DOI:10.19476/j.ysxb.1004.0609.2018.08.17

尾矿膏体屈服应力演化规律

张连富1, 2,吴爱祥1, 2,王洪江1, 2,程海勇1, 2,王贻明1, 2

(1. 北京科技大学 土木与资源工程学院,北京 100083;

2. 金属矿山高效开采与安全教育部重点实验室,北京 100083)

摘 要:以谦比希铜矿的尾砂作为试验样品,对质量分数为64%~73%的尾砂浆体进行流变试验,研究其流变特性,预测该矿膏体的临界浓度。传统测量方法认为流动性指数为1时的料浆浓度即为临界浓度,试验发现,该方案得到的数值较为保守。研究料浆浓度与其屈服应力之间的关系,发现两者呈显著的DoseResp函数关系,为精确预测料浆特性提供有效方法。得到屈服应力随料浆浓度变化的演化规律,基于屈服应力增长速率,演化分为两个阶段:单调递增阶段和单调递减阶段。屈服应力在浓度变化范围内具有极大值和极小值,可以通过DoseResp函数精确预测,而屈服应力变化速率的“极大值点”即为“临界浓度”。因此,确定谦比希铜矿膏体临界浓度为70.73%,与试验结果吻合。

关键词:尾砂;流变学;临界浓度;屈服应力;演化规律

文章编号:1004-0609(2018)-08-1631-06 中图分类号:TD853.34 文献标志码:A

浅部资源的逐渐枯竭迫使我国矿山不断增加对深部资源的开发力度,充填采矿作为地下开采的有效手段,得到了越来越多的重视。由于浆体浓度的差异,充填可以分为低浓度、高浓度、膏体充填3种。浓度是决定料浆性能的重要因素,制成高浓度的料浆甚至膏体,不仅仅能够节约用水,也能够减少充填体养护中的排水,对膏体性能的好坏有显著影响[1-2]。目前在高浓度浆体和膏体的界定上,学者们并未能取得成熟的结论,制约了膏体技术的应用与推广。

国内外学者在界定不同浓度充填方式的理论研究上开展了大量工作。陈广文等[3]认为高浓度输送中浆体细颗粒浓度不应小于6.7%(质量分数),并据此建立了输送浆体的浓度判据;BOGER[4]在试验过程中发现了管道中浆体的层流和紊流之间的转变现象,印证了浆体临界浓度的存在;刘同有[5]在概念上对高、低浓度料浆进行了划分,认为“临界流态浓度”是存在的。高浓度和低浓度浆体的界限划定得到了充分研究,相关理论和经验比较丰富,但膏体作为浆体研究的新领域,与高浓度浆体之间的区分并不清晰,相关研究亟待补充。翟永刚等[6]、刘超等[7]研究了膏体不同剪切速率下的剪切特性,基于膏体服从宾汉塑性体特性的观点,提出了依据流动性指数计算临界浓度的方法。而在该理论下,浆体浓度能且只能为临界浓度时才能制成膏体,这与实际经验不符合,而且不利于指导生产。

本文作者从传统的H-B模型出发,首先分析基于流动性能指数确定膏体临界浓度的合理性;在试验结果的基础上,分析料浆浓度和屈服应力的关系曲线,得出两者之间的拟合函数模型,并基于研究结果提出新的尾矿膏体临界浓度的检测方法。将研究结果应用在工程实践中,可以为膏体充填的实施提供指导和借鉴,有利于膏体技术的应用与推广。

1 实验

1.1 实验材料及仪器

选取谦比希铜矿提供的尾矿浆作为试验材料,为了尽可能多地研究不同浓度下的浆体流变特性,将料浆浓度从64%到73%(质量分数)共分成10个梯度进行试验。使用Brookfield R/S+型流变仪检测浆体的流变特性,如图1所示。该仪器广泛用于悬浮体和刚性膏体流变特性的测量,由于精确度较高,得到国外研究者的青睐。该型流变仪相较于过去的毛细管黏度计,其十字型转子设计对样品破坏程度低,低转速状态下也能测量浆体的屈服应力,精确性较高[8-9]。

