挤压镁合金薄壁方管的耐撞性能

来源期刊:中国有色金属学报(英文版)2019年第6期

论文作者:李志刚 杨海峰 张照生 孙野 韩郅通 韦济飞

文章页码:1223 - 1232

关键词:镁合金方管;耐撞性能;长度/宽度比;应变率;诱导特征

Key words:magnesium square tube; crashworthiness; length/width ratio; strain rate; induced feature

摘 要:对不同长度的完整AZ31B镁合金薄壁方管和A6063铝合金薄壁方管以及具有诱导特征的薄壁管进行不同应变率的轴向压缩试验研究。研究发现,压缩过程中镁合金薄壁管局部屈曲,进而断裂,其中在断裂阶段出现3种耐撞性能断裂模式,分别是水平断裂、斜向断裂和螺旋断裂。相比于铝合金方管,镁合金薄壁管的吸能效果较差。在上述研究基础上,进一步分析长宽比、应变率和诱导特征对薄壁管耐撞性能的影响。结果表明,随着长宽比从1增加到4,镁合金薄壁管的最大压缩载荷和整体吸能比以幂函数的规律减小,而铝合金薄壁管则基本保持不变。随着压缩速率从5×10-5增加到10 m/s,镁合金薄壁管的主要耐撞性能参数以指数形式增加,而铝合金薄壁管则变化很小。此外,本文作者引入的圆孔和缝的诱导特征未明显提高镁合金薄壁管的吸能效果,因此,后期需要在薄壁管不同位置设计更多种类和尺寸的诱导特征来提高镁合金薄壁管的吸能比。

Abstract: Axial compression tests were conducted on AZ31B magnesium and A6063 aluminum thin-walled square tubes with varied lengths and induced features at different compression rates. In compression, the magnesium tubes exhibited a “local buckling and fracture” mode, with three fracture patterns, i.e. “horizontal”, “double-oblique”, and “spiral” fractures. In general, the magnesium tube showed an inferior crashworthiness to the aluminum square tube. In addition, the effects of L/W ratio, strain rate and induced features on the crashworthiness of thin-walled square tubes were investigated. With an increase in the L/W ratio (L and W represent the tube length and width, respectively) from 1 to 4, the maximal force and global specific energy absorption decreased in a power-law trend for the magnesium tubes, while they remained approximately constant for the aluminum tubes. Furthermore, as the compression rate increased from 5×10-5 to 10 m/s, the primary crashworthiness parameters of the magnesium tubes increased in an approximately exponential manner, while for the aluminum tubes, they changed slightly. Finally, the involved induced features were proven to be not an effective method to improve the specific energy absorption of magnesium tubes, thus, more trigger types, locations, and sizes will be evaluated in future to improve the energy-absorption ability.

Trans. Nonferrous Met. Soc. China 29(2019) 1223-1232

Zhi-gang LI1, Hai-feng YANG1, Zhao-sheng ZHANG2, Ye SUN3, Zhi-tong HAN1, Ji-fei WEI1

1. School of Mechanical, Electronic and Control Engineering, Beijing Jiaotong University, Beijing 100044, China;

2. School of Mechanical Engineering, Beijing Institute of Technology, Beijing 100081, China;

3. Jilin Jihua Construction and Maintenance Limited Company, Jilin 132021, China

Received 6 September 2018; accepted 30 December 2018

Abstract: Axial compression tests were conducted on AZ31B magnesium and A6063 aluminum thin-walled square tubes with varied lengths and induced features at different compression rates. In compression, the magnesium tubes exhibited a “local buckling and fracture” mode, with three fracture patterns, i.e. “horizontal”, “double-oblique”, and “spiral” fractures. In general, the magnesium tube showed an inferior crashworthiness to the aluminum square tube. In addition, the effects of L/W ratio, strain rate and induced features on the crashworthiness of thin-walled square tubes were investigated. With an increase in the L/W ratio (L and W represent the tube length and width, respectively) from 1 to 4, the maximal force and global specific energy absorption decreased in a power-law trend for the magnesium tubes, while they remained approximately constant for the aluminum tubes. Furthermore, as the compression rate increased from 5×10-5 to 10 m/s, the primary crashworthiness parameters of the magnesium tubes increased in an approximately exponential manner, while for the aluminum tubes, they changed slightly. Finally, the involved induced features were proven to be not an effective method to improve the specific energy absorption of magnesium tubes, thus, more trigger types, locations, and sizes will be evaluated in future to improve the energy-absorption ability.

Key words: magnesium square tube; crashworthiness; length/width ratio; strain rate; induced feature

1 Introduction

Magnesium and aluminum alloys have become more and more attractive in designing vehicle, aircraft, and other products [1-5]. Thin-walled structures made from conventional steel materials have been commonly used as energy-absorption systems and, in particular, the square tubes have been commonly used as vehicle front rail, aircraft floor structure, building roof structure etc. To determine whether thin-walled square tubes made of magnesium and aluminum are suitable for using as crash components, it is necessary to evaluate the crash-worthiness of the square tubes.

