文章编号:1004-0609(2014)01-0188-09

退火温度对连铸-轧制成形铜包铝复合扁排组织与性能的影响

吴永福1, 2,刘新华1, 2,谢建新1, 2

(1. 北京科技大学 材料先进制备技术教育部重点实验室,北京 100083;

2. 北京科技大学 新材料技术研究院,北京 100083)

摘 要:研究退火温度对连铸-轧制成形铜包铝复合扁排组织、界面结构与结合强度、力学性能以及电学性能的影响。结果表明:铜包覆层在300 ℃开始再结晶,400 ℃时再结晶完成;芯部铝靠近铜包覆层的剧烈变形区在200 ℃完成再结晶;而在中心部位,粗晶区在250 ℃时已开始再结晶,400 ℃时再结晶完成。铜包铝复合扁排的抗拉强度和伸长率在300 ℃以下退火时变化较小,在300 ℃以上退火时变化显著。随着退火温度的增加,界面结合强度先增大后减少。在250 ℃及以下温度退火时,界面处无明显金属间化合物相生成,因此,在此温度范围内,界面结合强度随着退火温度的升高而升高;退火温度在300~400 ℃时,界面处有金属间化合物相生成,且随温度升高,界面厚度由约1 μm增大到约4 μm,界面结合强度由54.0 MPa逐渐降低到25.8 MPa。铜包铝复合扁排的电阻率主要受基体金属组织状态的影响,随着退火温度的升高,铜包铝扁排的电阻率逐渐降低;在本实验条件下,当界面处金属间化合物层的厚度不大于4 μm时,金属间化合物层对电阻率的影响不明显。

关键字:连铸-轧制法;铜包铝扁排;退火;界面;性能

中图分类号:TG156.2 文献标志码:A

Effect of annealing temperature on texture and properties of copper cladding aluminum flat bar fabricated by continuous casting and subsequent rolling technology

WU Yong-fu1, 2, LIU Xin-hua1, 2, XIE Jian-xin1, 2

(1. Key Laboratory for Advanced Materials Processing, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China;

2. Institute for Advanced Materials and Technology, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The copper cladding aluminum (CCA) flat bar was fabricated by continuous casting-rolling technology, and then, the effects of annealing temperature on the texture, interface structure and bonding strength, mechanical and electrical properties of CCA flat bar were investigated. The results show that the recrystallization of the copper sheath starts at 300 ℃, and completes at 400 ℃. The aluminum along the copper sheath is in the severe deformation zone, and the recrystallization almost completes at 200 ℃. However, the recrystallization of aluminum core in the coarse grain zone starts at 250 ℃, and completes at 400 ℃. The variations of tensile strength and elongation are small when the annealing temperature is below 300 ℃, but becomes large above 300 ℃. The interface bonding strength ascends, and then descends as the annealing temperature rising. When the annealing temperature is not higher than 250 ℃, there is no intermetallic phase generates at the interface, because of which the bonding strength ascends at this temperature range. However, when the annealing temperature is 300-400 ℃, the intermetallic phase forms at the interface, the interface layer thickness increases from about 1 μm to 4 μm, the bonding strength descends from 54.0 MPa to 25.8 MPa. The electrical resistivity is influenced mainly by the microstructures of the component metals. The electrical resistivity of the CCA flat bar descends as the annealing temperature rising. Under the experimental conditions, the interface layer at the interface is less than 4 μm, which has little influence on the electrical resistivity of the CCA flat bar.

Key words: continuous casting-rolling method; copper cladding aluminum flat bar; annealing; interface; property

与纯铜扁排相比,铜包铝复合扁排具有低密度、低成本等优点[1],可广泛应用于配电母线槽,中、高频加热设备,各种控制柜,电力、冶金、化工等行业的大型汇流排等。采用连铸直接复合成形铜包铝复合棒坯,然后经过平辊轧制成形铜包铝复合扁排,是谢建新等开发的一种复合扁排短流程高效成形加工新工艺[2-3]。退火是加工过程中降低变形抗力、改善塑性加工性能的不可缺少的工序,也是产品性能调控的重要手段。在退火工艺中,相对于保温时间,退火温度是影响材料性能更重要的因素[4]。

