文章编号:1004-0609(2014)01-0145-07

激光熔覆NiCrMn-WC复合涂层的组织与耐磨性

王 璐,胡树兵,单炜涛,胡 可,张 磊

(华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074)

摘 要:为了提高高品质液压油缸的耐磨性能,使用45钢作为模拟材料,采用YLR-4000型光纤激光器在其表面进行激光熔覆,制备NiCrMn+WC复合涂层。利用金相显微镜(OM)和扫描电镜(SEM)分析其显微组织和微观形貌,利用X线衍射仪及能谱分析涂层的相结构和成分,并测量了其硬度以及磨损性能,获得最优的工艺参数。结果表明:激光熔覆层的致密度良好,无明显的孔洞出现;熔覆层硬度较基体的提高3~5倍,且在一定范围内,随着扫描速度的增加以及扫描功率的减少,熔覆层的硬度强化效果明显;硬质相的加入使其表面的耐磨性显著提高,在扫描速度为360 mm/min,功率为2.5 kW,WC含量为30%(质量分数)时,熔覆层的各项性能达到最优。

关键词:液压油缸;激光熔覆;能量密度;硬度;耐磨性

中图分类号:TG174.44 文献标志码:A

Microstructure and wear resistance of laser cladding NiCrMn-WC composite coatings

WANG Lu, HU Shu-bing, SHAN Wei-tao, HU Ke, ZHANG Lei

(Key Laboratory of Material Processing and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: In order to improve the wear resistance of high-quality hydraulic cylinder, 45 steels were used as the simulative materials, the surface layers NiCrMn-WC composite coatings were fabricated by laser cladding. The microstructure and morphology were analyzed by optical microscopy (OM) and scanning electron microscopy (SEM), the phases and component elements were analyzed by X-ray diffractometry (XRD) and energy dispersive spectrometry (EDS), the microhardness and wear-resistance were tested, and the optimal parameters were obtained. The results show that the appropriate treatment parameters result in good performance of the clad layers with no defects, the microhardness of the CZ is 3-5 times larger than that of the substrate, and the microhardness is promoted as the power reducing and the scanning speed increasing, the wear-resistance is improved with the hard phases adding, each property comes to the best when the power is 2.5 kW, the scanning speed is 360 mm/min and the WC content is 30% (mass fraction).

Key words: hydraulic cylinder; laser cladding; energy density; microhardness; wear-resistance

液压油缸在工业机械中应用广泛,然而由于其锻造材料一般选用塑韧性较好的中碳钢,其表面硬度一般较低,约为28~32HRC[1](280~300 HV),表面磨损是其的主要失效形式,在很大程度上缩短液压油缸的工作寿命。为了提高油缸表面的耐磨损性能,传统的热处理工艺一般是在其表面进行渗碳处理,使其表面硬度增加至48~52HRC [2](480~540 HV),然而,在高频响的复杂环境下还是不能达到高耐磨性要求。传统的镀铬工艺对材料表面硬度提升较小,且在循环冲击磨损下,其表面镀铬层易产生局部剥落,亦不能成为改善液压油缸表面耐磨性的有效方法。激光熔覆技术相对于传统的表面改性技术,有着冷却速度快(高达106 ℃/s),热畸变小,稀释度低,能够进行选区熔覆,易于实现自动化等优点,是一种理想的表面改性技术,在工业中有着广泛的应用[3-4]。它通过在基材表面添 加熔覆材料,利用高能密度激光束快速加热,使熔覆材料和基体表层发生熔化,并通过基体的激冷作用实现快速凝固,从而形成与基体呈冶金结合,且具有良好性能的表面涂层[5-10]。杨胶溪等[11]在Cr12钢基体上利用激光熔覆技术上制备出了WC/Ni涂层,显著地提升了基体表面的耐磨损性能;ZHOU等[12]在45钢基体上制备出了多道搭接Fe基WC复合涂层,并测量了不同试验参数下熔覆层的磨损性能,其磨损质量损失较基体减少50%;YANG等[13]在钛合金表面制备出了TiCN/Ti涂层,其熔覆层的硬度较基体的提高了约3~6倍,相应的耐摩损性能也有很大的提高。

