DOI: 10.11817/j.ysxb.1004.0609.2020-39450

功率密度对Cr12MoV激光熔覆层组织及耐磨性的影响

王 烨1,盛圆圆1, 2,柳 铭1, 2,刘 麟1, 2,宋瑞宏1,陈 杰1

(1. 常州大学 机械工程学院,常州 213164;

2. 常州大学 江苏省绿色过程装备重点实验室,常州 213164)

摘 要:以Cr12MoV冷模具钢为研究对象,采用不同的激光功率密度在Cr12MoV表面熔覆WC质量分数为40%的Ni60WC40复合涂层。随后对熔覆后试样的涂层熔覆界面、熔覆表面微观组织和成分的形成进行探讨,并通过摩擦磨损实验研究各熔覆层的耐磨损性能。结果表明:随着激光熔覆功率密度的提高,熔覆层厚度逐渐增大,熔覆区纵向组织从尚未完全熔化的团絮状及棒状晶逐渐向晶粒更为细小的花瓣晶转变;熔覆区横向组织从长短不一的花瓣晶及鱼骨状树枝晶逐渐向晶粒尺寸更为细小的长条形枝晶转变;CrNiC、CrFeNi等铬碳化合物和WN、CoN等金属固溶体的产生增强涂层的细晶强化作用。在激光功率密度为111.30 W/mm2时,试样表现出相对最优的耐磨性能。

关键词:激光熔覆;熔覆区;摩擦;磨损;Ni60WC40

文章编号:1004-0609(2020)-02-0355-09 中图分类号:TG335.86;O354.3 文献标志码:A

Cr12MoV冷作模具钢具有优异的淬透性、淬硬性、硬度和抗弯强度等性能,是制造冲模、冷镦模等模具的重要材料,被广泛应用于各种横截面大、形状复杂的曲面零件和模具[1-3]。由于Cr12MoV钢本身韧性相对较差,且模具生产工况条件苛刻,常受到较高的循环应力及冲击力作用,表面易发生磨损、裂纹等失效形式[4-7],严重影响模具的寿命、可靠性和稳定性[8]。因此,提高Cr12MoV钢表面耐磨性能具有重要的工业应用价值。

目前,在实际工业中一般采用渗碳[9]、激光淬火强化[10]、离子注入[11]和热喷涂强化等[12-13]提高Cr12MoV冷作模具钢表面的耐磨损等性能,但上述表面强化方法不同程度的存在强化层脱落、表面变形开裂或成本高昂等缺点。相较于上述强化技术,激光熔覆技术具有涂层变形小、结合强度高、稀释率低和组织致密等优点,因此,近年来激光熔覆作为一种提高金属表面性能的新技术,受到广泛的研究关注[14-17]。激光熔覆的工艺原理是将涂层粉末材料在激光作用下熔覆在微熔的金属基体表面,制备出具有冶金结合形式的致密涂层,进而显著提高金属材料的抗疲劳、耐腐蚀和耐磨损等特性[18-19]。Ni60WC40复合粉末作为一种优良的激光熔覆粉末,可在相对较低的温度下熔化,且Ni60WC40与Cr12MoV熔点相近,从而实现更好的冶金结合[20-21]。同时,粉末中的WC硬度高、耐磨性好,并可与Ni基材料形成良好的润湿,因而Ni60WC40复合熔覆层的耐磨损和硬度等明显优于纯Ni基熔覆层[22]。目前,国内外对Cr12MoV等冷作模具钢的表面强化研究主要集中在抗疲劳、抗腐蚀等方面[23-26],在激光熔覆提高冷作磨具钢耐磨损性能、尤其在激光熔覆凝固过程中熔覆层微观组织对其耐磨损性能影响的研究较少。

本文采用激光熔覆技术在Cr12MoV冷作模具钢表面熔覆Ni60WC40复合涂层,研究激光功率密度对熔覆层微观组织热性及其耐磨损性能的影响,探讨微观组织形貌特性及耐磨损性能提高的原因,以期为Cr12MoV等冷作模具钢的表面激光熔覆技术应用提供参考依据。

1 实验

激光熔覆涂层材料为Ni60WC40球形复合粉末,颗粒大小为15~45 mm,其化学成分如表1所列。激光熔覆实验所用基材为Cr12MoV冷作模具钢,试样尺寸为120 mm×60 mm×10 mm,其化学成分如表2所列。采用预制粉末涂层法,首先用酒精溶液清洗基材试样表面,其次用稀释后的丙酮乙醇溶液均匀适量渗透进粉末中,再将Ni60WC40粉末平铺1.5 mm的厚度在试样表面,然后在烘箱中烘2~3 h,直至干燥。

