基于变速试验原理的材料切削加工性能快速评价方法

刘瑶,蒋炳炎,申瑞霞,彭华建

(中南大学 机电工程学院 现代复杂装备设计与极端制造教育部重点实验室,湖南 长沙,410083)

摘 要:针对传统的材料切削加工性能评价方法所需时间长、成本高,新型工件材料切削加工性能难以评价,切削参数尤其是切削速度难以达到最优化等问题,设计出一套从定量和定性2个方面快速评价材料切削加工性能的变速切削试验方法,并在其基础上实施验证性试验。该方法以Heginbotham和Pandey提出的变速试验原理为基础,采用相对可切削系数表征材料切削性能。研究结果表明:利用该方法对工件材料进行切削试验,所得的结果与刀具磨损理论结果相符,可信度高是切削速度评价范围扩大;同时,在变速切削条件下刀具达到失效标准时间短,节约了大量的工件材料和试验时间,从而实现材料切削加工性能的快速评价。此外,该评价方法的相关切削条件依据单刃车刀寿命试验标准ISO 3685—1993设计,具有通用性,以便于不同科研人员之间的信息互换。

关键词:切削加工性能;变速切削;评价方法

中图分类号:TG115.6 文献标志码:A 文章编号:1672-7207(2010)03-0948-05

Rapid evaluating method of machinability based on

variable-speed testing principle

LIU Yao, JIANG Bing-yan, SHEN Rui-xia, PENG Hua-jian

(Key Laboratory of Modern Complex Equipment Design and Extreme Manufacturing, Ministry of Education,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: The traditional methods for evaluating machinability are costly and time-consuming, so the machinability of new material is difficult to evaluate, and the cutting parameters, in particular the cutting speeds of machining, are hard to be optimized. Therefore, a novel method was designed to evaluate the machinability of material, which is based on variable-speed testing principle proposed by Heginbotham and Pandey. The method characterized by relative machinable coefficient, could accomplish the assessment of machinability from quantitative and qualitative aspects in a short time. Furthermore, a confirmatory test was conducted to prove the feasibility of the method. The test results are consistent with theory results of tool wear, and the scope of cutting speed is extended. Moreover, with high reliability of machinability evaluation, a large number of materials can be saved since the tool life is short in the condition of variable-speed cutting. In addition, the method adopts ISO 3685—1993 which is widely used, which makes technical exchanges more convenient.

key words: machinability; variable-speed cutting; evaluating method

对于具有高硬度、高强度、低导热性等一系列特点的新型工程材料[1-2],利用传统评价方法对其切削加工性能评价存在时间长、成本高的不足。目前,应用较多的材料切削加工性能评价方法有单参数评价法和基于模糊理论的多参数评价法。单参数评价方法是利用刀具切削寿命、切削力、切削温度和已加工表面等参数中的1项来评价工件材料的切削加工性能[3-5]。单参数法简便、直观、灵活性大,但由于切削条件选择具有主观性和片面性,使其所得结果的通用性较 差。王细洋等[6]针对不同类型零件,从材料、零件热处理、结构和标准化4个方面评价其切削加工性 能。该方法继承了单参数评价法的优点,且更加全 面,但仍有较大片面性,可信度不高。基于模糊理论的多参数评价法是借助综合评判的方法对材料切削加工性能进行总体评价,目前较常用的方法是加权平均法。加权平均法是根据各因素的重要程度而赋予不同的权重,然后,对每一评价标准项下的评定结果进行加权平均处理[7-9]。多参数法能较全面的反映材料切削加工性能,但由于设定影响因素权重的过程具有主观性,评价结果可信度不高,且表征参数多,评价过程时间长。本文作者设计了一套材料切削加工性能快速评价方法,以相对可切削系数表征材料切削加工性能,通过变速切削扩大切削速度评价范围,并据此进行实验研究,探讨该方法的准确性和可行性。