For the aluminum tubes, a large number of studies have been conducted to investigate the deformation/ fracture mode, load carrying and energy-absorption ability through analytical analysis and compressive tests [6-11]. In addition, numerical simulations have been performed to predict the buckling/fracture behavior and the crashworthiness [12-19].

Compared with aluminum tubes, few studies have been performed on the crashworthiness of magnesium tubes. Because these relevant studies have been introduced in a recent work by LI et al [20], in this extension study, they are briefly summarized below. BEGGS et al [21] and YOON et al [22] investigated the failure mode and crashworthiness of AZ31B and AZ61 magnesium circular tubes, respectively. SAMER et al [23] analyzed the effect of trigger on the crash mode of magnesium hexagonal tube. ZHU et al [24] investigated the force variation and fracture behavior of top-hat AM60B magnesium tubes with crush initiator under axial crush and bending conditions. DΦORUM et al [25,26] proposed a “shear-bolt” energy absorption for magnesium components. STEGLICH et al [27] and WU et al [28] assessed the crashworthiness of magnesium rectangular structures under quasi-static compressive conditions. WAGNER [29] and ROSSITER et al [30] performed simulations on magnesium double-top-hat and rectangular tubes under compression respectively, in attempt to reproduce the fracture processes.

The above studies provided promising results on elucidating the crush behavior and crashworthiness of magnesium circular and square tubes. However, (1) the experimental data on magnesium tubes with different lengths under different compression rates are very limited; (2) for dynamic tests, the compression rate cannot generally be kept constant due to the drop tower test method used and meanwhile the involved strain rate range is quite narrow; (3) the effect of induced features, like hole or crack, on the crashworthiness of magnesium tube was not investigated. In our recent work [20], the aforementioned relevant problems on AZ31B magnesium circular tubes have been investigated. In review of differences existing in the fracture pattern and crashworthiness mechanism between magnesium circular and square tubes, as an extension, in the present work, we sought to address the effects of the tube length, strain rate and induced features on crashworthiness of square tubes. In addition, crashworthiness ability between square magnesium and aluminum tubes was also comparatively studied.

2 Experimental

2.1 Specimens

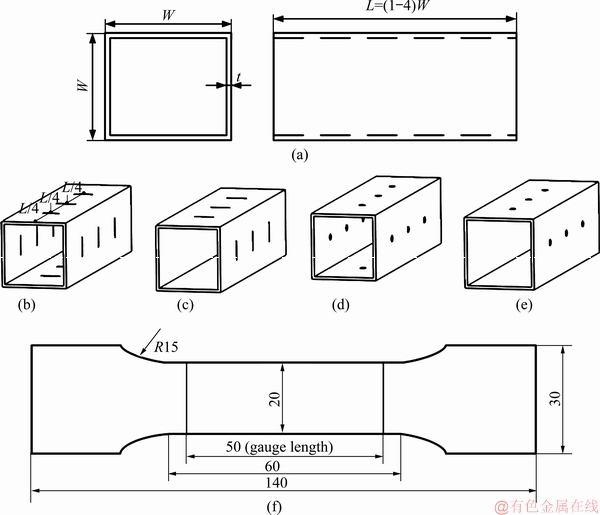

A series of axial crush tests were performed on pristine square tubes of AZ31B magnesium and A6063 aluminum with lengths of (1-4)W as well as on those with induced features. The cross-section dimensions of the magnesium and aluminum tubes were 50 mm × 50 mm × 2 mm and 40 mm × 40 mm × 2 mm, respectively (Fig. 1(a)). In addition to the pristine tubes, tubes with induced features such as symmetrically or asymmetrically distributed cracks or holes were also tested (Figs. 1(b-e)). In the case of the magnesium tubes, the cracks were 20 mm × 1 mm and the hole diameter was 5 mm. For the aluminum tubes, the cracks were 16 mm × 1 mm, and the hole diameter was 5 mm. The locations and distributions of the cracks and holes are shown in Fig. 1(b). In addition, Fig. 1(f) shows the shape of specimens used for obtaining the mechanical properties of AZ31B magnesium and A6063 aluminum alloys, in which the specimens were cut from the walls of the square tubes along the axial direction.

2.2 Axial crush tests

Fig. 1 Geometry of magnesium and aluminum tubes (a), symmetrical distribution of cracks (b), asymmetrical distribution of cracks (c), symmetrical distribution of holes (d), asymmetrical distribution of holes (e) and geometry and size of test specimens used to obtain mechanical properties (f) (unit: mm)

A WDW-100 universal machine and a servo- hydraulic Instron VHS-160/100-20 testing machine were used to execute the static and dynamic tests, respectively. High-speed cameras were used to monitor the deformation mode and fracture patterns. The primary parameters of the test setup were described in the previous study [20].