表1 Ni60WC40粉末化学成分

Table 1 Chemical composition of Ni60WC40 powder (mass fraction, %)

表2 Cr12MoV化学成分

Table 2 Chemical composition of Cr12MoV (mass fraction, %)

采用IPG YLS-2000高功率光纤激光器对已铺设涂层的试样进行激光熔覆。在7 mm/s的扫描速度下分别选用800 W、1000 W、1200 W、1400 W的激光功率进行激光熔覆,光斑搭接率为60%,光斑直径为4 mm,试样编号及其对应的熔覆工艺参数如表3所列。激光功率密度是指单位光斑面积内的激光束能量大小,是激光熔覆过程中粉末涂层对热量吸收的关键性影响参数。其计算表达式如下:

(1)

(1)

式中:Pw为激光功率密度,W/mm2;P为激光功率,W;s为光斑面积,mm2。本文实验激光器的光斑形状为圆形,因此,

(2)

(2)

式中:D为光斑直径,mm,整理可得

(3)

(3)

将上述相关参数代入式(3)中即得激光功率密度。

表3 涂层制备工艺参数

Table 3 Experimental parameters used in laser cladding

利用CFT-1型多功能材料表面综合性能测试仪进行摩擦磨损实验,实验所用载荷5 N,摩擦副主轴转速1000 r/s,摩擦半径5 mm,摩擦实验时间40 min。使用扫描电子显微镜(JSM-6510)观察试样涂层熔覆界面、熔覆层表面和磨痕的微观形貌,并对熔覆界面进行EDS选区分析。

2 分析与讨论

2.1 试样激光熔覆纵向微观组织形貌

图1所示为不同功率密度下Cr12MoV钢激光熔覆层的熔覆界面微观组织形貌。图1(ai)、(bi)、(ci)、(di)分别对应A、B、C、D 4个试样,其中下标1、2、3分别表示试样涂层横截面、熔覆区和热影响区的微观形貌。纵观图1(a1)~(d1)可知各熔覆层分层界面明显,但在不同激光功率密度下,熔覆层厚度及组织形貌有显著区别。图中A、B、C、D 4个试样的熔覆区平均厚度分别为约100 mm、300 mm、420 mm和700 mm。图1(a1)右侧边缘熔覆区内可见球团状白色物质;图1(b1)熔覆区颜色较亮,存在诸多白色致密状物质;图1(c1)和(d1)中存在诸多分布较为密集且形状不一的花样或团状物质,且图1(c1)涂层厚度不均。初步分析涂层熔覆区形貌差异原因如下:图1(a1)、(b1)试样的激光熔覆功率密度较低,熔覆过程中熔池温度较低且保持时间较短,而WC粉末的熔点高,激光能量尚未充分传递到WC颗粒内部时熔池已开始凝固,WC粉末只有部分发生分解,大部分保持原状,从而呈现图1(a1)、(b1)熔覆区的白色致密状物质;随着激光功率密度的增加,熔池内温度升高且保持时间增加,更多WC粉末进入熔池,使得熔池尺寸增大[27],且在基体微熔工况下,促使二者更好的结合而形成更为均匀致密的激光熔覆层。

图1 涂层横截面、熔覆区和热影响区的微观形貌

Fig. 1 Microstructure morphologies of coating cross section((a1)-(d1)), cladding zone((a2)-(d2)) and heat affected zone((a3)-(d3))

