文章编号:1004-0609(2011)07-1562-08

镁合金微弧氧化陶瓷层表面的电泳成膜机理

蒋永锋1, 杨华山1, 包晔峰1, 刘益阳2

(1. 河海大学 机电工程学院,常州 213022;2. 江苏鸿业涂料科技产业有限公司,常州 213016)

摘 要:研究镁合金微弧氧化(PEO)陶瓷层表面的电泳成膜机理;分析工艺参数对复合膜层耐蚀性的影响。采用扫描电镜、示波器和盐雾试验机等分别研究复合膜层的表面和截面形貌、电泳过程中电流变化规律及腐蚀防护性能。结果表明:在电泳成膜过程中,微弧氧化陶瓷层微孔处被击穿,电泳回路产生电流,电泳漆带电粒子先在微孔处沉积,然后向周围移动并沉积,当电流降为0时,电泳过程结束。随着陶瓷层厚度和粗糙度的增加,陶瓷层被击穿时间延长,电泳漆粒子沉积时间缩短。微弧氧化陶瓷层的腐蚀速率是微弧氧化/电泳涂装复合膜层的6.286倍,说明镁合金微弧氧化陶瓷层经电泳处理后,其耐蚀性得到了显著的增强。

关键词:镁合金;微弧氧化;电泳沉积;成膜机理

中图分类号:TG174.461 文献标志码:A

Formation mechanism of electrophoretically

deposited organic layer on PEO film of magnesium alloy

JIANG Yong-feng1, YANG Hua-shan1, BAO Ye-feng1, LIU Yi-yang2

1. College of Mechanical and Electrical Engineering, Hohai University, Changzhou 213022, China;

2. Jiangsu Hongye Coatings Co., Ltd., Changzhou 213016, China)

Abstract: The formation mechanism of organic layer within ceramic layer by the electrophoretic deposition (EPD) was investigated. The influence of processing parameters on the corrosion resistance of the composite coating was analyzed. The surface and cross-section morphologies, variation of current in the EPD and corrosion protection were evaluated using scanning electron microscope, oscilloscope and salt spray tester, respectively. The results indicate that the breakthrough and current appears in the EPD process. As a result, the charged particles in electrophoretic paint are firstly deposited within micropores on the ceramic layer, and then spread out. When the current of the EPD becomes 0, the electrophoretic deposition is completed. A long time for breakthrough and a reduction for the EPD time occur with the increase of the thickness and roughness of the ceramic layer. The corrosion rate of the PEO coating is 6.286 times as fast as that of the composite coating. This is of practical significance for magnesium alloys in the formation of organic layer within ceramic layer to improve corrosion resistance.

Key words: magnesium alloy; plasma electrolytic oxide; electrophoretic deposition; formation mechanism

镁合金具有密度低、比强度和比刚度高、阻尼系数小及电磁屏蔽性好等特点,在汽车、电子产品、航空航天等领域得到了广泛应用[1-3]。 但表面易腐蚀的缺点限制了其在这些领域中的发展。

近年来,微弧氧化(Plasma electrolytic oxidation, PEO)技术因工艺简单、处理能力强,在镁合金表面处理中受到广泛关注[4-8]。但镁合金微弧氧化陶瓷层存在孔隙率高及组织疏松[9]等缺陷,这些缺陷极大地影响了基体的腐蚀防护性能,使Cl-等腐蚀介质侵蚀基体的速度加快[10]。采用后处理可封闭镁合金微弧氧化陶瓷层表面孔隙,阻隔Cl-等腐蚀介质腐蚀基体的通道。目前,微弧氧化陶瓷层后处理方法较多,如溶胶-凝胶法[11]、化学镀法[12]、水热处理法[13]和电泳涂装法等。其中,溶胶-凝胶处理工艺复杂,且溶胶-凝胶颗粒大,较难进入陶瓷层孔隙;水热处理虽简单,但处理温度较高,能耗高,且封闭效果受水质和pH值影响较大;化学镀处理后的镀层与陶瓷层结合强度较差;电泳涂装工艺简单、成本低廉,既可以提高腐蚀防护性能又可以起到外观装饰效果,是目前镁合金微弧氧化陶瓷层较好的后处理方法之一[14]。迄今为止,有关基于镁合金微弧氧化陶瓷层表面电泳(Electrophoretic deposition, EPD)的机理及工艺参数对复合膜层性能影响的研究较少[15-16]。