图1 Brookfield R/S+型流变仪

Fig. 1 Brookfield R/S+ rheometer

1.2 试验方案

1.2.1 试验原理

很多研究表明,当尾砂浆体的浓度发生变化时,描述其流变特性的流变模型也可能不同。尾矿砂浆随着浓度的升高依次表现为牛顿体、屈服伪塑性体和宾汉塑性体。甘阳等[10]提出浆体达到饱和状态的宾汉体时,相应浆体浓度就是膏体的临界浓度。所以,研究浆体的流变特性是计算膏体临界浓度的主要思路,目前使用的计算方法多在此基础上发展而来。

在描述膏体流变的模型中,Herschel-Bulkley模型具有3个参数,与两参数模型包括Bingham模型、Casson模型等相比精度更高,得到更广泛的应用。其通式如下:

(1)

(1)

式中: 为剪切应力,Pa;

为剪切应力,Pa; 为屈服应力,Pa;

为屈服应力,Pa; 为刚度系数/黏度系数,Pa·s;

为刚度系数/黏度系数,Pa·s; 为剪切速率,s-1;n为流态性能指数。

为剪切速率,s-1;n为流态性能指数。

其中, ,

, 为所测得的表观黏度,Pa·s。当n<1时为屈服伪塑性体;n=1时为宾汉塑性体;n>1时为屈服膨胀体[6]。

为所测得的表观黏度,Pa·s。当n<1时为屈服伪塑性体;n=1时为宾汉塑性体;n>1时为屈服膨胀体[6]。

1.2.2 试验过程

1) 在200 mL烧杯中配置料浆,每种浓度下配制料浆的质量均为300 g,搅拌约5 min。

2) 将烧杯放置于流变仪下,料浆浸没搅拌转子(十字形转子V40_20_3tol),记录料浆的各项流变参数:试验中剪切应力以固定速度加载到300 Pa,转子转动时,该时刻的剪切应力记作静态屈服应力;测定浆体在不同剪切速率下(0~100 s-1)的表观黏度和剪切应力。

2 结果与分析

2.1 基于H-B模型确定膏体临界浓度

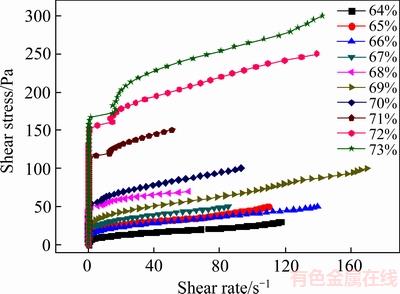

试验测得的浆体在不同浓度下剪切速率与剪切力的关系曲线如图2所示。

图2 不同浓度下浆体剪切速率和剪切力的关系曲线

Fig. 2 Relationship between shear rate and shear stress of slurry in various concentration

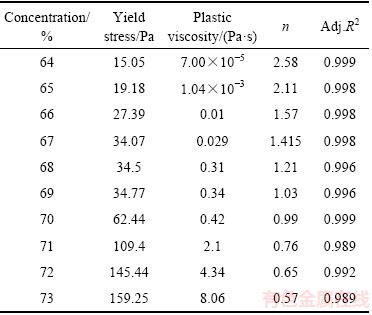

基于H-B模型,根据流变仪得到的屈服应力、黏度等参数,回归出不同浓度下浆体对应的流动性能指数,相关结果见表1。表1中Adj.R2为调整确定系数,用来说明方程的拟合优劣。

表1 料浆流变参数及回归

Table 1 Rheological parameters and its regression results of slurry

根据表1数据,得到不同浓度下膏体的屈服应力变化曲线,见图3。由图3可知,料浆的屈服应力存在一个急剧增长的过程,浓度低于69%时,屈服应力增长缓慢,而浓度增加到71%时,料浆屈服应力已经整整提高了两倍,达到109.4Pa。而后,浓度继续升高,屈服应力有增速放缓的趋势。国外有学者认为只有屈服应力达到200(±25) Pa才叫做膏体[12-13],故需要一个准确的拟合模型对屈服应力的变化进行描述,便于确定料浆屈服应力是否能达到“膏体标准”。屈服应力过大时,膏体将流动困难,只能依靠泵送。如果膏体能够泌出少量的水,对其管道运输来说起到了润滑作用,这更利于膏体技术的推广应用,而这一观念得到越来越多的认同。所以,膏体的屈服应力值应适当调低,以利于管道输送的进行。