为进一步探讨激光功率密度对熔覆层微观组织的影响,分别取试样熔覆区及热影响区的微观形貌进行分析。图(a2)~(d2)分别是A、B、C和D 4个试样的熔覆区微观形貌。图1(a2)中可见白色团絮状颗粒和少量花瓣状晶体存在,白色团絮状颗粒主要为未熔的WC聚集物,花瓣状晶体是少量已熔的WC粉末所形成的晶粒。熔覆区中产生白色团絮状颗粒主要原因是激光功率密度较小,致使WC粉末在激光熔覆过程中因能量吸收不足而未能完全熔化,大部分WC粉末仅发生微熔且团聚残留在基体表面的结果[28]。图1(b2)可见熔覆区组织含有点状、棒状及“人”字形枝晶,主要以短棒状枝晶为主,这主要由于激光功率密度较小,熔池保存时间较短且冷却速度较快,部分溶解粉末尚未长大就结晶,故而形成短棒状枝晶。图1(c2)可见四角、六角形花瓣晶及独立花瓣晶,其中以四角星形花瓣晶为主,各瓣晶体长度约为3~4 mm,部分四角星形花瓣晶尖端有更长的枝晶产生,长度约为8~10 mm。这是由于功率密度进一步提高后熔池中过冷区面积增加,枝晶尖端排出溶质,改变了固液界面温度,使相对过冷度发生变化,提高了合金枝晶尖端溶质扩散的驱动力[29],因此在四角星花瓣的尖端有生长出了更长更细的枝晶。图1(d2)中有大量雪花状带核共晶组织存在,其相比于图1(c2)可见晶体组织更为细小均匀。形成该组织的原因是在激光功率密度逐步提高的情况下,组织的相变驱动力增强[30],组织形核率提高,进而细化晶体组织。

图1(a3)~(d3)所示分别为A、B、C和D 4个试样热影响区的形貌。可见各图中均有大小不一的马氏体存在,但从图1(a3)~(d3)各图中马氏体不断变细变小,且轮廓越来越清晰,尤以图1(d3)中胞状晶的分布最为均匀和细小。分析原因可知,激光熔覆过程中,熔池凝固过程自下而上,随着激光束的移动,热影响区很快发生凝固,激光熔覆产生的高温达到了基体的淬火温度,故而产生马氏体。

2.2 熔覆层表面微观组织形貌及XRD分析

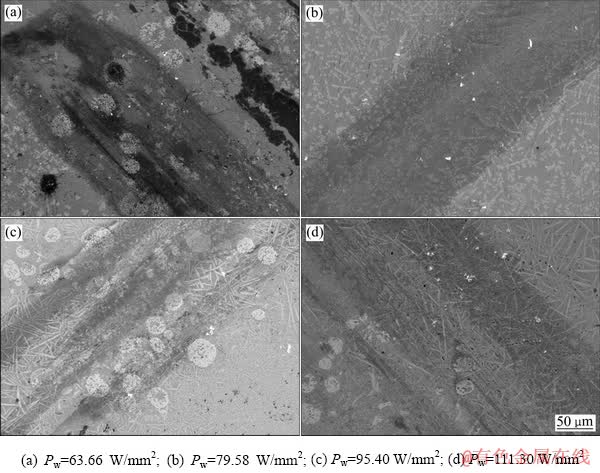

图2(a)~(d)所示分别为试样A、B、C和D的熔覆层表面微观形貌。图2(a)中有大量三角和四角形花瓣晶存在,且各瓣组织长短不一,在热流及溶质原子的扩散场的作用下,晶体在凝固过程中,传热传质快的方向的晶粒生长速率就快[29],因此,形成了长度不一的花瓣晶。图2(b)中可观察到大量鱼骨状树枝晶,且树枝晶中存在明显的一次枝晶和二次枝晶。这是由于随着功率密度的增加,熔池的凝固速率更高,液固界面前沿成分过冷区逐渐增大,使得固液界面发生胞/枝转变,胞状树枝晶就发展成为高度分枝的鱼骨状树枝晶。图2(c)中可观察到长条形枝晶,其组织致密、未观察到明显的气孔、裂纹等缺陷。相比于图2(b)中晶体不再发生分支,且其本身较细较长,约为40 mm。发生这种转变的主要原因在于熔池凝固过程中凝固速度大于枝晶转变的临界速度后,枝晶形貌将随着凝固速度的增加而逐渐转为细化,进而在凝固组织显现细小的枝晶结构。这种细小的枝晶结构将显著增强涂层的强度和硬度,提高其力学性能[31]。图2(d)中可观察到更为细小的长条状晶体,长度约为5 mm,相较图2(c)可见发生了进一步的晶粒细化。这说明激光功率密度的提高为熔池提供了一个更佳的冶金结合环境,使得熔池内温度梯度和凝固速度的比值降低,冷却速率和过冷度增大,促使形核率增加,单位体积内晶粒数量增加,最终导致熔覆层晶粒越发细小。在一定范围内,细小的晶粒组织有利于提高熔覆层表面强度和硬度,进而提高塑性和韧性[32-33]。对比4种功率密度下的熔覆层组织可知,A、B试样熔覆区大多以花瓣晶及鱼骨状树枝晶为主,且花瓣晶及鱼骨状树枝晶的大小和规模都较大,而C、D熔覆层虽然也是以树枝状组织为主,但树枝晶的形状更为单一且尺寸更小。花瓣晶及鱼骨状树枝晶的减少,有利于减少熔覆层内部的内应力,促进晶粒细化,提高熔覆层的强度极限及耐磨性能[34]。