本文作者通过多功能示波器和扫描电镜等,从宏观和微观角度研究微弧氧化陶瓷层表面电泳涂装的机理及工艺参数对复合膜层腐蚀防护性能的影响。

1 实验

实验材料为压铸镁合金AZ91D,其化学成分(质量分数)为Al 8.3%~9.7%,Zn 0.35%~1.00%,Mn 0.15%~0.50%,Si 0.1%,Cu 0.03%,Ni 0.002%,Fe 0.005%,余量为Mg。试样板尺寸为5 cm×5 cm×0.1 cm。微弧氧化处理采用自制10 kW微弧氧化电源,电解液主要成分为硅酸钠及氢氧化钠。电泳涂装处理采用自制电源,槽液为环氧HED-5000型红色阴极电泳漆(电导率为1 544 μS/cm,pH值为5.9),微弧氧化处理后的试样接电泳电源阴极,不锈钢接阳极,两极间距为7 cm,电泳涂装完用高压水枪洗去试样表面浮漆,放入红外加热烘箱烘干固化20~30 min。

采用盐雾试验测定膜层的耐蚀性。试验条件如下:向质量浓度为(50±5) g/L的NaCl溶液中加入0.26 g CuCl2·H2O晶体,精度在0.02 g以内,并加入冰乙酸调节溶液的pH值在3.0~3.1之间,温度为(50±2) ℃,腐蚀时间为320 h,采用质量损失法评价腐蚀结果,即?m= m 1-m 0, m 0为原始试样质量,m 1为腐蚀试样的质量,? m为质量损失试验方法如下:定期检查试样,每次检查试样需经去离子水清洗,用滤纸吸干水珠,用FA1604型电子分析天平称量试样质量。

采用多功能示波器分析电泳时试样的电流变化曲线;采用TT260型厚度测量仪及TR200手持粗糙度仪分析微弧氧化陶瓷层的厚度及粗糙度;采用JSM-6360IA型扫描电镜(SEM)观察膜层的表面和截面形貌,结合宏观现象分析陶瓷层表面的电泳成膜过程及机理。

2 结果与分析

2.1 镁合金微弧氧化陶瓷层表面电泳涂装前、后的形貌分析

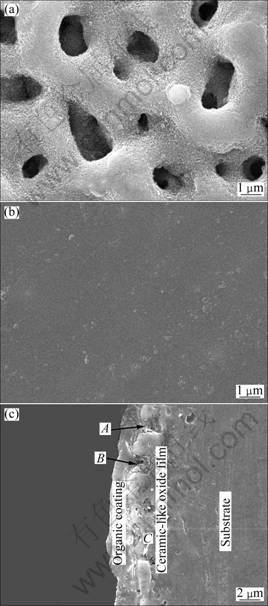

图1所示为镁合金微弧氧化陶瓷层表面电泳涂装前、后的SEM像。由图1(a)可以看出,电泳涂装前,AZ91D镁合金微弧氧化陶瓷层表面密布着直径为0.5~3 μm的微孔,微孔形状为圆状或椭圆状。在腐蚀环境中,这些微孔处是Cl-与Mn+(陶瓷层或基体中金属阳离子)等介质结合产生腐蚀微电池的诱发点。图1(b)所示为陶瓷层表面电泳涂装后的表面形貌。由图1(b)可以看出,电泳漆覆盖了陶瓷层表面所有微孔;结合图1(c)中的A、B和C点可以看出,电泳有机层很好地嵌入陶瓷层孔隙中,烘干固化后的有机层与微弧氧化陶瓷层嵌合较好,阻隔腐蚀介质进入镁合金基体的通道,避免了微孔处诱发腐蚀的发生。