1 评价与试验方法

材料切削加工性能快速评价是通过车削的方法快速评价工件材料在粗加工条件下的切削加工性能,为2种或多种材料切削加工性能的比较以及当切削深度、进给量、刀具耐用度一定时切削速度的选择提供理论依据。

在切削试验中,本评价方法利用变速的方法评价工件材料在较大切削速度范围内的切削加工性能,与传统相对可切削系数评价法相比,扩展了速度评价范围,能够更全面地评价其切削加工性能。同时,以一种切削加工性能较好且较通用材料的刀具使用寿命为基准,通过比较切削其他材料时的刀具使用寿命获得相对可切削系数,从而来评价其切削加工性能。此评价方法较真实地反映了2种或多种材料在较宽速度范围内切削加工性能的优劣,可信度高,具有较高的应用价值,实现了材料切削加工性能的快速评价,节约了工件、刀具材料和大量的试验时间。同时,本方法依据单刃车刀寿命试验标准ISO 3685—1993[10]设计切削试验方案,使其具有更大通用性,便于不同科研人员之间的信息互换。

1.1 评价方法设计

1.1.1 原理

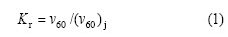

在相同条件下切削不同材料,在切削速度v一定时,刀具使用寿命tv较长,或在刀具使用寿命t一定时切削速度vt较大的材料,其加工性能较好;反之,其加工性能较差。设定刀具使用寿命t=60 min时,切削速度vt可写作v60;同样,当刀具寿命为30和15 min时,切削速度分别为v30和v15。 一般以切削正火状态45号钢的v60作为比较不同材料切削加工性能的基准,写作(v60)j,而将其他各种材料的vt与其相比,该比值称为相对加工系数Kr,即

对Kr大于1的材料,其加工性能比45号钢的加工性能好;对Kr小于1的材料,其加工性能比45号钢差。vt和Kr是最常用的加工性能指标,在不同的加工条件下都适用。比较据系数Kr,确定材料是否易于切削。系数Kr较大,则材料较易切削;系数较小,则材料较难切削。

材料切削加工性能快速评价试验方案根据Heginbotham和Pandey提出的变速切削评价原理[11]设计,采用外圆变速车削法,其原理如图1所示。

图1 外圆切削原理图

Fig.1 Principle of cutting excircle

在使用相同刀具的条件下,车削2根不同直径的同种工件材料。记录后刀面平均磨损量sB达到0.3 mm时所需要的路程、切削次数和初始切削速度,通过计算将泰勒公式vt-1/k=C中的系数C和k求出,从而定量确定t与v的关系。求出当刀具寿命为60 min时的最大切削速度v60,并设参照工件材料45号钢的切削加工性能指数为100,采用

求出待评价材料的可切削性指数Kv,用于评价材料的切削加工性能。

1.1.2 切削用量

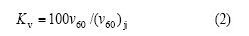

对工件进行变速车削,在Z轴方向每进给1 mm增加1次转速,增加量为1 r/min。车床的初始转速为100 r/min,终止转速为600 r/min[12]。在试验条件为粗加工的条件下,依据单刃车刀寿命试验标准ISO 3685—1993的4组标准切削条件(如表1所示),选择C组数据作为此次试验的切削条件。

表1 标准切削条件

Table 1 Standard machining conditions

1.1.3 结果处理

定性比较工件材料的切削加工性能,绘制切削路程与后刀面平均磨损量的关系曲线,比较不同材料的曲线形状、斜率及达到指定后刀面磨损量时切削的路程;定量比较工件材料的切削加工性能,通过比较vt来定量确定材料的切削加工性能;比较切屑形态(由于切屑是切削过程中热量散发最重要的途径,是否容易断屑决定了切削热能否及时散出),找出影响材料切削加工性能优劣的原因。