图2 熔覆层表面微观形貌

Fig. 2 Microstructure morphologies of cladding zone under different laser power densities

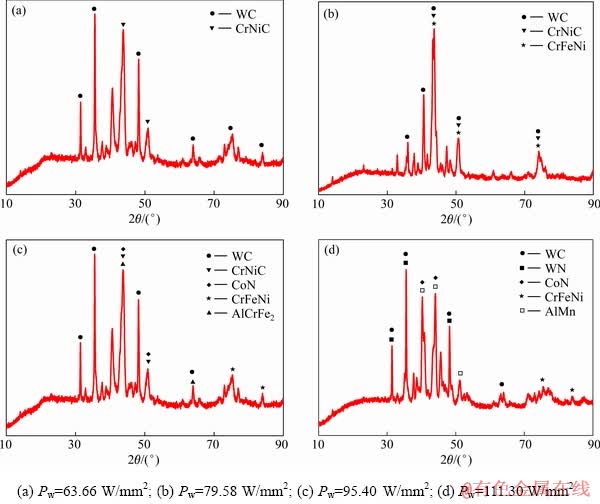

图3(a)~(d)所示分别为试样A、B、C、D的涂层熔覆区横向截面XRD物相分析结果。当激光功率密度为63.66 W/mm2时,如图3(a)所示,熔覆层物相包括WC和CrNiC。当激光功率密度增至79.58W·mm-2时(见图3(b)),有新的物相CrFeNi产生,这是因为随着激光功率密度的提高,熔池温度逐渐上升,W、C元素逐渐过渡到熔覆层中,与高温熔池中的Cr、Fe、Ni等元素发生原位化合反应[34],生成较多析出物,促使鱼骨状树枝晶的形成。随着激光功率密度的继续提高(见图3(c)、(d)),试样C和试样D中除铬碳化合物的产生外还有新的物相CoN、WN生成,其中CrNiC和CrFeNi等铬碳化合物是激光熔覆过程中元素相互作用产生的强化相,对提高涂层的硬度及耐磨性有重要作用。此外,CoN、WN等金属固溶体的产生也增强了涂层的细晶强化作用[8],致使组织更为细小均匀。

2.3 涂层耐磨性分析

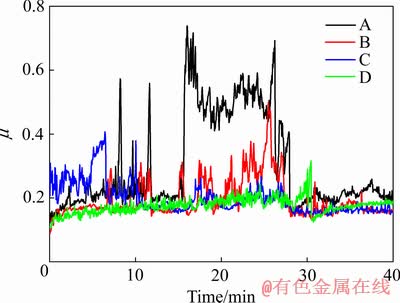

试样A、B、C、D的摩擦因数曲线及表面磨痕的磨损形貌分别如图4、5所示,表4所列为熔覆层磨损性能数据表,h表示磨痕深度,Ra表示表面粗糙度,μ表示平均摩擦因数。A试样在实验中期摩擦因数波动较为剧烈,实验28 min之后摩擦因数逐渐趋于稳定,平均摩擦因数数值约为0.31。B试样在实验中期摩擦因数亦为有所波动,且在实验16~25 min内摩擦因数波动相对较为剧烈,平均摩擦因数约为0.20。结合表4及图5(a)、(b)可知,这是因为激光熔覆过程功率密度较小时,WC粉末未完全与基材发生冶金结合而形成较为粗大疏散的组织,使得表面粗糙度较大,进而导致摩擦副在实验过程中贴合不好,出现磨合期较长、摩擦因数波动剧烈的现象。C试样虽在前期有小范围波动,但约10 min之后逐渐趋于稳定,平均摩擦因数约为0.20。结合表4及图5(c)可见磨痕较浅且不连续,说明磨损表面接触不好,耐磨性较差。D试样在整个摩擦过程相对较为稳定,中间并未出现较明显的波动,平均摩擦因数约为0.15。同时结合表4及图5(d)可见 磨痕较浅,同时也磨痕也较为平整。这是由于随着激光功率密度的提升,更多的WC粉末进入熔池与基材结合,使基材发生固溶强化,增强了其强韧性[35]。此外,熔池保存时间相对较长,熔池中晶体有足够时间生长细化,熔覆层产生的马氏体组织更为细小致密[36],使其硬度及耐磨性能均得到提高,且表面平整性更好,从而在摩擦过程中表现出了良好的耐磨性。

