均匀化态Al-3.2Mg-0.4Er铝合金的热变形行为

来源期刊:中国有色金属学报(英文版)2016年第4期

论文作者:彭建 王永建 钟丽萍 彭龙飞 潘复生

文章页码:945 - 955

关键词:铝镁合金;热变形;本构方程;塑性加工图

Key words:Al-Mg alloy; hot deformation; constitutive model; processing map

摘 要:在573~723 K、0.001~1 s-1变形条件下研究均匀化态Al-3.2Mg-0.4Er铝合金的热变形行为。基于热压缩实验结果,构建综合考虑应变速率、变形温度和应变的唯象本构方程,同时建立再结晶动力学方程和塑性加工图。结果显示:所构建的本构模型能准确地预测Al-3.2Mg-0.4Er铝合金在热变形过程中的流变应力。再结晶组织的演变和再结晶体积分数可以由所建立的动力学方程以S曲线形式进行描述。此外,构建了合金在不同应变下的热塑性加工图,得到均匀化态Al-3.2Mg-0.4Er铝合金的较优加工条件为573 K、0.001 s-1及723 K、0.001~1 s-1.

Abstract: The hot deformation behavior of the homogenized Al-3.2Mg-0.4Er aluminum alloy was investigated at 573-723 K under strain rates of 0.001-1 s-1. On the basis of compression experimental results, an accurate phenomenological constitutive equation that coupled the effects of strain rate, deformation temperature and strain was modeled. Furthermore, a kinetic model of dynamic recrystallization and processing map were also presented. The results show that the flow stress of the studied Al-3.2Mg-0.4Er alloy can be predicted accurately using the proposed constitutive model. The evolution of microstructure and the volume fraction of dynamic recrystallization can be described exactly in terms of S-curves with the proposed kinetic model. Moreover, the processing maps for hot working at different strains were constructed, suggesting the optimum processing conditions for this alloy are 573 K, 0.001 s-1 and 723 K, 0.001-0.1 s-1.

Trans. Nonferrous Met. Soc. China 26(2016) 945-955

Jian PENG1,2, Yong-jian WANG1, Li-ping ZHONG1, Long-fei PENG1, Fu-sheng PAN1,2

1. State Key Laboratory of Mechanical Transmission, College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Chongqing Academy of Science and Technology, Chongqing 401123, China

Received 26 May 2015; accepted 4 December 2015

Abstract: The hot deformation behavior of the homogenized Al-3.2Mg-0.4Er aluminum alloy was investigated at 573-723 K under strain rates of 0.001-1 s-1. On the basis of compression experimental results, an accurate phenomenological constitutive equation that coupled the effects of strain rate, deformation temperature and strain was modeled. Furthermore, a kinetic model of dynamic recrystallization and processing map were also presented. The results show that the flow stress of the studied Al-3.2Mg-0.4Er alloy can be predicted accurately using the proposed constitutive model. The evolution of microstructure and the volume fraction of dynamic recrystallization can be described exactly in terms of S-curves with the proposed kinetic model. Moreover, the processing maps for hot working at different strains were constructed, suggesting the optimum processing conditions for this alloy are 573 K, 0.001 s-1 and 723 K, 0.001-0.1 s-1.

Key words: Al-Mg alloy; hot deformation; constitutive model; processing map

1 Introduction

The Al-Mg series alloys are widely used in aerospace and vehicle industries owing to their good combined properties, such as medium strength, high ductility, excellent corrosion resistance, and welding ability [1]. Demand for alloys with further reduced mass and thickness, high efficiency, good mechanical properties and corrosion resistance, has recently increased. To meet these requirements, efforts have been expended to improve the workability and mechanical properties of these alloys. Recent studies have shown that adding small amount of Er could significantly improve the thermal stability, increase the strength, and refine the grain structure of Al-Mg alloys [2-4]. GAO et al [5] reported that the addition of 0.2% Er (mass fraction) can refine dendritic structure and change the morphology and size of Fe-phase of aluminum alloys. Moreover, the nanoscaled Al3Er phase formed during aging process can improve the strength and recrystallization resistance. WU et al [6] found that during hot deformation, the constituents with Er and Mg fracture first and act as the microcrack sources due to the stress concentration and then the solution treatment after thermomechanical process is a fundamental procedure to improve the mechanical properties of the Al-Mg alloys by the addition of Er element. Furthermore, Er can be added into the Al-based alloys as an attractant to improve the precipitation hardening response and the thermal stability, such as Al-Zr [7]. All of these beneficial effects of Er are attributed to the formation of nanoscaled Al3Er phase, which is L12 structure and coherent or semi-coherent with Al matrix. Given the rapid cooling rate during conventional DC casting, most of the Er atoms dissolve in the Al matrix, resulting in a supersaturated solid solution that decomposes via precipitation of dispersed particles during homogenization prior to hot rolling or extrusion [8].

