文章编号:1004-0609(2016)-09-1943-09

磁场强度和沉积时间对AZ31B镁合金表面MAO/Ti涂层结构及性能的影响

崔学军1, 2,刘春海1, 2,杨瑞嵩1, 2,李明田1, 2,林修洲1, 2

(1. 四川理工学院 材料科学与工程学院,自贡 643000;

2. 四川理工大学 材料腐蚀与防护四川省重点实验室,自贡 643000)

摘 要:通过微弧氧化和多弧离子镀两种等离子体技术,在AZ31B镁合金表面制备MAO/Ti复合涂层。采用SEM、EDS、XRD、电化学等手段表征涂层的形貌、元素组成、物相结构及其在3.5% NaCl(质量分数)溶液中的腐蚀行为。结果表明:随着磁场电流从0 A增加到20 A, 30 min沉积的MAO/Ti涂层表面大尺寸熔滴粒子数量逐渐减少,真空室温度由128 ℃增加到192 ℃;10 A磁场电流作用下,当沉积时间由30 min延长到120 min时,真空室温度迅速增加,MAO/Ti涂层表面呈现微裂纹,表面液体熔滴粒子的数量增加;无外加磁场时,随着沉积时间从30 min延长到120 min,MAO/Ti涂层表面呈现大量球形熔滴颗粒,Ti镀层厚度逐渐增加并完全覆盖MAO膜;多弧离子镀过程未改变MAO镁合金的主要物相结构;MAO/Ti涂层φcorr正移,Jcorr降低。外加轴向磁场,过滤带电以及中性大颗粒粒子,有利于致密化镀层,但提高弧斑运动速度,升高阴极靶温度,增加靶材的液滴数量,必须加以控制;Ti镀层提高了MAO膜对镁合金基体的腐蚀防护能力,但仍有待于通过工艺调整致密化镀层,进一步强化MAO/Ti涂层的综合性能。

关键词:镁合金;涂层;微弧氧化;物理气相沉积;钛;耐蚀性

中图分类号:TG 174.4 文献标志码:A

材料表面合金化是金属表面防护的重要手段之一,尤其是金属氮化物硬质涂层,因其硬度高,耐磨、耐蚀、耐热性能好等优点,已广泛应用于镁合金基体的表面改性[1-11]。然而,镁合金基体较软,其结构和物理性质(弹性/塑性/热膨胀系数)与硬质涂层匹配性相对较差,膜基结合不牢固,从而导致涂层过早失效。为提高硬质涂层与基体之间的结合力,往往在涂层与基体之间引入金属过渡层。钛和镁都是密排六方点阵结构,且晶格常数a值相近。因此,一些研究[5-8]以Ti为过渡层,制备了结合力较好的TiN/Ti硬质涂层。LI等[8]认为,硬质涂层中存在残余张应力(结构应力和热应力引起),如果残余应力过大,将破坏涂层的力学性能,而过渡层Ti能够通过塑性变形释放应力,从而提高了涂层与基体之间的附着力。然而,直接在镁合金表面沉积Al、Al/Ti复合涂层,截面形貌显示Al/Ti涂层与基体之间存在界面缺陷[11],这表明以Al或Al/Ti为过渡层存在着界面结合问题。

众所周知,镁合金经微弧氧化(MAO)处理后,可在其表面原位生长出与基体呈冶金结合的耐蚀、高硬度MgO多孔陶瓷(也称微弧氧化膜),这种膜层一般由内部致密层和表面多孔层构成[2, 12-13]。致密层通过物理屏蔽作用阻挡腐蚀介质与基体的接触,提高涂层的腐蚀防护能力;而疏松层易于为腐蚀介质提供通道,加速涂层剥离和基体腐蚀,但却能有效降低涂层的内应力,提高其与后续涂层的结合强度[14-15]。由此,基于镁合金表面陶瓷层与基体的冶金结合及表面微观多孔的特性,利用MAO和物理气相沉积(PVD)两种等离子体技术,本文作者提出了一种在镁合金表面构建硬质涂层的方法[16],试图通过适当的工艺将Ti、Al等金属渗入陶瓷层的多孔层中,为后续氮化物硬质涂层提供陶瓷/金属复合过渡层,增强涂层间的界面结合强度,提高涂层的耐蚀、耐磨及力学等综合性能。

多弧离子镀技术因其设备简单、金属离化率高、绕射性好等优点,而被广泛用于制备金属镀层[17-19]。

张钧等[19]采用弧辉渗镀技术在AZ91D表面沉积了TiN-CrN复合涂层,涂层硬度达到了HK0.011433,显著提高了镁合金基体的耐磨性能。ZHAO等[3]利用多弧离子镀技术在AZ91D表面制备TiN、TiAlN硬质涂层,TiN涂层硬度是镁合金基体的两倍,显著提高了镁合金的耐磨性能。然而,这种高密度等离子体中往往伴随大量的金属液滴,为了减少液滴的产生及其在样品表面的沉积,通常在阴极靶周围外加轴向磁场,利用磁过滤方法减少大颗粒(液滴)的数量[20]。本文作者主要研究多弧离子镀技术中的磁场强度与沉积时间对AZ31B镁合金表面MAO/Ti涂层结构及性能的影响,为后期进一步研究复合硬质涂层提供必要的过渡层制备工艺。

