与变形热效应对材料变形的软化作用基本相当。

3 本构模型的建立

选取修正后的的峰值应力建立GH625镍基高温合金的热压缩过程的本构方程,研究[4-5]表明,金属材料高温塑性变形的流变应力主要取决于应变(ε)、变形温度(T)和应变速率( ),通常应用公式(1)~(3)来表示流变应力的本构模型。

),通常应用公式(1)~(3)来表示流变应力的本构模型。

图3 不同变形条件下GH625镍基合金修正前后真应力—应变曲线

Fig.3 True stress—strain curves of GH625 Ni-based alloy before and after correction under different deformation conditions: (a)  =10-2 s-1;(b)

=10-2 s-1;(b)  =10-1 s-1;(c)

=10-1 s-1;(c)  =1 s-1;(d)

=1 s-1;(d)  =10 s-1

=10 s-1

1) 在低应力水平下:

, ασ≤0.8 (1)

, ασ≤0.8 (1)

2) 在高应力水平下:

, ασ≥0.8 (2)

, ασ≥0.8 (2)

3) 在所有应力水平下:

, ασ为任意值 (3)

, ασ为任意值 (3)

式中:α、β、n和A为与温度无关的常数,且满足条件α=β/n;Q为材料变形激活能;R为摩尔气体常数;T为热力学温度。

ZENER和HOLLOMON[9]提出并实验验证了应变速率( )和温度(T)的关系可用Z参数表示,即Zener-Hollomon参数,并结合式(3)可得

)和温度(T)的关系可用Z参数表示,即Zener-Hollomon参数,并结合式(3)可得

(4)

(4)

分别对式(1)和(2)两边取对数可得

ln =B1+n1lnσ (5)

=B1+n1lnσ (5)

ln =B2+βσ (6)

=B2+βσ (6)

式中:B1和B2为与温度有关的常数。

当温度一定时,β和n1分别为ln —lnσ和ln

—lnσ和ln —σ曲线的斜率,采用线性回归处理,可得ln

—σ曲线的斜率,采用线性回归处理,可得ln —σ和ln

—σ和ln —lnσ的关系曲线,分别如图4(a)和图4(b)所示。经循环计算代入可得在1 000~1 050 ℃的变形条件下,ασ≥0.8,而在1 100~1 200 ℃的变形条件下,ασ≤0.8,故取图4(a)中1 000~1 100 ℃时的3条曲线斜率的平均值得β=0.029 6,取图4(b)中1 150和1 200 ℃时的2条直线斜率的平均值得n1=5.237 8,则α=β/n=0.005 651 MPa-1。

—lnσ的关系曲线,分别如图4(a)和图4(b)所示。经循环计算代入可得在1 000~1 050 ℃的变形条件下,ασ≥0.8,而在1 100~1 200 ℃的变形条件下,ασ≤0.8,故取图4(a)中1 000~1 100 ℃时的3条曲线斜率的平均值得β=0.029 6,取图4(b)中1 150和1 200 ℃时的2条直线斜率的平均值得n1=5.237 8,则α=β/n=0.005 651 MPa-1。

对式(3)两边取对数并微分可得

(7)

(7)

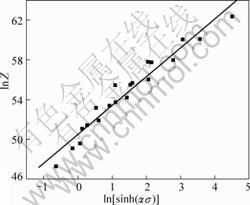

式(7)右边的两项分别为一定温度下ln —ln[sinh(ασ)]关系曲线的斜率(见图5(a))和一定应变速率下ln[sinh(ασ)—1 /T关系曲线的斜率(见图5(b))。将所得的斜率的平均值代入式(7)可得GH625镍基合金的热变形激活能Q=635.38 kJ/mol。

—ln[sinh(ασ)]关系曲线的斜率(见图5(a))和一定应变速率下ln[sinh(ασ)—1 /T关系曲线的斜率(见图5(b))。将所得的斜率的平均值代入式(7)可得GH625镍基合金的热变形激活能Q=635.38 kJ/mol。

将式(4)两边取对数可得

lnZ=lnA+nln[sinh(ασ)] (8)