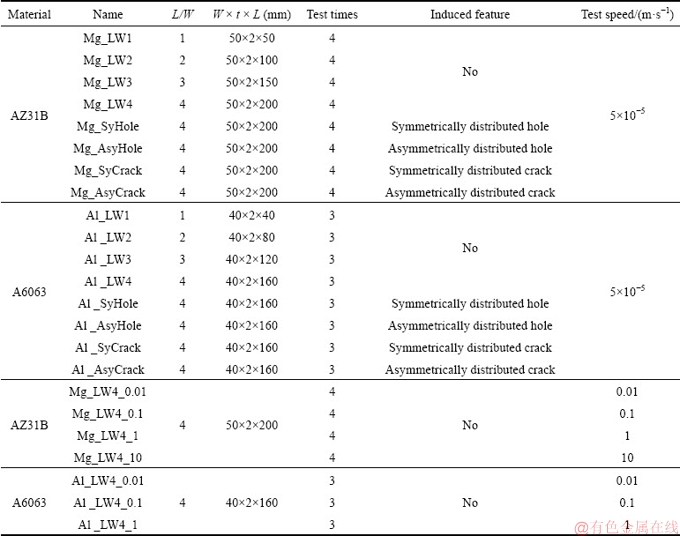

The test matrices for the quasi-static and dynamic axial crush tests are presented in Table 1. The magnesium and aluminum tubes were cut into four lengths corresponding to L/W ratios of 1, 2, 3 and 4. Quasi-static crush tests were performed on the pristine tubes with L/W ratios of 1, 2, 3 and 4 as well as on the tubes with the induced features with L/W of 4. Dynamic compression tests were performed on tubes with L/W of 4 at four different compression rates, while for the aluminum tubes, three strain rates were used, owing to the constraint of test setup.

2.3 Crashworthiness evaluation parameters

In this section, the maximal force (Fmax), mean force (Fmean), energy absorption (E), specific energy absorption (SEA) and global specific energy absorption (GSEA) were used to evaluate the load-carrying and crash- worthiness performances of magnesium and aluminum tubes under different conditions. All these parameters have been defined in the previous study [20] except the GSEA, which was calculated by the energy absorbed by the tube divided by the tube total mass.

3 Results

3.1 Mechanical properties of magnesium and alloy tubes

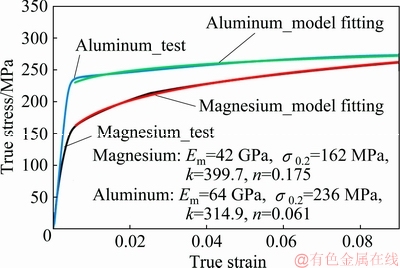

The elastic-plastic mechanical properties of magnesium and aluminum alloys are shown in Fig. 2. The elastic modulus (Em) is the slope of the elastic stage of the stress-strain curve. The initial yield stress was determined based on the 0.2% offset criterion (σyp=σ0.2). To reflect the hardening characteristics, the power-law material model [31] given in Eq. (1) was used to fit the plastic strain (σp) and stress (σy) data to obtain the hardening exponents (n) and strength coefficients (k) and the results are incorporated in Fig. 2.

(1)

(1)

where σyp is the strain corresponding to the initial yield stress.

Table 1 Test matrices for quasi-static and dynamic axial crush tests

Fig. 2 Mechanical properties of magnesium AZ31B and aluminum A6063 tubes

3.2 Influence of L/W ratio on crush behavior of magnesium and aluminum square tubes

3.2.1 Deformation and facture mode of magnesium square tubes

The overall crush failure process of the magnesium square tubes with L/W ratios included buckling and fracturing stages.

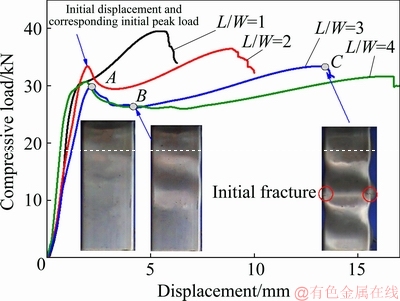

(1) Buckling stage

Figure 3 shows the buckling process and the load-displacement history of the magnesium tube. When the tube was initially compressed, it underwent an elastic compressive deformation. The contact force increased almost linearly until the first peak load was observed. As the tube was compressed further, slight symmetric buckling occurred, and the compressive force started to decrease, reaching a trough value. With compression continuing, the tube entered the material hardening stage, and two opposing walls bent inward at the concavity position while the other two opposing walls bent outward at the bulging position. The corresponding compressive force increased again until the second peak load was reached. The buckling (bulge or concavity) number, nb, was found to be approximately equal to the L/W ratio (nb≈L/W) and the crush displacement before fracture generally increased in proportion to L. With further compression, the tube entered into the fracturing stage.

Fig. 3 Buckling process and load-displacement histories of magnesium tubes with different L/W ratios