图1 镁合金微弧氧化陶瓷层表面电泳涂装前后的SEM像

Fig.1 SEM images of coatings: (a) Surface morphology of PEO film; (b) Surface morphology of composite coating; (c) Cross-section morphology of composite coating

2.2 微弧氧化陶瓷层膜厚及粗糙度对电泳涂装的 影响

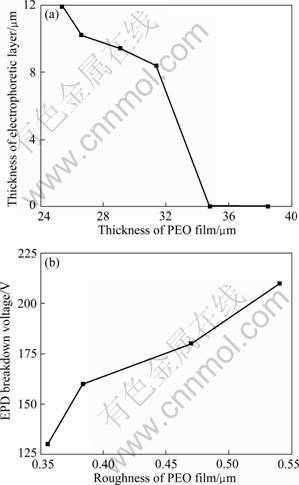

图2所示为恒定电泳电压下陶瓷层厚度与沉积电泳层厚度的关系及微弧氧化陶瓷层表面粗糙度与电泳电压的关系。从图2(a)可以看出,随着陶瓷层厚度的增加,在240 V电泳电压和90 s时间的条件下,电泳层厚度逐渐下降,当膜厚大于34.8 μm后,电泳漆附着困难,陶瓷层表面未见电泳层。这是因为环氧HED-5000型红色阴极电泳漆的工作电压范围为100~240 V,当陶瓷层厚度大于34.8 μm后,陶瓷层阻抗较大,电泳回路中未能形成电流,没有电场力驱动电泳漆粒子泳向陶瓷层,从而使电泳漆粒子无法沉积在陶瓷层表面。从图2(b)可以看出,随着粗糙度的增加,电泳涂装所需的击穿电压升高,可能是由于微弧氧化的时间延长后,陶瓷层表面微孔凝固后的口径增大,但孔隙数量减少,陶瓷层表面致密性增加,陶瓷层阻抗增大,所以电泳电压升高。

图2 陶瓷层厚度和粗糙度对电泳涂装的影响

Fig.2 Influence of thickness (a) and roughness (b) of PEO film during electrophoretic deposition

2.3 微弧氧化/电泳涂装复合膜层的耐蚀性

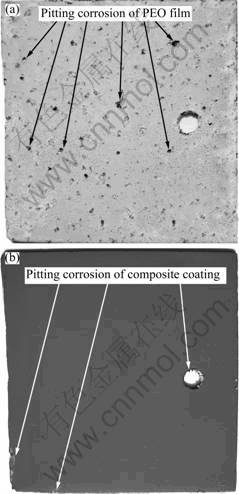

图3所示为微弧氧化陶瓷层和微弧氧化/电泳涂装复合膜层经320 h盐雾腐蚀后的表面形貌。从图3(a)可以看出,陶瓷层表面存在大量腐蚀孔洞,箭头所指处为大而深的腐蚀孔(孔深大于孔径)。 结合图1(a)的显微形貌可知,这些腐蚀孔洞是镁合金微弧氧化反应放电的通道,显微照片中直径较大的黑点为大而深的腐蚀孔。由图3(b)可以看到,膜层表面几乎没有腐蚀的痕迹,腐蚀孔极少,仅有的腐蚀部位为试样边角及挂钩处,这是由于电泳漆覆盖了陶瓷层表面微孔,如图1(b)中显微结构所示。

图3 经320 h盐雾腐蚀后样品的表面形貌

Fig.3 Surface morphologies of different samples after 320 h salt spray corrosion: (a) PEO film; (b) Composite coating