铜/铝复合材料在较高温度下进行加工或退火时,容易在界面处形成金属间化合物层,对复合材料力学性能和导电性能产生直接影响。大量研究结果表明[5-9],铜/铝界面金属间化合物层厚度大于2 μm后,界面的断裂方式从延性断裂转变为脆性断裂,界面结合强度显著降低。王秋娜[7, 10]等研究了退火温度对静液挤压和拉拔成形铜包铝复合线材的组织性能影响规律,结果表明,复合线材的铜包覆层在350 ℃完成再结晶,退火温度继续升高将导致晶粒长大,伸长率明显降低。ABBASI等[6]、LEE等[11]和BRAUNOVIC等[12]对铜/铝接头的研究发现,铜/铝界面化合物层的厚度增大导致电阻率升高。连铸直接复合成形的原理是铜包覆层(铜管)首先凝固,随后铝液充入铜管中凝固,形成铝芯[13]。因此,该方法的复合过程是液态铝与具有较高温度和清洁内表面的铜管接触,然后形成复合界面的过程,所制备的铜包铝复合材料的组织与界面结构等与现有各种固-固复合工艺所制备的铜包铝复合材料明显不同[14]。另一方面,连铸时形成的铜/铝复合界面在轧制过程中发生变形、破碎等现象,使界面性能发生变化。因此,研究退火对连铸-轧制成形扁排的组织性能的影响,对于合理制定铜包铝复合扁排的退火工艺和精确控制产品性能具有指导意义。

本文作者以连铸-轧制成形的铜包铝复合扁排为对象,重点研究退火温度对显微组织、界面结构及结合强度、扁排力学性能和电学性能的影响,探讨基体金属组织和界面结构对性能的影响规律与作用机理。

1 实验

1.1 铜包铝复合扁排的成形

实验所用铜包铝复合扁排的制备工艺为:采用水平连铸直接复合法成形50 mm×30 mm×3 mm×R4 mm(宽度×厚度×铜层厚度×圆角半径)矩形断面铜包铝复合棒材[15],然后经过5道次平辊轧制及1道次精整拉拔成形铜包铝复合扁排[16]。轧制设备为二辊轧机,轧辊直径400 mm,室温轧制,轧制速度8 m/min,轧制过程无润滑。拉拔在链式拉拔机上进行,拉拔润滑剂为20号机油。所成形的铜包铝复合扁排宽度为60 mm,厚度为8 mm,圆角半径为4 mm,表面光亮、形状规整、界面结合良好,外观形貌如图1 所示。轧制成形的铜包铝复合扁排的铜包覆层和铝芯的化学成分如表1和2所列。

图1 铜包铝复合扁排宏观形貌

Fig. 1 Macromorphology of copper cladding aluminum flat bar

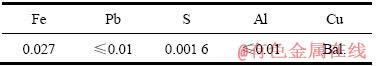

表1 铜包覆层的化学成分

Table 1 Chemical compositions of copper sheath (mass fraction, %)

表2 铝芯的化学成分

Table 2 Chemical compositions of Al core (mass fraction, %)

1.2 退火制度与性能评价

采用SGM4810AE箱式退火炉对拉拔后扁排进行退火处理,退火炉的控温精度为±1 ℃,退火温度范围为200~400 ℃,退火的保温时间为1 h,退火后空冷。

金相观察沿着扁排的轧制方向取样,试样经砂纸磨光、机械抛光后,铜包覆层采用配比为FeCl3 (5 g)+HCl(2 mL)+H2O(90 mL)的三氯化铁溶液侵蚀,铝芯采用配比为HF(10 mL)+H2O(90 mL)的氢氟酸溶液侵蚀。采用NIKON ECLIPSE LV150正置式反射金相显微镜观察显微组织。

采用维氏显微硬度仪检测铜包覆层和铝芯的显微硬度,加载载荷为25 g,加载时间为10 s,每个试样检测5个点的硬度,然后取平均值。采用拉伸试验评价铜包铝复合扁排的抗拉强度和伸长率等力学性能。拉伸试样为全截面铜包铝复合扁排,试样长度300 mm,标距125 mm;试验设备为200 kN万能材料试验机,夹头移动速度3 mm/min。

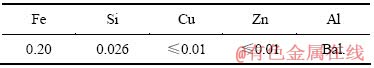

参考GB/T 6396—1995中规定的层状复合材料层间结合强度(剪切强度)拉剪试验方法评价铜包铝复合扁排的界面结合强度(剪切强度)。试样的形状和尺寸如图2所示。拉剪试验设备采用10 kN万能材料试验机,夹头移动速度为0.5 mm/min。采用ZEISS EVO 18扫描电子显微镜观察界面层的微观形貌,采用BRUKER QUANTAX EDS系统分析界面附近的成分。

图2 铜包铝复合扁排拉剪试验样品尺寸图

Fig. 2 Shear tensile test specimen of CCA flat bar (Unit: mm)

采用Applent AT510直流电阻测试仪分析铜包铝复合扁排的电阻率,样品长度800 mm。力学性能、界面剪切强度、电学性能等评价试验在每一种条件下重复3个试样,然后取平均值。