1.2 试验方法

根据上述评价方案,对试验工件进行变速切削试验,以验证该评价方法的可行性。试验采用LEADWELL-T8数控车床进行切削试验,采用VMS-15100影像测量仪获取刀具图像并测量后刀面磨损值。工件材料为45号钢,长度为560 mm,直径为96 mm。刀具属机夹外圆涂层车刀,材料牌号为YW1,刀片型号为31003CZ。根据表1选取单边切削深度为2.5 mm,进给量为0.4 mm,车床主轴转速在200~700 r/min范围内变化。

具体切削试验步骤如下:

(1) 根据试验方案进行数控编程,并进行计算机仿真,确保程序正确无误。

(2) 将工件和刀具装夹在车床上,设定工件坐标零点。

(3) 按照试验方案对工件进行变速车削。

(4) 切削长度每增加250 mm时,利用影像测量仪采集刀具主后刀面磨损部位图像,将其导入图形处理软件中计算刀面平均磨损量sB,记录备用。若sB达到或超过0.3 mm,则停止车削,如未达到,则重复以上车削。

(5) 试验结束后,整理试验设备,收集切屑采集图像。

2 试验结果与分析

2.1 刀具后刀面形态与磨损量

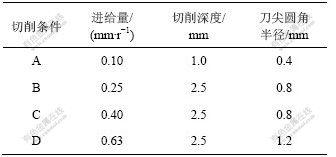

后刀面磨损主要与材料的抗热震性、硬度和抗氧化黏着能力有关[13],后刀面磨损量是衡量切削性能的重要指标[14-15]。图2~5所示为切削不同行程时后刀面形态。

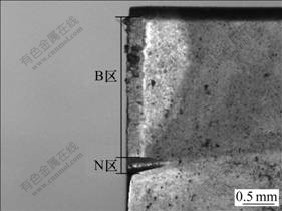

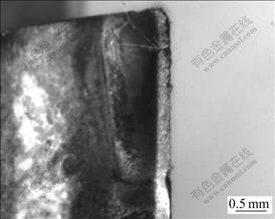

由图2~5可见:后刀面出现了明显磨损,并随切削长度的增长呈逐步扩大趋势;图3和图4中有明显的磨损区域,并可以分辨出在切深2.5 mm对应的车刀处有明显的沟槽,同时也呈扩大趋势,且形成了典型的后刀面磨损B区和N区[16],磨损在参与切削的切削刃中部较均匀,B区磨损带的宽度一致。由于加工硬化层的影响,靠近工件外表面处的N区磨损较为严重;在后刀面磨损图片中可以发现,有不同程度的金属附着物,存在一定量的积屑。由图5可见:当切削长度达到2 500 mm,即切削时间为23 min时,后刀面出现了崩刃现象,刀具发生失效,切削次数少,评价时间短。后刀面磨损量与切削时间的关系见图6。由图6分辨出初期磨损阶段、正常磨损阶段和剧烈磨损阶段,与刀具磨损理论较吻合[17]。

图2 切削试验前后刀面形态

Fig.2 Shape of flank face before cutting

图3 切削长度为500 mm时后刀面形态

Fig.3 Shape of flank face when cutting length is 500 mm

图4 切削长度为2 250 mm时后刀面形态

Fig.4 Shape of flank face when cutting length is 2 250 mm

图5 切削长度为2 500 mm时后刀面形态

Fig.5 Shape of flank face when cutting length is 2 500 mm

图6 后刀面磨损量与切削时间的关系

Fig.6 Relationship between flank wear and cutting time

2.2 前刀面月牙洼磨损

前刀面有明显的月牙洼磨损,并呈扩大趋势,说明断屑槽的存在仍会产生月牙洼磨损,如图7所示。

图7 切削长度为2 250 mm时前刀面形态

Fig.7 Shape of rake face when cutting length is 2 250 mm

2.3 切屑形态

在切削过程中切屑可以分为2种:在速度较低时,为较短的“C”形切屑[18];在速度较高时,为较长的带状切屑。切屑的长度随速度的增加而变长。这说明在低速切削时,断屑槽能较好控制切屑的形态。但随着速度的提高,开始大量出现带状切屑,说明当速度提高到较大时,断屑槽不能很好地控制切屑的形态。