将所求Q值和不同变形温度下的应变速率代入式

图4 应变速率与流变应力的关系曲线

Fig.4 Relationship between strain rate and flow stress: (a) ln —σ; (b) ln

—σ; (b) ln —lnσ

—lnσ

(4),可得到不同的Z值,绘制lnZ—ln[sinh(ασ)]关系曲线,如图6所示,可得n=3.52,A=8.338×1021 s-1,α=β/n=0.008 404 MPa-1。

将求得的Q、n、A和α等参数代入式(3),获得修正后GH625镍基合金的高温变形本构方程:

(9)

(9)

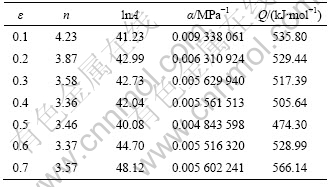

采用上述计算Q、n、lnA和α值的方法可计算出不同应变量下的材料常数如表2所列,对表2数据进行非线性拟合回归求出α、Q、n和lnA 值与应变量之间的函数关系式:

n=4.493-0.017ε-27.032ε2+81.22ε3-93.77ε4+41.467ε5

(10)

α=0.01932-0.15386ε+0.67235ε2-1.43ε3+1.485ε4-0.6ε5

(11)

图5 ln —ln[sinh(ασ)]曲线和ln[sinh(ασ)—1/T曲线

—ln[sinh(ασ)]曲线和ln[sinh(ασ)—1/T曲线

Fig.5 ln —ln[sinh(ασ)] (a) and ln[sinh(ασ)—1/T (b) curves

—ln[sinh(ασ)] (a) and ln[sinh(ασ)—1/T (b) curves

图6 流变应力与Z参数关系

Fig.6 Relationship between flow stress and Zener-Hollomon parameter

Q=573.585-568.8ε+3273.7ε2-10417.06ε3+

14444.59ε4-6613.48ε5 (12)

lnA=41.1246-5.82ε+212.1ε2-979.04ε3+

1563.187ε4-789.49ε5 (13)

表2 不同应变量下α、Q、n和lnA的值

Table 2 Values of α, Q, n and lnA at different strains

式(10)~(13)并综合式(1)~(3)构成GH625合金的高温变形本构模型,利用该模型可计算不同变形条件下的流变应力曲线,并与修正后的真应力—应变曲线作比较。图7(a)所示为应变速率为10 s-1时不同变形温

图7 GH625镍基合金的高温变形修正的应力—应变曲线与计算的应力—应变曲线的比较

Fig.7 Comparison between corrected stress—strain curves and calculated stress—strain curves of GH625 Ni-based alloy after high-temperature deformation at  of 10 s-1 (a) and temperature of 1 150 ℃ (b)

of 10 s-1 (a) and temperature of 1 150 ℃ (b)

度下计算值与修正值的比较。图7(b)所示为温度为 1 150 ℃时不同应变速率下计算值与修正值的比较。由图7可以看出,计算的曲线与实测修正的应力—应变曲线吻合得较好,最大误差不超过15%,能准确地反映GH625合金的高温变形力学行为。

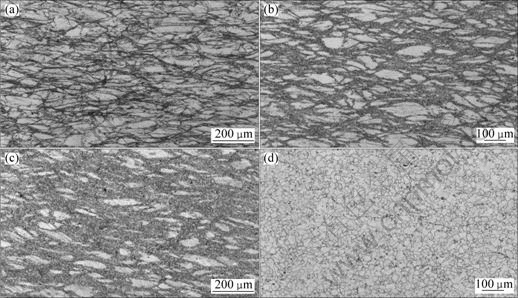

4 温度对GH625镍基合金高温变形组织的影响

GH625镍基高温合金在 =1 s-1,ε=0.7时的变形组织如图8所示。由图8可以看出,在变形温度为1 000 ℃时,原始组织中的大晶粒沿变形方向被严重拉长,部分大晶粒晶界周围有细小的再结晶晶粒出现,表明此时动态再结晶开始形核;在1 050 ℃时,合金中原来的大晶粒逐渐被细小晶粒取代;在1 100 ℃时,少量被拉长的变形大晶粒夹杂在细小的等轴再结晶晶粒中,呈现混晶组织;在1 200 ℃时,动态再结晶已经完成,呈现完全的动态再结晶组织,此时平均晶粒尺寸约为22.21 μm。由此可见,变形温度对合金的变形组织有很大影响,在1 s-1,1 200 ℃时发生了完全动态再结晶,合理控制热变形温度可以得到均匀、细小的等轴再结晶晶粒组织,使变形后的内部组织得到 改善。