图3 涂层熔覆区横向截面XRD分析

Fig. 3 XRD patterns of cross-sectional morphology for cladding zone

图4 激光熔覆层的摩擦因数曲线

Fig. 4 Friction coefficient of laser cladding coatings

表4 激光熔覆层的摩擦性能数据

Table 4 Tribological parameters of laser cladding coatings

3 结论

1) 不同的激光熔覆功率密度使得Cr12MoV基体表面形成厚度及形貌不同的熔覆涂层。随着功率密度的增大,熔覆层厚度逐渐增加,熔覆区纵向组织从未完全熔化的团絮状及棒状晶逐渐向晶粒更为细小的花瓣晶转变,熔覆区组织细化现象亦逐渐增加。

2) 同时,随着激光功率密度的增加,熔覆区横向组织从长短不一的花瓣晶及鱼骨状树枝晶逐渐向晶粒尺寸更为细小的长条形枝晶转变。激光功率密度越高,熔池内冷却速率和过冷度越大,晶体形核率越高,晶粒细化越明显,从而使得增强熔覆层表面强度和硬度,塑性和韧性也越好。

3) 当激光功率密度Pw为111.30 W/mm2时,试样的摩擦因数最为稳定且数值最小,说明其耐磨性能最好,这主要得益于其较为平整的接触表面及由激光熔覆引入的固溶强化相作用,增强了其耐磨性能。

图5 激光熔覆层表面磨痕微观形貌

Fig. 5 Microstructure morphologies of worn surface for laser cladding coating

REFERENCES

[1] WU B, LIU P, DUAN J, DENG L, ZENG X, WANG X. Study on picosecond pulse laser ablation of Cr12MoV cold work mold steel[J]. Materials & Design, 2016, 110: 549-557.

[2] 郭宝莲, 赵春明, 王应楠, 张庆余, 苏慧心. 冷作模具钢Cr12MoV的热处理和强韧性[J]. 哈尔滨工业大学学报, 1981(3): 77-87.

GUO Bao-lian, ZHAO Chun-ming, WANG Ying-nan, ZHANG Qing-yu, SU Hui-xin. Heat treatment and strength-ductility of Cr12MoV steel used for cold-working[J]. Journal of Harbin Institute of Technology, 1981(3): 77-87.

[3] 张 垒, 孔德军. Cr12MoV冷作模具钢渗铬层界面能谱分析[J]. 中南大学学报(自然科学版), 2016, 47(2): 430-435.

ZHANG Lei, KONG De-jun. Energy spectrum analysis of chromized coating interface for Cr12MoV cold working die steel[J]. Journal of Central South University (Science and Technology) , 2016, 47(2): 430-435.

[4] PANG G X, CHEN Z Y, LI Z L, WANG Y J. Research on ion nitriding temperature effect on wear resistance of 35CrMo steel[J]. Advanced Materials Research, 2011, 341/342: 128-132.

[5] 庄乔乔, 张培磊, 李明川, 闫 华, 于治水. 铜合金表面激光熔覆Ni-Ti-Si涂层微观组织及耐磨性能[J]. 中国激光, 2017(11): 57-63.

ZHUANG Qiao-qiao, ZHANG Pei-lei, LI Ming-chuan, YAN Hua, YU Zhi-shui. Microstructures and wear resistance properties of Ni-Ti-Si coatings on copper alloy surface by laser cladding[J]. Chinese Journal of Lasers, 2017(11): 57-63.

[6] GUO Y, ZHANG Z B, ZHOU R C, HOU S F, WANG B H. Microstructure and mechanical properties of alloy 617B[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1106-1113.

[7] ZHANG P, ZHU Q, CHEN G, QIN H Y, WANG C J. Grain size based low cycle fatigue life prediction model for nickel-based superalloy[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(10): 2102-2106.

[8] WANG C, GAO Y, ZENG Z, FU Y. Effect of rare-earth on friction and wear properties of laser cladding Ni-based coatings on 6063Al[J]. Journal of Alloys & Compounds, 2017, 727(15): 278-285.