3 结论

(1) 采用基于变速原理的材料切削加工性能评价方法对工件进行2次不同切削速度范围的变速切削,即可完成工件材料切削加工性能的评价,且变速切削可使刀具在20 min左右时间失效,工件材料用量少,评价周期短,缩短了新型材料切削加工性能的研究周期,为切削参数优化提供现实依据,减少了生产过程中的盲目性。

(2) 以相对可切削系数表征工件材料的切削加工性能,依照单刃车刀寿命试验标准ISO 3685—1993设计试验参数,保证获得的评价结果准确无误。切削试验所得的刀具磨损曲线与刀具磨损理论曲线相吻合。

(3) 该评价方法可根据需要设定变速范围,并在该范围内对工件材料的切削加工性能实施快速准确评价,扩展了传统评价方法的切削速度范围。同时,由于该方法依照国际标准设计,使不同科研人员之间的信息互换变得更为便利,通用性更佳。

参考文献:

[1] 张新明, 彭卓凯, 邓运来, 等. Mg-9Gd-4Y-0.6Mn 合金在293~723 K时的变形行为及微观组织演变[J]. 中南大学学报: 自然科学版, 2006, 37(2): 223-228.

ZHANG Xin-ming, PENG Zhuo-kai, DENG Yun-lai, et al. Deformation behavior and microstructure evolution of Mg-9Gd-4Y-0.6Mn alloy at 293-723 K[J]. Journal of Central South University: Science and Technology, 2006, 37(2): 223-228.

[2] 熊翔, 旷文敏, 肖鹏, 等. 模压法制备C/C-SiC复合材料的力学性能[J]. 中南大学学报: 自然科学版, 2008, 39(3): 486-492.

XIONG Xiang, KUANG Wen-min, XIAO Peng, et al. Mechanical properties of C/C-SiC composites by compression molding[J]. Journal of Central South University: Science and Technology, 2008, 39(3): 486-492.

[3] Salak A. New short time face turning method for testing[J]. Materials Processing Technology, 2006, 176: 62-69.

[4] 古可成, 刘红, 李启东, 等. 由硬度凹坑形貌预测金属材料塑性及切削加工性[J]. 现代制造工程, 2006(5): 84-86.

GU Ke-cheng, LIU Hong, LI Qi-dong, et al. Research on plasticity and machinability of metal materials from the morphology of hardness indentation[J]. Modern Manufacturing Engineering, 2006(5): 84-86.

[5] 王妮燕, 蒋仕军, 罗军, 等. Y45S20易切削钢的工艺优化[J]. 钢铁, 2002, 37(10): 48-51.

WANG Ni-yan, JIANG Shi-jun, LUO Jun, et al. Process optimization for free cutting steel Y45S20[J]. Iron and Steel, 2002, 37(10): 48-51.

[6] 王细洋, 万在红. 基于知识的零件切削加工工艺性评价[J]. 现代制造工程, 2002(2): 11-13.

WANG Xi-yang, WAN Zai-hong. An approach to evaluating cutting machinability[J]. Modern Manufacturing Engineering, 2002(2): 11-13.

[7] 韩鹰, 于多年, 韩英淳. 可加工陶瓷材料可加工性的模糊综合评价[J]. 机械工程材料, 2006, 30(8): 28-30.

HAN Ying, YU Duo-nian, HAN Ying-chun. A fuzzy and comprehensive evaluation of the machinability for processible ceramic materials[J]. Materials for Mechanical Engineering, 2006, 30(8): 28-30.

[8] 陈杰, 罗红波, 吴双. 材料切削性能的模糊综合评判[J]. 机械, 2002, 29(5): 62-64.

