文章编号:1004-0609(2014)11-2755-07

充芯连铸铜包铝复合材料的界面形成机理

张建宇1, 2,曾祥勇1,韩艳秋1,姚金金1,吴春京1

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 河北工程大学 机电工程学院,邯郸 056038)

摘 要:采用垂直充芯连铸法制备断面尺寸为60 mm×14 mm×7 mm(长×宽×圆角半径)、铜包覆层厚度为2 mm的铜包铝复合材料,并采用扫描电子显微镜(SEM)、能谱仪(EDS)、X射线衍射仪(XRD)和透射电子显微镜(TEM)等对界面的形貌和组成进行表征。结果表明:铜包铝复合材料界面层在近铜侧主要由平面状的Cu9Al4(I区)和胞状的CuAl2(II区)两区组成,在近铝侧为α(Al)+CuAl2伪共晶组织(III区),而在Cu9Al4和CuAl2之间还残存未转变的高温相Cu3Al2+x。基于分析结果,提出了充芯连铸铜包铝的界面形成机理。

关键词:铜包铝复合材料;充芯连铸;界面;形成机理

中图分类号:TG335 文献标志码:A

Formation mechanism of interface in copper cladding aluminum composites fabricated by core-filling continuous casting

ZHANG Jian-yu1, 2, ZENG Xiang-yong1, HAN Yan-qiu1, YAO Jin-jin1, WU Chun-jing1

(1.School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Mechanical and Electrical Engineering, Hebei University of Engineering, Handan 056038, China)

Abstract: Copper cladding aluminum (CCA) composites with the section dimensions of 60 mm×14 mm×7 mm (length×width×round angle radius) and the sheath thickness of 2 mm were fabricated by vertical core-filling continuous casting (VCFC) technology, and the micro-morphology and composition at the interface of CCA composites were characterized by scanning electron microscopy (SEM), energy dispersive X-ray spectrometry (EDS), X-ray diffractometry (XRD) and transmission electron microscopy (TEM). The results show that the interface at the side of Cu is composed of the Cu9Al4 planar layer (zone I) and CuAl2 cellular layer (zone II), and that at the Al side is α(Al)+CuAl2 pseudo eutectic structure (zone III) , in addition, the high temperature phase Cu3Al2+x is remained between Cu9Al4 and CuAl2. Thus, the formation mechanism of interface in CCA composites fabricated by core-filling continuous casting was proposed.

Key words: copper cladding aluminum composites; core-filling continuous casting; interface; formation mechanism

铜包铝双金属层状复合材料具有电导率高、耐蚀性好、密度低、性价比高等特点,在信号传输和电力输送等领域获得越来越广泛的应用[1]。目前,工业上的制备方法主要有铸造-挤压法、静液挤压法、轧制压接法和包覆焊接法等,但这些方法普遍存在界面结合差和表面处理困难等缺点[2]。充芯连铸复合法是谢建新等[3-4]开发的制备铜包铝复合材料的新工艺,具有工艺流程短、所制备的坯料界面达到冶金结合、可实现大断面复合坯料成形等优点,具有良好的应用前景。

充芯连铸铜包铝界面结合本质上属于Cu和Al的固液反应扩散结合,Cu/Al界面会生成较厚的金属间化合物层,其组成和分布很大程度上影响结合界面的性能及后续加工[5-6]。因此,弄清楚Cu/Al界面金属间化合物生长规律,不仅对揭示Cu/Al异种材料扩散反应的本质具有重要的理论意义,而且对实际制备过程中的工艺控制具有指导作用。

近年来,国内外对于Cu和Al的固液反应扩散进行了较多研究,并取得了一系列成果。WANG等[7]在700 ℃温度下将Cu/Al扩散偶等温扩散20 min,在氩气保护下缓慢冷却到室温,界面金属间化合物从铜侧到铝侧依次为δ(Cu3Al2)、ξ(Cu4Al3)、η2(CuAl)和θ(CuAl2)。XU等[8]的研究表明,在与WANG等[7]相同的加热工艺条件下,等温扩散后快速冷却到室温,界面金属间化合物从铜侧到铝侧依次为β(Cu3Al)、γ1(Cu9Al4)、ε2(Cu3Al2+x)和η2。MORENO等[9]将温度为688 ℃的铝液浇入预热温度为458 ℃的铜模中,然后随炉冷却,通过界面分析发现在铜固溶体α(Cu)和CuAl2+α(Al)伪共晶组织之间存在Cu9Al4、CuAl和CuAl2这3种金属间化合物。由这些研究结果可以看出,界面组织结构与界面的热历史过程有关,工艺条件不同,界面组织结构不同。