图3 屈服应力与料浆浓度关系

Fig. 3 Relationship between yield stress and slurry concentration

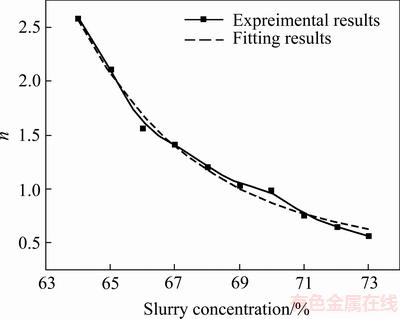

绘制n值与浓度关系图如图4所示。由图4可知,浆体浓度增长的情况下,n值呈现指数下降的趋势。用Origin 2015软件对浓度-流动指数曲线进行拟合,函数为 ,拟合结果:a= 0.42127,b=3.64856×107,c=-3.84401,其中Adj.R2=0.99002。由该方程得出当y=1时,x取值为69.11。可知,利用流动性能指数预测的该矿全尾砂临界浓度为69.1%。由图3可知,该浓度条件下料浆屈服应力较低,能够满足管道输送的要求。这一结果是在假设该矿提供的尾砂制成的料浆符合宾汉塑性体特征成立的基础上得到,意味着只有达到临界浓度的料浆才是膏体,而浓度超过或低于临界浓度时都不能称作膏体。这与国内外学者认可的屈服应力在一定范围内的料浆即为膏体的概念不一致,未对膏体浓度的范围进行必要的划定,应用起来比较困难。

,拟合结果:a= 0.42127,b=3.64856×107,c=-3.84401,其中Adj.R2=0.99002。由该方程得出当y=1时,x取值为69.11。可知,利用流动性能指数预测的该矿全尾砂临界浓度为69.1%。由图3可知,该浓度条件下料浆屈服应力较低,能够满足管道输送的要求。这一结果是在假设该矿提供的尾砂制成的料浆符合宾汉塑性体特征成立的基础上得到,意味着只有达到临界浓度的料浆才是膏体,而浓度超过或低于临界浓度时都不能称作膏体。这与国内外学者认可的屈服应力在一定范围内的料浆即为膏体的概念不一致,未对膏体浓度的范围进行必要的划定,应用起来比较困难。

图4 料浆浓度与n值关系曲线

Fig. 4 Relationship between slurry concentration and value n

2.2 料浆浓度对屈服应力的影响

用流动指数预测临界浓度的方法有其局限性,许多学者在分别计算临界浓度的过程中,发现浆体浓度与n值之间的关系曲线类型不固定,拟合求解比较麻烦。料浆浓度在64%~73%之间变化时,屈服应力在69%之前一直保持在低水平,然后在70%附近快速升高,这意味着前后两个不同时期间存在“突变”发生的结点,即所求的“临界浓度”。分析后发现,虽然前后两个时期屈服应力增长快慢有所差异,但在“临界浓度”附近仍是连续的,如果能够求得这一浓度变化范围内料浆浓度与屈服应力的拟合函数,则能为通过该拟合函数预测临界浓度创造条件。

根据曲线的形状,选取4种函数模型,应用Origin 2015分别进行非线性拟合,相关拟合结果见表2,3种拟合图像见图5。

表2 拟合结果比较表

Table 2 Comparison between fitting results

图5 料浆浓度与屈服应力关系的拟合结果

Fig. 5 Fitting curves of relationship between slurry concentration and yield stress

从表2可以看出,4种拟合函数中Ploy4、DoseResp和Logistic能够较好地拟合试验得到的数据,且DoseResp函数的调整相关系数在四者中最大,说明DoseResp函数是拟合函数的最佳选择。另一方面,Ploy4函数虽然在64%~73%之间对数据拟合度良好,但当料浆浓度低于64%或者高于73%时出现“反常”变化,即低值范围内得到屈服应力为负值,高值范围内屈服应力急剧增加,与试验结果不符。而DoseResp函数和Logistic函数两者拟合结果较为接近,拟合曲线几乎重合,考虑到前者拟合度更高,故选取DoseResp函数作为最终的拟合函数类型。