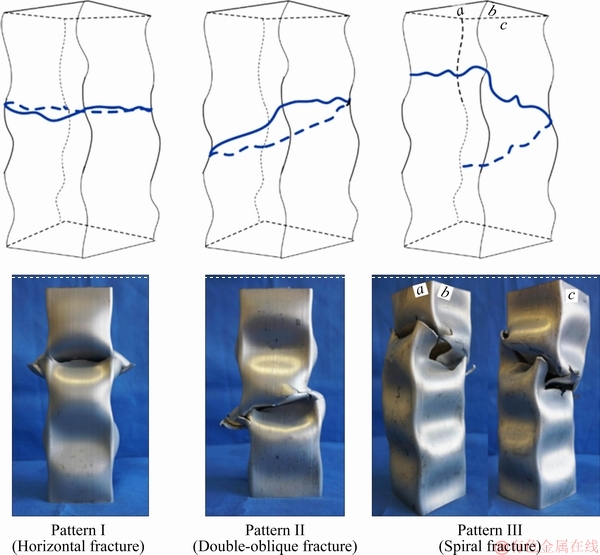

(2) Fracturing stage

In fracture stage, at first, a small initial fracture occurred from one buckling position. This fracture then propagated along the tube wall. Three patterns were observed during the propagation of the fracture, as shown in Fig. 4. In the case of the type I pattern, the fracture expanded along the cross-section of the tube, with the fracture surface parallel to the horizontal plane, named “horizontal fracture.” For the type II pattern, the fracture passed through three concaves and one bulging buckling positions. Furthermore, there were two horizontal fracture lines and two oblique fracture lines that were inclined at an angle of approximately 30° with respect to the horizontal plane, called “double-oblique” fracture. In the case of the type III pattern, the fracture line passed through three concave buckling positions on the tube wall in a manner of a spiral curve, thus, we named this type of fracture the “spiral fracture”. Type I fracture pattern occurred for tubes with L/W ratios of 1, 2, 3 and 4, type II fracture occurred mainly for L/W ratios of 3 and 4, and type III fracture pattern only occurred for an L/W ratio of 4.

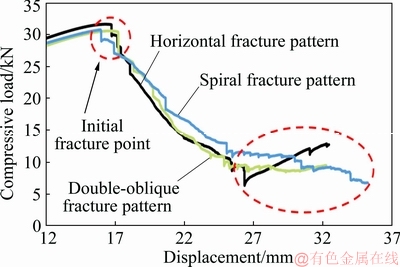

The fracture stages of the load-displacement curves for these three patterns are shown in Fig. 5. For all the patterns, once the fracture occurred, the compressive force decreased rapidly from the peak load to a low value. The curves then show differences in behavior, as marked by the dashed ellipse. In the case of the horizontal fracture pattern, the tubes fractured into two segments at certain time point and the upper segments were supported by the lower segments, thus, the compressive force began to increase again from the lowest value. In the cases of the double-oblique and spiral fracture patterns, fracture occurred from different buckling positions at different time points, thus, the compressive forces decreased with further compression.

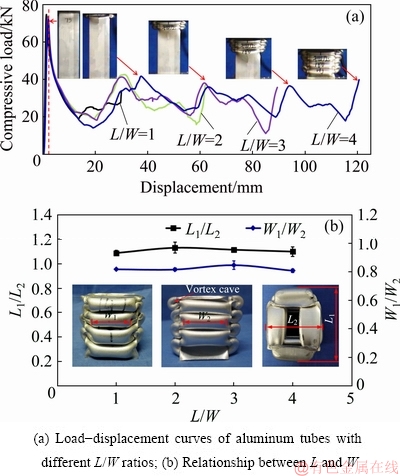

3.2.2 Deformation mode of aluminum square tubes

The representative progressive folding deformation mode was observed for the aluminum square tubes. Several folds were formed along the tube length, with each fold corresponding to one fluctuating cycle of the load-displacement curve as shown in Fig. 6(a). The number of folds (nf) was approximately equal to the L/W ratio (nf ≈L/W) and the total compression displacement (ΔL) increased in proportion to the initial length of the pristine tube (L). Interestingly, after compression, the sizes of the bulging fold on the adjacent sides were not the same. As shown in Fig. 6(b), the distance between the bulging folds on two opposite sides (denoted as L1) was greater than that between the folds on the other two sides (denoted as L2), and the width corresponding to the folds with greater distance (denoted as W1) was smaller than that of the other folds (denoted as W2). As the bulging folds first formed, two symmetric vortex caves generated together as shown in Fig. 6(b), whereas no obvious vortex cave occurred for the adjacent folds. This led to the fact that the widths of the folds with the vortex caves were smaller than those of the adjacent folds and further caused the bulging folds to expand outside to a large degree, owing to the volume incompressibility. The L1/L2 and W1/W2 ratios were 1.11±0.03 and 0.82±0.02, respectively.

Fig. 4 Three fracture patterns of magnesium square tubes (L/W=4) under compression

Fig. 5 Load-displacement curves showing stages of three fractures patterns of magnesium tubes