2 结果与分析

2.1 退火温度对显微组织的影响

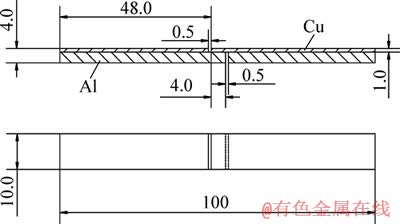

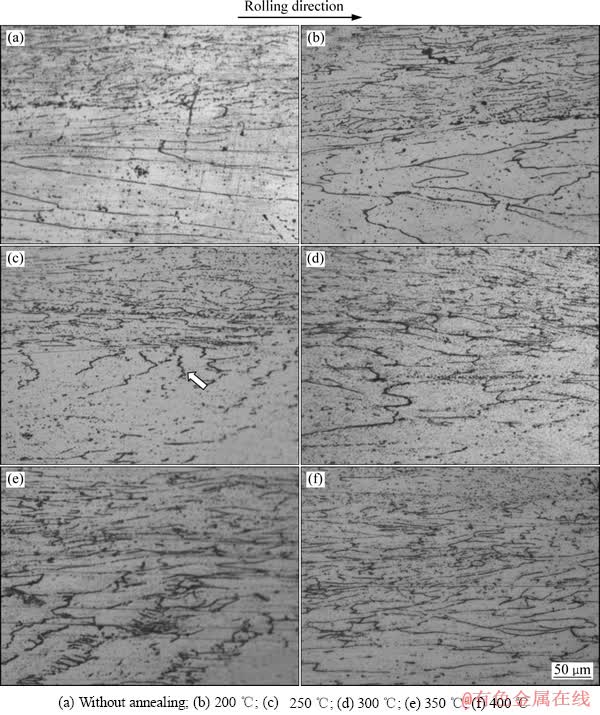

在200~400 ℃温度退火1 h,复合扁排铜包覆层轧制方向的显微组织如图3所示。由图3(a)可以看出,经过轧制和拉拔变形后,铜包覆层的显微组织为沿着轧制方向排列的纤维晶组织,晶粒内部分布着大量的变形带,晶界模糊。当退火温度为200~250 ℃时,铜包覆层显微组织特征未发生明显变化,主要发生回复现象,即随着退火温度的升高,晶粒内部的变形带减少,晶界变得清晰,但未观察到再结晶组织,如图3(b)~(c)所示。当退火温度为300 ℃时,开始出现再结晶组织,随着退火温度的升高,再结晶组织的比例增大,如图3(d)~(e)所示。当退火温度升高到400 ℃时,再结晶完成,铜包覆层的组织转变为细小的等轴晶,晶粒内部分布大量的退火孪晶,如图3(f)所示。综上所述,复合扁排铜包覆层在250 ℃及以下温度退火时仅发生回复现象,在300 ℃退火时开始再结晶,在400 ℃退火时,再结晶完成。

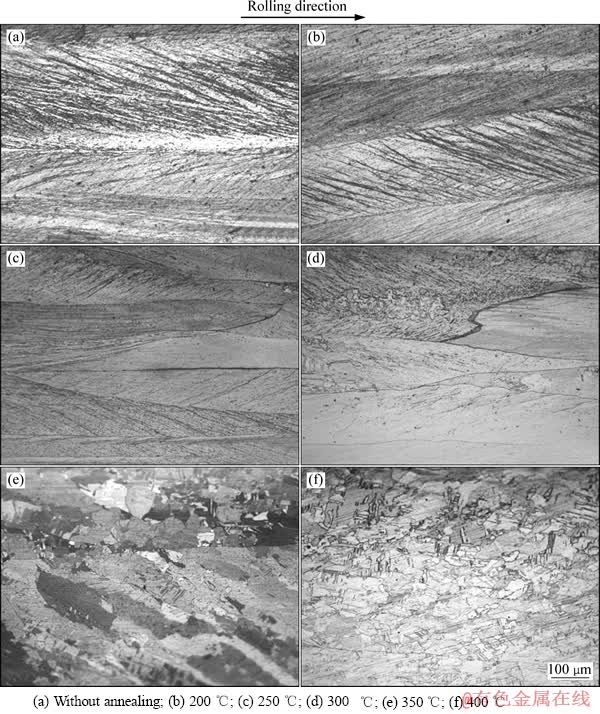

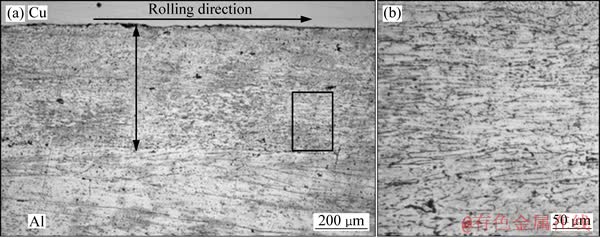

铜包铝复合扁排芯部铝的加工态组织分为两个区域:靠近铜层的剧烈变形区和中心部分的粗晶区,如图4所示。图中4(b)为图4(a)中方框部分的局部放大图。铜包铝复合棒材在轧制时,硬度较高的铜包覆层与轧辊直接接触,将轧制压力传递给芯部铝,与铜层接触的这部分铝的剪切变形剧烈,在靠近铜层的部分形成一层宽度约600 μm的剧烈变形区,该区域形成细小的轧向排布晶粒。中心部分的晶粒变形程度较小,形成沿着轧制方向分布的纤维组织,晶界较为模糊。

