文章编号:1004-0609(2014)08-1984-08

AZ31镁合金挤压板坯的二次变形行为

张义伟1,魏 峰2,刘育锋3,丁汉林1,李殿凯1,杨 磊1

(1. 安徽工业大学 材料科学与工程学院,马鞍山 243002;

2. 无锡福镁轻合金科技有限公司,无锡 214183;

3. 河南新乡铁路摩擦材料厂,新乡 453002)

摘 要:采用Gleeble-3500热模拟试验机对AZ31镁合金挤压板坯进行平面应变压缩实验,研究镁合金二次变形条件下的热变形行为。结果表明,AZ31镁合金挤压板坯二次变形中发生明显的动态再结晶,进一步细化了再结晶晶粒,且二次变形削弱了挤压板坯的(0002)基面织构强度。DEFORM 3D有限元模拟结果表明,当应变速率一定时,变形温度是决定再结晶晶粒大小的主要因素,而当变形温度一定时,高应变速率所引起的显著温升不利于应变累积,因而再结晶晶粒细化效果并不明显。

关键词:镁合金;二次变形;动态再结晶;数值模拟

中图分类号:TG111.7;TG379 文献标志码:A

Secondary deformation behavior of AZ31 magnesium extruded sheet

ZHANG Yi-wei1, WEI Feng2, LIU Yu-feng3, DING Han-lin1, LI Dian-kai1, YANG Lei1

(1. School of Materials Science and Engineering, Anhui University of Technology, Ma’anshan 243002, China;

2. Wuxi Fumei Light Alloy Technology Co., Ltd., Wuxi 214183, China;

3. Xinxiang Railway Friction Material Manufactory, Xinxiang 453002, China)

Abstract: The plain strain compression experiment of AZ31 magnesium extruded sheet was performed on thermal simulation machine Gleeble-3500 in order to investigate the secondary deformation behavior. The results show that the dynamic recrystallization occurs during the secondary deformation of AZ31 magnesium extruded sheet, resulting in the further refinement of grain size of extruded sheet and the weakening of (0002) basal texture. The numerical simulation based on DEFORM 3D shows that the recrystallized grain size depends strongly on the deformation temperature at a constant strain rate, while at a constant deformation temperature, the higher temperature increment resulted from the higher strain rate is unfavorable for the accumulation of strain and then reduces the effect of secondary deformation on the grain refinement.

Key words: magnesium alloy; secondary deformation; dynamic recrystallization; numerical simulation

随着镁合金制备、加工与表面处理等关键技术的不断突破,镁合金材料在通讯电子、汽车工业和航天工业等领域中的应用日趋广泛[1-3]。然而,镁的密排六方晶体结构决定了其室温塑性变形性能相对较差,故通常通过加热到一定温度并采用挤压、轧制等热变形方式来制备镁合金板材、型材或管材等[4-7]。与钢和铝相类似的是,镁合金板材的应用前景更为广阔,因而,目前对镁合金板材制备工艺的研究及其对板材性能影响的研究较多[8-12]。考虑到变形前初始组织对板材最终组织和力学性能的影响,研究者提出了镁合金板材制备的挤压-轧制工艺[13-14],以便通过挤压开坯的方式为轧制提供初始晶粒尺寸相对铸造合金较小的坯料,期望获得组织更为均匀、晶粒更为细小的镁合金轧板。然而,经初次变形后的镁合金板坯,往往已形成了较为强烈的(0002)织构[15-19],对后续板材的轧制带来了较大困难。

本文作者通过Gleeble-3500热模拟机的平面应变压缩实验并结合DEFORM-3D刚黏塑性有限元理论分析方法,探讨AZ31镁合金挤压板坯二次变形的可行性,分析变形温度和应变速率对平面应变压缩后试样组织特征的影响规律,模拟研究平面应变压缩试样中应变场、温度场等分布,并将实验结果与模拟结果进行对比分析,为镁合金板材的挤压-轧制制备工艺提供一定的理论基础。