3.2.3 Crashworthiness comparison between magnesium and aluminum square tubes with different L/W ratios

Fig. 6 Load-displacement curves and fold sizes of aluminum tubes

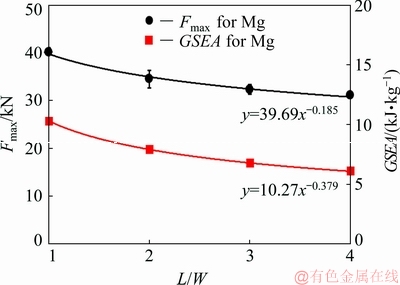

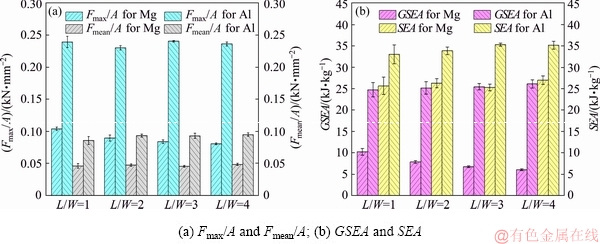

The aforementioned parameters (Fmax, Fmean, E, SEA and GSEA) were calculated to evaluate the load-carrying and energy-absorption ability of magnesium and aluminum square tubes. When calculating SEA, the crush displacement was taken to be the point where the magnesium tube fractured seriously and lost the energy-absorption ability, and for aluminum tubes, the crush displacement was taken to correspond to the point where they were compactly compressed and completely folded. For magnesium tubes, as the L/W ratio increased from 1 to 4, Fmax and GSEA decreased in a power-law trend by approximately 22.5% and 40.8%, respectively (Fig. 7); whereas for Fmean and SEA, no obvious changes occurred. As for aluminum tubes, these 4 parameters remained approximately constant, irrespective of the tube length.

Fig. 7 Variations in Fmax and GSEA with L/W for magnesium tubes

The comparison of the load-carrying and energy- absorption abilities of the magnesium and aluminum tubes are shown in Fig. 8. To ensure consistency, Fmax and Fmean were divided by the cross-sectional areas of the tubes, denoted as Fmax/A and Fmean/A, respectively. It is clearly seen that the load-carrying ability (represented by Fmax/A and Fmean/A) and energy-absorption level (represented by GSEA and SEA) of magnesium tubes were lower than aluminum tubes, irrespective of the L/W ratio.

3.3 Influence of compression rate on crash behavior of magnesium and aluminum square tubes

Fig. 8 Crashworthiness comparison between magnesium and aluminum square tubes

Fig. 9 Crashworthiness parameter variation with compression rate for magnesium (a) and aluminum (b) tubes

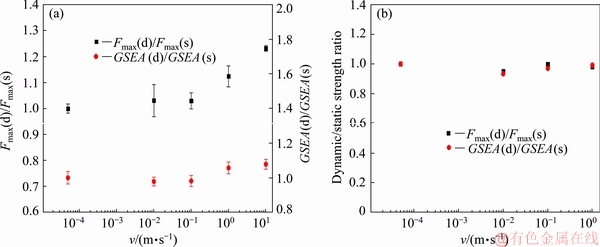

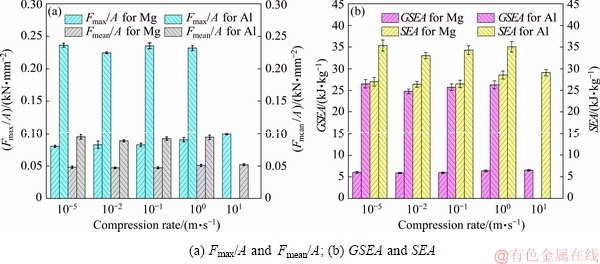

The crush modes of the magnesium and aluminum tubes with L/W=4 under dynamic compression are similar with those observed in quasi-static tests. The Fmax, Fmean, SEA and GSEA values under the dynamic conditions were normalized to dynamic strength ratios, as Fmax(d)/Fmax(s), Fmean(d)/Fmean(s), GSEA(d)/GSEA(s) and SEA(d)/SEA(s), respectively, through dividing by the corresponding values under quasi-static condition. Considering the fact that the dynamic strength ratios of Fmax, Fmean, GSEA and SEA are approximately the same for a constant L/W ratio, therefore, only the variation of dynamic ratios of Fmax and GSEA with compression rate (v) are shown in Fig. 9 (for clarity, the abscissa axis is given in a logarithmic scale). For the magnesium tubes, these two strength ratios show an approximately exponential increasing trend with compression rate. In contrast, the dynamic strength ratios of the aluminum tubes changed very slightly as the compression rate varied from 5×10-5 to 1 m/s.

Figure 10 shows the comparison between magnesium and aluminum tubes in terms of different crashworthiness parameters at multiple compression rates. The crashworthiness parameters of magnesium tubes increased with the increase of compression rate and the aluminum tubes generally kept constant, thus, the crashworthiness difference between them gradually reduced with increasing compression rate. Nevertheless, the crashworthiness capability of magnesium tube under dynamic condition was still inferior to that of aluminum tubes. This is because the fracture mode and the energy-absorption mechanism of the magnesium tubes did not obviously change with compression rate.

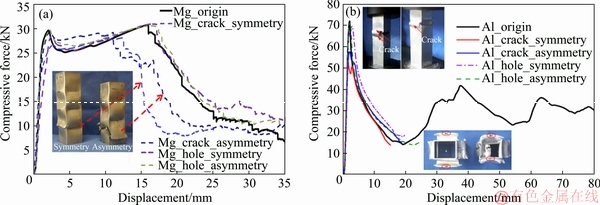

3.4 Influence of induced features on crush behavior of magnesium and aluminum square tubes

The loading curves and failure modes of magnesium and aluminum tubes with cracks and holes as well as the pristine magnesium tubes under static compression are respectively shown in Figs. 11(a) and (b). Clearly, the crashworthiness of the magnesium tubes with holes was similar to that of the pristine tubes, while the tubes with crack features showed an inferior performance, in which the symmetrically distributed cracks decreased the crashworthiness more significantly. In comparison, for the aluminum tubes, in general, all the involved induced features changed the deformation from progressive folding mode of the pristine tubes to a local folding-fracture mode, owing to the plastic hinges being destroyed, and therefore, they significantly decreased the energy-absorption ability. As for the peak force, the cracks decreased it significantly, while the holes did not have an obvious effect.