由DoseResp函数特征可知,对于函数而言,y=27.36是其函数值下限,y=164.03是其函数值上限,而在点A(77.03,95.70)处,函数斜率最大,且斜率值为y(1)=0.63×ln(10)×(164.03-27.36)=198.65(见图6)。该点处的料浆浓度无论升高或者降低,都会对屈服应力产生显著影响,刘超等[7]认为料浆屈服应力开始快速增加时的浓度为临界浓度,却没有考虑在浓度的全部取值范围内屈服应力的变化范围,取值较为保守。例如,谦比希铜矿尾砂制成的料浆由DoseResp函数预测得知其最大屈服应力为164.03 Pa,如果认为临界浓度点在35 Pa附近,将远低于屈服应力中值点A的。

从料浆浓度对屈服应力影响的角度出发,A点对应的浓度即为临界浓度。以A点为分界点,低于A点浓度的区域为第一阶段,屈服应力增长速率不断增加,并在A点附近达到峰值;高于A点浓度的区域为第二阶段,屈服应力增长速率不断减小,并无限趋近于0。从该函数可以得出,膏体的临界浓度为70.73%,与H-B模型求得的临界浓度相比较高了1.63%,误差范围在2.3%左右。由函数曲线可知,通过DoseResp函数得到的临界浓度为膏体充填设计提供了更加直观的参考,膏体浓度在实际应用中应在小于临界浓度的一定范围内,因为该范围内屈服应力较小,管道输送较容易,符合实际生产需求。

从图6可知,当料浆浓度偏小或偏大时,屈服应力分别趋近于极小值37.36和极大值164.03。料浆在浓度达到饱和状态时屈服应力增长放缓,并趋近于某值是符合经验的,因为水分过少时,固体成分含量对屈服应力的影响将不再是关键因素,此时屈服应力主要由固体成分间的摩擦导致,但前提是固体成分在干燥情况下不发生板结。料浆浓度较低时,由该式可知,屈服应力趋近于一个极小值,这可能是因为低浓度时固体成分的间距较大,相互作用较弱,对屈服应力增长的作用有限。由上述结果分析,如果膏体定义为屈服应力在200(±25) Pa的料浆[13-14],那么该矿提供的尾矿将不能直接用于制作膏体,因为其屈服应力的上限是164.03 Pa,远低于膏体定义的屈服应力范围。因此需要对膏体形成的机理作更进一步的研究。

在获得临界浓度计算方法的同时,得到了尾矿膏体屈服应力的演化规律。料浆的屈服应力变化的范围是确定且可预测的,在试验数据有限的情况下,求解出相应尾矿料浆的屈服应力演化函数,即可以预测料浆的一些流变性能,应用价值比较高。结合其他学者的相关研究成果,将更加全面直观地描述浓度对料浆屈服应力的影响机理,有利于膏体充填的发展与推广。

图6 料浆浓度与屈服应力关系曲线的特征

Fig. 6 Characteristics of relationship curve between slurry concentration and yield stress

2.3 工程应用

谦比希铜矿位于赞比亚境内,为了减少对当地宝贵水资源的使用,保障地下开采的安全性,决定采用膏体充填采矿法[15]。首先利用深锥浓密机将尾矿制成膏体,再利用充填泵输送到井下采场。为了研究该矿尾砂制成的膏体浓度范围,从孔隙率、流变学两个角度进行了确定。由密实和松散孔隙率计算得到的膏体浓度期望值为67.84%,而根据流动性能指数确定的膏体临界浓度回归值为69.1%。

利用DoseResp函数拟合结果,确定膏体临界浓度为70.73%。与前两种方法所得结果相比较,DoseResp函数拟合的结果更大,但选取的出发点不同,后者更多的参考了料浆浓度对屈服应力的影响。综上所述可知,3个角度确定的脱水浓度最大值为70.73%,实际脱水浓度应为70%。因此,建议谦比希尾矿膏体浓度范围为67%~70%。