1 实验

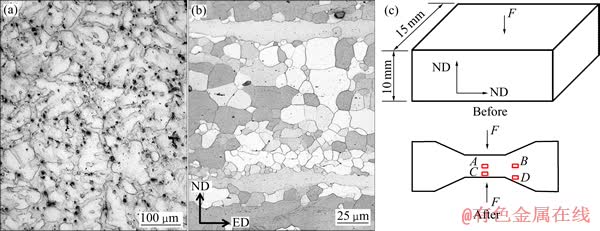

实验采用商用AZ31镁合金为研究对象,其名义化学成分(质量分数)为3%Al,1%Zn以及余量的Mg和不可去除杂质。将AZ31铸锭经1250 t卧式挤压机制备成宽度为90 mm、厚度为10 mm的挤压板坯,从挤压板坯上截取20 mm×15 mm×10 mm的长方块试样,以供在Gleeble-3500 热模拟机上进行平面应变压缩实验,AZ31铸锭和挤压板坯的显微组织及试样的取样方式如图1所示。

对于Gleeble平面应变压缩实验,由于其变形区域内的应力状态、流动状态及热传导等均与轧制过程的相似,故通常采用平面应变压缩实验来模拟研究轧制过程的流动应力与组织演变等[20]。本实验中,将试样以10 ℃/s的速度加热至变形温度并保温 180 s后压缩至真应变量-1.0,压缩后试样快速气冷至室温以便组织观察,其中实验温度分别设定为350、400和450 ℃,变形速率设定为0.3、1和3 s-1,每次压缩过程中均保持实验温度及变形速率恒定。

平面应变压缩后试样自中心平行于ND-ED面(ND为挤压板坯法线方向,ED为挤压板坯挤压方向)剖开,金相组织的观察区域如图1(c)所示。金相试样经粗磨、精磨、精抛至镜面,经苦味酸溶液(苦味酸5 g,醋酸13 mL,酒精70 mL,蒸馏水12 mL)腐蚀、吹干后在Leica DM4000 LED型金相显微镜上进行组织观察。EBSD观察用试样经自动研磨后,先后经0.3 μm Al2O3悬浊液研磨10 min、0.04 μm悬浊液精抛40 min,采用FEI NanoSEM 430高分辨场发射扫描电镜及HKL Channel 5进行织构分析。

平面应变压缩实验过程中记录并保存不同变形条件下的应力-应变曲线,将应力-应变曲线直接导入DEFORM 3D有限元软件的材料数据库中,对平面应变压缩过程进行动态仿真模拟,考察平面应变压缩过程中工件的变形情况及温度场和应变场等的分布与变化情况。

2 结果与分析

2.1 组织观察与分析

图1 AZ31镁合金显微组织及平面应变压缩实验试样示意图

Fig. 1 Microstructures of as-cast AZ31 alloy(a) and extruded sheet(b) and schematic diagram(c) of samples for plain strain compression conducted on Gleeble-3500 machine

由图1可以看出,AZ31铸锭中较多的Mg17Al12相沿晶界分布,而经过挤压前的均匀化处理和挤压过程的高温变形,Mg17Al12相基本完全固溶于基体中,挤压板坯的再结晶晶粒不均匀分布,且部分沿挤压方向拉长的未再结晶晶粒依然存在。

图2所示为镁合金板坯经400 ℃、1 s-1压缩后变形区域内不同位置处的显微组织。显然,中心区域(见图2(a))的晶粒均匀细小,再结晶程度相对较为完全,这是由挤压板坯的中心部位累积变形量大、畸变程度高、再结晶形核数目多等原因引起的。对比挤压板坯原始组织(见图1)可知,经过挤压变形后的再结晶晶粒尺寸明显小于挤压板坯的晶粒尺寸,尤其是中心区域,这充分说明镁合金经挤压后的二次变形可进一步细化再结晶晶粒尺寸。而图2(b)(对应图1(c)中B区域)的组织与挤压板坯较为接近,只是在部分区域发生的动态再结晶,这可能是由于该位置在二次变形过程中,应变变化较小,再结晶晶粒形核率较小等原因所造成的(见图2(b));对于挤压板坯D处(见图2(d))的组织,晶粒大小不均匀,再结晶的晶粒分布呈现明显的流线型长条状,这与板坯平面应变压缩时该区域较为复杂的金属流动和应变累积过程所致。