在本次研究中,考虑到45钢是常用的液压油缸铸造材料,且在机械制造中有着广泛的应用,Ni基涂层有着良好的性能,而WC更兼顾了较高的硬度、良好的塑性,以及在熔融金属中良好的润湿性[14]。为此,本文作者选择以调质态45钢作为液压油缸材料,利用激光熔覆技术在其表面制备了NiCrMn+WC复合耐磨涂层,对熔覆层的显微组织进行了分析,并给出不同工艺参数及WC含量对涂层性能的影响规律,为工业大规模应用提供理论工艺基础。

1 实验

1.1 试验材料与设备

本次试验所选用的基体材料为调质态(淬火温度850 ℃,回火温度600℃)45钢,试样尺寸为100 mm(长)×100 mm(宽)×10(厚) mm,其经过表面打磨,清洗、去污及干燥处理后。分别配置Ni基合金粉末(成份见表1),Ni +10%WC、Ni +30%WC、Ni+50%WC(质量分数)粉末,并用球磨机进行球磨6 h,使其充分混合均匀,采用预置涂层法将已配置好的粉末分别涂覆在不同试样表面,厚度约1.5 mm,预制试块在200 ℃保温2 h待用。

采用YLR-4000型光纤激光器在每块试样表面进行扫描,扫描时偏离角为10°;光斑尺寸为4 mm;扫描功率分别选用1.5、2.5和3.5 kW,并在每种功率下分别选用240、360和480 mm/min的扫描速度。

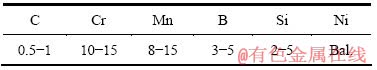

表1 Ni基合金粉末成分

Table 1 Composition of Ni-base alloy powder (mass fraction, %)

1.2 试验方法

将按照常规方法制备金相试样,试样由砂纸打磨并抛光,经王水腐蚀后,用OLYMPUS-TOKYO型金相显微镜观察熔覆层组织,采用Sirion200场发扫描电镜对实验样品微观组织形貌进行观察,并采用Sirion200系统中的Gensis60型能谱仪对熔覆层中的化学成分进行了分析,利用X射线衍射仪对熔覆层进行物相分析。

采用DHV-1000型显微硬度计对试样截面进行硬度测试,加载力为1.96 N,并绘制由熔覆层表面至基体的显微硬度分布图。采用MM-2000型磨损试验机对试样表面进行磨损试验,对磨试样为GCr15。测量熔覆层表面的磨损性能时,保持待测试样不动,试样以200 r/min的转速转动。选用真空泵油进行润滑,每分钟10滴,每对试样磨损时间累计10 h,每2 h称质量一次。每次磨损前后,先后用汽油、丙酮超声清洗上下试样,并烘干,用精度为0.1 mg的分析天平称质量,以磨损质量损失来评价熔覆层的耐磨性能。

2 结果与分析

2.1 激光熔覆层的显微组织

材料表面经激光熔覆涂层后截面由外向内一般分为熔覆层(Clad zone,CZ),稀释层(Dilution zone,DZ),热影响区域(Heat-affected zone,HAZ)[15]。