=1 s-1,ε=0.7时的变形组织如图8所示。由图8可以看出,在变形温度为1 000 ℃时,原始组织中的大晶粒沿变形方向被严重拉长,部分大晶粒晶界周围有细小的再结晶晶粒出现,表明此时动态再结晶开始形核;在1 050 ℃时,合金中原来的大晶粒逐渐被细小晶粒取代;在1 100 ℃时,少量被拉长的变形大晶粒夹杂在细小的等轴再结晶晶粒中,呈现混晶组织;在1 200 ℃时,动态再结晶已经完成,呈现完全的动态再结晶组织,此时平均晶粒尺寸约为22.21 μm。由此可见,变形温度对合金的变形组织有很大影响,在1 s-1,1 200 ℃时发生了完全动态再结晶,合理控制热变形温度可以得到均匀、细小的等轴再结晶晶粒组织,使变形后的内部组织得到 改善。

由于镍基合金是低层错能金属,其滑移面上的不全位错之间的层错带(扩展位错)较宽,很难汇聚成全位错,因而在热变形过程中不易发生刃位错的攀移和螺位错的交滑移,故动态再结晶是合金动态软化的主要方式[16-17]。当变形温度较低时,位错可动性较差,难以形成高密度的位错缠结,导致再结晶形核率较低,只在少量大晶粒晶界周围有细小的再结晶晶粒出现(见图8(a));当变形温度较高时,位错易于运动,再结晶形核位置增多,形核率增大,动态再结晶程度提高;当温度为1 200 ℃时,发生完全动态再结晶。

5 结论

1) 合金在变形过程中受摩擦和变形热效应的影响很大。在有摩擦的情况下,材料的变形抗力增大,但未改变材料变形的宏观规律和材料变形的峰值应力位置;温度的升高导致材料变形抗力下降,特别是在高应变速率下,如 =10 s-1,温度升高的影响不能忽略。

=10 s-1,温度升高的影响不能忽略。

2) GH625合金的变形抗力相当大,在变形的初始阶段受加工硬化的影响,应力值迅速上升至最高值,而后由于动态软化作用应力—应变曲线趋于稳态流变。利用修正后的峰值应力,计算得到GH625镍基合金的高温材料常数:Q=635.38 kJ/mol,α=0.008 404 MPa-1,n=3.52;通过非线性回归建立GH625镍基合金包含应变量的高温变形本构模型,该模型能准确地反应GH625合金的高温变形力学行为。

3) 热变形温度对合金的变形组织有很大影响,在应变速率为10-1 s-1时,随着热变形温度的升高,合金发生动态再结晶的体积分数增加,在1 000~1 100 ℃时,发生部分动态再结晶;当温度到达1 200 ℃时,发生完全动态再结晶,此时平均晶粒尺寸约为22.21 μm。

图8 在 =1.0 s-1和ε=0.7,不同变形温度时GH625镍基合金的变形组织

=1.0 s-1和ε=0.7,不同变形温度时GH625镍基合金的变形组织

Fig.8 Deformed microstructures of GH625 Ni-based alloys at =1.0 s-1 and ε=0.7 under different temperatures: (a) 1 000 ℃; (b) 1 050 ℃; (c) 1 100 ℃; (d) 1 200 ℃

=1.0 s-1 and ε=0.7 under different temperatures: (a) 1 000 ℃; (b) 1 050 ℃; (c) 1 100 ℃; (d) 1 200 ℃

REFERENCES

[1] SHANKAR V, SANKARA B, RAO K, MANNAN S L. Micro- structure and mechanical properties of Inconel 625 superalloy [J]. Journal of Nuclear Materials, 2001, 288: 222-232.

[2] DONG J X, ZHANG M C, ZENG Y P, XIE X S. Phase transformation and characteristics in freckle areas for inconel 625 superalloy[J]. Acta Metallurgica Sinica, 2005, 18(1): 47-54.

[3] 赵宇新. GH625合金的冷变形及其对力学性能的影响[J]. 材料工程, 2000(9): 36-37.