1 实验

基体为AZ31B镁合金,规格30 mm×30 mm×2 mm,其化学组成(质量分数,%)为:2.94 Al,0.9 Zn,0.23 Mn,0.01 Si,0.01 Cu,0.003 Fe,0.00053 Ni,余量Mg。对镁合金样品依次进行碱洗除油→超声清洗→烘干→打磨→丙酮超声→水洗→冷风吹干→备用。截面样品制备流程:弯弓截取试样→镶嵌机样→打磨→清洗→浸蚀→丙酮超声→喷金→备用。

微弧氧化处理[21]采用微弧氧化成套设备(QX-30,成都齐兴真空镀膜有限公司),主要包括交流脉冲电源、搅拌系统和冷却循环系统。电解液由20 g/L KOH、15 g/L Na2SiO3、3 g/L NaF组成,试剂均为化学纯。镁合金样品用铝线连接,作为阳极,不锈钢筒(d 150 mm×300 mm)为阴极。采用恒压控制模式,电压260 V,频率300 Hz,占空比30%,温度低于45 ℃,氧化时间10 min。MAO样品位去离子超专长清洗后吹干,备用。

采用多功能弧辉离子渗镀设备(QX-500,成都齐兴真空镀膜有限公司)制备Ti镀层。该设备主要由真空反应室、真空系统、电控系统和冷却系统等组成。电控系统可提供弧源电流、磁场电流及脉冲负偏压。将试样固定在真空反应室内的样品支架上(靶基距离约396 mm),待室内真空度抽至5.0 m Pa时,通入氩气(99.99%)500 mL/min,并开启脉冲负偏压(负偏压800 V,占空比80%,频率300 Hz)辉光清洗样品5 min。然后将偏压调至100 V,并将氩气流量调至230 mL/min以控制真空度在1 Pa左右,引燃Ti靶(纯度99.5%),对试样进行过渡层沉积,镀膜结束后待真空室温度自然冷却至60 ℃以下,泄真空取样。本实验研究的磁场强度通过电流调节,为方便讨论,后面的分析中以磁场电流代之,其大小分别为0、5、10、15、20 A;沉积时间分别为30、60、90、120 min。

采用装配能谱仪(EDS,X-Flash Detector 410-M,Bruker,Germany)的扫描电子显微镜(SEM,VEGA 3 SBU,Tescan,Czechia)表征膜层的表面、截面形貌及其元素组成,加速电压为20 kV。利用X射线衍射仪(D2 PHASER, Bruker, Germany) Cu-Kα检测膜层的物相组成。利用电化学工作站(CHI660E,上海辰华公司),在室温条件下测试样品在3.5% NaCl(质量分数)溶液中的极化曲线,其中,采用带有1 cm2小孔的电解池建立标准三电极体系,参比电极为饱和甘汞电极(SCE),辅助电极为面积3 cm2的Pt片,工作电极为待测试样,其有效暴露面积为1 cm2。测量时,先对试样的开路电位进行测试,待体系稳定后,进行动电位极化曲线测试,扫描范围为相对开路电位±0.5 V,扫描速度为1 mV/s。每个试样重复测量3次,考察测量结果的重现性和涂层的稳定性。以3次测量的中间值为样品的最终测量数据,并利用计算机软件(CHI, Version 12.23, USA)拟合数据,得出腐蚀过程动力学参数:自腐蚀电位(φcorr)、自腐蚀电流密度(Jcorr)、极化电阻(Rp)以及塔菲尔斜率(ba和bc)。

2 实验结果

2.1 工艺参数与温度的关系

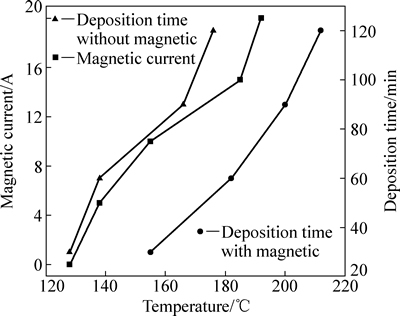

图1所示为制备Ti镀层的磁场电流和沉积时间与真空室温度的关系。由图1可看出,随着磁场电流从0 A增加到20 A,真空室内的温度由128 ℃升高到了192 ℃;在固定磁场电流10 A的条件下,沉积时间从30 min增加到120 min时,温度由155 ℃升高到了212 ℃。可见,增加磁场电流或者外加磁场条件下增加沉积时间,都引起了真空室内温度近似的线性增长。然而,在无外加磁场条件下,当沉积时间从30 min增加到120 min时,温度仅由128 ℃升高到了176 ℃。虽然,未引入磁场条件下室内温度随着沉积时间也是近似的线性增加过程,但与外加10 A为磁场相比,这个相同沉积时间内温度降低了近40 ℃。在制备Ti镀层的过程中,也观察到引入外加磁场时,靶材表面的弧斑更集中,旋转速度加快,弧光变得更加细碎,这种现象表明引入外加磁场或增加磁场电流必然会引起室内温度的急剧升高。