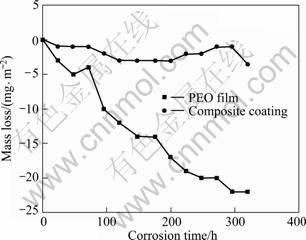

图4所示为微弧氧化陶瓷层与微弧氧化/电泳涂装复合膜层在加速盐雾腐蚀试验中的质量损失对比。在320 h的腐蚀时间里,微弧氧化陶瓷层(厚度为46.3 μm)单位面积腐蚀质量损失速率为27.5 mg/h,微弧氧化/电泳涂装复合膜层(总厚度为44.7 μm,其中陶瓷层为28.4 μm,电泳层为16.3 μm)单位面积腐蚀质量损失速率为4.375 mg/h,微弧氧化/电泳涂装复合膜层的质量损失速率仅为微弧氧化陶瓷层的1/6.286。这是因为镁合金微弧氧化陶瓷层由致密层和疏松层组成,致密层孔隙少而小,疏松层孔隙大而多,孔隙的存在为Cl-等离子提供腐蚀通道。Cl-等腐蚀离子的半径较小,易吸附在陶瓷层孔隙中,可与Mn+结合产生强烈的感应离子导电,使孔隙处离子杂乱移动,形成腐蚀微电池。当微电池的电场强度达到某一临界值时即发生点蚀。随着腐蚀的不断进行,腐蚀孔处溶液的pH值逐渐下降,酸性的增加造成腐蚀孔的扩大和加深。陶瓷层表面电泳涂装后,电泳漆粒子和颜料沉积于陶瓷层微孔内及表面,烘干时发生交联固化反应,反应后的电泳层较好地铺盖于陶瓷层,封闭微弧氧化陶瓷层上的点蚀源——微孔,阻断Cl-等腐蚀性离子进入镁合金基体通道,防止腐蚀微电池的形成,从而降低镁合金的腐蚀速率。微弧氧化/电泳涂装复合膜层质量的减少是由于挂钩处的铁丝与陶瓷层紧密接触和边角处的应力集中导致这两处漆层较薄,电泳层未完全覆盖挂钩和尖角处的陶瓷层,导致电泳涂装挂钩和边角处的腐蚀质量损失。

2.4 镁合金微弧氧化陶瓷层表面电泳成膜过程及机理分析

2.4.1 陶瓷层表面电泳成膜过程

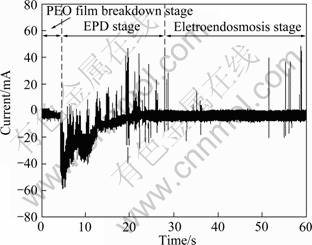

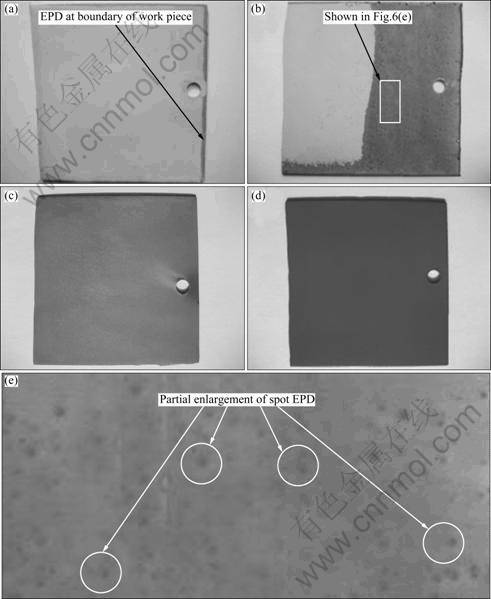

陶瓷层表面电泳成膜的必要条件是电场的形成,在电场的驱动下,电泳漆粒子才可以泳向陶瓷层。陶瓷层表面电泳成膜的电流波形图及电泳成膜过程分别如图5和6所示。从图5可以看出,微弧氧化陶瓷层表面电泳成膜初期0~4 s为陶瓷层击穿阶段;4~5 s出现峰值电流阶段;5~23.5 s为电泳漆粒子附着阶段,即电沉积阶段;23.5 s后,为电泳层中水的渗析阶段。