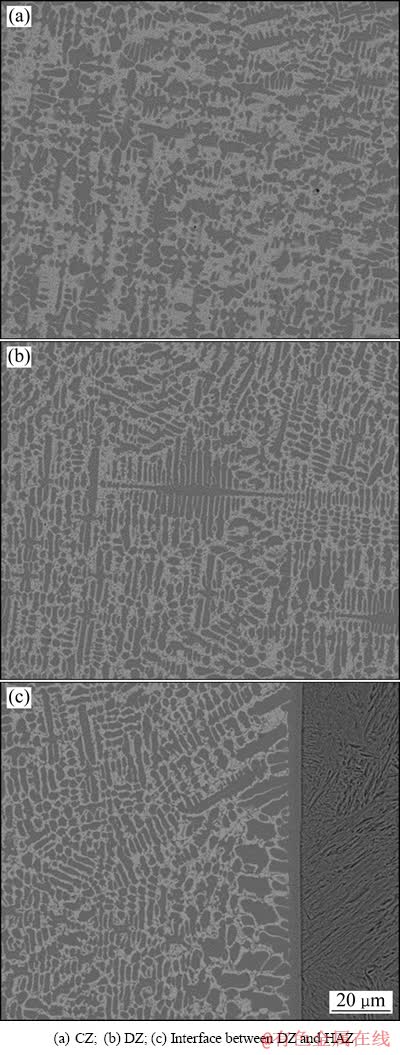

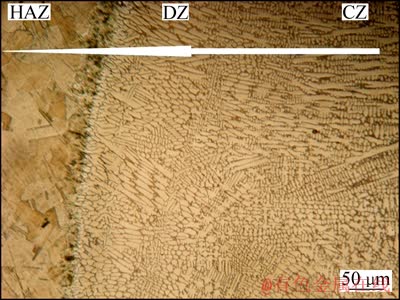

图1所示为各个区域的SEM像。由图1可以看出,激光熔覆层的致密度较高,无明显的裂纹及孔洞出现,从熔覆层到稀释层,晶粒的生长形态依次为等轴晶、树枝晶和平面晶。这可以通过熔池凝固理论模型[16]来解释。熔融态金属冷却凝固体时,当冷却速度非常大,将会发生非平衡转变。激光熔覆时,在熔覆层和基体界面处的温度梯度最大,但此时的结晶速度最小,所以熔池金属会以生长为平面晶的方式长大,形成一层细小的平面晶区[17]。而随着固/液界面的推移,温度梯度也就随之减小,结晶速度逐渐加大,此时将形成枝状晶,以及等轴晶。从图2所示的金相照片也可以清楚地看出这一变化趋势,并且可以看出,熔覆层、稀释层和基体直接形成良好的冶金结合。

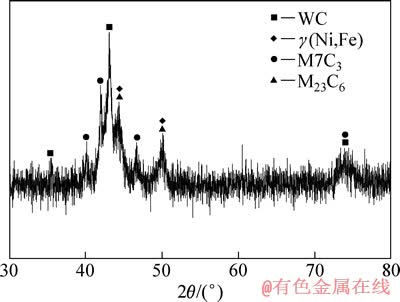

对熔覆层进行XRD物相分析,结果表明,熔覆层中主要是由γ(Ni,Fe)、M7C、M23C6和WC等相组成,其中,M7C和M23C6的出现,说明在激光照射过程中,WC由于受热产生了分解,其中的C元素与Fe和Cr等元素重新结合,形成新的沉淀相(见图3)。