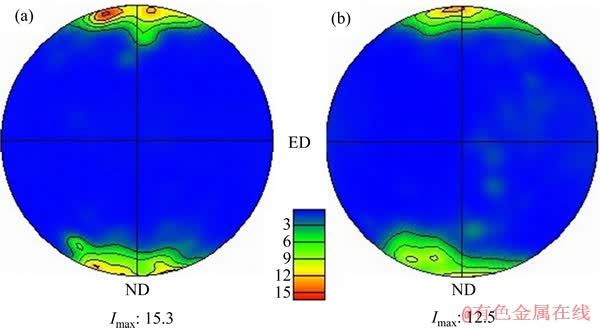

2.2 织构分析

图3所示为AZ31镁合金的织构分析结果。由图3(a)可见,原始挤压板坯的AZ31镁合金存在强烈的(0002)基面织构(晶胞(0002)基面平行于挤压方向,且c轴平行于板坯法线方向),(0002)极图的最大极密度为15.3。图3(b)所示为挤压板坯经400 ℃、1 s-1变形条件压缩后试样中心区域A处的(0002)基面织构,(0002)极图的最大极密度为12.5。可见,虽然压缩后的AZ31镁合金板材中依然呈现较强的基面织构,但板坯基面织构强度明显降低,其可能的原因是在二次变形过程中,部分再结晶晶粒的基面发生了偏转,导致其c轴不再完全平行于板坯法线方向。

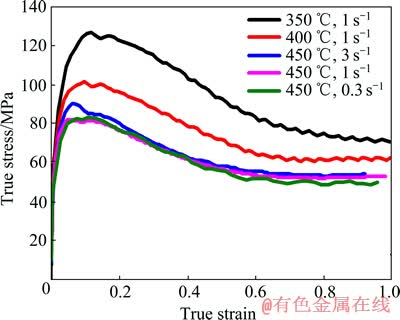

2.3 应力-应变曲线分析

图4所示为不同变形条件下 AZ31 挤压板坯压缩过程中的应力-应变曲线。从图4可以看出,在考察的温度和变形速率范围内,流变应力均随变形程度的增加而不断增大,至某一峰值后平缓下降,最后降至某一稳态值,表现出明显的动态再结晶特征[21],这与图2中组织观察所得到的结论相一致。还可以看出,当应变速率一定时,变形温度越高,则峰值应力和稳态应力越小,而当变形温度一定时,随着应变速率的增加,流变应力的峰值亦稍有增加。这是因为变形温度升高时,原子的热激活过程增强,位错的活动能力增强,变形过程中开动更多的位错进行滑移和攀移,从而导致应力峰值及稳态流变应力值的降低,而随着应变速率的增加,位错发生速率增加,位错攀移及位错反应等引起的硬化强化,导致流变应力峰值和稳态应力值也随之增大。此外,图4中的对比分析可以看出,变形速率对AZ31挤压板坯平面应变压缩过程流变应力影响并不显著,而变形温度对流变应力的影响则显得十分明显。

图3 AZ31镁合金挤压板和平面应变压缩变形后试样的织构分析

Fig. 3 Texture analysis of AZ31 extruded sheet(a) and plain strain compressed sample(b)

图4 不同条件下AZ31挤压板坯平面应变压缩过程的真应力-真应变曲线

Fig. 4 True stress-strain curves of AZ31 extruded sheet compressed under different deformation conditions