在0~4 s陶瓷层击穿阶段,电流几乎保持为0,电泳漆中水发生电解、树脂发生溶解反应,即

(1)

(1)

(2)

(2)

电泳漆粒子不发生附着,如图6(a)所示,仅边界处存在红色颜料粒子的沉淀吸附。这是因为红色颜料粒子的直径小于1~3 μm的陶瓷层微孔直径,由于电泳过程的搅拌作用和陶瓷层表面微孔的毛细管作用,少量颜料粒子被吸附在微孔内形成沉淀吸附。

图4 微弧氧化陶瓷层和微弧氧化/电泳涂装复合膜层经腐蚀后的质量损失曲线

Fig.4 Mass loss curves of PEO film and composite coatings after corrosion

图5 微弧氧化陶瓷层表面电泳成膜电流

Fig.5 Current of electrophoretic deposition on PEO film

结合图6(b)、(e)与图5中4~5 s的峰值电流可 知,陶瓷层被击穿的瞬间,电泳回路中产生较大的电流,使微弧氧化陶瓷附近产生大量OH-,电泳漆中的颜料粒子伴随着聚合物阳离子R-NH+(R-NH+为环氧HED-5000型红色阴极电泳漆电离后产生的水溶性阳离子群体)在瞬间泳向陶瓷层边界处。在边界处,阳离子R-NH+与颜料粒子优先泳向微孔处,所以,微孔处颜色较深。这是因为镁合金微弧氧化陶瓷层边界处烧结缺陷多、膜层薄、阻抗较低,在相同电泳极板距(7 cm)下,阻抗较低的微孔处电场强度E较高,而电泳漆粒子均匀分散在漆液中,带电量q基本相同(见式(3))[17]:

F=E×q (3)

式中:F为电泳漆粒子在电场中受到的库仑力;E为微弧氧化陶瓷层表面分布的电场强度;q为电泳漆带电粒子的电量。

图6 陶瓷层表面电泳成膜过程试样表面形貌

Fig.6 Surface morphologies of sample of electrophoretic deposition on PEO film: (a) 0-4 s; (b) 4-5 s; (c) 5-23.5 s; (d) After 23.5 s; (e) Partial enlargement of (b)

由于陶瓷层边界微孔处受到的库仑力F较大,所以,在相同极板距下电泳漆粒子先游向微孔处。在微孔处,阳离子R-NH+与阴离子OH-相互作用失去亲水性,在陶瓷层以R-N形式沉积,反应式如下:

R—NH++OH-→R—N+H2O (4)

5~23.5 s为电泳漆粒子附着沉积阶段。电泳漆粒子在右边界微孔处先出现点沉积,因电泳漆附着后具有绝缘性,当微孔处电泳层的阻抗增加到一定值时,电场开始向其他阻抗较低部位移动。从图6(c)可知,电泳漆粒子在陶瓷层表面完全沉积一层较薄的漆层后,又开始在右边界处沉积。当微弧氧化/电泳涂装复合膜层的阻抗较大时,电泳回路中的电场无法使电泳漆粒子泳向陶瓷层,电泳漆粒子不再沉积,此时,电泳电流接近0,电场微弱。

23.5 s后,电流很弱,电泳漆粒子不再移动,但此时电泳层致密性较差,膜中含水分约为2%~5%(质量分数),这些水分在微弱电场下从漆膜中渗析出来,电泳漆粒子与陶瓷层间的水分层消失,因此,电泳层紧密吸附于陶瓷层[18]。