Fig. 10 Comparison of crashworthiness parameters of magnesium and aluminum square tubes at different strain rates

Fig. 11 Loading curves and failure modes of magnesium (a) and aluminum (b) tubes with induced features

For the magnesium tubes, the hole features did not affect the fracture modes. This was probably because the size of the hole occupied only a small portion of the tube wall. While for the tubes with crack features, the buckling degree was smaller than that of the pristine specimens. At fracture stage, the tubes with symmetrically distributed cracks fractured directly from the four cracks, with the upper segment plugging into the lower segment, causing the force to decrease dramatically. For the asymmetrically distributed cracks, fracture firstly occurred at the two existing crack locations, and then it propagated horizontally to the other sides, thus, the force decreased relatively slowly compared to the tube with the symmetrically distributed cracks.

For the aluminum tubes with both symmetrically and asymmetrically distributed cracks, the folds generated between the two cracks and at the crack location, respectively (Fig. 11(b)). While for the tubes with these holes, the wall buckled and folds generated at the hole positions. For both the crack and hole features, with continuing compression, fracture occurred from the root of the fold or the hole/crack position.

4 Discussion and future work

In this study, the load-carrying and energy- absorption ability of magnesium and aluminum square tubes was evaluated and compared. It is found that the peak load of the magnesium square tubes gradually decreased and the compressive displacement before fracture increased with L/W ratio increasing from 1 to 4. This conclusion is partially consistent with WU et al [28], who reported that compressive displacement of magnesium square tubes increased as the tube length increased by two times. In addition, this conclusion is also close with another study on magnesium circular tubes by BEGGS et al [21]. In addition, the compression rate has certain effect on the compression peak/mean load and GSEA of the magnesium tubes, but only has slight effect on the aluminum tubes. This is because the AZ31B magnesium alloy is a strain-rate sensitive material owing to its HCP crystalline micro-structure [32-34]; however, the mechanical properties of the aluminum alloy tested in this study are strain-rate insensitive as it ranged from 10-4 to 103 s-1 [35,36].

In general, the magnesium square tubes primarily exhibited local buckling and fracture mode and three patterns were observed at the fracture stage. In another study, ZHU et al [24] investigated the fracture behavior of top-hat AM60B magnesium tubes with crush initiator under axial crush condition. The fracture pattern was found to be similar with fracture pattern I of intact tubes and the pattern of tubes with asymmetric crack induced features in our study. The magnesium square tubes showed inferior energy-absorption ability compared with the aluminum square tubes, which absorbed energy through generating multiple folds. Different from this point, in our previous study on the crashworthiness of magnesium circular tubes [20], several fracture modes were observed, in which the splitting mode had relatively high energy-absorption ability, and it exceeded aluminum circular tubes under dynamic compression condition due to strain-rate sensitivity. Therefore, for crashworthiness application, it is necessary to improve the ductility of magnesium or in attempt to alter the buckling and fracture modes of the square tube to further improve the energy-absorption ability. In this study, the variation of collapse mode of magnesium tubes with length/width ratio was investigated, next step, the variation by thickness/width ratio should be further studied. It is found that the introduced crack and hole features did not have positive effects on the failure mode and energy-absorption ability of the square tubes. In the next step, more trigger types, locations, and sizes as well as the tube thickness will be comprehensively evaluated through simulation or experimental methods to improve the energy-absorption ability of the magnesium square tubes.

5 Conclusions

(1) The magnesium square tubes exhibited local buckling and fracture modes and at fracture stage, three fracture patterns, horizontal, double-oblique, and spiral fractures were obtained.

(2) The magnesium tube showed an inferior energy-absorption ability to the aluminum square tube. With increasing L/W, the peak load and the global specific energy absorption decreased in a power-law trend for magnesium tubes, and they remained approximately constant for aluminum tubes.

(3) The crashworthiness of the magnesium tube increased in an approximately exponential manner with the compression rate, whereas it changed slightly for the aluminum tube. Nevertheless, the crashworthiness of the magnesium square tube was still lower than that of the aluminum tube at high compression rate.

(4) The introduced crack and hole features did not have positive effects on the failure mode and energy-absorption ability of the magnesium tubes, more trigger types, locations, and sizes as well as the tube thickness should be evaluated for the full understanding of crashworthiness ability of magnesium tubes.

References

[1] LI Z G, ZHANG D N, PENG C L, MA C S, ZHANG J H, HU Z M, ZHANG J Z, ZHAO Y N. The effect of local dents on the residual ultimate strength of 2024-T3 aluminum alloy plate used in aircraft under axial tension tests [J]. Engineering Failure Analysis, 2015, 48: 21-29.