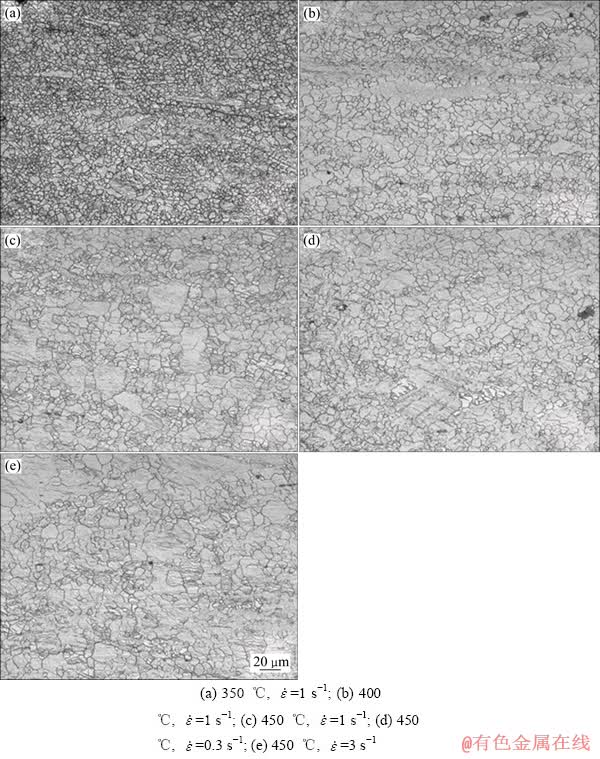

2.4 变形条件对显微组织的影响

由图2所示的金相组织可知,AZ31挤压板坯经400 oC平面应变压缩后,中心区域处的再结晶相对较为完全,为了研究不同变形条件对显微组织的影响,不同变形条件下试样的组织观察均选取其中心区域处进行对比分析,结果如图5所示。

由图5可以看出,在所研究的温度和应变速率范围内,AZ31挤压板经二次变形后,其中心区域均发生了较为完全的动态再结晶,且晶粒分布比挤压板的晶粒分布更为均匀。其中,变形温度对再结晶晶粒尺寸的影响较为显著,且随着变形温度的升高,再结晶平均晶粒尺寸由350 ℃时的7 μm增大至400 ℃时的12 μm及450 ℃时的20 μm(见图5(a)~(c))。显然,温度的升高使得晶界扩散和晶界迁移能力增加,促使变形中的位错重新调整,有利于位错的合并和位错密度的降低,从而促进了动态再结晶晶粒的长大。

对比分析图5(c)~(e)可以看出,变形速率的变化对再结晶晶粒尺寸的影响并不十分明显,与变形速率对应力-应变曲线中峰值应力和稳态应力的影响基本一致。一般认为,再结晶驱动力是变形金属的储存能提供的,当应变速率较低时,金属原子充分扩散、储存能较少使得再结晶驱动力减少,因而只能在高能量起伏的区域首先形核,再结晶形核率较低,而当应变速率较高时,产生同样压缩变形程度所需的时间短,部分区域位错来不及抵消和合并,再结晶形核位置多,晶粒细化明显。另外,在高应变速率下,变形时间较短,再结晶晶粒来不及长大也是导致再结晶晶粒尺寸较小的原因之一。造成本实验中变形速率对再结晶晶粒尺寸影响不大的可能原因是当变形速率较大时试样压缩过程中产生的温升现象比较明显,而较高的实际温度不利于储存能的累积,且高温下再结晶晶粒的生长速率较大,因而减弱了高应变速率对再结晶晶粒的细化作用,这一推论在下述的有限元模拟中将得到进一步证实。

图5 不同变形条件下AZ31挤压板平面应变压缩后的显微组织

Fig. 5 Microstructures for samples compressed under different deformation conditions

2.5 变形过程的DEFORM 3D模拟

图2和图5的组织分析结果表明,变形条件对压缩板坯的再结晶晶粒大小及分布影响显著。本实验中利用DEFORM模拟研究平面应变压缩后试样中的应变场和温度场分布,以进一步分析变形条件对压缩板坯动态再结晶行为的影响规律。