经过200~400 ℃温度退火1 h,复合扁排铝芯轧制方向的显微组织如图5所示。由图5可看出,在200 ℃退火时,剧烈变形区由于变形程度较大,在较低温度即发生再结晶,再结晶晶粒较为细小;而中心部分未观察到再结晶组织,晶粒仅发生回复,晶粒内部缺陷减少,晶界由模糊变得清晰,如图5(b)所示。在250 ℃退火时,中心部分变形程度较小的区域内开始出现锯齿形晶界,表明已开始再结晶,如图5(c)中箭头所示的位置。当退火温度为300~350 ℃时,中心部分变形程度较小的晶粒中的再结晶比例增大;当退火温度为400 ℃时,两区之间的分界面模糊,两区之间的晶粒大小差异变小,再结晶完成。但由于芯部铝的各个位置上初始晶粒大小以及变形程度不一致,经400 ℃退火后,边部剧烈变形区与中心区的晶粒大小仍有一定差异。

2.2 退火温度对力学性能的影响

图3 退火温度对扁排铜包覆层显微组织的影响

Fig. 3 Effect of annealing temperature on microstructures of copper sheath

图4 冷加工态铜包铝复合扁排铝芯沿轧制方向的显微组织

Fig. 4 Microstructures of aluminum core of CCA flat bar along rolling direction after cold working

图5 退火温度对铜包铝复合扁排铝芯显微组织的影响

Fig. 5 Effect of annealing temperature on microstructure of aluminum core of CCA flat bar

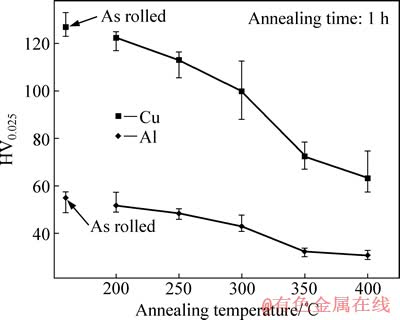

图6 退火温度对铜包铝复合扁排的铜层和铝芯显微硬度的影响

Fig. 6 Effect of annealing temperature on microhardness of copper sheath and aluminum core of CCA flat bar

在200~400 ℃退火1 h后,铜包铝复合扁排的铜包覆层和芯部铝的显微硬度HV0.025的变化如图6所示。由图6可知,退火温度为200~300 ℃时,铜包覆层和铝芯的显微硬度降低较慢,退火温度高于300 ℃后,显微硬度降低的幅度加大。由退火温度对显微组织的影响可知,铝中心部分的再结晶开始温度约为250 ℃,而铜包覆层的为300 ℃。因此,在200~300 ℃退火时,铜包覆层与铝中心部分的再结晶晶粒比例仍较低,软化效果不明显,对显微硬度的影响不大。当退火温度高于300 ℃时,再结晶晶粒所占比例增加明显(见图3(e)与图5(e)),因此,退火温度高于300 ℃后,显微硬度降低较为明显。但在350℃后,铜包覆层硬度值降低放慢,而铝芯的硬度变化很小。

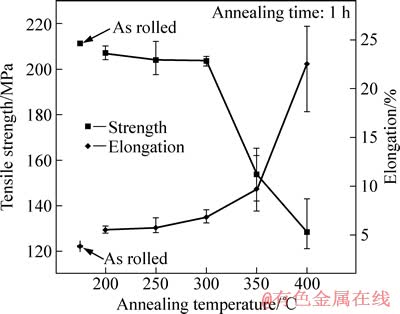

在200~400 ℃对铜包铝复合扁排进行退火,退火温度对扁排抗拉强度和伸长率的影响如图7所示。从图7可以看出,未退火的铜包铝复合扁排的抗拉强度和伸长率分别为211.1 MPa和3.8%。在300 ℃及以下温度退火时,抗拉强度降低很小,伸长率上升缓慢;退火温度高于300 ℃时,抗拉强度显著降低,伸长率显著上升;当退火温度为400 ℃时,抗拉强度降低至128.4 MPa,伸长率升高至22.5%。由前述退火温度对铜/铝组织的影响分析可知,在350 ℃退火时,铜包覆层和芯部铝的再结晶均未完成,两者的内部组织不均匀,这是导致在该温度下退火时抗拉强度降低幅度而伸长率升高幅度较小的主要原因。