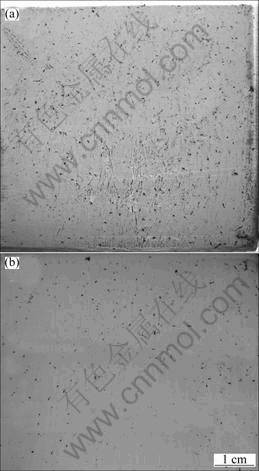

2.4.2 陶瓷层表面电泳成膜机理

图7(a)所示为采用SiC水砂纸除去电泳有机层后的陶瓷表面形貌,发现大量点状电泳漆的存在。图7(b)所示为完全磨掉陶瓷层后镁板表面形貌,表面仍发现许多电泳漆粒子的存在。结合文献[19]所述,微孔贯穿于整个微弧氧化陶瓷层,但陶瓷层不同部位的孔洞数量和孔径不同。可以推断,镁合金微弧氧化处理后,陶瓷层表面弧光熄灭,熔融产物立即冷却凝固,但致密层内部仍可能存在薄弱部位(微孔),陶瓷层表面电泳成膜电流从这些微孔处产生,使颜料粒子伴随着电泳漆粒子沉积于陶瓷层表面。

图7 去除有机层及陶瓷层后试样的表面形貌

Fig.7 Surface morphologies of electrophoretic panit infiltrating into PEO film: (a) Surface of PEO film after polished by SiC paper; (b) Naked magnesium alloy after polished by SiC paper

因微孔贯穿整个陶瓷层,陶瓷层的击穿可能是热击穿和化学击穿共同作用的结果。热击穿作用在陶瓷层内部,化学击穿作用在陶瓷层外部与电泳漆接触处,这两种击穿作用与微孔处的电离作用使陶瓷层微孔处电导大大增加。

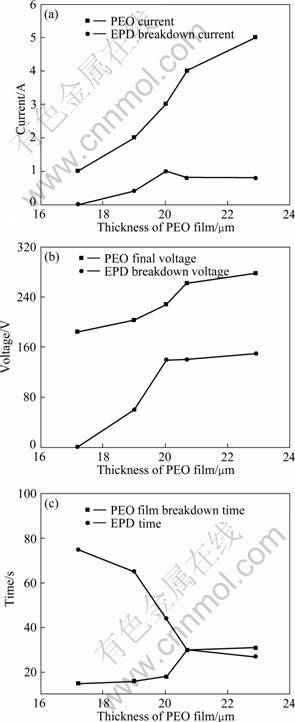

在陶瓷层的不同厚度情况下,陶瓷层被击穿时电流、电压、击穿时间及电沉积时间都不相同,如图8所示。从图8(a)和(b)可以看出,随着陶瓷层厚度的增加,电泳时击穿电流和电压呈增大趋势。结合CHANG[20]所述镁合金微弧氧化陶瓷层的生长模型可知,当陶瓷层较薄时,疏松层向外生长快,致密层向内生长慢,疏松层厚度占陶瓷的层厚度的比例大于60%;当陶瓷层厚度逐渐增加,疏松层生长速度减缓,致密层生长速度加快,致密层厚度占陶瓷层厚度的比例大于60%。当陶瓷层较薄时,陶瓷层被击穿的有效厚度为小于40%的致密层,需要击破的能量较低,电泳时,陶瓷层被击穿的电流和电压低。当陶瓷层增厚时,致密层增厚,需要击穿的能量较高,电泳时陶瓷层被击穿的电流和电压随之增加。当陶瓷层厚度大于20.029 μm时,陶瓷层击穿电流和电压变化较小,可能由于致密层有效厚度一定,电泳时陶瓷层被击穿的能量恒定,所以,电流和电压变化趋势减小。当陶瓷层厚度增加到一定值(结合图2(a)可知为34.8 μm)时,致密层所占比例较大,且贯穿于致密层的孔隙已很小,在电泳漆额定工作电压为100~240 V范围内,陶瓷层已不能被击穿,从而电泳漆粒子不能沉积在其表面。