[9] 魏秋平, 王钰言, 陈 中, 刘培植, 余志明. W18Cr4V高速钢渗铬热处理对HFCVD金刚石膜生长的影响[J]. 中国有色金属学报, 2011, 21(7): 1623-1631.

WEI Qiu-ping, WANG Yu-yan, CHEN Zhong, LIU Pei-zhi, YU Zhi-ming. Effect of high temperature diffusion chromizing pretreatment of W18Cr4V high speed steel ob growth of diamond films by HFCVD[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(7): 1623-1631.

[10] YAN M F, WANG Y X, CHEN X T, GUO L X, ZHANG C S, YOU Y, BAI B, CHEN L, LONG Z, LI R W. Laser quenching of plasma nitrided 30CrMnSiA steel[J]. Materials & Design, 2014, 58 (6): 154-160.

[11] JIN J, SHAO T. Effects of single- and dual-element ion implantation on tribomechanical properties of Cronidur 30 bearing steel[J]. Surface & Coatings Technology, 2018, 344(25): 303-311.

[12] GAO S, HOU J S, GUO Y A, ZHOU L Z. Phase precipitation behavior and tensile properties of as-cast Ni-based superalloy during heat treatment[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(9): 1735-1744.

[13] 周超极, 朱 胜, 王晓明, 韩国峰, 周克兵, 徐安阳. 热喷涂涂层缺陷形成机理与组织结构调控研究概述[J].材料导报, 2018, 32(19): 77-87.

ZHOU Chao-ji, ZHU Sheng, WANG Xiao-ming, HAN Guo-feng, ZHOU Ke-bing, XU An-yang. A review on thermally sprayed coating defects formation mechanism and microstructure modification[J]. Materials Reports, 2018, 32(19): 77-87.

[14] PEREIRA J, ZAMBRANO J, LICAUSI M, TOBAR M, AMIGO V. Tribology and high temperature friction wear behavior of MCrAlY laser cladding coatings on stainless steel[J]. Wear, 2015, 330/331: 280-287.

[15] FU B, FENG K, LI Z. Study on the effect of Cu addition on the microstructure and properties of NiTi alloy fabricated by laser cladding[J]. Materials Letters, 2018, 220(1): 148-151.

[16] 顾赛男, 王广原, 秦 渊, 杨 森. 激光熔覆W-Cu复合材料的组织形貌与工艺参数的相关性[J]. 中国激光, 2018, 45(4): 170-177.

GU Sai-nan, WANG Guang-yuan, QIN Yuan, YANG Sen. Correlation between process parameters and microstructure morphologies of W-Cu composites fabricated by laser cladding[J]. Chinese Journal of Lasers, 2018, 45(4): 170-177.

[17] 刘秀波, 王 勉, 乔世杰, 翟永杰, 周仲炎, 罗迎社, 涂 溶. TA2合金激光熔覆钛基自润滑耐磨复合涂层的高温摩擦学性能[J]. 摩擦学学报, 2018, 38(3): 283-290.

LIU Xiu-bo, WANG Mian, QIAO Shi-jie, ZHAI Yong-jie, ZHOU Zhong-yan, LUO Ying-she, TU Rong. High temperature tribological properties of laser cladding titanium matrix self-lubricating wear resistant composite coating on TA2 alloy[J]. Tribology, 2018, 38(3): 283-290.

[18] 张鹏飞, 李玉新, 李 亮, 苏科强, 张宏建, 尉利强, 赵占勇. 7075铝合金表面激光熔覆Ti/TiBCN复合涂层的组织及性能[J]. 中国表面工程, 2018, 31(2): 159-164.

ZHANG Peng-fei, LI Yu-xin, LI Liang, SU Ke-qiang, ZHANG Hong-jian, WEI Li-qiang, ZHAO Zhan-yong. Microstructure and properties of Ti/TiBCN coating on 7075 Aluminum alloy surface by laser cladding[J]. China Surface Engineering, 2018, 31(2): 159-164.

[19] LI J, LUO X, LI G J. Effect of Y2O3 on the sliding wear resistance of TiB/TiC-reinforced composite coatings fabricated by laser cladding[J]. Wear, 2014, 310(1/2): 72-82.

[20] 李福泉, 冯鑫友, 陈彦宾. WC含量对WC/Ni60A激光熔覆层微观组织的影响[J]. 中国激光2016, 43(4): 117-124.