SU等[10]通过检测界面结合良好的充芯连铸铜包铝棒的结合界面发现,在铜固溶体α(Cu)与铝固溶体α(Al)之间,依次存在Cu9Al4、CuAl2和α(Al)+CuAl2伪共晶等3层组织。对于其形成过程,SU等[10]用MORENO提出的界面形成机理进行了解释:当铜与铝液开始接触后,首先发生铜的溶解,形成液相扩散层,由于激冷作用在铜的基底上首先形成CuAl2,然后在铜固溶体α(Cu)与CuAl2之间,通过固态反应扩散形成Cu9Al4,铜在液态铝中形成的扩散层在随后的快速凝固中形成CuAl2相和伪共晶组织α(Al)+CuAl2。但实际上充芯连铸法与模铸法生产工艺不同,其界面的热历史过程不同,所以MORENO针对模铸法提出的界面形成机理并不能很好地解释铜包铝充芯连铸的界面组织。因此,本文作者针对垂直充芯连铸的铜包铝复合材料界面进行了详细研究,并提出了铜包铝充芯连铸的界面形成机理。

1 实验

垂直充芯连铸铜包铝的工艺原理如图1所示。复合连铸开始时,铜液充入结晶器中先凝固成铜管并通过牵引机构连续引出。随后铝液通过石墨芯管连续充入铜管中,通过结晶器的一次冷却和喷水二次冷却控制铝的凝固过程以及铜铝之间的界面反应,从而连续制备铜包铝复合材料。

本实验中以截面尺寸为60 mm×14 mm×7 mm(长×宽×圆角半径)、铜层厚度2 mm的铜包铝复合材料为研究对象,以Cu含量为99.7%(质量分数)的纯铜和Al含量为99.7%的纯铝为原料,在自行研制的垂直充芯连铸机[11]上制备铜包铝复合材料。制备工艺参数如下:铜液温度为1200 ℃,铝液温度为750 ℃,一次冷却水流量为360 L/h,石墨套与铜结晶器接触长度为40 mm,二次冷却水流量为180 L/h,二次冷却水液面在石墨结晶器出口位置以下50 mm,连铸速度为100 mm/min,石墨芯管长度为100 mm。所制备的铜包铝复合材料如图2所示。由图2可见,铜包覆层厚度均匀,界面复合良好,铝芯无气孔和冷隔等铸造缺陷。

图1 垂直充芯连铸铜包铝复合材料工艺原理示意图

Fig. 1 Schematic diagram of vertical core-filling continuous casting for CCA composites

图2 铜包铝复合材料的宏观形貌(左边为纵剖面)

Fig. 2 Macro-morphologies of CCA composites (longitudinal section on left side)

在所制备的复合良好的铜包铝铸坯上用线切割截取试样,将试样经砂纸磨光和机械抛光后,用1%HF试剂侵蚀。采用扫描电子显微镜(SEM)和能谱仪(EDS)分析界面层的结构形貌和成分;将铜铝试样从界面剪断,采用X射线衍射仪(XRD)对拉剪断裂后的界面进行分析以确定界面处的物相;从试样中切取包含铜铝复合界面的直径3 mm的圆薄片,在砂纸上研磨至厚度约30 μm,然后在离子减薄机上进行离子减薄轰击,采用透射电镜(TEM)进一步分析界面层内物相。

2 结果与讨论

2.1 铜包铝复合材料界面组织结构

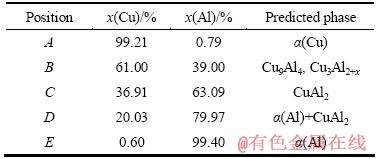

图3(a)和(b)所示为铜包铝复合材料横截面的背散射(BSE)电子像,其相应各点的EDS成分分析结果如表1所列。结合这些结果可看出,在纯铜和纯铝之间存在金属间化合物界面层,厚度约为220 μm。界面层从铜侧到铝侧可清晰地分为3层结构:I区、II区和III区,I区为厚度较小的层状组织,其厚度约为2 μm,其成分与Cu9Al4和Cu3Al2+x等化合物接近,由于电子探针的分辨率较低,很难通过成分分析来判断其相结构。II区呈胞状形态,其凸缘伸向III区,其中一些呈块状分布于III区内,从成分上判断为CuAl2相。III区所占的比例最大,呈层片状分布,从成分上判断为CuAl2+α(Al)伪共晶组织。图3(c)和(d)所示为界面层的EDS线扫描分析,可以看出,II区和III区均存在成分平台,具有明显的液相内析出组织的特征。