图8 不同陶瓷层厚度下电泳击穿时的电流、电压以及导通时间和电沉积时间

Fig.8 Break down current (a), voltage (b) and PEO film breakdown time and EPD time on PEO film (c) at different thicknesses

从图8(c)中可以看出:当膜厚较薄时,陶瓷层击穿时间较短,电泳漆的沉积时间较长;随着陶瓷层厚度的增加,陶瓷层击穿时间延长,电泳漆沉积时间缩短。这是由于陶瓷层厚度越薄,有效击穿厚度越薄,击穿时间越短;当陶瓷层薄时,阻抗较低,在一定电泳电压和时间下,陶瓷层阻抗与可沉积的电泳层阻抗一定,导致电泳层沉积时间延长。

3 结论

1) 对微弧氧化陶瓷层进行电泳涂装,在相同电压条件下,随着陶瓷层厚度的增加,电泳层厚度逐渐降低;随着陶瓷层表面粗糙度的增大,电泳涂装击穿电压升高。

2) 320 h的盐雾腐蚀中,微弧氧化陶瓷层单位面积的质量损失速率为0.027 5 g/h,而微弧氧化/电泳涂装复合膜层单位面积的质量损失速率为0.004 375 g/h,微弧氧化陶瓷层的腐蚀速率为微弧氧化/电泳涂装复合膜层的腐蚀速率的6.286倍。

3) 陶瓷层表面电泳成膜时,先在陶瓷层边界处的微孔成膜,进而向周边移动沉积。当微弧氧化/电泳涂装复合膜层阻抗较大时,电泳时的电场将无法使电泳漆粒子泳向陶瓷层,电泳过程结束。其过程分为4个阶段:0~4 s为陶瓷层击穿阶段;4~5 s为微孔处击穿产生电流阶段;5~23.5 s为电泳漆粒子沉积阶段;23.5 s后为电泳漆层中的水渗析阶段。

4) 微弧氧化陶瓷层表面电泳成膜的电流是由于陶瓷层微孔处击穿产生的。在电泳涂装过程中,随着陶瓷层厚度的增加,陶瓷层被击穿时的电流和电压升高,击穿时间增加,而电泳漆沉积时间缩短。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] YANG Z, LI J P, ZHANG J X, LORIMER G W, ROBSON J. Review on research and development of magnesium alloys[J]. Acta Metallurgica Sinica: English Letters, 2008, 21(5): 313-328.

[3] ONO S. Surface phenomena and protective film growth on magnesium and magnesium alloys[J]. Metallurgical Science and Technology, 1998, 16: 91-104.

[4] SUNDARARAJAN G, RAMA KRISHNA L. Mechanisms underlying the formation of thick alumina layers through the MAO layer technology[J]. Surface and Layers Technology, 2003, 167: 269-277.

[5] WANG Y, WANG J, ZHANG J, ZHANG Z. Characteristics of anodic layers oxidized to different voltages on AZ91D Mg alloy by micro-arc oxidization technique[J]. Materials and Corrosion, 2005, 56 (2): 88-92.

[6] YEROKHIN A L, NIE X, LEYLAND A, MATTHEWS A. Characterization of oxide films produced by plasma electrolytic oxidation of a Ti-6Al-4V alloy[J]. Surface and Coatings Technology, 2000, 130: 195-206.

[7] ARRABAL R, MATYKINA E, HASHIMOTO T, SKELDON P, THOMPSON G E. Characterization of AC PEO layers on magnesium alloys[J]. Surface and Layers Technology, 2009, 203: 2207-2220.

[8] GUO H F, AN M Z, HUO H B, XU S. WU L J. Microstructure characteristic of ceramic coatings fabricated on magnesium alloys by micro-arc oxidation in alkaline silicate solutions[J]. Applied Surface Science, 2006, 252: 7911-7916.