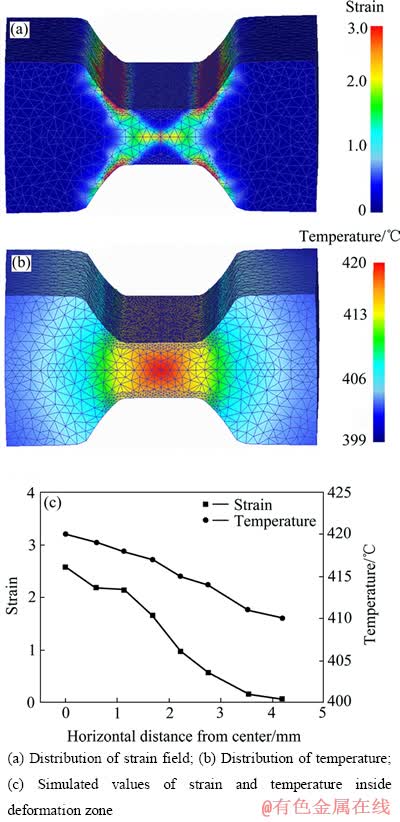

图6所示为挤压板坯在400 ℃下经1 s-1速率压缩后试样内应变场和温度场分布的模拟结果。可以看出,压缩后试样内的应变和温度分布都不太均匀,尤其是在被压缩区域内表现更为突出。图6(a)中应变分布的模拟结果表明,在与压缩砧头侧面接触处的应变值最大,这主要是由该区域的摩擦较大所引起的,在实际压缩过程中,该区域容易产生裂纹,尤其是当变形温度较低或变形速率较快时。此外,变形区域内的应变则呈明显的X型分布,这是压缩过程中变形区域在正向压应力和压缩砧头侧面产生的剪切力的共同作用下导致金属的不均匀流动所引起的,其中,变形区域中心位置处的应变最高,而与砧头正面接触处和变形区域边缘处的金属基本没有发生变形。

图6(b)中变形区域内的温度分布并未出现与应变相类似的分布特征,但温度的最大值依然出现在变形区域的中心处,且呈向变形区域边缘处逐渐降低的趋势。值得注意的是,压缩后试样中产生明显的温升现象,即变形后温度明显高于初设温度,这是由于试样在变形过程中吸收的塑性变形功迅速转化成为热能所引起的。一般来说,这种现象在高变形速率下尤为明显[22]。

图6(c)所示为压缩试样变形区域内自中心处沿水平方向向变形区域边缘处变化时的应变值和温度大小的变化情况。随着距中心处距离的增加,应变和温度值均明显下降,尤其是远离中心处的应变值几乎为零。一般来说,只有当变形量达到或超过某一临界值时动态再结晶才有可能有发生[23],因此,在远离变形区域处由于其应变量并未达到临界值而未能发生动态再结晶,这也正是图2(b)区域的显微组织中只发现少量动态再结晶晶粒的主要原因。同样地,与砧头正面直接接触的区域(见图2(c))和与砧头侧面接触的区域(见图2(d))内的显微组织也表现出与应变分布相对应的特征。

图6 挤压板坯经400 ℃,1 s-1压缩后应变和温度模拟结果

Fig. 6 Simulated distributions of strain and temperature in sheet compressed at 400 ℃ with strain of 1 s-1

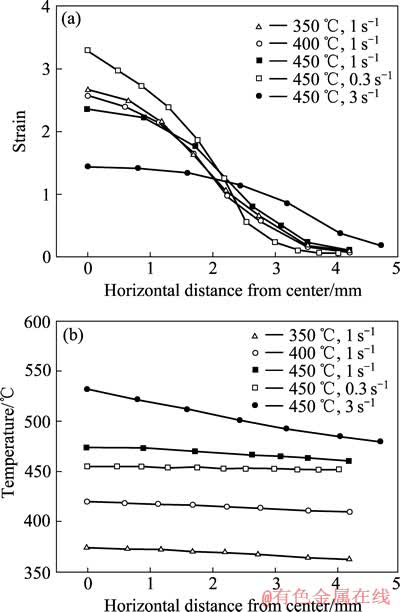

图7 不同变形条件下压缩试样变形区域内的应变和温度分布

Fig. 7 Distributions of strain(a) and temperature(b) inside deformation zone of sheets compressed under different conditions

不同变形条件下压缩试样变形区域内的应变和温度分布如图7所示。可以看出,在所有变形条件下,变形区域内的应变和温度均是随着距中心处距离的增加而降低的,只是下降的程度有所差别,其中,变形速率越大,变形区域内中心处和边缘处的应变差值越小,而温度差值则越大。