图1 磁场电流和沉积时间与真空室温度的关系

Fig. 1 Relationships between temperature and magnetic current and deposition time

2.2 磁场电流大小对膜层表面形貌的影响

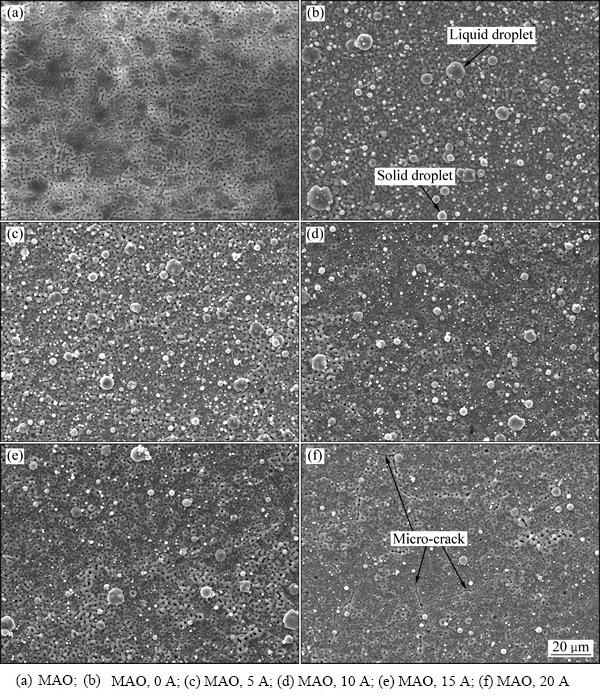

图2(a)所示为MAO膜的表面形貌,具有密集的微孔及“火山口状”熔融物,是典型的微弧氧化膜特征,这种微观结构与微弧氧化过程及膜层的形成机制有关[22-23]。图2(b)~(f)所示为不同磁场电流下所得MAO/Ti复合涂层的表面形貌,表面分布尺寸大小不等的球形和片状两种白亮颗粒。在多弧离子镀过程中,电弧弧斑轰击靶材的表面,由于电弧温度很高,引起靶材的表面熔化,其中有部分未电离的中性原子就会以液滴的形式喷射出来,沉积在基体表面形成球形颗粒,可称为固体熔滴;而电离的中性原子以及伴随的等离子体,在沉积过程中与其它粒子发生碰撞,有的尺寸变小,有的互相结成集团,沉积到基体表面后便形成了液体熔滴[17-18, 24]。

在固定沉积时间为30 min时,磁场电流从0 A增加到20 A,MAO/Ti复合涂层的表面形貌中仍能明显可见MAO膜的形貌特征(见图2(b)~(f)),即Ti镀层并未完全覆盖MAO膜。且随着磁场电流的增加,MAO膜表面的熔滴数量明显减少,尤其是大尺寸熔滴颗粒。这表明靶材周围施加的轴向磁场,对Ti靶溅射出来的大颗粒起到了显著的过滤作用,但同时它也导致了沉积速率的大幅度下降。此外,在图2(f)中的膜层表面出现明显的微裂纹,而在MAO膜的表面未见微裂纹,这应该与磁场电流增加引起的温度急剧升高有关。

图2 微弧氧化膜与不同磁场电流下沉积30 min后所得MAO/Ti复合涂层的表面形貌

Fig. 2 Surface morphologies of MAO and MAO/Ti coatings prepared at different magnetic currents for 30 min