[9] TILLOUS E K, TOLL-DUCHANOY T, BAUER-GROSSE E. Microstructure and 3D microtomographic characterization[J]. Surface and Coating Technology, 2009, 203: 1850-1855.

[10] DUAN Hong-ping, DU Ke-qin, YAN Chuan-wei, WANG Fu-hui. Electrochemical corrosion behavior of composite coaings of sealed MAO film on magnesium alloy AZ91D[J]. Electrochimica Acta, 2006, 51: 2898-2908.

[11] SHANG Wei, CHEN Bai-zhen, SHI Xi-chang, CHEN Ya, XIAO Xiang. Electrochemical corrosion behavior of composite MAO/sol-gel layers on magnesium alloy AZ91D using combined micro-arc oxidation and sol-gel technique[J]. Journal of Alloys and Compounds, 2009, 474: 541-545.

[12] ZENG Li-yun, YANG Shi-wei, ZHANG Wei, GUO Ya-huan, YAN Chuan-wei. Preparation and characterization of a double-layer layer on magnesium alloy AZ91D[J]. Electrochimica Acta, 2010, 55: 3376-3383.

[13] WANG Zhou-cheng, TANG Yi, XU Jie. Study of micro-arc anodic oxidation film and water treatment on the AZ91D magnesium alloy[J]. Journal of Xiamen University: Natural Science, 2006, 45: 292-295.

[14] 袁 兵, 袁 森, 蒋百灵, 袁 芳. 镁合金微弧氧化及后续涂装耐盐雾腐蚀的研究[J]. 材料保护, 2006, 39(9): 15-19.

YUAN Bing, YUAN Sen, JIANG Bai-ling, YUAN Fang. Study of micro-arc oxidation and follow-up painting films corrosion resistant by salt spray on magnesium alloy[J]. Materials Protection, 2006, 39(9): 15-19.

[15] FUKUDA H, MATSUMOTO Y. Formation of Ti-Si composite oxide films on Mg-Al-Zn alloy by electrophoretic deposition and anodization[J]. Electrochimica Acta, 2005, 50: 5329-5333.

[16] 时惠英, 杨 巍, 蒋百灵. 镁合金微弧氧化-电泳复合膜层的腐蚀性能[J]. 腐蚀与防护, 2007, 28(9): 442-444.

SHI Hui-ying, YANG Wei, JIANG Bai-ling. Corrosion performance of micro-arc oxidation and electrophoresis complex layers on magnesium alloy[J]. Corrosion and Protection, 2007, 28(9): 442-444.

[17] 欧阳晶, 蒋百灵. 铝合金微弧电泳复合膜层的工艺制备[J]. 材料保护, 2008, 41(2): 37-39.

OUYANG-jing, JIANG Bai-ling. Characterization of composite coatings produced by plasma electrolytic oxidation plus cathodic electrophoretic deposition on aluminum alloy[J]. Materials Protection, 2008, 41(2): 37-39.

[18] 宋 华, 王锡春. 电泳涂装技术[M]. 北京: 化学工业出版社, 2008: 12-15.

SONG Hua, WANG Xi-chun. Electrophoretic coating[M]. Beijing: Chemical Industry Press, 2008: 12-15.

[19] BLAWERT C, HEITMANN V, DIETZEL W, NYKYFORCHYN H M, KLAPKIV M D. Influence of process parameters on the corrosion properties of electrolytic conversion plasma coated magnesium alloys[J]. Surface and Layers Technology, 2005, 200: 68-72.

[20] CHANG Li-min. Growth regularity of ceramic layer on magnesium alloy by plasma electrolytic oxidation[J]. Journal of Alloys and Compounds, 2009, 468: 462-465.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(50901031);中央高校基本科研业务费项目(2009B30314);江苏省重点实验室开放研究基金资助项目(HB0051)

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:包晔峰,教授,博士;电话:13861282381;E-mail:baoyf@hhuc.edu.cn.