CHEN Jie, LUO Hong-bo, WU Shuang. Research of metal cutting database based on fuzzy[J]. Machinery, 2002, 29(5): 62-64.

[9] 吴斌, 夏伟, 汤勇, 等. 基于模糊理论和数据库技术的材料切削加工性评价[J]. 机械设计与制造工程, 2000, 29(2): 84-86.

WU Bin, XIA Wei, TANG Yong, et al. Evaluation of machinability based on fuzzy and database technology[J]. Machine Design and Manufacturing Engineering, 2000, 29(2): 84-86.

[10] ISO 3685—1993, Tool-life testing with single point turning tools[S].

[11] B米尔斯, A H雷德福. 工程材料的可切削性[M]. 高元坤, 译. 北京: 国防工业出版社, 1989: 125-136.

Mills B, Redford A H. Machinability of engineering material[M]. GAO Yuan-kun, trans. Beijing: Defense Industry Press, 1989: 125-136.

[12] Eugene W. Comparative machinability of brasses, steels and aluminum alloys: CDA’s universal machinability index[J]. Machine Tools and Manufacture, 2005, 25: 850-856.

[13] 李鹏南, 唐思文, 张厚安, 等. Ti(C, N)基金属陶瓷刀具的高速切削性能与磨损机理[J]. 中国有色金属学报, 2008, 18(7): 1286-1291.

LI Peng-nan, TANG Si-wen, ZHANG Hou-an, et al. Cutting performance and wear mechanism of Ti(C, N)-based cermets tools in high speed cutting[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1286-1291.

[14] 白力静, 朱晓东, 肖继明, 等. 碳膜刀具干式钻削Al_Si合金的切削性能及其减摩机制[J]. 中国有色金属学报, 2006, 16(9): 1534-1538.

BAI Li-jing, ZHU Xiao-dong, XIAO Ji-ming, et al. Machinability and anti-adhesive wear performance of carbon coated tools in drilling of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1534-1538.

[15] 夏琦, 张志明, 沈荷生. 微波等离子体刻蚀脱碳预处理对金刚石涂层刀具附着力和切削性能的影响[J]. 机械工程材料, 2000, 24(4): 11-14.

XIA Qi, ZHANG Zhi-ming, SHEN He-sheng. Influence of microwave plasma-etching decarbonization on adhesion and cutting properties of CVD diamond coating tools[J]. Materials for Mechanical Engineering, 2000, 24(4): 11-14.

[16] 周泽华. 金属切削原理[M]. 上海: 上海科学技术出版社, 1993: 42-55.

ZHOU Ze-hua. Principle of metal-cutting[M]. Shanghai: Shanghai Science and Technology Press, 1993: 42-55.

[17] 韩成良, 管航敏, 高大明, 等. 两种TiC基金属陶瓷的组织结构与刀具切削性能[J]. 机械工程材料, 2006, 30(11): 21-28.

HAN Cheng-liang, GUAN Hang-min, GAO Da-ming, et al. Microstructure and cutting properties of two kinds of TiC-based cermets[J]. Materials for Mechanical Engineering, 2006, 30(11): 21-28.

[18] 陆剑中, 孙家宁. 金属切削原理与刀具[M]. 北京: 机械工业出版社, 2005: 176-179.

LU Jian-zhong, SUN Jia-ning. Principle of metal-cutting and tools[M]. Beijing: Machinery Industry Press, 2005: 176-179.

收稿日期:2009-05-05;修回日期:2009-08-19

基金项目:国家高技术研究发展计划(“863”计划)项目(2007AA04Z351)

通信作者:蒋炳炎(1963-),男,浙江浦江人,博士,教授,从事新型特种材料加工装备的设计与制造研究;电话:0731-88836035;E-mail: jby@mail.csu.edu.cn

(编辑 陈爱华)