2.3 沉积时间对膜层表面形貌的影响

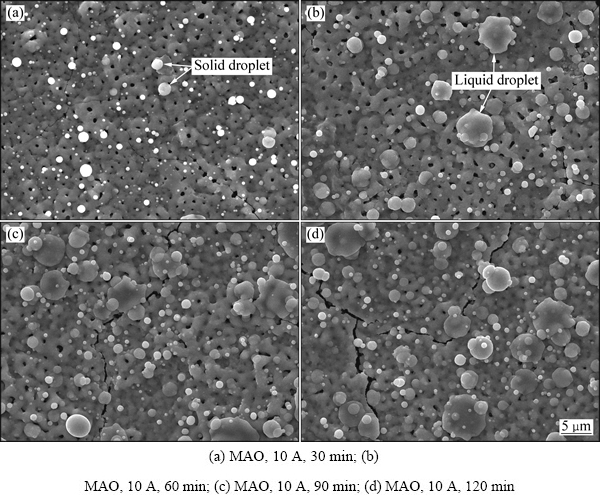

图3所示为10 A磁场电流条件下不同沉积时间所得MAO/Ti复合涂层的表面形貌。由图3可见,随着沉积时间从30 min增加到120 min,膜层表面的熔滴颗粒数量逐渐增加,但仍不能完全覆盖MAO膜。同时,随着沉积时间的增加,微弧氧化MAO膜表面的微裂纹明显延伸和长大。由图1可知,外加磁场时,温度随沉积时间的延长增加更快。而镁合金、MAO膜以及Ti镀层线膨胀系数存在较大差异,这必然引起MAO膜表面微裂纹的萌生和长大(见图3(c)~(d))。微裂纹的产生和生长,必然降低微弧氧化膜对镁合金基体的腐蚀防护。此外,随着沉积时间的增加,可见膜层表面的大尺寸液体熔滴颗粒增多,固体颗粒虽也有增加趋势,但仍以小尺寸颗粒为主。表明磁过滤可有效减少或消除大颗粒,但液体熔滴颗粒的增加以及尺寸的增大,可能与磁场引起的温度升高有关。

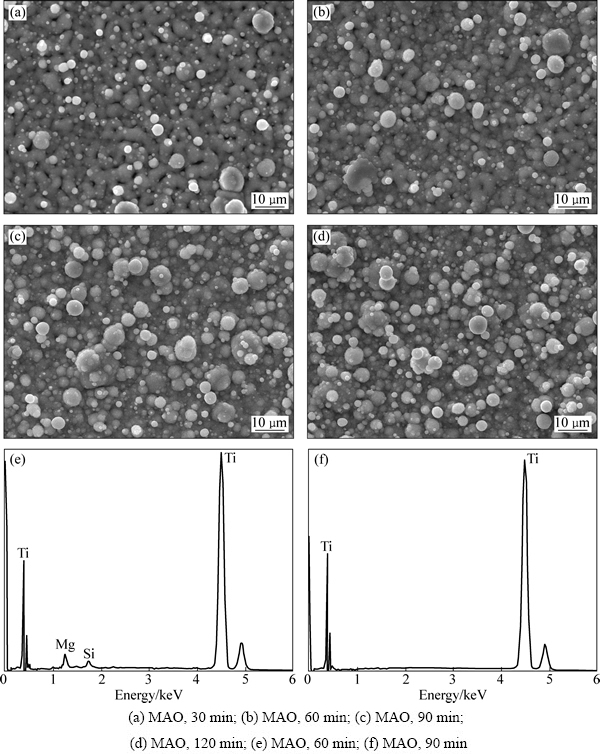

图4所示为无外加磁场条件下不同沉积时间所得MAO/Ti复合涂层的表面形貌及元素组成。当沉积时间为30 min和60 min时,复合涂层的表面仍可见MAO膜的微孔等形貌特征(见图4(a)~(b));当沉积时间为90 min和120 min时,不能观察到MAO膜的形貌特征(见图4(c)~(d))。为了确定Ti镀层是否完全覆盖MAO膜,采用EDS对复合膜层表面进行了元素面扫描分析(见图4(e)~(f))。当沉积时间为60 min时,复合膜由Mg、Si和Ti元素组成。Mg和Si来自MAO膜[25],而Ti来自Ti镀层。然而,沉积时间为90 min时,复合膜仅由Ti元素组成,而未检测到Mg和Si元素。由此可确定沉积时间为90 min时,Ti镀层已完全覆盖MAO膜。

与图3相比,在相同时间内的膜层表面覆盖了更多Ti颗粒;而且,Ti镀层以大尺寸球形颗粒为主,而液体熔滴几乎没有,从而证实了外加磁场能过滤掉尺寸较大的固体颗粒,大幅度降低沉积速率。