图1 Ni基合金涂层截面的显微组织

Fig. 1 Cross-sectional microstructures of Ni coating

图2 Ni基合金涂层截面的金相照片

Fig. 2 Cross-sectional metallograph of Ni coating

图3 熔覆层的物相分析

Fig. 3 XRD phases analysis results of CZ

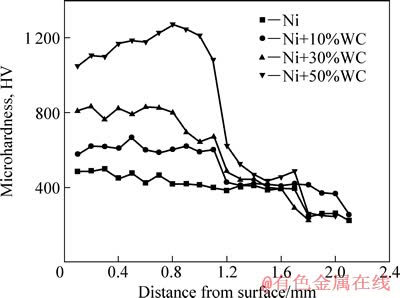

2.2 激光熔覆层的硬度

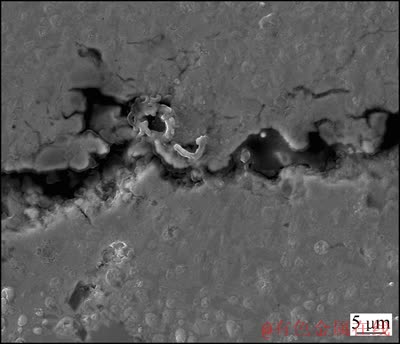

对试样截面进行显微硬度的测量,从表面至基体,每隔50 μm测量一个点,并作出硬度分布图。图4所示为功率2.5 kW、扫描速度240 mm/min时不同含量WC合金粉末经激光熔覆到基体表面后熔覆层的硬度分布规律。由图4可以看出,激光熔覆NiCrMn+WC合金粉末后熔覆层的硬度较基体(240HV)提升2~5倍左右,且WC的含量比例越高,硬度的提升越明显。造成这种现象主要是因为未熔WC颗粒以及熔覆时产生的M7C3和M23C6为硬质相,可以起到弥散强化的效果;而熔解的WC所形成的元素,可以固溶到γ-Ni中,产生固溶强化效果,WC含量的增加使得弥散强化和固溶强化的效果越明显,故其硬度也就越高。然而,尽管WC含量比例的增加能够显著提高熔覆层的硬度,但经多次试验表明,当合金粉末中WC含量达到50%时,由于硬质相的过度聚集,内应力增加,会导致熔覆层内开裂,不利于材料表面的强化。图5所示为典型的熔覆层开裂形貌。

图4 WC含量对涂层硬度的影响

Fig. 4 Effect of WC content on microhardness of coating

图5 层内开裂形貌

Fig. 5 Morphology of intraformational cracking

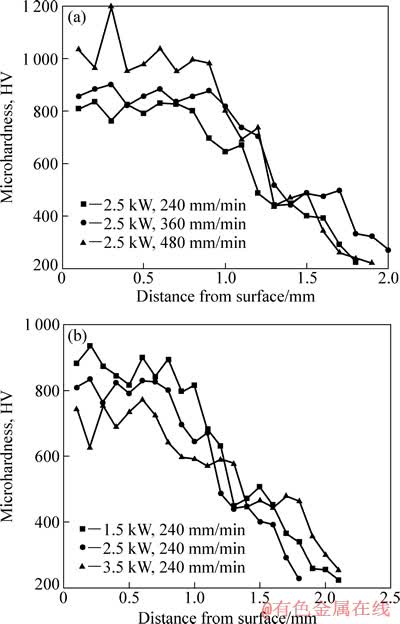

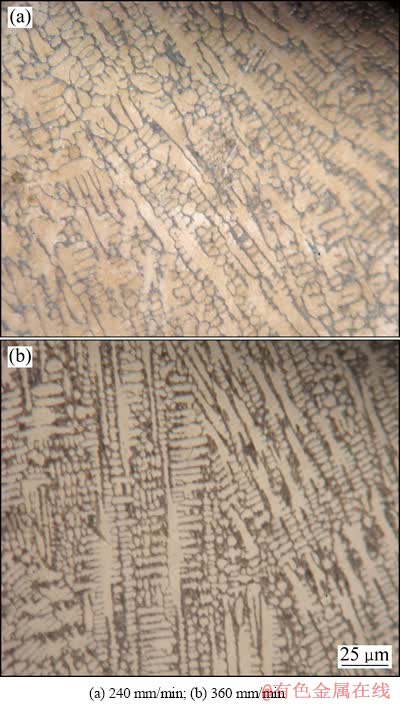

图6所示为扫描速率与扫描功率对硬度分布规律的影响。从图6中可以看出,经过激光熔覆NiCrMn+WC硬质合金层后,材料表面的硬度得到显著的提升,且随着扫描速率的增加以及扫描功率的降低,硬度的提升也就越显著。造成这种规律的原因可以通过能量密度的变化来解释。定义单位时间内照射在试样表面单位面积上的能量为能量密度。能量密度增高,基体与熔覆层的受热量增加,使得熔覆层稀释率升高,较高的稀释率不利于熔覆层获得良好且均匀的性能,与此同时,充分的受热时间能够使熔覆层凝固速度减小,相对保温时间增大,导致形成的晶粒粗大。根据细晶强化原理,在成份相同的情况下,晶粒较为细小的组织其硬度较大。图7所示为相同功率(2.5 kW)不同扫描速率下Ni基熔覆层金相照片。由图7可以看出,较大的扫描速度(见图7(b))下可以得到较小的晶粒,有利于硬度的提高。过高的功率密度会使熔覆层烧损,达不到基体表面强化的目的,另外,较小扫描速度可以减少WC的沉积,使WC均匀的分布在熔覆层内;而过小的功率密度不能够使熔覆层与基体表面同时熔化,不能够形成良好的冶金结合,亦不能使基体表面得到强化。