LI Fu-qvan, FENG Xin-you, CHEN Yan-bin. Influence of WC content on microstructure of WC/Ni60A laser cladding layer[J]. Chinese Journal of Lasers, 2016, 43(4): 117-124 .

[21] 臧春城, 王延忠, 张以都, 李金华, 曾 红, 张德强. 激光熔覆Ni60+35WC-Ni涂层的微观组织和摩擦磨损特性[J]. 稀有金属, 2015(5): 385-391.

ZANG Chun-cheng, WANG Yan-zhong, ZHANG Yi-du, LI Jin-hua, ZENG Hong, ZHANG De-qiang. Microstructure and tribological behavior of Ni60+35WC-Ni coating produced by laser cladding[J]. Chinese Journal of Rare Metals, 2015(5): 385-391

[22] 周圣丰, 戴晓琴, 郑海忠. 激光熔覆与激光—感应复合熔覆WC-Ni60A涂层的结构与性能特征[J]. 机械工程学报, 2012, 48(7): 113-118.

ZHOU Sheng-feng, DAI Xiao-qin, ZHENG Hai-zhong. Characteristics on structure and properties of WC-Ni60A coatings by laser cladding and laser-induction hybrid cladding[J]. Journal of Mechanical Engineering, 2012, 48(7): 113-118.

[23] MORGADO J M, MATITO A, TORRELO A, SCHWARTZ L B, ORFAO A, ESCRIBANO L. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding[J]. Optics & Laser Technology, 2015, 68: 191-201.

[24] YU T, DENG Q, GANG D, YANG J. Effects of Ta on microstructure and microhardness of Ni based laser clad coating[J]. Applied Surface Science, 2011, 257(11): 5098-5103.

[25] CHEW Y, PANG J H L, BI G, SONG B. Effects of laser cladding on fatigue performance of AISI 4340 steel in the as-clad and machine treated conditions[J]. Journal of Materials Processing Technology , 2017, 243: 246-257.

[26] 许金沙. 外载作用下激光熔覆WC/Ni复合涂层的疲劳断裂行为研究[D]. 上海: 华东理工大学, 2014: 1-110.

XU Jin-sha. Researches on the fracture and fatigue behaviors laser cladded WC/Ni composite coating under applied load conditions[D]. Shanghai: East China University of Science and Technology, 2014: 1-110.

[27] 孙 琳, 位超群, 隋欣梦, 陈 卓, 张维平. SiC颗粒尺寸对TiNi基熔覆层组织与性能的影响[J]. 中国激光, 2018, 45(5): 54-60.

SUN Lin, WEI Chao-qun, SUI Xin-meng, CHEN Zhuo, ZHANG Wei-ping. Effects of SiC particle size on microstructure and properties of TiNi based cladding layers[J]. Chinese Journal of Lasers, 2018, 45(5): 54-60.

[28] 张德强, 郝延杰, 李金华. 激光熔覆工艺参数对Ni60A熔覆层性能影响[J]. 机械设计与制造, 2017(1): 115-118.

ZHANG De-qiang, HAO Yan-jie, LI Jin-hua. Effects of laser cladding laser parameter on ni60a performance of cladding layer[J]. Machinery Design & Manufacture, 2017(1): 115-118.

[29] FISHER D J. Fundamentals of solidification[M]. Beijing: Higher Education Press, 1986.

[30] CUI Ze-qin, SHI Hai-xia, WANG Wen-xian, XU Bing-she. Laser surface melting AZ31B magnesium alloy with liquid nitrogen-assisted cooling[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1446-1453

[31] 胡 锐, 何其武, 王一川, 寇宏超, 李金山, 毕晓勤, 傅恒志. 凝固速率对Cu-1.0wt%Cr合金界面形态及枝晶演变的影响[J]. 材料热处理学报, 2006, 27(1): 43-45.

HU Rui, HE Qi-wu, WANG Yi-chuan, KOU Hong-chao, LI Jin-shan, BI Xiao-qin, FU Heng-zhi. Effect of directional solidification rates on the interface morphology and dendrite growth of the hypoeutectic Cu-1.0wt%Cr alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(1): 43-45.

[32] 邱星武, 李 刚, 任 鑫, 邱 玲. 扫描速度对激光熔覆Ni基涂层组织性能的影响[J]. 稀有金属材料与工程, 2009, 38(s1): 325-328.