The information on hot deformation parameters of homogenized Al-3.2Mg-0.4Er alloy is scarce, thereby limiting the applications of the Al-3.2Mg-0.4Er alloy. Therefore, this study aimed to characterize the high temperature deformation behavior of the homogenized Al-3.2Mg-0.4Er alloy through the hot compression experiment. Several modeling approaches, including flow stress-strain curves, phenomenological constitutive model, kinetic model of DRX and processing map, were used to characterize the deformation behavior of the homogenized Al-3.2Mg-0.4Er alloy.

2 Experimental

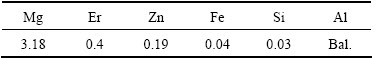

Cylindrical specimens (d8 mm × 12 mm) were machined from the Al-3.2Mg-0.4Er alloy ingot, and the chemical composition of the studied alloy is shown in Table 1. The alloy was then homogenized at 723 K for 12 h. The hot compression corresponding to a 60% height reduction was performed on a Gleeble thermo- mechanical simulator at 573-723 K in a strain rate range of 0.001-1 s-1. The specimens were heated at a heating rate of 5 K/s and then held at a certain temperature for 5 min. The specimens were compressed to a true strain of 0.9 and then quenched in water immediately to maintain the deformed microstructure. For microstructure observation, all the specimens were sectioned parallel to the longitudinal compression axis. The microstructure was characterized by electro-polishing the specimens using a solution consisting of 10% perchloric acid and 90% methanol and observing them under an optical microscope.

Table 1 Chemical composition of Al-3.2Mg-0.4Er alloy (mass fraction, %)

3 Results and discussion

3.1 Flow stress analysis

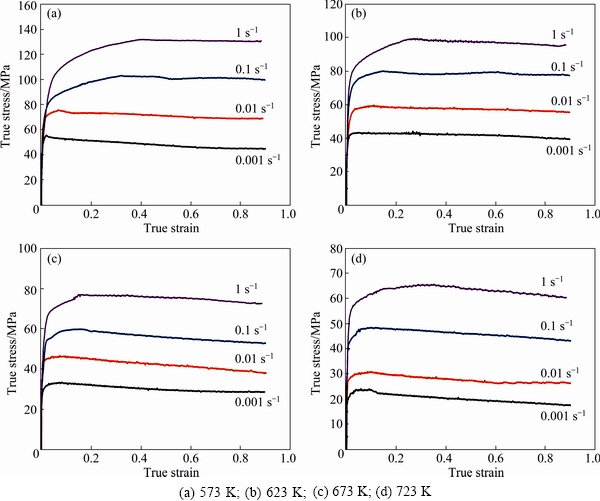

Figure 1 shows the microstructure of the Al-3.2Mg-0.4Er alloy homogenized at 723 K for 12 h. The average grain size of this alloy after the homogenization heat treatment is approximately 359 μm. The hot deformation behavior of the homogenized Al-3.2Mg-0.4Er alloy was studied by hot compression in a strain rate range of 0.001 s-1-1 s-1 at 573-723 K. Figure 2 shows typical true stress-strain curves obtained during hot compression of Al-3.2Mg-0.4Er alloy. The flow stress is generally sensitive to strain rate and deformation temperature. The decrease in strain rate and increase in temperature indicate a significant decrease in flow stress. The work hardening at the beginning of hot compression results in the rapid increase of flow stress. Moreover, with the increase in strain, dislocation density and potential driving force or recovery increase. Meanwhile, nucleation and growth of new grains occur. Additionally, an obvious feature of the flow curves is the lack of clear evidence of DRX which is usually identified by a distinct peak [9]. However, to clarify the occurrence of dynamic recrystallization, some precise tests on the microstructure of the deformed specimens should be carried out.