表1 铜包铝复合材料界面的EDS成分分析结果

Table 1 Results of EDS composition analysis of interface in CCA composites

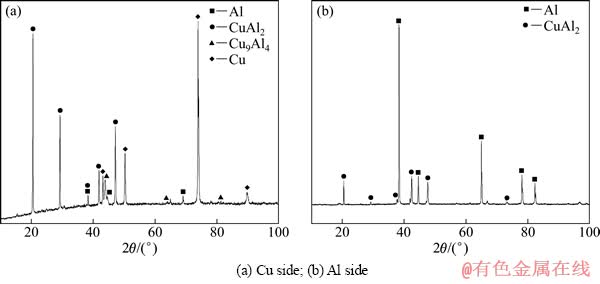

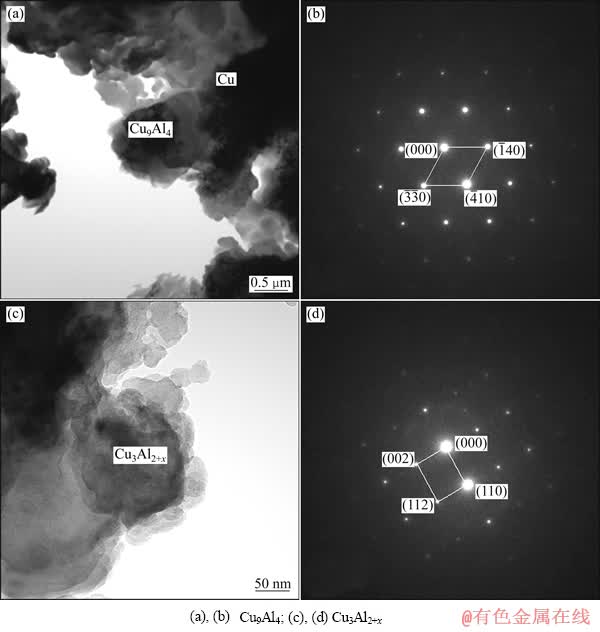

图4所示为断裂表面的XRD谱。由图4可见,复合界面处的金属间化合物种类主要是CuAl2和Cu9Al4,其中铜侧主要是Cu、CuAl2和少量的Cu9Al4,铝侧主要是Al和CuAl2。为进一步确定较薄区域的物相,用透射电子显微镜检测界面处的相组成(见图5),衍射斑点标定结果(见图5(b)和(d))显示,扩散区域中靠近铜侧的金属间化合物为Cu9Al4和Cu3Al2+x,其中Cu9Al4相为立方结构,点阵常数为a=b=c=0.87068 nm,Cu3Al2+x相为高温相,密排六方结构,点阵常数为a=0.4146 nm,c=0.5063 nm。

综上分析可以确定界面各层的物相,即铜侧呈平面状分布的界面层I区主要是Cu9Al4相,另外存在少量的高温未转变相Cu3Al2+x,呈胞晶生长的II区为CuAl2相,而呈层片状的III区为CuAl2+α(Al)伪共晶组织。

图3 铜包铝复合材料界面层背散射电子(BSE)像和EDS线扫描分布

Fig. 3 Backscattered electron images ((a), (b)) and EDS line profiles ((c), (d)) of interface in CCA composites

图4 铜包铝复合材料断裂表面的XRD谱

Fig. 4 XRD patterns of interface in CCA composites after shear test

图5 铜包铝复合材料界面的TEM明场像和选区衍射斑点

Fig. 5 TEM bright field images and corresponding selected area electron diffraction patterns of interface in CCA composites

2.2 充芯连铸铜包铝复合材料界面形成机理

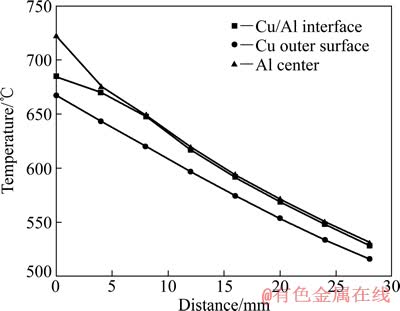

充芯连铸铜包铝复合材料界面本质上属于固液结合,其界面化合物的形成过程与界面热历史过程有关。图6所示为上述连铸参数下铜包铝温度场计算机模拟结果,其模拟方法和参数设置参见文献[12]。由图6可以看出,铜包铝充芯连铸法的温度场具有以下特点:1) 在铝液从石墨芯管流出而和铜管开始接触的位置,铜管的温度较高,其内外温度均略高于铝的熔点且温差较小,与铝液开始接触的铜管内表面温度与铝液温度大致相等,在稳定连铸过程中不存在模铸法中的激冷作用;2) 铜铝界面的冷却速度较大,一般降低到共晶温度以下大概需要十几秒时间,在短短几分钟内即 可降低到室温。所以,铜与铝的界面结合是Cu/Al界面从铝熔点以上一定温度连续冷却的固液连接过程,界面层是铜与铝液发生界面反应扩散以及随后的快速凝固共同作用的结果。其形成过程可结合铜铝二元合金相图[13]来描述,如图7所示。