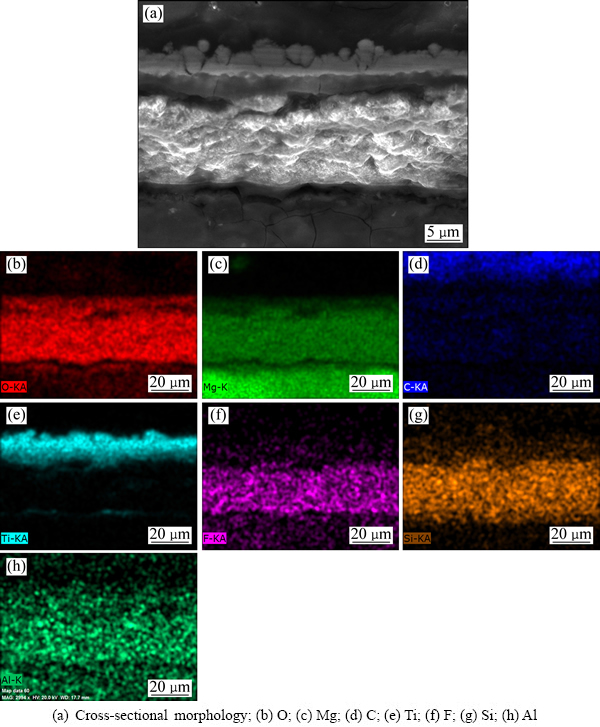

2.4 MAO/Ti涂层截面形貌及元素组成

图5所示为无外加磁场条件下沉积120 min所得MAO/Ti复合涂层的截面形貌及元素组成。由图5(a)可见,MAO/Ti复合涂层厚度12~13 μm,其中MAO膜厚约10 μm,Ti镀层厚度为2~3 μm;MAO膜与Ti镀层之间较为紧密,存在少量微裂纹,这与试样截面打磨和抛光过程中温度升高而引起的截面分离有关。但仍可见Ti镀层与MAO膜之间的界面有部分互渗的现象,表明MAO膜与Ti镀层之间不是单纯的附着关系,这有利于增强界面结合强度。一般的多弧离子镀涂层具有良好的附着力,其原因之一是轰击的等离子体携带的动能变为热能,从而对基体表面产生了一个自加热效应,从而提高基体表面层组织的结晶性能,进而促进化学反应和扩散作用[20]。

图3 磁场电流条件下不同沉积时间所得MAO/Ti复合涂层的表面形貌

Fig. 3 Surface morphologies of MAO/Ti coatings prepared by varying deposition time with magnetic

图4 无外加磁场条件下不同沉积时间所得MAO/Ti复合涂层的表面形貌及元素组成

Fig. 4 Surface morphologies ((a)-(d)) and element composition ((e)-(f)) of MAO/Ti coatings prepared by varying deposition time without magnetic

图5 无磁场电流条件下沉积120 min所得MAO/Ti复合涂层的截面形貌及元素组成

Fig. 5 Cross-sectional morphologies of MAO/Ti coating and its EDS elemental map scanning results

图5(b)~(h)所示为截面形貌对应的元素面分布,MAO/Ti复合涂层中存在O、Mg、F、Si、Al和Ti等元素,其中,O、Mg、F、Si、Al来自基体和MAO膜,而Ti来自Ti镀层。从截面元素O的面分布可见,MAO膜和Ti镀层之间存在部分互渗的现象。

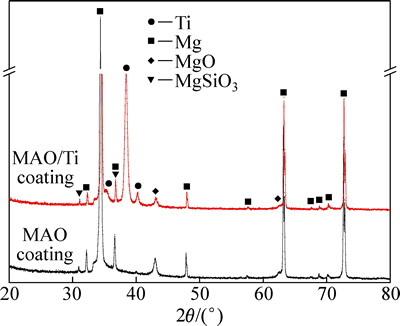

2.5 MAO/Ti涂层的物相组成

图6所示为MAO与MAO/Ti涂层样品的XRD谱。与标准卡片比对,MAO样品主要由Mg、MgO和MgSiO3 3种物相组成,未检测到氟化物衍射峰;MAO/Ti复合涂层除了MAO样品中检测到的物相外,还检测到金属Ti,表明Ti以晶体的形式存在,且按(110)晶向优先生长。此外,制备Ti镀层过程,并未改变MAO膜的主要物相结构。

2.6 极化曲线

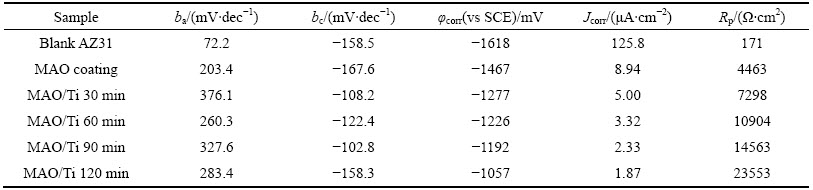

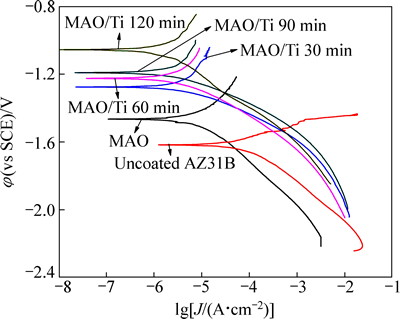

由图2和3可知,引入外加磁场后,在MAO膜表面并未获得完全覆盖的Ti镀层;而且,由于加速的轰击粒子引起真空室内温度迅速升高,导致MAO膜表面微裂纹的萌生和生长。这将降低MAO/Ti复合涂层对镁合金基体较差的腐蚀防护能力。相反,无外加磁场条件下,随着沉积时间的增加,在MAO表面获得了完全覆盖的Ti镀层(见图4(c)~(d))。研究表明[9],在镁合金基体表面预镀Ti,可提高后续涂层对镁合金的腐蚀和耐磨性能。但也有文献报道[9],Ti与Mg的标准电极电位相差较大,容易在腐蚀介质中形成电偶电池而加速基体腐蚀和涂层剥离。因此,对无外加磁场条件获得的涂层样品进行了极化曲线测试,考察其对镁合金基体的腐蚀防护能力(见图7),通过电化学软件模拟的相关电化学参数值如表1所列。