[2] LI Z G, FENG R X, WANG Y, WANG L S. Experimental study on the effect of dents induced by impact on the fatigue life of 2024-T3 aluminum alloy plate [J]. Engineering Structures, 2017, 137: 236-244.

[3] SU M N, YOUNG B, GARDNER L. The continuous strength method for the design of aluminium alloy structural elements [J]. Engineering Structures, 2016, 122: 338-348.

[4] GUO L L, FUJITA F. Effect of deformation mode, dynamic recrystallization and twinning on rolling texture evolution of AZ31 magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(6): 1094-1102.

[5] WANG F F, WENG M, ZHANG H W, HAN Z Q. Effects of under- aging treatment on microstructure and mechanical properties of squeeze-cast Al-Zn-Mg-Cu alloy [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(10): 1920-1927.

[6] ZHANG X W, SU H, YU T X. Energy absorption of an axially crushed square tube with a buckling initiator [J]. International Journal of Impact Engineering, 2009, 36(3): 402-417.

[7] XU F, TIAN X, LI G. Experimental study on crashworthiness of functionally graded thickness thin-walled tubular structures [J]. Experimental Mechanics, 2015, 55(7): 1339-1352.

[8] LU G, YU T X. Energy absorption of structures and materials [M]. Cambrige: Woodhead Publishing, 2003.

[9] LIU M, ZHANG L L, WANG P J, CHANG Y C. Buckling behaviors of section aluminum alloy columns under axial compression [J]. Engineering Structures, 2015, 95: 127-137.

[10] LANGSETH M, HOPPERSTAD O S. Local buckling of square thin-walled aluminium extrusions [J]. Thin-walled Structures, 1997, 27(1): 117-126.

[11] GUILLOW S R, LU G, GRZEBIETA R H. Quasi-static axial compression of thin-walled circular aluminium tubes [J]. International Journal of Mechanical Sciences, 2001, 43(9): 2103-2123.

[12] HOSSEINI-TEHRANI P, PIRMOHAMMAD S. Collapse study of thin-walled polygonal section columns subjected to oblique loads [J]. Journal of Automobile Engineering, 2007, 221(7): 801-810.

[13] MIYAZAKI M, NEGISHI H. Deformation and energy absorption of aluminum square tubes with dynamic axial compressive load [J]. Journal of Japan Institute of Light Metals, 2002, 52(7): 308-312.

[14] QIAO J S, CHEN H Y, CHEN J H. Investigation of axial anti-collapse behavior of square aluminum alloy tube 6063 [J]. Journal of Lanzhou University of Technology, 2006, 32(2): 14-17. (in Chinese)

[15] ZHANG X, WEN Z Z, ZHANG H. Axial crushing and optimal design of square tubes with graded thickness [J]. Thin-walled Structures, 2014, 84: 263-274.

[16] SIMHACHALAM B, SRINIVAS K, RAO C L. Energy absorption characteristics of aluminium alloy AA7xxx and AA6061 tubes subjected to static and dynamic axial load [J]. International Journal of Crashworthiness, 2014, 19(2): 139-152.

[17] ZOU X, GAO G J, DONG H P, XIE S C, CHEN G, TAN T. Crashworthiness analysis and structural optimisation of multi-cell square tubes under axial and oblique loads [J]. International Journal of Crashworthiness, 2017, 22(2): 129-147.

[18] MARZBANRAD J, KESHAVARZI A, ABOUTALEBI F H. Influence of elastic and plastic support on the energy absorption of the extruded aluminium tube using ductile failure criterion [J]. International Journal of Crashworthiness, 2014, 19(2): 172-181.

[19] HOOPUTRA H, GESE H, DELL H, WERNER H. A comprehensive failure model for crashworthiness simulation of aluminium extrusions [J]. International Journal of Crashworthiness, 2004, 9(5): 449-464.

[20] LI Z G, YANG H F, HU X W, WEI J F, HAN Z T. Experimental study on the crush behavior and energy-absorption ability of circular magnesium thin-walled tubes and the comparison with aluminum tubes [J]. Engineering Structures, 2018, 164: 1-13.

[21] BEGGS P D, SONG W, EASTON M. Failure modes during uniaxial deformation of magnesium alloy AZ31B tubes [J]. International Journal of Mechanical Sciences, 2010, 52(12): 1634-1645.

[22] YOON J, LEE Y, HUH H. Investigation of deformation and collapse mechanism for magnesium tube in axial crushing test [J]. Journal of Mechanical Science and Technology, 2013, 27(10): 2917-2921.

[23] SAMER F, TARLOCHAN F, SAMAKA H, KHALID K S. Improvement of energy absorption of thin walled hexagonal tube made of magnesium alloy by using trigger mechanisms [J]. International Journal of Research in Engineering and Technology, 2013, 2(10): 173-180.

[24] ZHU F, CHOU C C, YANG K H, CHEN X M, WAGNER D, BILKHU S. Application of AM60B magnesium alloy material model to structural component crush analysis [J]. International Journal of Vehicle Safety, 2012, 6(2): 178-190.