QIU Xing-wu, LI Gang, REN Xin, QIU Ling. Influence of scanning speed on microstructure and properties of Ni based laser cladding coating[J]. Rare Metal Materials and Engineering, 2009, 38(s1): 325-328.

[33] WANG C, GAO Y, WANG R, WEI D, CAI M, FU Y. Microstructure of laser-clad Ni60 cladding layers added with different amounts of rare-earth oxides on 6063 Al alloys[J]. Journal of Alloys & Compounds, 2018, 740: 1099-1107.

[34] CHEN X, QIN X, ZHU Z, GAO K. Microstructural evolution and wear properties of the continual local induction cladding NiCrBSi coatings[J]. Journal of Materials Processing Technology, 2018, 262: 257-268.

[35] 高中堂, 谭金强, 郭 卫, 张传伟. 镍基和铁基激光熔覆材料对熔覆层组织及性能的影响[J]. 热加工工艺, 2017, 46(20): 161-164.

GAO Zhong-tang, TAN Jin-qiang, GUO Wei, ZHANG Chuan-wei. Effect of Ni-based and Fe-based laser cladding materials on microstructure and property of cladding layer[J]. Hot Working Technology, 2017, 46(20): 161-164.

[36] 徐滨士, 方金祥, 董世运, 刘晓亭, 闫世兴, 宋超群, 夏 丹. FV520B不锈钢激光熔覆热影响区组织演变及其对力学性能的影响[J]. 金属学报, 2016, 52(1): 1-9.

XU Bin-shi, FANG Jin-xiang, DONG Shi-yun, LIU Xiao-ting, YAN Shi-xing, SONG Chao-qun, XIA Dan. Heat-affected zone microstructure evolution and its effects on mechanical properties for laser cladding[J]. Acta Metallurgica Sinica, 2016, 52(1): 1-9.

Power density effect on microstructure and wear resistance of laser cladding coatings on Cr12MoV

WANG Ye1, SHENG Yuan-yuan1, 2, LIU Ming1, 2, LIU Lin1, 2, SONG Rui-hong1, CHEN Jie1

(1. School of Mechanical Engineering, Changzhou University, Changzhou 213164, China;

2. Jiangsu Key Laboratory of Green Process Equipment, Changzhou University, Changzhou 213164, China)

Abstract: The composite coatings of Ni60WC40 (mass fraction, %) were cladded on Cr12MoV mold steel by laser cladding with different power density. The interface and surface microstructure of cladded coatings and the surface composition were investigated, and moreover, the wear resistance of cladded coatings was tested. The results indicate that the thickness of cladded coating increases with the raising of laser cladding power density. In addition, the unmelted flocculent and rod-shaped crystals, which are in the longitudinal microstructure of the cladded zone, gradually transforms to the finer petal crystals. The lateral microstructure of cladded coating is transferred from petal crystals with various sizes and fishbone dendrites to long strip dendrites with finer grain size. The generation of chromium carbons (CrNiC, CrFeNi, etc.) and metal solid solution (WN, CoN, etc.) improves the coatings strengthened subjected to the fine grain. With 111.30 W/mm2 of laser power density, the coating performs the best running-in tribological behaviors.

Key words: laser cladding; cladded zone; friction; wear; Ni60WC40

Foundation item: Projects(51601021, 51671037, 51441001) supported by the National Natural Science Foundation of China; Project(17KJA460002) supported by the Natural Science Foundation of Jiangsu Higher Education Institutions, China; Project(2017M611718) supported by the China Postdoctoral Science Foundation, China; Project(GDZB-002) supported by Qing Lan Project of Jiangsu Province and “Six Talent Peaks” of Jiangsu Province, China; Project(KYCX18_2647) supported by Postgraduate Research & Practice Innovation Program of Jiangsu Province, China

Received date: 2019-01-14; Accepted date: 2019-09-28

Corresponding author: LIU Lin; Tel: +86-519-81169803; E-mail: liulin@cczu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51601021,51671037,51441001);江苏省高校自然科学研究重大项目(17KJA460002);中国博士后科学基金面上项目(2017M611718);2017年江苏省“青蓝工程”优秀青年骨干教师项目;江苏省第十四批“六大人才高峰”高层次人才计划项目(GDZB-002);江苏省研究生实践创新计划项目(KYCX18_2647)

收稿日期:2019-01-14;修订日期:2019-09-28

通信作者:刘 麟,副教授,博士;电话:0519-81169803;E-mail:liulin@cczu.edu.cn