Fig. 1 Microstructure of Al-3.2Mg-0.4Er alloy homogenized at 723 K for 12 h

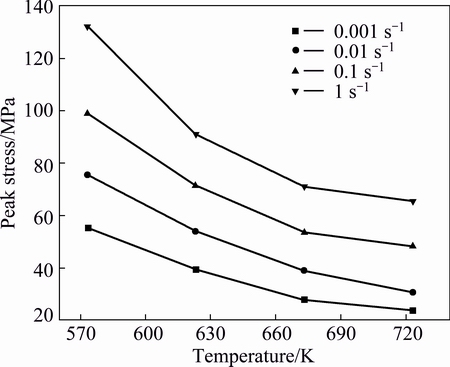

Figure 3 shows the effect of deformation parameters on peak stress of the Al-3.2Mg-0.4Er alloy. The peak stress decreases with increasing deformation temperature and decreasing strain rate. Moreover, the decreasing rate of peak stress decreases with decreasing strain rate from 1 to 0.001 s-1 at low temperatures, whereas peak stress decreases smoothly at high temperatures of 673 and 723 K.

3.2 Constitutive equation

In order to improve the prediction accuracy of the flow stress of the Al-3.2Mg-0.4Er alloy, a phenomenological constitutive model, which considers the coupled effects of strain rate, strain and deformation temperature on the flow behavior of material, is presented [10]. This phenomenological constitutive model can be expressed as follows:

(1)

(1)

where B(T) and n(T) are material constants, which are functions of forming temperature; material constant C(T,ε) represents the effects of strain and deformation temperature on the flow behavior of material; σp is the peak stress under different deformation conditions.

Fig. 2 True stress-strain curves of Al-3.2Mg-0.4Er alloy deformed at various strain rates and temperatures

Fig. 3 Relationships between peak stress and temperature at various strain rates

3.2.1 Determination of σp

The Arrhenius equation, which gives better approximations between Zener-Hollomo parameter and flow stress, is widely accepted to describe the hot deformation behavior of alloys [11]. This theory can be expressed as follows:

(2)

(2)

(3)

(3)

where

in which σ is the flow stress under a given strain (MPa);  is the strain rate (s-1); Q is the activation energy of hot deformation (kJ/mol); T is the thermodynamic temperature (K); R is the mole gas constant (8.314 J/(mol·K)); α, β and n1 are material constants with the relationship of α=β/n1.

is the strain rate (s-1); Q is the activation energy of hot deformation (kJ/mol); T is the thermodynamic temperature (K); R is the mole gas constant (8.314 J/(mol·K)); α, β and n1 are material constants with the relationship of α=β/n1.

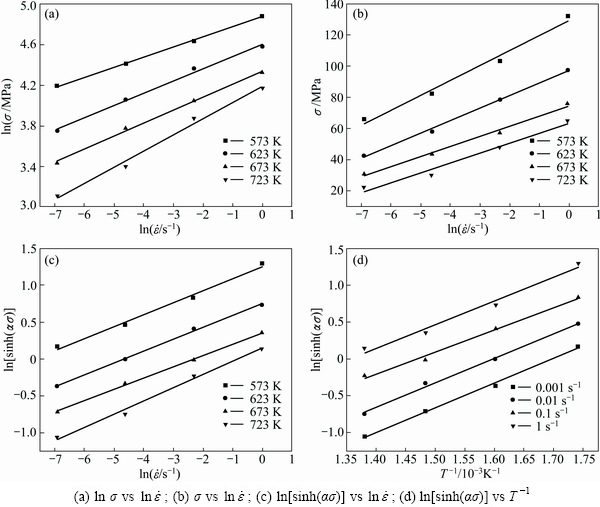

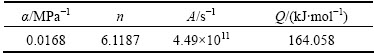

Fig. 4 Linear relationships among various parameters of Al-3.2Mg-0.4Er alloys

Table 2 Material constants obtained for homogenized Al-3.2Mg-0.4Er alloy

Figure 4 illustrates the relationships among σ,  , ln[sinh(ασ)] and T -1, and the material constants are listed in Table 2. Here, the solving process in detail can be seen in Refs. [12,13]. So, the mathematic model for peak stress of the studied Al-3.2Mg-0.4Er alloy is summarized as follows:

, ln[sinh(ασ)] and T -1, and the material constants are listed in Table 2. Here, the solving process in detail can be seen in Refs. [12,13]. So, the mathematic model for peak stress of the studied Al-3.2Mg-0.4Er alloy is summarized as follows:

(4)

(4)

3.2.2 Determination of B(T) and n(T)

In this work, the reference strain rate ( ) is set as 0.001 s-1, and Eq. (1) can be simplified as

) is set as 0.001 s-1, and Eq. (1) can be simplified as

σ=σp+B(T)εn(T) (5)

Taking the natural logarithm of both sides of Eq. (5) gives

ln(σp-σ)=ln[-B(T)]+n(T)ln ε (6)