图6 MAO与无外加磁场条件下沉积120 min所得MAO/Ti涂层样品的XRD谱

Fig. 6 XRD patterns of MAO coating and MAO/Ti coatings prepared without magnetic for 120 min

结合图7和表1,空白镁合金AZ31的φcorr和Jcorr分别为-1648 mV和125.8 μA/cm2,MAO 处理后,其φcorr正移了151 mV,Jcorr降低了近两个数量级。这表明MAO膜能降低镁合金基体的腐蚀速度,起到了腐蚀保护的作用。与MAO样品相比,沉积30 min的MAO/Ti复合涂层样品的φcorr正移了190 mV;Jcorr变化较小,但仍呈现出减小的趋势。并且,随着沉积时间由30 min增加到120 min,其φcorr由-1277 mV正移到了1057 mV,Jcorr 由5 μA/cm2减小到1.87 μA/cm2。

表1 与图7对应的极化曲线电参数模拟值

Table 1 Fitting results of polarization curves from Fig. 7

图7 空白样品和涂层样品在3.5% NaCl 溶液中的极化曲线

Fig. 7 Polarization curves of bare and coated AZ31B Mg alloys in 3.5% NaCl solution

φcorr正移意味着腐蚀的难度增加;而Jcorr的减小说明腐蚀速度降低。此外,MAO/Ti复合涂层样品的Rp值明显大于空白镁合金和MAO样品,Rp的增大表明涂层的致密性增加,腐蚀难度进一步增大。由此可见,Ti镀层进一步增强了MAO膜对镁合金的腐蚀防护能力。

3 分析与讨论

多弧离子镀的等离子体由电子、正离子、液滴等组成。未加轴向磁场时,等离子体在负向电压的作用沉积到基体上,并经过形核、长大直至生成Ti镀层(见图4)。然而,当外加轴向磁场时,电子和离子的运动是沿着磁力线方向螺旋前进沉积在基底上;而带电大颗粒子也会沿着磁力线方向运动,但它们的质量和电荷之比与电子和离子相比较大,在运动过程中将与等离子体分离而沉积在管壁上;不带电的液滴或固态的大颗粒不受磁场约束,由于惯性将作直线运动,其大部分也将撞向管壁而失去动能沉积在弯管壁上或掉落在真空室中。因此,增加磁场电流强度,或是磁场作用下延长沉积时间,都未获得覆盖完全的MAO/Ti复合涂层(见图2(b)~(f)和图3)。此外,外加轴向磁场后,MAO膜表面未能被Ti镀层完全覆盖,这也与弧靶和样品之间的距离有关,相关工作将在以后的工艺实验中进行具体研究。

增大磁场电流提高了约束磁场强度,可减少弧斑运动阻力,提高弧斑运动速度,降低弧斑在靶材上的停留时间从而减少液滴的产生[19]。因此,随着磁场电流的增大,MAO/Ti复合涂层表面的大颗粒液滴数量减少(见图2(b)~(f))。然而,增大电流使电弧更加细碎,旋转速度更快,反而提高了阴极靶材表面的温度,增加了表面液滴的发射,因此,随着沉积时间的增加,MAO/Ti复合涂层表面出现了大量的液体熔滴(见图3)。

通过对MAO/Ti复合涂层的极化曲线分析,可知Ti镀层进一步增强了MAO膜对镁合金基体的腐蚀防护能力。然而,与MAO样品相比,除MAO/Ti复合涂层的φcorr显著正移外,其Jcorr虽有减小的趋势,但数值降低程度较小,与MAO样品的Jcorr处于同一数量级,表明Ti镀层强化腐蚀防护的效果不明显。这应与Ti镀层的致密性有关。由实验可知,这些MAO/Ti复合涂层未引入外加磁场(见图3),由此Ti镀层中将存在大量的大尺寸颗粒,导致镀层中存在孔隙,致密性差(见图4(a))。因此,在以后的研究中,将综合考虑多种因素,如降低磁场电流、降低阴极靶材温度或减小靶材与样品间的距离等,致密化Ti镀层。

4 结论

1) 随着外加轴向磁场电流的增加,提高了约束磁场强度,减少了靶材表面液滴的产生,减少了MAO/Ti涂层表面的大尺寸熔滴粒子数量。

2) 外加磁场作用下,随着沉积时间的延长,真空室温度显著升高,MAO/Ti涂层表面的大尺寸液体熔滴颗粒数量增加。

3) 无外加磁场作用下,MAO/Ti涂层表面以球形沉积粒子为主,且随着沉积时间的延长,Ti镀层厚度逐渐增加,沉积时间为90 min时,可完全覆盖MAO膜。

4) MAO/Ti涂层界面结合良好,Ti镀层进一步强化了MAO膜对镁合金基体的腐蚀防护能力。

REFERENCES

[1] 高正源, 潘复生. 镁合金表面功能涂层制备与界面表征技术的研究进展[J]. 功能材料, 2012, 43(14): 1875-1879.