3 结论

1) 利用Herschel-Bulkley模型计算出不同浓度下的料浆流动性指数,并利用流动性指数拟合出膏体的临界浓度为69.1%。该值是基于膏体符合宾汉塑性体特征这一观点选取,且认为达到临界浓度的料浆是膏体,与生产实际不相符。

2) Ploy4、DoseResp和Logistic和Slogistic1 4种函数中,DoseResp函数能够最好地拟合料浆浓度和屈服应力之间的函数关系,且调整相关系数为0.99085,拟合度高。料浆浓度和屈服应力之间的函数关系式为 ,该式说明料浆屈服应力是可以预测的。

,该式说明料浆屈服应力是可以预测的。

3) 发现了膏体料浆屈服应力演化规律,浓度对屈服应力的作用可以分为2个阶段:第一阶段,随着浓度升高,屈服应力增长速率不断升高,并在临界浓度处达到峰值;第二阶段中,随着浓度升高,屈服应力增长速率不断降低。此外,料浆屈服应力在全部浓度变化范围内存在极大值和极小值,屈服应力变化速率的“极大值点”即为“临界浓度”。

4) 根据DoseResp函数计算出的临界浓度为70.73%,与流动性指数确定的69.1%的流动性指数相比大了1.63%,误差约为2.3%。分析可知, DoseResp函数拟合得到的临界浓度比实际值略大,流动性指数得到临界浓度比实际值略小。

REFERENCES

[1] DOUCET J, PARADIS R. Thickening/mud stacking technology- an environmental approach to residue management[C]// Proceedings of the 13th International Seminar on Paste and Thickened Tailings. Perth: Australian Centre For Geomechanics, 2010: 3-21.

[2] REID C, BECAERT V, AUBERTIN M, ROSENBAUM R K, DESCHENES L. Life cycle assessment of mine tailings management in Canada[J]. Journal of Cleaner Production, 2009, 17(4): 471-479.

[3] 陈广文, 古德生, 高 泉. 高浓度浆体的浓度判据及其层流输送特性[J]. 中国有色金属学报, 1995, 5(4): 35-39.

CHEN Guang-wen, GU De-sheng, GAO Quan. The concentration of high concentration slurry transport properties of laminar flow criterion[J]. The Chinese Journal of Nonferrous Metals, 1995, 5(4): 35-39.

[4] BOGER D V. Rheology and minerals industry[J]. Mineral Processing and Extractive Metallurgy Review, 2000, 20(1): 1-25.

[5] 刘同有. 充填采矿技术与应用[M]. 北京: 冶金工业出版社, 2001.

LIU Tong-you. Technology and application of filling mining[M]. Beijing: Metallurgical Industry Press, 2001.

[6] 翟永刚, 吴爱祥, 王洪江, 陈琴瑞, 肖云涛, 寿震宇. 全尾砂膏体充填临界质量分数[J]. 北京科技大学学报, 2011, 33(7): 795-799.

ZHAI Yong-gang, WU Ai-xiang, WANG Hong-jiang, CHEN Qin-rui, XIAO Yun-tao, SHOU Zhen-yu. Threshold mass fraction unclassified-tailings paste for backfill mining[J]. Journal of University of Science and Technology Beijing, 2011, 33(7): 795-799.

[7] 刘超, 王洪江, 吴爱祥, 王 勇. 铜钼矿细粒全尾膏体浓度范围确定[J]. 岩石力学与工程学报, 2015(S1): 3432-3438.

LIU Chao, WANG Hong-jiang, WU Ai-xiang, WANG Yong. Determination of concentration range of fine unclassified tailings paste in copper-molybdenum mine[J]. Chinese Journal of Rock Mechanics and Engineering, 2015(S1): 3432-3438.

[8] NGUYEN Q D, AKROYD T, de KEE D C, ZHU L. Yield stress measurements in suspensions: An inter-laboratory study[J]. Korea-Australia Rheology Journal, 2006, 18(1): 15-24.

[9] BARNES H A, NGUYEN Q D. Rotating vane rheometry: A review[J]. Journal of Non-Newtonian Fluid Mechanics, 2001, 98(1): 1-14.