图6 石墨芯管出口以下不同位置与温度关系

Fig. 6 Relationship between temperature and distance from orifice to measurement points

当温度高于铝熔点一定值时,铝液从石墨芯管中流出与铜管接触,铝原子向铜基体中扩散导致铜快速溶解,在界面处瞬间形成极薄的铜铝扩散区,当达到一定浓度时,铜铝金属间化合物在扩散区形核[14-15]。从铜铝二元合金相图可以看出,在高于铝熔点的温度下,界面反应扩散理论上可生成ε2、γ1和β相。由于在此温度范围内,β相生长速度较慢[16],而充芯连铸铜包铝的接触反应时间较短,仅仅考虑ε2和γ1相。另外,由于γ1相具有固态反应扩散特征[5],所以可认为ε2首先在铜基底上形核,并在极短的时间侧向长大生成连续层(见图7(a))。

随着温度降低,当ε2形成连续层后,铜与ε2相之间会发生固相反应扩散生成化合物γ1,同时γ1和ε2化合物以“形成溶解机制”[17]生长,即金属间化合物/铜界面向基体方向移动生成新的化合物层。同时,金属间化合物发生溶解,金属间化合物/液体扩散层界面也向铜基体方向移动,两者速度的差异导致金属间化合物的长大。另外,铜原子在铝液中的扩散导致液相扩散层增厚。由于铜在液体铝中的扩散系数远大于铜原子在固体铝中的扩散系数,因此,液相扩散层的厚度远大于金属间化合物的厚度(见图7(b))。

图7 充芯连铸铜包铝复合材料界面形成机理示意图

Fig. 7 Schematic diagrams showing formation mechanism of interface in CCA composites fabricated by core-filling continuous casting (DL: Diffusion layer, S: Solid phase, L: Liquid phase)

随着温度进一步降低到铝的熔点温度下,铜管内的纯铝由于熔点高而先发生凝固,而液相扩散层由于熔点低,仍保持液态。由于液相扩散层中存在浓度梯度,金属间化合物/液相扩散层界面仍向铜侧迁移(见图7(c))。

随着温度进一步降低到624~592 ℃温度区间,在624 ℃会发生包晶反应L+ε2=η1,在592 ℃会发生包晶反应L+η1=θ,此时,与液相扩散层相平衡的化合物相由ε2转变为θ。由于冷却速度较快,凝固过程是非平衡包晶转变,可能存在残余的ε2或者η1 (见图7(d),其中残余未转变的金属间化合物被省略)。

随着进一步冷却,铜侧液相扩散层凝固析出先共晶θ相,并向液相扩散层中生长,将铝原子向液相中排出,而铝侧液相扩散层也可能凝固析出先共晶α(Al)相,并向液相扩散层生长,铜原子向液相中排出,液相扩散区铜浓度梯度越来越小,液相扩散层浓度趋于一致,在549 ℃、一定过冷度时发生共晶反应L=α+θ,析出θ+α(Al)伪共晶组织(见图7(e))。在扩散层转变为固相后直到室温的冷却过程中,由于固态反应扩散速度很慢,界面扩散过程一般不予考虑。

3 结论

1) 充芯连铸铜包铝界面层从铜侧到铝侧可分为3层结构:I区为厚度较小的层状组织,主要含Cu9Al4相和包晶转变的残余相Cu3Al2+x,II区为CuAl2相,III区为层片状α(Al)+CuAl2伪共晶相。

2) 铜包铝界面层的形成是液态铝与固态铜之间发生界面反应扩散和快速凝固共同作用的结果,即Cu9Al4相主要是通过固相扩散形成,CuAl2和α(Al)+CuAl2伪共晶相通过液相扩散层快速凝固形成。

REFERENCES

[1] GIBSON A. The economics of copper clad aluminum bimetallic cables[J]. Wire & Cable Technology International, 2005, 33(4): 82-83.

[2] 张建宇, 姚金金, 曾祥勇, 韩艳秋, 吴春京. 铜包铝复合材料研究进展[J]. 中国有色金属学报, 2014, 24(5): 1275-1284.