图7 退火温度对铜包铝复合扁排抗拉强度和伸长率的影响

Fig. 7 Effect of annealing temperature on tensile strength and elongation of CCA flat bar

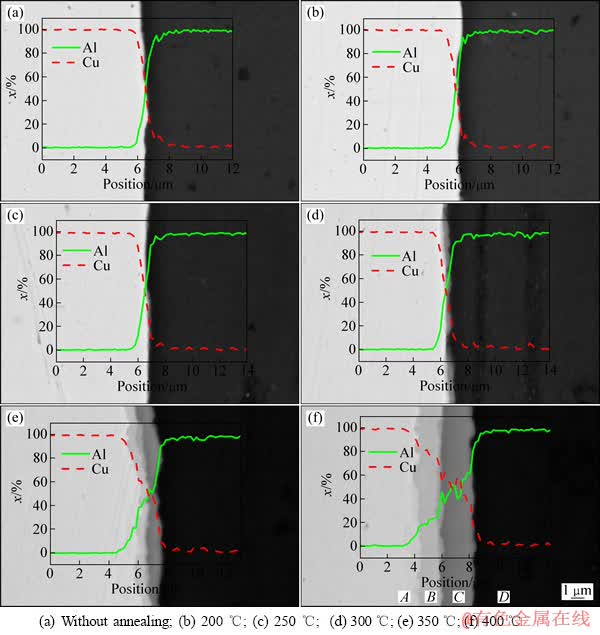

图8 退火温度对铜包铝复合扁排界面结构的影响

Fig. 8 Effect of annealing temperature on interfacial structure of CCA flat bar

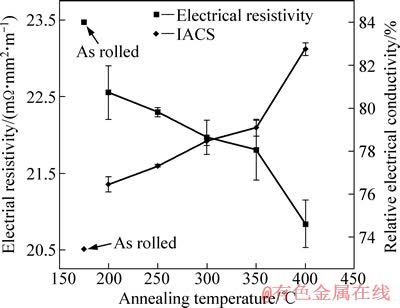

表3 图8(f)中界面层EDS成分分析结果

Table 3 EDS composition analysis results of interface layer in Fig. 8(f)

由图3和5可知,虽然铜包覆层和芯部铝在300 ℃均已开始再结晶,但再结晶组织的比例很小,对抗拉强度和伸长率的影响较小。因此,在300 ℃以上退火时,随着再结晶组织的比例逐渐增大,铜包铝复合扁排的抗拉强度降低,伸长率升高。当退火温度达到400 ℃时,铜包覆层和芯部铝发生完全再结晶,铜包铝复合扁排的抗拉强度显著降低,伸长率显著提高。

2.3 退火温度对界面结构的影响

退火温度对界面结构的影响如图8所示。由图8(b)和(c)可以看出,在200~250 ℃温度范围内退火1 h,铜/铝界面处没有明显的界面相生成,两种金属之间成分过渡区较窄。当退火温度为300 ℃时,界面处可观察到新的界面组织,但并没有形成连续的层状分布,界面层厚度约1 μm,如图8(d)所示;当退火温度达到350 ℃时,两层界面相已形成连续的层状分布,在成分曲线上有明显的平台,说明有新相生成[17],界面层厚度达到2 μm;退火温度为400 ℃时,界面相厚度增大,厚度达到4 μm,通过如表3所列的EDS分析,并结合Cu-Al相图[18]和相关研究[14, 19],可判断两层新相分别为Cu9Al4和CuAl2相。

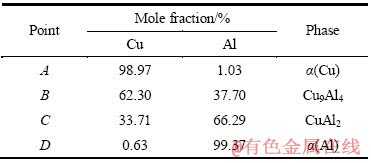

2.4 退火温度对界面结合强度的影响

在200~400 ℃退火1 h后,界面结合强度的变化如图9所示。冷轧态铜包铝复合扁排具有较高的界面剪切强度,达到49.3 MPa。这是因为铜包铝复合扁排轧制坯料采用水平连铸直接复合成形,坯料的界面清洁无污染,达到冶金结合,在轧制成形过程中,由于较大的压下率(73.3%),铜/铝两种金属间产生大量的新鲜金属结合有利于界面结合强度的提高。由图9可知,界面结合强度随着退火温度的升高先增大后减小,在250 ℃退火1 h时,界面结合强度达到最大,为62.8 MPa;当退火温度高于300 ℃时,随着退火温度的升高,界面结合强度开始降低;当退火温度为400 ℃时,平均界面结合强度降低至25.8 MPa。