GAO Zheng-yuan, PAN Fu-sheng. Development of fabrication processes and adhesion measurement of functional surface coating on magnesium alloys[J]. Journal of Functional Materials, 2012, 43(14): 1875-1879.

[2] VLADIMIROV B V, KRIT B L, LYUDIN V B, MOROZOVA N V, ROSSIISKAYA A D, SUMINOV I V, EPEL’FELD A V. Microarc oxidation of magnesium alloys: A review[J]. Surf Eng Appl Electrochem, 2014, 50(3): 195-232.

[3] ZHAO H, WANG X H, LIU Q L, CHEN L J, LIU Z. Structure and wear resistance of TiN and TiAlN coatings on AZ91 alloy deposited by multi-arc ion plating[J]. Transaction of Nonferrous Metals Society of China, 2010, 20(S2): s679-s682.

[4] MIAO Q, CUI C E, PAN J D. CrN-TiN multilayer coating on magnesium alloy AZ91 by arc-glow plasma depositing process[J]. Surf Coat Technol, 2007, 201: 5077-5080.

[5] KAMINSKI J, TACIKOWSKI M, BROJANOWSKA A, KUCHARSKA B, WIEZCHON T. The effect of tightening on the corrosion properties of the PVD layers on magnesium AZ91D alloy[J]. Journal of Surface Engineering Materials and Advanced Technology, 2014, 4: 270-281.

[6] ZHOU H, CHEN F, YAO B, HAN G J, JAWID A. Properties of the TiN coatings on previously Ti ion-implanted magnesium alloy substrate[J]. Surf Coat Technol, 2007, 201:6730-6733.

[7] SUN Y, LU C, YU H L, KIETTIEU A, SU L H, ZHAO Y, ZHU H T, KONG C. Nanomechanical properties of TiCN and TiCN/Ti coatings on Ti prepared by filtered arc deposition[J]. Mat Sci Eng A, 2015, 625: 56-64.

[8] LI H T, WANG Q, ZHUANG M H, WU J J. Characterization and residual stress analysis of TiN/TiCN films on AZ31 magnesium alloy by PVD[J]. Vacuum, 2015, 112: 66-69.

[9] WU G S, AHANAGHI A, ZHAO Y, ZHANG X M, XU R Z, WU Z W, LI G Y, CHU PAUL K. The effect of interlayer on corrosion resistance of ceramic coating/Mg alloy substrate in simulated physiological environment[J]. Surf Coat Technol, 2012, 206: 4892-4898.

[10] WU G S, DAI W, ZHENG H, WANG A Y. Improving wear resistance and corrosion resistance of AZ31 magnesium alloy by DLC/AlN/Al coating[J]. Surf Coat Technol, 2010, 205: 2067-2073.

[11] WU G S. Fabrication of Al and Al/Ti coatings on magnesium alloy by sputtering[J]. Mater Lett, 2007, 61: 3815-3817.

[12] NARAYANAN T S N S, PARK I S, LEE M H. Strategies to improve the corrosion resistance of microarc oxidation (MAO) coated magnesium alloys for degradable implants: Prospects and challenges[J]. Prog Mater Sci, 2014, 60: 1-71.

[13] SONG G L, SHI Z. Corrosion mechanism and evaluation of anodized magnesium alloys[J]. Corros Sci, 2014, 85: 126-140.

[14] GU Y, XIONG W, NING C, ZHANG J. Residual stresses in microarc oxidation ceramic coatings on biocompatible AZ31 magnesium alloys[J]. J Mater Eng Perform, 2012, 21: 1085-1090.

[15] ARRABAL R, MOTA J M, CRIADO A, PARDO A, MOHEDANO M, MATYKINA E. Assessment of duplex coating combining plasma electrolytic oxidation and polymer layer on AZ31 magnesium alloy[J]. Surf Coat Technol, 2012, 206: 4692-4703.

[16] 崔学军, 林修洲, 刘春海, 金永中, 杨瑞嵩, 李明田, 龚 敏. 一种轻金属及其合金表面复合涂层的制备方法: 中国, 2014100950038.1[P]. 2014-03-14.

GUI Xue-jun, LIN Xiu-zhou, LIU Chun-hai, JIN Yong-zhong, YANG Rui-song, LI Ming-tian, GONG Min. A method to prepare composite coatings on a light metal and its alloy: China, 201410095038.1[P]. 2014-03-14.

[17] CAI F, ZHANG S H, LI J L, CHEN Z, LI M X, WANG L. Effect of nitrogen partial pressure on Al-Ti-N films deposited by arc ion plating[J]. Appl Surf Sci, 2011, 258: 1819-1825.

[18] ZHANG J, L  H M, CUI G Y, JING Z, WANG C. Effects of bias voltage on the microstructure and mechanical properties of (Ti,Al,Cr)N hard films with N-gradient distributions[J]. Thin Solid films, 2011, 519: 4818-4823.