[25] D RUM C, HOPPERSTAD O S, LADEMO O G, LANGSETH M. An experimental study on the energy absorption capacity of thin-walled castings [J]. International Journal of Impact Engineering, 2006, 32(5): 702-724.

RUM C, HOPPERSTAD O S, LADEMO O G, LANGSETH M. An experimental study on the energy absorption capacity of thin-walled castings [J]. International Journal of Impact Engineering, 2006, 32(5): 702-724.

[26] D RUM C, HOPPERSTAD O S, LADEMO O G, LANGSETH M. Energy absorption capacity for thin-walled AM60 castings using a shear-bolt principle [J]. Computers & Structures, 2007, 85(1): 89-101.

RUM C, HOPPERSTAD O S, LADEMO O G, LANGSETH M. Energy absorption capacity for thin-walled AM60 castings using a shear-bolt principle [J]. Computers & Structures, 2007, 85(1): 89-101.

[27] STEGLICH D, TIAN X, BOHLEN J, RIEKEHR S, KASHAEV N, KAINER K U, HUBER N. Experimental and numerical crushing analyses of thin-walled magnesium profiles [J]. International Journal of Crashworthiness, 2015, 20(2): 177-190.

[28] WU Z B, GUI L J, FAN Z J. Axial compression tests and energy absorption characteristics of extruded magnesium alloy AZ31B rectangular tubes [J]. Engineering Mechanics, 2015, 32(10): 183-190. (in Chinese).

[29] WAGNER D A, LOGAN S, WANG K, SKSZEK T. FEA predictions and test results from magnesium beams in bending and axial compression[C]// Detroit: SAE 2010 World Congress & Exhibition, 2010.

[30] ROSSITER J, INAL K, MISHRA R. Numerical modeling of the failure of magnesium tubes under compressive loading [J]. Journal of Engineering Materials and Technology, 2012, 134(2): 169-184.

[31] HALLQUIST J O. LS-DYNA keyword user’s manual [M]. Livemore: Livermore Software and Technology Corporation, 2007: 299-800.

[32] DAVIES C H J. The effect of twinning on strain rate sensitivity during the compression of extruded magnesium alloy AZ31 [J]. Materials Science Forum, 2007, 539: 1723-1728.

[33] LIVESCU V, CADY C M, CERRETA E K, HENRIE B L, GRAY G T. The high strain rate deformation behavior of high purity magnesium and AZ31B magnesium alloy [C]// LUO A A, NEELAMEGGHAM N, BEALS R. Magnesium Technology. Warrendale, PA: TMS, 2006: 153-158.

[34] SONG W Q, BEGGS P, EASTON M. Compressive strain-rate sensitivity of magnesium–aluminum die casting alloys [J]. Materials & Design, 2009, 30(3): 642-648.

[35] LINDHOLM U, BESSEY R, SMITH G. Effect of strain rate on yield strength, tensile strength and elongation of three aluminum alloys [J]. Materials Science and Engineering A, 1971, 6(1): 119-133.

[36] MANES A, PERONI L, SCAPIN M, GIGLIO M. Analysis of strain rate behavior of an Al 6061 T6 alloy [J]. Procedia Engineering, 2011, 10: 3477-3482.

李志刚1,杨海峰1,张照生2,孙 野3,韩郅通1,韦济飞1

1. 北京交通大学 机械与电子控制工程学院,北京 100044;

2. 北京理工大学 机械与车辆学院,北京 100081;

3. 吉林吉化建修有限公司,吉林 132021

摘 要:对不同长度的完整AZ31B镁合金薄壁方管和A6063铝合金薄壁方管以及具有诱导特征的薄壁管进行不同应变率的轴向压缩试验研究。研究发现,压缩过程中镁合金薄壁管局部屈曲,进而断裂,其中在断裂阶段出现3种耐撞性能断裂模式,分别是水平断裂、斜向断裂和螺旋断裂。相比于铝合金方管,镁合金薄壁管的吸能效果较差。在上述研究基础上,进一步分析长宽比、应变率和诱导特征对薄壁管耐撞性能的影响。结果表明,随着长宽比从1增加到4,镁合金薄壁管的最大压缩载荷和整体吸能比以幂函数的规律减小,而铝合金薄壁管则基本保持不变。随着压缩速率从5×10-5增加到10 m/s,镁合金薄壁管的主要耐撞性能参数以指数形式增加,而铝合金薄壁管则变化很小。此外,本文作者引入的圆孔和缝的诱导特征未明显提高镁合金薄壁管的吸能效果,因此,后期需要在薄壁管不同位置设计更多种类和尺寸的诱导特征来提高镁合金薄壁管的吸能比。

关键词:镁合金方管;耐撞性能;长度/宽度比;应变率;诱导特征

(Edited by Wei-ping CHEN)

Foundation item: Project (2017JBM041) supported by the Fundamental Research Funds for the Central Universities, China; Project (51505024) supported by the National Natural Science Foundation of China; Project supported by the Foundation of Zhejiang Key Laboratory of Automobile Safety Technology of China

Corresponding author: Zhi-gang LI; Tel: +86-13436980207; E-mail: zgli@bjtu.edu.cn

DOI: 10.1016/S1003-6326(19)65029-6