图6 不同扫描速率和功率下显微硬度分布

Fig. 6 Microhardness distribution at different scanning speeds and powers

图7 功率2.5 kW时不同扫描速率下熔覆层的显微组织

Fig. 7 Microstructures of coating at 2.5 kW and different scanning speeds

2.3 激光熔覆层的耐磨性

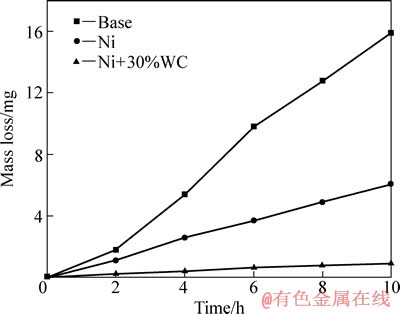

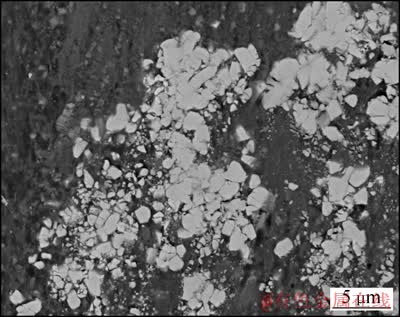

图8对比研究了基体、Ni基涂层以及NiCrMn+ WC合金涂层的磨损质量损失。从图8中可以看出,经过激光熔覆Ni+WC合金涂层后,45钢基体表面的耐磨损性能得到了显著的提升。对于基体及纯Ni基涂层而言,磨损开始理想状况为线接触,但是经过一段时间的磨损之后,材料表面会由于磨损出现契合摩擦副的一个凹面,增大了摩擦面积,因此,在质量损失曲线上呈现磨损加剧的情况。由于Ni基涂层的硬度远大于45钢基体的,故其耐磨损性能明显优于基体的。熔覆涂层在添加了WC之后,熔覆层在磨损过程的初始阶段,Ni基合金元素化物由于其硬度相对较低,在磨料的作用下先行被磨损。随着磨损的进行,Ni基合金元素化物的不断磨去,WC颗粒开始凸露出来,此时WC颗粒作为主要的承载相。因与其对磨的GCr15钢中强化相碳化铬的硬度比WC的低,高硬度的WC颗粒阻止GCr15钢切入涂层。并且,熔覆层中的金属都具有一定的塑性变形能力,当轴承钢对涂层施加外力时,内嵌WC颗粒的金属Ni会发生一定的塑性变形,吸收了部分能量,延缓了WC颗粒的拔出、脱落,提高了涂层的耐磨性能。由于WC颗粒具有较高的硬度,可起到阻碍磨粒磨损的作用,因此,可以看到磨损进行的中期会有变缓的趋势,但是当WC颗粒周围的基质不断发生挤压磨去后,其中的WC颗粒将破碎以至于发生脱落(见图9)。