H M, CUI G Y, JING Z, WANG C. Effects of bias voltage on the microstructure and mechanical properties of (Ti,Al,Cr)N hard films with N-gradient distributions[J]. Thin Solid films, 2011, 519: 4818-4823.

[19] 张 钧, 赵彦辉. 多弧离子镀技术与应用[M]. 北京: 冶金工业出版社, 2007.

ZHANG Jun, ZHAO Yao-hui. Technology and application of multi-arc ion plating[M]. Beijing: Metallurgical Industry Press, 2007.

[20] 崔学军, 王 荣, 魏劲松, 白成波, 林修洲. 电参数对AZ31B镁合金微弧氧化膜微观形貌及耐蚀性的影响[J]. 中国腐蚀与防护学报, 2014, 34(6): 495-501.

CUI Xue-jun, WANG Rong, WEI Jin-song, BAI Cheng-bo, LIN Xiu-zhou. Effect of electrical parameters on micromorphology and corrosion resistance of micro-arc oxidation coating on AZ31B Mg alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2014, 34(6): 495-501.

[21] MI T, JIANG B, LIU Z, FAN L. Plasma formation mechanism of microarc oxidation[J]. Electrochi Acta, 2014, 123: 369-377.

[22] AL BOSTA M M S, MA K J. Suggested mechanism for the MAO ceramic coating on aluminium substrates using bipolar current mode in the alkaline silicate electrolytes[J]. Appl Surf Sci, 2014, 308: 121-138.

[23] ZHANG S H, WANG L, WANG Q M, LI M X. A superhard CrAlSiN superlattice coating deposited by multi-arc ion plating: I. Microstructure and mechanical properties[J]. Surf Coat Technol, 2013, 214: 160-167.

[24] CUI X J, LIN X Z, LIU C H, YANG R S, ZHENG X W, GONG M. Fabrication and corrosion resistance of a hydrophobic micro-arc oxidation coating on AZ31 Mg alloy[J]. Corros Sci, 2015, 90: 402-412.

Effects of magnetic field and deposition time on structure and properties of MAO/Ti coating on AZ31B magnesium alloy

CUI Xue-jun1, 2, LIU Chun-hai1, 2, YANG Rui-song1, 2, LI Ming-tian1, 2, LIN Xiu-zhou1, 2

(1. School of Materials and Chemical Engineering, Sichuan University of Science and Engineering, Zigong 643000, China;

2. Material Corrosion and Protection Key Laboratory of Sichuan Province,

Sichuan University of Science and Engineering, Zigong 643000, China)

Abstract: The MAO/Ti composite coating was fabricated on AZ31B Mg alloy through a combined process of micro-arc oxidation (MAO) with multi-arc ion plating. The morphology, composition, phase structure and corrosion resistance of the coatings were evaluated using SEM, EDS, XRD and electrochemical methods. The results show that, with the magnetic current increasing from 0 A to 20 A, the temperature of vacuum chamber increases to 192 ℃ from 128 ℃, and the number of the droplet with large size on MAO/Ti coating decreases. When the deposition time increases from 30 min to 120 min at magnetic current of 10 A, the temperature of vacuum chamber increases sharply, the droplet number increases gradually, and the surface of MAO/Ti coating appears micro-cracks. However, under condition without magnetic field, the surface of the MAO/Ti coating presents plenty of droplets with the deposition time increases from 30 min to 120 min, and the surface of MAO coating is coated gradually by the Ti coating. The phase structures of MAO coating don’t change during this multi ion plating, while the φcorr of the MAO/Ti coating shifts to a positive potential, and the Jcorr decreases slightly. It can be concluded that the neutral or charged particles with large size may be filtered or decreased by controlling the magnetic current. Meanwhile, the magnetic increases movement velocity of the arc spot and rises the temperature of the cathode target, which could result in an increasing of droplets on the MAO/Ti coating. Although all results prove that the Ti coating further enhances the corrosion protection ability of the MAO coating on AZ31 Mg alloy, the compact Ti coating is required to be fabricated to provide a better properties through process optimization.

Key words: magnesium alloy; coating; plasma electrolytic oxidation; physical vapour deposition; titanium; corrosion resistance

Foundation item: Project(12ZA261) supported by the Key Research Project of Sichuan Education Department, China; Project(2013CL01) supported by the Opening Project of the Material Corrosion and Protection Key Laboratory of Sichuan Province, China; Project(2014RC18) supported by the Talent Introduction Funds of the Sichuan University of Science and Engineering, China

Received date: 2015-10-12; Accepted date: 2016-03-10

Corresponding author: CUI Xue-jun; Tel: +86-813-5505670; E-mail: cxj_2046@163.com

(编辑 李艳红)

基金项目:四川省教育厅重点项目(12ZA261);材料腐蚀与防护四川省重点实验室开放基金(2013CL01);四川理工学院人才引进基金资助项目(2014RC18)

收稿日期:2015-10-12;修订日期:2016-03-10

通信作者:崔学军,副教授,博士;电话:0813-5505670;E-mail:cxj_2046@163.com