界面结合强度的变化规律与界面化合物层的变化规律相对应。CHEN等[8]和PENG等[9, 20]研究表明,常规工艺复合铜/铝界面氧化物等污染、元素扩散和金属间化合物相的生成是影响界面结合强度的3个主要因素。如前所述,由于轧制铜包铝复合扁排的坯料采用水平连铸直接复合成形,界面无污染,达到了冶金结合,界面结合强度仅受元素扩散和界面金属间化合物相的影响。在250 ℃及以下温度退火时,由于界面处没有金属间化合物相生成,铜/铝之间仅发生扩散,界面处组织以固溶体为主,这有利于提高界面结合强度。在200~250 ℃退火时,元素扩散为界面结合强度的主要影响因素。当退火温度升高到300 ℃时,由于扩散过程加剧,金属间化合物相生长的热力学和动力学条件得以满足,在界面处开始生成金属间化合物相。在300 ℃及以上退火1 h后,金属间化合物相在界面处形成且厚度逐渐增加,由于金属间化合物具有硬脆性[21],受力过程中容易在金属间化合物层发生应力集中现象而产生裂纹[22-23],使得界面结合强度显著降低。即在300~400 ℃退火时,界面金属间化合物相的生成和长大是界面结合强度的主要影响因素。

另外,与尺寸较小的复合丝材不同[10],相对基体金属来说厚度较薄的脆性界面金属间化合物层对铜包铝复合扁排的纵向力学性能影响很小。

图9 退火温度对铜包铝复合扁排界面结合强度(剪切强度)的影响

Fig. 9 Effect of annealing temperature on interfacial shear bonding strength of CCA flat bar

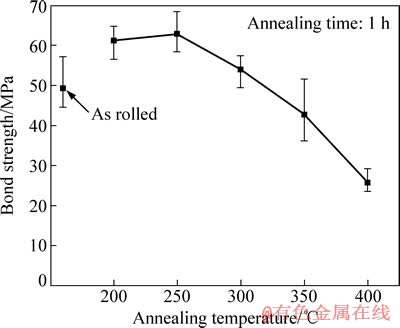

2.5 退火温度对电学性能的影响

在200~400 ℃下对铜包铝复合扁排进行退火,扁排电阻率(沿长度方向测量的电阻率标记为纵向电阻率)和相对导电率的变化如图10所示。由图10可知,未退火的铜包铝复合扁排电阻率为23.48 mΩ·mm2/m。随着退火温度的升高,纵向电阻率单调减小,在400℃退火时电阻率为20.84 mΩ·mm2/m。

对于单一材料,在化学成分和测试温度相同的条件下,影响材料电阻率的主要因素是晶体内的夹杂和晶格缺陷(包括空位、位错和晶界等)[24-25],对于复合材料,还应考虑界面结构的影响[11, 21, 26]。在300 ℃以下退火时,由于回复作用,基体金属晶粒内部的空位和位错减少,使得电阻率降低、导电率升高。在300 ℃以上温度退火时,基体金属开始再结晶,虽然再结晶使得晶界增多不利于电阻率的降低,但再结晶晶粒内的位错密度大大降低,因此,在开始再结晶后,扁排的电阻率仍然呈下降趋势。结合图8可知,铜包铝复合扁排在300 ℃退火时开始在界面处生成金属间化合物相,并在400 ℃达到4 μm厚的连续层状分布,但由图10可以看出,界面金属间化合物层对电阻率的升高的影响不大,电阻率仍然呈降低趋势,这与ABBASI等[6]、LEE等[11]和BRAUNOVIC等[12]的研究结果不一致。这可能是因为几种主要的Cu/Al金属间化合物的电阻率为纯铝的3~6倍[21, 27],在ABBASI等[6]的研究中,电流方向与界面法向一致,纯铜和纯铝以及金属间化合物层构成了一个串联电路,金属间化合物层增强了整个电路的电阻,而在本研究的条件下,电流的方向平行于铜包铝复合扁排的界面方向,降低了界面层对电流传输的阻碍作用。

综上所述,铜包铝扁排的电阻率主要受基体金属组织状态的影响,随着再结晶组织比例的增大,电阻率逐渐降低。从350 ℃升高到400 ℃时,基体金属的组织由不完全再结晶组织转变为完全再结晶组织,因此在该温度区间的电阻率变化较显著。在本文实验条件范围内,界面处金属间化合物层的厚度不大于4 μm的条件下,金属间化合物层对扁排纵向电阻率无明显影响。

图10 退火温度对铜包铝复合扁排纵向电阻率与相对导电率的影响

Fig. 10 Effect of annealing temperature on longitudinal electrical resistivity and relative electrical conductivity of CCA flat bar