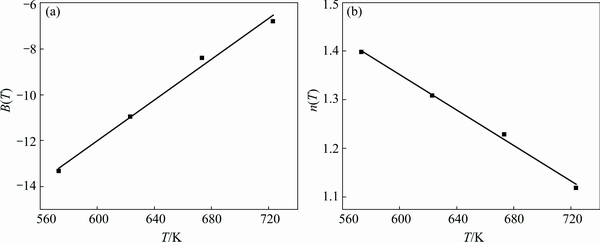

The relationships between ln(σp-σ) and ln ε at a strain rate of 0.001 s-1 and all of the studied deformation temperatures can be easily obtained from the measured stress–strain data (Fig. 5). By linear fitting, we accepted the values of B(T) and n(T) to be -13.3297, -10.9624, -8.40065 and -6.7739 MPa, and 1.39806, 1.30895, 1.229 and 1.1191 for the cases with deformation temperatures of 573, 623, 673 and 723 K, respectively. Then, Fig. 6 indicates that there is a relatively good linear relationship between material constants B(T), n(T) and deformation temperature and can be represented as

(7)

(7)

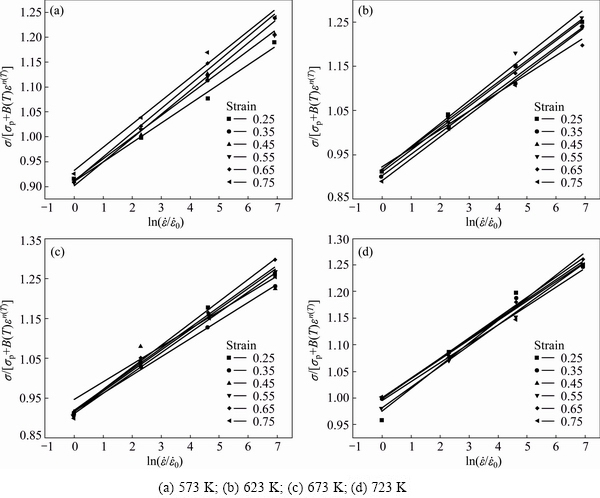

3.2.3 Determination of C(T, ε)

Similarly, Eq. (1) can be expressed as

(8)

(8)

The reference strain rate ( ) was also set as 0.001 s-1 for Eq. (8). Based on the measured stress–strain data, the relationship between σ/[σp+B(T)εn(T)] and

) was also set as 0.001 s-1 for Eq. (8). Based on the measured stress–strain data, the relationship between σ/[σp+B(T)εn(T)] and  at different deformation temperatures can be easily obtained, as shown in Fig. 7.

at different deformation temperatures can be easily obtained, as shown in Fig. 7.

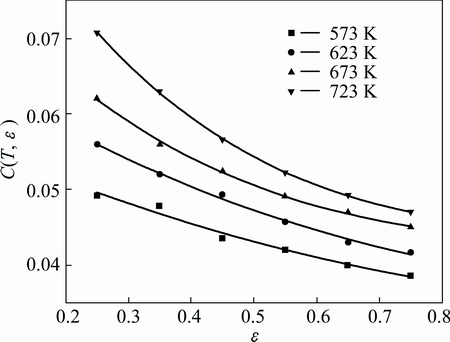

By using the linear fitting method, we obtained the relationships between C(T,ε) and strain at different deformation temperatures, as shown in Fig. 8.

Fig. 5 Relationships among ln(σp-σ) and ln ε at strain rate of 0.001 s-1 and different forming temperatures

Fig. 6 B(T) vs T (a) and n(T) vs T (b) at strain rate of 0.001 s-1

Fig. 7 Relationships between σ/[σp+B(T)εn(T)] and  under different deformation conditions

under different deformation conditions

Fig. 8 Relationships between C(T, ε) and strain ε at different deformation temperatures

The value of C(T,ε) evidently increases with increasing deformation temperature at a given strain; conversely, it decreases with increasing strain at a given deformation temperature. Moreover, the relationship among C(T, ε), deformation temperature and strain can be expressed as

(9)

(9)

Finally, the proposed phenomenological constitutive model for Al-3.2Mg-0.4Er alloy can be summarized as

(10)

(10)

Table 3 shows the errors between the predicted peak stress and the measured peak stress under different experimental conditions. To evaluate the accuracy of the established constitutive model, we evaluated the relative error between the measured (σm) and predicted (σp) peak stresses. The relative error (E) is defined as

(11)

(11)

The maximum relative error in the flow stress estimate is 8.24%, indicating that the proposed phenomenological constitutive model provides an accurate prediction of the flow stress of the studied Al-3.2Mg-0.4Er alloy.