图8 样品的磨损质量损失

Fig. 8 Wear mass loss of samples

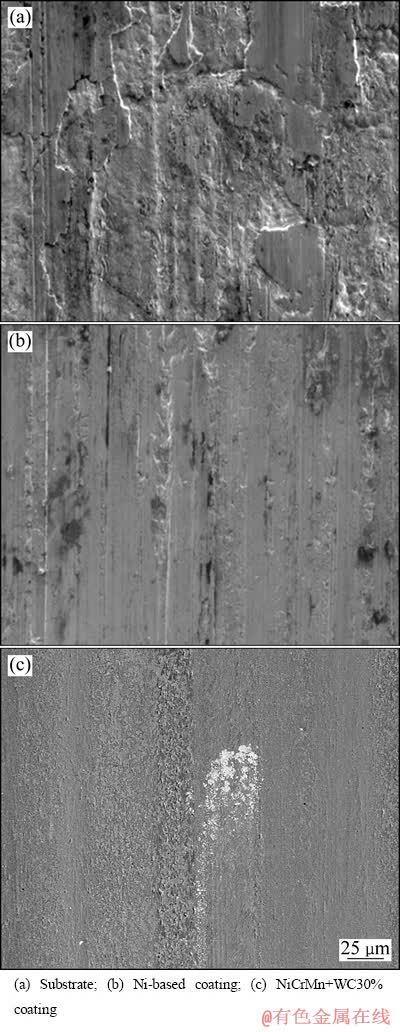

图10所示为样品的磨损形貌。从图10所显示的3种材料不同的磨损形貌可看出,较轻的磨粒磨损和少量粘着磨损,而NiCrMn+WC合金涂层中,因为有硬质相的加入,其磨损方式转变成了轻微的磨粒磨损。

图9 破碎WC颗粒的形貌

Fig. 9 Morphology of cracked WC particle

图10 样品的磨损形貌

Fig. 10 Morphologies of worn surfaces of samples

3 结论

1) 通过激光熔覆的方法在45钢表面制备的NiCrMn+WC硬质合金涂层,在合适的工艺参数下,熔覆层的致密度较高,无明显的裂纹及孔洞出现,且与基体呈良好的冶金结合,当WC含量超过50%(质量分数)时,熔覆层内易产生层内开裂。

2) 45钢表面熔覆的NiCrMn+WC涂层,其硬度比基体提高了3~5倍,且工艺参数与WC含量对硬度的影响规律为:在一定范围内,增加扫描速度为200~600 mm/min),降低功率(4~1.5 kW)以及增加WC的含量(质量分数50%以下)比例都可以提高熔覆层的硬度。

3) 在45钢表面熔覆NiCrMn+WC硬质合金涂层,可以很好地改善基体的耐磨损性能,其磨损质量损失比基体降低了约94%,且磨损类型从粘着磨损转变为轻微的磨粒磨损。

4) 分析各个工艺参数下熔覆层的性能,得到最优的工艺参数功率2.5 kW,扫描速度360 mm/min,最佳涂层配比为70%NiCrMn+30%WC(质量分数)。

REFERENCES

[1] 冯 刚. 瓦楞单面机液压油缸的失效分析及改进[J]. 润滑与密封, 2009, 34(1): 98-100.

FENG Gang. Failure Analysis and improvement of the hydraulic system corrugated card-board single side machine[J]. Lubrication Engineering, 2009, 34(1): 98-100.

[2] 何 智, 高 超, 王三俊, 高永卫, 王广军. AV90-2轴流压缩机轴承座漏油故障分析及处理[J]. 润滑与密封, 2006(1): 132-136.

HE Zhi, GAO Chao, WANG San-jun, GAO Yong-wei, WANG Guang-jun. Analysis and dispose of bearing box leakage oil trouble for AV90-2 axial compressor[J]. Lubrication Engineering, 2006(1): 132-136.

[3] 张 松, 张春华, 康煜平. 钛合金表面激光熔覆原位生成TiC增强复合涂层[J]. 中国有色金属学报, 2001, 11(6): 1026-1030.

ZHANG Song, ZHANG Chun-hua, KANG Yu-ping. Mechanism of in-situ formation of TiC particle reinforced Ti-based composite coating induced by laser melting[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 1026-1030.

[4] 马乃恒, 梁工英, 苏俊义. 激光熔覆工艺参数对TiCp/Al表层复合材料的影响[J]. 中国有色金属学报, 2001, 11(6): 1041-1044.

MA Nai-heng, LIANG Gong-ying, SU Jun-yi. Influence of technological parameters on interface bonding and structure uniformity of in-situ synthesis TiCp/Al composites in laser cladding process[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 1041-1044.