3 结论

1) 铜包覆层在250 ℃及以下温度退火时,仅发生回复现象,在300 ℃时,开始再结晶;400 ℃时,再结晶完成。铝芯靠近铜层的剧烈变形区在200 ℃退火即完成再结晶,而中心部位粗晶区在250 ℃开始再结晶,在400 ℃再结晶完成。

2) 在300 ℃以下退火时,随着退火温度的升高,铜包铝复合扁排的抗拉强度降低和伸长率升高的趋势均不明显,但在300 ℃以上时,变化显著。未退火复合扁排的抗拉强度和伸长率分别为211.1 MPa和3.8%;400 ℃退火后,抗拉强度降低至128.4 MPa,伸长率升高至22.5%。

3) 在250 ℃以下退火,界面处无明显金属间化合物相生成,界面结合强度随着温度的升高而升高,250 ℃退火1 h的界面结合强度达到62.8 MPa;高于300 ℃退火,界面处开始生成金属间化合物相,界面结合强度明显降低,400 ℃退火1 h,界面层厚度达到4 μm,界面结合强度降低为25.8 MPa。

4) 随着退火温度的升高,铜包铝复合扁排的纵向电阻率由加工态的23.48 mΩ·mm2/m逐渐降低为400 ℃退火后的20.84 mΩ·mm2/m,这主要是受基体金属的组织状态的影响,而在界面层的厚度不大于4 μm的条件下,界面层对电阻率无明显影响。

REFERENCES

[1] 罗奕兵, 刘新华, 谢建新. 矩形截面铜包铝导电排的导电性能及断面形状结构的影响[J]. 北京科技大学学报, 2009, 30(10): 1292-1297.

LUO Yi-bing, LIU Xin-hua, XIE Jian-xin. Effects of sectional form and configuration on the conductivity of copper cladding aluminum bars with a rectangle section[J]. Journal of University of Science and Technology Beijing, 2009, 30(10): 1292-1297.

[2] 谢建新, 刘新华, 刘雪峰, 罗奕兵. 一种高性能铜包铝矩形横断面复合导电母排及其制备工艺: 中国, ZL200810057668.4[P]. 2008-02-04.

XIE Jian-xin, LIU Xin-hua, LIU Xue-feng, LUO Yi-bing. A high performance rectangle cross section copper cladding aluminum composite electric busbar and manufacturing process: China, ZL200810057668.4[P]. 2008-02-04.

[3] 罗奕兵, 刘新华, 谢建新. 铜包铝复合棒材平辊轧制宽展变形行为[J]. 中国有色金属学报, 2009, 19(11): 1976-1981.

LUO Yi-bing, LIU Xin-hua, XIE Jian-xin. Lateral spreading deformation behavior in flat rolling of copper cladding aluminum composite rods[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1976-1981.

[4] CHEN S D, KE F J, ZHOU M, BAI Y L. Atomistic investigation of the effects of temperature and surface roughness on diffusion bonding between Cu and Al[J]. Acta Materialia, 2007, 55(9): 3169-3175.

[5] CHEN C Y, HWANG W S. Effect of annealing on the interfacial structure of aluminum-copper joints[J]. Materials Transactions, 2007, 48(7): 1938-1947.

[6] ABBASI M, KARIMI TAHERI A, SALEHI M T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process[J]. Journal of Alloys and Compounds, 2001, 319(1/2): 233-241.

[7] 王秋娜, 刘新华, 刘雪峰, 谢建新. 退火温度对冷静液挤压铜包铝线材组织和力学性能的影响[J]. 金属学报, 2008, 44(6): 675-680.

WANG Qiu-na, LIU Xin-hua, LIU Xue-feng, XIE Jian-xin. Effect of annealing temperature on the microstructures and properties of copper cladding aluminum wire prepared by cold hydrostatic extrusion[J]. Acta Metallurgica Sinica, 2008, 44(6): 675-680.

[8] CHEN C Y, CHEN H L, HWANG W S. Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate[J]. Materials Transactions, 2006, 47(4): 1232-1239.

[9] PENG X K, WUHRER R, HENESS G, YEUNG W Y. On the interface development and fracture behaviour of roll bonded copper/aluminium metal laminates[J]. Journal of Materials Science, 1999, 34(9): 2029-2038.

[10] 王秋娜, 刘新华, 刘雪峰, 谢建新. 冷拉拔铜包铝细丝的退火工艺与组织性能研究[J]. 材料工程, 2008(7): 30-35.

WANG Qiu-na, LIU Xin-hua, LIU Xue-feng, XIE Jian-xin. Study on annealing process and microstructure and properties of cold drawing copper cladding aluminum thin wires[J]. Journal of Materials Engineering, 2008(7): 30-35.