Table 3 Comparison of calculated and measured peak stresses

3.3 DRX modeling and microstructure evolution

The kinetic model of DRX can predict the evolution of microstructure and volume fraction of DRX in terms of S-curves, which is usually expressed by Avrami equation. The kinetic model of DRX evolution can be expressed as [14,15]

(12)

(12)

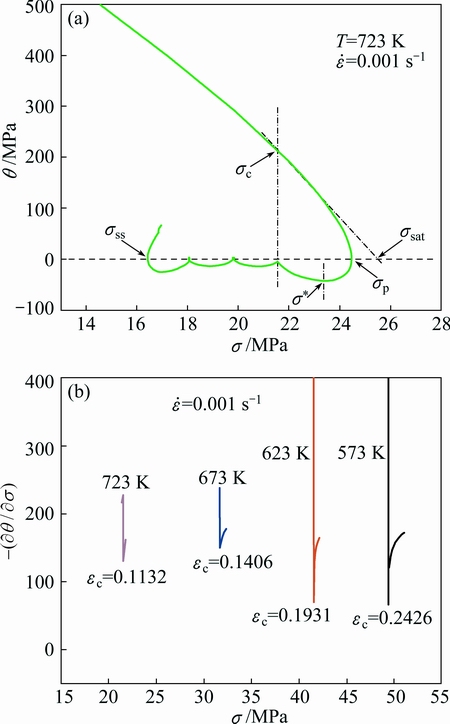

where XDRX is the volume fraction of DRX grain, and εc is the critical strain. The inflections in the plot of θ-σ up to the peak point of the true stress–strain curves were determined to indicate the occurrence of DRX. θ is the strain hardening rate, and the value of σp (peak stress) is the point at θ=0. The stress σss is the steady state stress under DRX. The stress σsat is defined by the extrapolation of the θ–σ plot to θ=0 using the linear portion of the curve relation to σ values just below σc. Moreover, the inflections in the plot of θ–σ up to the peak point of the true strain–stress curves are determined to indicate the occurrence of DRX. The inflection point in the θ-σ curve in Fig. 9(a) is determined by the minimum point in the  vs σ curve in Fig. 9(b), which is the initiation of DRX. The value of ε* can be obtained when the value of θ reaches the negative peak (

vs σ curve in Fig. 9(b), which is the initiation of DRX. The value of ε* can be obtained when the value of θ reaches the negative peak ( ), which corresponds to a valley point of θ vs σ plot after the peak point of the true stress–strain curves as shown in Fig. 9(a). The kinetics model of DRX can also be expressed as

), which corresponds to a valley point of θ vs σ plot after the peak point of the true stress–strain curves as shown in Fig. 9(a). The kinetics model of DRX can also be expressed as

(13)

(13)

Substituting σsat, σss, ε*, and εc obtained at different deformation temperatures and strain rates into Eq. (12), the mean values of the material constants k and n are calculated as k=-0.2 and n=2.4, respectively. Finally, the kinetic model of DRX evolution in this study can be proposed as

(14)

(14)

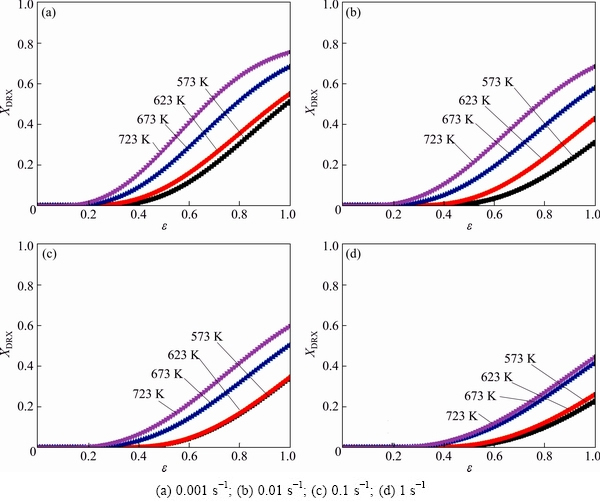

Figure 10 illustrates the effects of strain, strain rate, and deformation temperature on the DRX volume fraction based on Eq. (13).