ZHANG Jian-yu, YAO Jin-jin, ZENG Xing-yong, HAN Yan-qiu, WU Chun-jing. Research process of copper cladding aluminum composites[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1275-1284.

[3] XIE J X, WU C J, LIU X F, LIU X H. A Novel forming process of copper cladding aluminum composite materials with core-filling continuous casting[J]. Materials Science Forum, 2007, 539/543: 956-961.

[4] 吴永福, 刘新华, 谢建新, 王连忠, 董晓文. 矩形断面铜包铝复合材料的水平连铸直接复合成形[J]. 中国有色金属学报, 2012, 22(9): 2050-2057.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin, WANG Lian-zhong, DONG Xiao-wen. Copper cladding aluminum composites materials with rectangle section fabricated by horizontal core-filling continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2050-2057.

[5] 吴永福, 刘新华, 谢建新. 连铸直接复合成形矩形断面铜包铝复合材料界面及其在轧制中的变化[J]. 中国有色金属学报, 2013, 23(1): 191-200.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Interface of copper cladding aluminum composite materials with rectangle section fabricated by horizontal core-filling continuous casting and its evolvement in rolling process[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 191-200.

[6] 吴永福, 刘新华, 谢建新. 退火温度对连铸-轧制成形铜包铝复合扁排组织与性能的影响[J]. 中国有色金属学报, 2014, 24(1): 188-196.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Effect of annealing temperature on texture and properties of copper cladding aluminum flat bar fabricated by continuous casting and subsequent rolling technology[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 188-196.

[7] WANG Q, LI D G, WANG K, WANG Z Y, HE J C. Effects of high uniform magnetic fields on diffusion behavior at the Cu/Al solid/liquid interface[J]. Scripta Materialia, 2007, 56: 485-488.

[8] XU B, TONG W P, LIU C Z, ZUO L, HE J C. Effects of high magnetic field on growth behavior of compound layers during reactive diffusion between solid Cu and liquid Al[J]. J Mater Sci Technol, 2011, 27(9): 856-860.

[9] MORENO D, GARRETT J, EMBURY J D. A technique for rapid characterization of intermetallics and interfaces[J]. Intermetallics, 1999, 7: 1001-1009.

[10] SU Y J, LIU X H, HUANG H Y, LIU X F, XIE J X. Interfacial microstructure and bonding strength of copper cladding aluminum rods fabricated by horizontal core-filling continuous casting[J]. Metallurgical and Materials Transactions A, 2011, 42: 4088-4099.

[11] 张建宇, 王屹峰, 万长青, 曾祥勇, 蔡 鹏, 吴春京. 铜包铝复合扁排立式充芯连铸设备的研制[J]. 特种铸造及有色合金, 2013, 33(3): 265-268.

ZHANG Jian-yu, WANG Yi-feng, WAN Chang-qing, ZENG Xiang-yong, CAI Peng, WU Chun-jing. Continuous cast forming machine with vertical core-filling for copper cladding aluminum composites bars[J]. Special Casting & Nonferrous Alloys, 2013, 33(3): 265-268.

[12] 张建宇. 垂直充芯连铸铜包铝复合材料成形机理及工艺控制[D]. 北京: 北京科技大学, 2013: 81-95.

ZHANG Jian-yu. Formation mechanism and process of vertical core-filling continuous casting for copper cladding aluminum composites[D]. Beijing: University of Science and Technology Beijing, 2013: 81-95.

[13] RIANI P, ARRIGHI L, MARAZZA R, MAZZONE D, ZANICCHI G, FERRO R. Ternary rare-earth aluminum systems with copper: A review and a contribution to their assessment[J]. Journal of Phase Equilibria and Diffusion, 2004, 25(1): 22-52.

[14] YU C H, LIN K L. The atomic-scale studies of the behavior of the crystal dissolution in a molten metal[J]. Chemical Physics Letters, 2006, 418: 433-436.

[15] LORD R A, Umantsev A. Early stages of soldering reactions[J]. Journal of Applied Physics, 2005, 98: 1-11.

[16] TANAKA Y, KAJIHARA M, WATANABE Y. Growth behavior of compound layers during reactive diffusion between solid Cu and liquid Al[J]. Materials Science and Engineering A, 2007, 445/446: 355-363.

[17] ABDELHADI O M, LADANI L. IMC growth of Sn-3.5Ag/Cu system: Combined chemical reaction and diffusion mechanisms[J]. Journal of Alloys and Compounds, 2012, 537: 87-99.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51274038)

收稿日期:2014-02-10;修订日期:2014-10-08

通信作者:吴春京,教授;电话:010-62332605;E-mail:cjwu @ mater.ustb.edu.cn