[10] 甘 阳, GEORGE V F. 颗粒间作用力影响颗粒体系流变性能的研究进展[J]. 科学通报, 2009, 54(1): 1.

GAN Yang, GEORGE V F. Progress in effect of the interaction between particles on the particle rheological propertises[J]. Chinese Science Bulletin, 2009, 54(1): 1.

[11] FALL M, CELESTIN J, HAN F S. Potential use of densified polymer-pastefill mixture as waste containment barrier materials[J]. Waste Management, 2010, 30(12): 2570-2578.

[12] JEWELL R J, FOURIE A B, LORD E R. Paste and thicekened tailings: A guide[M]. Perth: Australian Centre for Geomechanics, 2006.

[13] 王 勇, 吴爱祥, 王洪江, 杨锡祥, 周发陆, 周 勃. 从屈服应力角度完善膏体定义[J]. 北京科技大学学报, 2014, 36(7): 855-860.

WANG Yong, WU Ai-xiang, WANG Hong-jiang, YANG Xi-xiang, ZHOU Fa-lu, ZHOU Bo. Further development of paste definition from the viewpoint of yield stress[J]. Journal of University of Science and Technology Beijing, 2014, 36(7): 855-860.

[14] 王洪江, 王 勇, 吴爱祥, 翟永刚, 焦华喆. 从饱和率和泌水率角度探讨膏体新定义[J]. 武汉理工大学学报, 2011, 33(6): 85-89.

WANG Hong-jiang, WANG Yong, WU Ai-xiang, ZHAI Yong-gang, JIAO Hua-zhe. Research of paste new definition from the view point of saturation ratio and bleeding rate[J]. Journal of Wuhan University of Technology, 2011, 33(6): 85-89.

[15] 胡文达, 焦华喆, 王贻明, 吴爱祥, 张晋军, 施发伍. 基于H-B指数的谦比希铜矿全尾砂浆临界浓度确定[J]. 现代矿业, 2013(5): 17-19.

HU Wen-da, JIAO Hua-zhe, WANG Yi-ming, WU Ai-xiang, ZHANG Jin-jun, SHI Fa-wu. Confirmation of critical concentration of full tailings slurry of the chambishi copper mine which based on H-B index[J]. Modern Mining, 2013(5): 17-19.

Evolution law of yield stress in paste tailings

ZHANG Lian-fu1, 2, WU Ai-xiang1, 2, WANG Hong-jiang1, 2, CHENG Hai-yong1, 2, WANG Yi-ming1, 2

(1. School of Civil and Resources Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education, Beijing 100083, China)

Abstract: The rheological experiments on slurries with mass fraction of 64% to 73% were implemented using tailings from Chambishi Copper Mine to study the rheology and determine critical concentration of paste tailings. Previous studies thought the critical concentration was determined when value n is 1. However, recent experiments show that method underestimates critical concentration of paste tailings. The relationship between slurry concentration and yield stress through investigation, which accurately predicts slurry characteristics, is found with function DoseResp fitting. The evolution law of yield stress in paste tailings consists of two stages. The growth rate of yield stress increases in former stage but decreases in the later. Besides, maximum and minimum yield stress exist. The critical concentration is confirmed as maximum growth rate of yield stress emerges. Hence, the critical concentration of paste tailings from Chambishi Copper Mine is 70.73%, which coincides with experiment results.

Key words: tailings; rheology; critical concentration; yield stress; evolution law

Foundation item: Project(2017YFC0602903) supported by the Key Research and Development Program of China; Project(51674012) supported by the National Natural Science Foundation of China

Received date: 2017-07-10; Accepted date: 2017-11-15

Corresponding author: WU Ai-xiang; Tel: +86-10-62334680; E-mail: wuaixiang@126.com

(编辑 王 超)

基金项目:国家“十三五”重点研发计划资助项目(2017YFC0602903);国家自然科学基金资助项目(51674012)

收稿日期:2017-07-10;修订日期:2017-11-15

通信作者:吴爱祥,教授,博士;电话:010-62334680;E-mail: wuaixiang@126.com