Fig. 9 θ vs σ (a) and  θ/

θ/ σ vs σ (b) plots after peak points of true stress-strain curves

σ vs σ (b) plots after peak points of true stress-strain curves

Figure 10 describes the kinetics of DRX in terms of S-curves of the DRX volume fraction. The DRX can occur spontaneously when the critical strain is reached and when the volume fraction of DRX approaches 1 with increasing strain. The increase in deformation temperature and the decrease in strain rate result in the increase in the volume fraction of the recrystallized grains [16-18]. Thus, the tendency of dynamic recrystallization depends sensitively on deformation temperature and strain rate, which can be described by a single Z parameter. In addition, the deformation required for similar amount of DRX volume fraction increases as deformation temperature decreases at a given strain rate, indicating that DRX is delayed at a lower deformation temperature. By contrast, the deformation strain required for similar amount of DRX volume fraction increases with the increase in strain rate, indicating that DRX is also delayed. This result may be attributed to the reduced mobility of the grain boundaries with the decrease in temperature and increase in strain rate [19].

Fig. 10 DRX volume fraction (XDRX) of studied alloy at various temperatures and strain rates

Figure 11 shows the typical microstructures of Al-3.2Mg-0.4Er alloy after hot deformation. Figure 11(b) shows that the microstructure consists of elongated grains along with some newly refined grains (marked as blue oval), indicating that partial dynamic recrystallization occurred during hot deformation. Figures 11(a) and (b) show that when the specimen is deformed at 573 K, the accumulated energy increases, as dislocations do not have sufficient time to consume or continually generate at high strain rates. By contrast, dynamic recrystallization grains have more time to nucleate and grow at lower strain rates. In addition, the volume fraction of DRX in Fig. 11(a) increases with increasing deformation temperature compared with that in Fig. 11(c). Figures 10 and 11 indicate that the volume fraction of DRX in the studied alloy, which is evaluated using the DRX kinetic model, is comparatively accurate.

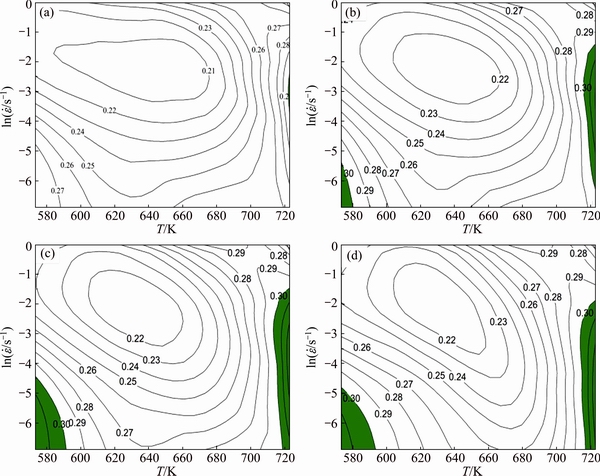

3.4 Processing maps

The processing map is useful in optimizing hot processing parameters and in controlling microstructure evolution in metals and alloys [20]. Processing maps were used to investigate the hot deformation behavior of Al-3.2Mg-0.4Er alloy at different temperatures based on the principle of dynamic material model (DMM) [21]. According to the DMM approach, the work piece in hot working is considered to be a dissipater of power that dissipates through temperature rising and microstructure evolution. Moreover, the ratio of the power used for microstructure evolution is reflected by the efficiency of power dissipation (η), which is a function of strain rate sensitivity, and can be defined as

(15)

(15)

where  is the strain rate sensitivity parameter. The variation of η with strain rate and deformation temperature constitutes a power dissipation map, from which some specific microstructure mechanisms can be preliminarily evaluated. A large η value is generally related to DRX during hot deformation.

is the strain rate sensitivity parameter. The variation of η with strain rate and deformation temperature constitutes a power dissipation map, from which some specific microstructure mechanisms can be preliminarily evaluated. A large η value is generally related to DRX during hot deformation.

The extremum principle of irreversible thermodynamics is applied to the continuum mechanics of large plastic flow to define the stability criterion [22]. The instability parameter ξ at different deformation temperatures and strain rates is expressed as follows:

(16)

(16)

Figure 12(a) shows the variation in the efficiency of power dissipation (η) of the alloy with temperature at a true strain of 0.3. The value of η shows varying tendencies at different strain rates with increasing temperature. Under strain rates of 0.001, 0.01 and 0.1 s-1, the η value initially decreases slightly as temperature rises from 573 to 623 K. Subsequently, the η value increases linearly. However, the η value increases with the increase in temperature under a high strain rate of 1 s-1, and then decreases as the temperature rises from 673 to 723 K. Moreover, Fig. 12(b) shows the effects of strain on the η value of the studied alloy under a strain rate of 0.01 s-1. Except for the slight decrease at the deformation temperature of 673 K, the η value increases gradually with increasing strain.