[11] LEE W B, BANG K S, JUNG S B. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing[J]. Journal of Alloys and Compounds, 2005, 390(1/2): 212-219.

[12] BRAUNOVIC M, ALEXANDROV N. Intermetallic compounds at aluminum - to - copper electrical interfaces: Effect of temperature and electric current[J]. IEEE Transactions on Components, Packaging, and Manufacturing Technology - Part A, 1994, 17(1): 78-85.

[13] 谢建新, 刘新华, 刘雪峰, 苏亚军. 一种包复材料水平连铸直接复合成形设备与工艺: 中国, 200610112817. 3[P]. 2008-04-02.

XIE Jian-xin, LIU Xin-hua, LIU Xue-feng, SU Ya-jun. Horizontal continuous direct composite cast forming equipment and technology of a cladding materials: China, ZL200610112817.3[P]. 2008-04-02.

[14] SU Y J, LIU X H, HUANG H Y, LIU X F, XIE J X. Interfacial microstructure and bonding strength of copper cladding aluminum rods fabricated by horizontal core-filling continuous casting[J]. Metallurgical and Materials Transactions A, 2011, 42(13): 4088-4099.

[15] 吴永福, 刘新华, 谢建新, 王连忠, 董晓文. 矩形断面铜包铝复合材料的水平连铸直接复合成形[J]. 中国有色金属学报, 2012, 22(9): 2500-2507.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin, WANG Lian-zhong, DONG Xiao-wen. Copper cladding aluminum composite materials with rectangle section fabricated by horizontal core-filling continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2500-2507.

[16] 吴永福, 刘新华, 谢建新. 矩形断面铜包铝连铸坯轧制成形导电扁排的工艺及性能[J]. 北京科技大学学报, 2012, 34(11): 1301-1307.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Rolling process and properties of copper cladding aluminum flat bars using continuous casting bars with the rectangle section[J]. Journal of University of Science and Technology Beijing, 2012, 34(11): 1301-1307.

[17] FUNAMIZU Y, WATANABE K. Interdiffusion in the Al-Cu system[J]. Transactions of the Japan Institute of Metals, 1971, 12(3): 147-152.

[18] MASSALSKI T. The Al-Cu (Aluminum-Copper) system[J]. Journal of Phase Equilibria, 1980, 1(1): 27-33.

[19] DROZDOV M, GUR G, ATZMON Z, KAPLAN W. Detailed investigation of ultrasonic Al-Cu wire-bonds: II. Microstructural evolution during annealing[J]. Journal of Materials Science, 2008, 43(18): 6038-6048.

[20] PENG X K, WUHRER R, HENESS G, YEUNG W Y. Rolling strain effects on the interlaminar properties of roll bonded copper/aluminium metal laminates[J]. Journal of Materials Science, 2000, 35(17): 4357-4363.

[21] RABKIN D M, RYABOV V R, LOZOVSKAYA A V, DOVZHENKO V A. Preparation and properties of copper-aluminum intermetallic compounds[J]. Powder Metallurgy and Metal Ceramics, 1970, 9(8): 695-700.

[22] LEE H T, CHEN M H, JAO H M, LIAO T L. Influence of interfacial intermetallic compound on fracture behavior of solder joints[J]. Materials Science and Engineering A, 2003, 358(1/2): 134-141.

[23] GUO Y J, QIAO G J, JIAN W Z, ZHI X H. Microstructure and tensile behavior of Cu-Al multi-layered composites prepared by plasma activated sintering[J]. Materials Science and Engineering A, 2010, 527(20): 5234-5240.

[24]  . Electrical resistivity of cyclically deformed copper[J]. Czechoslovak Journal of Physics, 1969, 19(3): 315-322.

. Electrical resistivity of cyclically deformed copper[J]. Czechoslovak Journal of Physics, 1969, 19(3): 315-322.

[25] HARRISON W A. Resistivity due to dislocations in copper[J]. Journal of Physics and Chemistry of Solids, 1958, 5(1/2): 44-46.

[26] MANESH H D. Assessment of surface bonding strength in Al clad steel strip using electrical resistivity and peeling tests[J]. Materials Science and Technology, 2006, 22(6): 634-640.

[27] RAYNE J A, SHEARER M P, BAUER C L. Investigation of interfacial reactions in thin film couples of aluminum and copper by measurement of low temperature contact resistance[J]. Thin Solid Films, 1980, 65(3): 381-391.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2009AA03Z532)

收稿日期:2012-09-28;修订日期:2013-05-30

通信作者:谢建新,教授,博士;电话:010-62332254;E-mail:jxxie@mater.ustb.edu.cn