从图中可以看出,当应变速率为1 s-1时,随着变形温度的增加,变形区域中心处的应变值逐渐降低(见图7(a)),但差别并不是很大,而温升值(变形后温度与初设温度之差)基本上维持在24 ℃左右(见图7(b))。在这种情况下,由Zener-Hollomon公式可知,此时再结晶晶粒尺寸则主要取决于变形温度,且随着变形温度的降低,再结晶晶粒减小,正如图5中的显微组织所示。

而当变形温度保持不变(450 ℃)时,随着应变速率的增加,变形区中心处的应变值逐渐减小而远离中心处的应变值则逐渐增加(见图7(a)),变形区域内的应变分布较为均匀。而图7(b)中的温度分布结果则表明,随着应变速率的增加,变形区域中心处的温升值由0.3 s-1时的5 ℃增加至3 s-1时的82 ℃,且变形区域内温度分布的均匀性降低。可见,较高的应变速率并没有导致变形中心区域高应变值的产生,其原因正是温升现象引起的较高的实际变形温度导致了累积应变的快速释放,从而导致高应变速率下变形区域内并未出现更为细小的再结晶晶粒(见图5(e))。

3 结论

1) AZ31镁合金挤压板坯在二次变形过程中发生了明显的动态再结晶,这进一步细化了挤压板坯的晶粒尺寸,同时削弱了挤压板坯的(0002)基面织构强度,为提高合金的塑性变形能力提供可能,也为镁合金挤压-轧制工艺的开发提供可能。

2) 镁合金挤压板坯二次变形时,当应变速率一定时,温度越高,再结晶晶粒尺寸越大,而当变形温度一定时,在本实验中所研究的应变速率范围内,较高的应变速率并未能引起再结晶晶粒的明显细化。

3) 有限元模拟结果表明,变形区域内组织的不均匀性主要由应变分布的不均匀性所引起的。当应变速率一定时,变形区域内累积应变差别不大,且温升值基本不随变形温度的变化而变化,此时的再结晶晶粒尺寸取决于变形温度;而当变形温度一定时,较高的应变速率引起变形区域内显著的温度升高,不利于应变的累积和储存能的增加,从而达不到细化晶粒的效果。

REFERENCES

[1] FRIEDRICH H, SCHUMANN S. Research for a/new age of magnesium in the automobile industry[J]. Journal of Materials Processing Technology, 2001, 117: 276-281.

[2] FROES F H, ELIEZER D, AGHION E. The science,technology and applications of magnesium[J]. JOM, 1998(9): 30-33.

[3] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[4] AGNEW S R, HORTON J A, LILLO T M, BROWN D W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing[J]. Scripta Materialia, 2004, 50: 377-381.

[5] YU Kun, RUI Shou-tai, WANG Xiao-yan, WANG Ri-chu, LI Wen-xian. Texture evolution of extruded AZ31 magnesium alloy sheets[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 511-516.

[6] DING Han-lin, KANAMORI Nao, HONMA Tomoyuki, KAMADO Shigeharu, KOJIMA Yo. FEM analysis for hot rolling process of AM60 alloy[J]. Transaction of Nonferrous Metals Society of China, 2008, 18(S1): 242-246.

[7] XIAO Han, ZHANG Shi-hong, ZHOU Rong, LU De-hong. Springback characteristics of AZ31 magnesium alloy as-extruded profile in warm tension-rotation bending process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): 416-421.

[8] WANG Q F, XIAO X P, HU J, XU W W, ZHAO X Q, ZHAO S J. An ultrafine-grained AZ31 magnesium alloy sheet with enhanced superplasticity prepared by accumulative roll bonding[J]. Journal of Iron and Steel Research, International, 2007, 14(5): 167-172.

[9] CHINO Y, KIMURA K, MABUCHI M. Deformation characteristics at room temperature under biaxial tensile stress in textured AZ31 Mg alloy sheets[J]. Acta Materialia, 2009, 57(5): 1467-1485.

[10] JAIN A, DUYGULU O, BROWN D W, TOME C N, AGNEW S R. Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy AZ31B sheet[J]. Materials Science and Engineering A, 2008, 486(1/2): 545-555.

[11] CHEN Zhen-hua, CHENG Yong-qi, XIA Wen-jun. Effect of equal-channel angular rolling pass on microstructure and properties of magnesium alloy sheets[J]. Materials and Manufacturing Processes, 2007, 22(1): 51-56.