Fig. 11 Microstructures of Al-3.2Mg-0.4Er alloy deformed under different conditions

Fig. 12 Variation of η value of alloy with temperature (a) at true strain of 0.3 and with strain (b) at strain rate of 0.01 s-1

Fig. 13 DMM processing maps of studied alloy at strains of 0.3 (a), 0.5 (b), 0.7 (c) and 0.9 (d)

Compared with Fig. 12(b), Fig. 12(a) reveals that temperature exerts a significant effect on the workability of the studied alloy. The relatively low η value indicates unstable microstructure evolution of the alloy during deformation, which is related to the dynamic strain aging, as well as initiation and growth of microcracks. Figures 13(a)–(d) show the processing maps developed under strains of 0.3, 0.5, 0.7 and 0.9, respectively. Figure 13 reveals that DRX is the dominant deformation mechanism with higher power dissipation efficiency of regions, and that unstable deformation may occur at low temperatures and high strain rates. The combination of Figs. 10-13 indicates that the optimum processing conditions are 573 K, 0.001 s-1 and 723 K, 0.001-0.1 s-1.

4 Conclusions

1) The flow stress of the studied Al-3.2Mg-0.4Er alloy can be predicted accurately using the proposed constitutive model, which exhibits hot deformation activation energy of 164.058 kJ/mol.

2) The kinetic model of DRX is described in terms of S-curves of the DRX volume fraction and can be expressed as:  , and

, and

the volume fraction of DRX tends to approach 1 as strain increases. Moreover, the volume fraction of the recrystallized grains increases with increasing deformation temperature and decreasing strain rate.

3) The deformation temperature exerts a significant effect on the workability of the studied alloy, and the relatively low η value indicates unstable microstructure evolution of the alloy during deformation, which is related to the dynamic strain aging and to the initiation and growth of microcracks. Moreover, the processing maps reveal that the optimum hot working conditions for Al-3.2Mg-0.4Er alloy are 573 K, 0.001 s-1 and 723 K, 0.001-0.1 s-1.

References

[1] SONG M, DU K, WEN S P, NIE Z R, YE H Q. In situ electron microscopy investigation of void healing in an Al-Mg-Er alloy at a low temperature [J]. Acta Materialia, 2014, 69: 236-245.

[2] ROSALBINO F, ANGELINI E, NEGRI S D E, SACCONE A, DELFINO S. Electrochemical behaviour assessment of novel Mg-rich Mg-Al-RE alloys (RE=Ce, Er) [J]. Intermetallics, 2006, 14: 1487-1492.

[3] ROSALBINO F, ANGELINI E, NEGRI S D E, SACCONE A, DELFINO S. Influence of the rare earth content on the electrochemical behaviour of Al-Mg-Er alloys[J]. Intermetallics, 2003, 11: 435-441.

[4] VO N Q, DUNAND D C, SEIDMAN D N. Improving aging and creep resistance in a dilute Al–Sc alloy by microalloying with Si, Zr and Er [J]. Acta Materialia, 2014, 63: 73-85.

[5] GAO Z H, LI H Y, LAI Y Q, OU Y X, LI D W. Effects of minor Zr and Er on microstructure and mechanical properties of pure aluminum [J]. Materials Science and Engineering A, 2013, 580: 92-98.

[6] WU Z G, SONG M, HE Y H. Effects of Er on the microstructure and mechanical properties of an as-extruded Al-Mg alloy [J]. Materials Science and Engineering A, 2009, 504: 183-187.

[7] LI H Y, GAO Z H, YIN H, JIANG H F, SU X, JIE B J. Effects of Er and Zr additions on precipitation and recrystallization of pure aluminum [J]. Scripta Materialia, 2013, 68: 59-62.

[8] SONG M, DU K, WEN S P, NIE Z R, YE H Q. In situ electron microscopy investigation of void healing in an Al-Mg-Er alloy at a low temperature [J]. Acta Materialia, 2014, 69: 236-245.

[9] WU Yuan-zhi, YAN Hong-ge, ZHU Su-qin, CHEN Ji-hua, LIU An-min, LIU Xian-lan. Flow behavior and microstructure of ZK60 magnesium alloy compressed at high strain rate [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 930-939.

[10] LI J Q, LIU J, CUI Z S. Characterization of hot deformation behavior of extruded ZK60 magnesium alloy using 3D processing maps [J]. Materials & Design, 2014, 56: 889-897.