ZHAO Yu-xin. Cold deformation behaviors of GH625 alloy and their effects on the mechanical properties[J]. Journal of Materials Engineering, 2000(9): 36-37.

[4] 毛信孚, 傅 莉, 谢 伟, 毛正岩. Inconel625合金摩擦焊接工艺研究[J]. 航空精密制造技术, 2006, 42(6): 44-47.

MAO Xin-fu, FU Li, XIE Wei, MAO Zheng-yan. Study on friction welding technology for superalloy Inconel 625[J]. Aviation Precision Manufacturing Technology, 2006, 42(6): 44-47.

[5] 周大勇, 刘文今, 钟敏霖, 李晓莉, 张伟明, 姜 峰. Inconel 625激光合金化层组织、性能与耐磨性研究[J]. 应用激光, 2004, 24(6): 36-37.

ZHOU Da-yong, LIU Wen-jin, ZHONG Min-lin, LI Xiao-li, ZHANG Wei-ming, JIANG Feng. The investigation on the microstructure, properties and wear resistance of the Inconel 625 laser alloyed layer[J]. Applied Laser, 2004, 24(6): 36-37.

[6] 张伟红, 张士宏. NiTi合金热压缩实验数据的修正及其本构方程[J]. 金属学报, 2006, 42(10): 1036-1040.

ZHANG Wei-hong, ZHANG Shi-hong. Correction of hot compression test data and constitutive equation of NiTi alloy[J]. Acta Metallurgica Sinica, 2006, 42(10): 1036-1040.

[7] SELLARS C M. Modelling microstructural development during hot rolling[J]. Materials Science and Technology, 1990, 6: 1072-1081.

[8] MEDINA S F, HEMADERZ C A. General expression of the Zener-Hollomon on parameter as a function of the chemical composition of low alloy and microalloyed steels[J]. Acta Materials, 1996, 44(1): 137-148.

[9] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1994, 15(1): 22-26.

[10] EBRAHIMI R, NAJAFIZADEH A. A new method evaluation of friction in bulk metal forming[J]. Journal of Metrials Processing Technology, 2004,152(2): 136-143.

[11] 汪大年. 金属塑性成形原理[M]. 北京: 机械工业出版社, 1982: 140.

WANG Da-nian. Principles of metal forming[M]. Beijing: China Machine Press, 1982:140.

[12] 彭大暑. 金属塑性加工原理[M]. 长沙: 中南大学出版社, 2004: 194-195.

PENG Da-shu. Principles of metal forming processes[M]. Changsha: Central South University Press, 2004: 194-195.

[13] HAMOUDA A M S. Effect of energy losses during an impact event on the dynamic flow stress[J]. Journal of Materials Processing Technology, 2002, 124(1/2): 209-215.

[14] LI L, ZHOU J, DUSZCZYK J. Determination of a constitutive relationship for AZ31B magnesium and validation through comparison between simulated and real extrusion[J]. Journal of Materials Processing Technology, 2006, 172 (3): 372-380.

[15] GOETZ R L, SEMIATIN S L. The adiabatic correction factor for deformation heating during the uniaxial compression test[J]. Journal of Materials Engineering and Performance, 2001, 10(6): 710-717.

[16] MCQUEEN H J, JONAS J J. Recent advances in hot working: fundamental dynamic softening mechanisms[J]. Journal of Applied Metalworking, 1984, 3(3): 233-241.

[17] 刘鹏飞, 刘 东, 罗子健, 孙文儒, 郭守仁, 胡壮麒. GH761合金的热变形行为与动态再结晶模型[J]. 稀有金属材料与工程, 2009, 38(2): 275-281.

LIU Peng-fei, LIU Dong, LUO Zi-jian, SUN Wen-ru, GUO Shou-ren, HU Zhuang-qi. Flow behavior and dynamic recrystallization model for GH761 superalloy during hot deformation [J]. Rare Metal Materials and Engineering, 2009, 38(2): 275-281.

(编辑 杨 华)

基金项目:国家自然科学基金和宝山钢铁股份有限公司联合资助项目(50834008)

收稿日期:2009-09-29;修订日期:2010-03-29

通信作者:李德富, 教授, 博士; 电话: 010-82241264; E-mail: lidf@grinm.com