[12] KIM W J, PARK J D, KIM W Y. Effect of differential speed rolling on microstructure and mechanical properties of an AZ91magnesium alloy[J]. Journal of Alloys and Compounds, 2008, 460(1/2): 289-293.

[13] ZHANG Bo-ping, TU Yi-fan, CHEN Jing-yi, ZHANG Hai-long, KANG Yong-lin, SUZUKI H G. Preparation and characterization of as-rolled AZ31 magnesium alloy sheets[J]. Journal of Materials Processing Technology, 2007, 184: 102-107.

[14] 李秀莲, 王茂银, 辛仁龙, 黄光杰, 刘 庆. AZ31镁合金挤压轧制过程微观织构演变[J]. 材料热处理学报, 2010, 31(5): 61-64.

LI Xiu-lian, WANG Mao-yin, XIN Ren-long, HUANG Guang-jie, LIU Qing. Texture evolution of AZ31 magnesium alloy during extrusion and rolling[J]. Transactions of Materials and Heat Treatment, 2010, 31(5): 61-64.

[15] YOSHIDA Y, ARAI K, ITOH S, KAMADO S, KOJIMA Y. Superplastic deformation of AZ61 magnesium alloy having fine grains[J]. Mater Trans, 2004, 45(8): 2537-2541.

[16] 郭 睿, 胡水平. 工艺因素对AZ31镁合金板材室温成形性能的影响[J]. 材料研究学报, 2013, 27(2): 207-211.

GUO Rui, HU Shui-ping. Effects of technical factors on formability of AZ31 magnesium alloys[J]. Chinese Journal of Materials Research, 2013, 27(2): 207-211.

[17] WAGNER L, HILPERT M, WENDT J. On methods for improving the fatigue performance of the wrought magnesium alloys AZ31 and AZ80[J]. Materials Science Forum, 2003, 419/422: 93-102.

[18] 刘华强, 唐 荻, 胡水平, 米振莉, 王 哲. 不同轧制工艺对AZ31镁合金薄板室温成形性能的影响[J]. 中国有色金属学报, 2012, 22(12): 3293-3299.

LIU Hua-qiang, TANG Di, HU Shui-ping, MI Zhen-li, WANG Zhe. Effects of rolling technology on forming properties of AZ31 magnesium alloy sheets at room temperature[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3293-3299.

[19] YANG P, YU Y, CHEN L, MAO W. Experimental determination and theoretical prediction of twin orientations in magnesium alloy AZ31[J]. Scripta Materialia, 2004, 50: 1163-1168.

[20] 潘红波, 唐 荻, 胡水平, 王潇潇. 平面应变压缩金属流变规律及影响因素分析[J]. 钢铁, 2008, 43(11): 59-64.

PAN Hong-bo, TANG Di, HU Shui-ping, WANG Xiao-xiao. Analysis on flow pattern of metal and its influencing factors during plane strain compression[J]. Iron and Steel, 2008, 43(11): 59-64.

[21] SAKAI T, JONAS J J. Dynamic recrystallization: Mechanical and microstructural considerations[J]. Acta Metals, 1984, 32: 189-209.

[22] DING Han-lin, WANG Tian-yi, YANG Lei, KAMADO S. FEM modeling of dynamical recrystallization during multi-pass hot rolling of AM50 alloy and experimental verification[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2678-2685.

[23] DING Han-ling, LIU Liu-fa, KAMADO Shigeharu, DING Wen-jiang, KOJIMA Yo. Investigation of the hot compression behavior of the Mg-9Al-1Zn alloy using EBSP analysis and a cellular automata simulation[J]. Modelling and Simulation in Materials Science and Engineering, 2009, 17: 025009.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51204003);安徽高校省级自然科学研究重点项目(KJ2011A051);教育部留学回国人员科研启动基金资助项目;人社部留学人员科技活动项目择优资助项目

收稿日期:2013-10-20;修订日期:2014-05-23

通信作者:丁汉林,副教授,博士;电话:0555-2311570;E-mail: hanlinding@yahoo.com