[11] WANG Jing, SHI Bao-liang, YANG Yuan-sheng. Hot compression behavior and processing map of cast Mg-4Al-2Sn-Y-Nd alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 626-631.

[12] ZHAO H Z, XIAO L, GE P, SUN J, XI Z P. Hot deformation behavior and processing maps of Ti-1300 alloy [J]. Materials Science and Engineering A, 2014, 604: 111-116.

[13] LI B, PAN Q, YIN Z. Microstructural evolution and constitutive relationship of Al-Zn-Mg alloy containing small amount of Sc and Zr during hot deformation based on Arrhenius-type and artificial neural network models [J]. Journal of Alloys and Compounds, 2014, 584: 406-416.

[14] LV B J, PENG J, SHI D W, TANG A T, PAN F S. Constitutive modeling of dynamic recrystallization kinetics and processing maps of Mg-2.0Zn-0.3Zr alloy based on true stress–strain curves [J]. Materials Science and Engineering A, 2013, 560: 727-733.

[15] LV B J, PENG J, WANG Y J, AN X Q, ZHONG L P, TANG A T, PAN F S. Dynamic recrystallization behavior and hot workability of Mg-2.0Zn-0.3Zr-0.9Y alloy by using hot compression test [J]. Materials & Design, 2014, 53: 357-365.

[16] MO W L, LU S P, LI D Z, LI Y Y. Effects of filler metal composition on inclusions and inclusion defects for ER NiCrFe-7 weldments [J]. Journal of Materials Science and Technology, 2013, 29: 458-466.

[17] EBRAHIMI G R, KESHMIRI H, MALDAD A R, MOMENI A. Dynamic recrystallization behavior of 13% Cr martensitic stainless steel under hot working condition [J]. Journal of Materials Science and Technology, 2012, 28: 467-473.

[18] QUAN G Z, YU S, WANG Y X, KANG B S, KU T W, SONG W J. Constitutive modeling for the dynamic recrystallization evolution of AZ80 magnesium alloy based on stress–strain data [J]. Materials Science and Engineering A, 2011, 528: 8051-8059.

[19] FENG D, ZHANG X M, LIU S D, DENG Y L. Constitutive equation and hot deformation behavior of homogenized Al-7.68Zn-2.12Mg- 1.98Cu-0.12Zr alloy during compression at elevated temperature [J]. Materials Science and Engineering A, 2014, 608: 63-72.

[20] BHATTACHARYA R, LAN Y J, WYNNE B P, DAVIS B, RAINFORTH W M. Constitutive equations of flow stress of magnesium AZ31 under dynamically recrystallizing conditions [J]. Journal of Materials Processing Technology, 2014, 214: 1408-1417.

[21] REN Fa-cai, CHEN Jun, CHEN Fei. Constitutive modeling of hot deformation behavior of X20Cr13 martensitic stainless steel with strain effect [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1407-1413.

[22] JI Ya-qi, QU Shun-de, HAN Wei-xin. Hot deformation and processing map of GH3535 superalloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 88-94.

彭 建1,2,王永建1,钟丽萍1,彭龙飞1,潘复生1,2

1. 重庆大学 材料科学与工程学院 机械传动国家重点实验室,重庆 400044;

2. 重庆科学技术研究院,重庆 401123

摘 要:在573~723 K、0.001~1 s-1变形条件下研究均匀化态Al-3.2Mg-0.4Er铝合金的热变形行为。基于热压缩实验结果,构建综合考虑应变速率、变形温度和应变的唯象本构方程,同时建立再结晶动力学方程和塑性加工图。结果显示:所构建的本构模型能准确地预测Al-3.2Mg-0.4Er铝合金在热变形过程中的流变应力。再结晶组织的演变和再结晶体积分数可以由所建立的动力学方程以S曲线形式进行描述。此外,构建了合金在不同应变下的热塑性加工图,得到均匀化态Al-3.2Mg-0.4Er铝合金的较优加工条件为573 K、0.001 s-1及723 K、0.001~1 s-1.

关键词:铝镁合金;热变形;本构方程;塑性加工图

(Edited by Wei-ping CHEN)

Foundation item: Project (2012BAF09B04) supported by the National Key Technology Research and Development Program of China; Project (2011DFR50950) supported by the International Technical Cooperation, China; Project (2014DFG52810) supported by the Ministry of Science and Technology of China

Corresponding author: Jian PENG; Tel: +86-23-65112291; Fax: +86-23-65102701; E-mail: jpeng@cqu.edu.cn

DOI: 10.1016/S1003-6326(16)64189-4