[5] YANG Jiao-xi, LIU Fa-lan, MIAO Xuan-he, YANG Feng. Influence of laser cladding process on the magnetic properties of WC-FeNiCr metal-matrix composite coatings[J]. Journal of Materials Processing Technology, 2012, 212(9): 1862-1868.

[6] HEMMATI I, OCELIK V, de HOSSON J Th M. The effect of cladding speed on phase constitution and properties of AISI 431 stainless steel laser deposited coatings[J]. Surface & Coatings Technology, 2011, 205(21/22): 5235-5239.

[7] MAN H C, ZHANG S, CHENG T F, GUO X. In situ formation of a TiN/Ti metal matrix composite gradient coating on NiTi by laser cladding and nitriding[J]. Surface & Coatings Technology, 2006, 200(16/17): 4961-4966.

[8] STGEORGES L. Development and characterization of composite Ni-Cr+WC laser cladding[J]. Wear, 2007, 263(1/6): 562-566.

[9] 王义厢, 李宝增, 宫耀华, 程占保. 45钢表面激光熔覆铁基合金涂层显微组织与性能[J]. 热加工工艺, 2008, 37(21): 131-133.

WANG Yi-xiang, LI Bao-zeng, GONG Yao-hua, CHENG Zhan-bao. Microstructure and performance of iron-based alloy laser cladding on 45 steel surface[J]. Hot Working Technology, 2008, 37(21): 131-133.

[10] 张永康. 激光加工技术[M]. 北京: 化学工业出版社, 2004.

ZHANG Yong-kang. Laser processing technology[M]. Beijing: Chemical Industry Publishing, 2004.

[11] 杨胶溪, 左铁钏, 王喜兵, 闫 婷, 刘华东. 激光熔覆WC/Ni 基硬质合金组织结构及耐磨性能研究[J]. 应用激光, 2008, 28(6): 450-454.

YANG Jiao-xi, ZUO Tie-chuan, WANG Xi-bing, YAN Ting, LIU Hua-dong. The Microstructure and Wear-resistant properties of WC/Ni based cemented carbide fabricated by laser cladding[J]. Applied Laser, 2008, 28(6): 450-454.

[12] ZHOU Sheng-feng, DAI Xiao-qin, ZHENG Hai-zhong. Microstructure and wear resistance of Fe-based WC coating by multi-track overlapping laser induction hybrid rapid cladding[J]. Optics & Laser Technology, 2012, 44(1): 190-197.

[13] YANG Yu-ling, ZHANG Duo, YAN Wei, ZHENG Yi-ran. Microstructure and wear properties of TiCN/Ti coatings on titanium alloy by laser cladding[J]. Optics and Lasers in Engineering, 2010, 48(1): 119-124.

[14] BAO Rui-liang, YU Hui-jun, CHEN Chuan-zhaong, QI Biao, ZHANG Li-jian. Development of laser cladding wear-resistant coating on Titanium alloys[J]. Surface Review and Letters, 2006, 13(5): 645-654.

[15] BAO Rui-liang, YU Hui-jun, CHEN Chuan-zhaong, QI Biao, ZHANG Li-jian. Development of laser cladding wear-resistant coating on Titanium alloys[J]. Surface Review and Letters, 2006, 13(5): 645-654.

[16] 魏 仑. 激光熔覆镍基金属陶瓷涂层的研究[D]. 昆明: 昆明理工大学, 2001.

WEI Lun. Study of laser cladding Ni-based ceramic coating[D]. Kunming: Kunming University of Science and Technology, 2001.

[17] HE Zhi-yong, XIANG Jin, ZHAO Zhong-xu. Plasma surface alloying of spheroidal graphite iron[J]. Surface and Coatings Technology, 2000, 131(1/3): 574-578

(编辑 李艳红)

基金项目:2010年省部产学研合作重大项目(2010A090200047);国际热核聚变实验堆计划专项(2010GB109000),华中科技大学与材料成型与模具技术国家重点实验室自主课题(09-10)

收稿日期:2013-03-20;修订日期:2013-10-10

通信作者:胡树兵,教授,博士;电话:027-87540057;E-mail:hushubing@163.com