DOI: 10.11817/j.ysxb.1004.0609.2020-35797

Ti60合金热变形过程中的软化机制

王天祥1,鲁世强1,王克鲁1,欧阳德来2,姚 泉1

(1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. 南昌航空大学 材料科学与工程学院,南昌330063)

摘 要:采用Thermecmaster-Z型热加工模拟试验机对Ti60合金进行等温恒应变速率压缩实验,通过分析流动应力-应变曲线的流动特征,计算加工硬化率,观察变形微观组织,并结合变形激活能的计算,研究该合金在变形温度为850~950 ℃、应变速率为0.001~10 s-1、真应变为0.51热变形条件下的软化机制。结果表明:Ti60合金在低应变速率(0.001~0.1 s-1)和高应变速率(1~10 s-1)区间流动应力-应变曲线分别呈现流动稳态型和流动软化型两种;加工硬化率曲线呈现无拐点特征;变形微观组织为动态回复组织,未出现动态再结晶现象;变形激活能在低应变速率区间和高应变速率区间分别为484.35 kJ/mol和500.76 kJ/mol,两者相差不大。综合这些结果可以判定,Ti60合金的软化机制以动态回复为主。

关键词:Ti60合金;加工硬化率;变形微观组织;变形激活能;软化机制

文章编号:1004-0609(2020)-06-1338-11 中图分类号:TG146.2+3 文献标志码:A

随着现代航空技术的不断发展,对材料的要求也越来越高。钛合金因其具备密度小、比强度高及耐腐蚀与耐热性能优异等诸多特点,被广泛应用于航空发动机的高温零部件[1]。Ti60合金是我国自主研发的近α型钛合金,它在室温性能、高温性能、蠕变性能、热稳定性、抗氧化性、疲劳性能以及断裂韧性等方面具有良好的匹配,能够在600 ℃环境下长期稳定服役,可以用于制造压气机叶片、轮盘、鼓桶以及整体叶盘等关键零部件[2-4]。另外,以Ti60合金为基体的连续SiC纤维增强Ti60基复合材料以其高比强度、高比刚度和良好的耐高温性能,成为超高音速宇航飞行器和下一代先进航空发动机的重要候选结构材料[5-6]。

采用物理气相沉积+热压或热等静压是制备连续SiC纤维增强Ti60基复合材料的最常用方法[7],在热压或热等静压过程中通过Ti60合金基体的塑性流动来实现连续SiC纤维增强Ti60基复合材料的致密化。由于Ti60合金在塑性流动过程中不同变形条件下的软化机制会有所不同[8],所以有必要对其进行研究。目前,已有不少学者通过各种不同方法研究了不同合金的软化机制,如赵子博等[9]通过分析流动应力-应变曲线和计算变形激活能,确定出了Ti60合金在温度为910~970 ℃,应变速率为0.001~10 s-1,压下量为75%的软化机制与α板条的动态再结晶有关;徐文臣等[10]利用流动应力-应变曲线特性、变形激活能和变形微观组织演变规律,给出了TA15钛合金在温度为550~1000 ℃,应变速率为0.01~1 s-1,压下量为65%软化机制为动态回复和动态再结晶;蔡赟等[11]在考虑流动应力-应变曲线和加工硬化率时,发现了AZ80镁合金在温度为200~400 ℃,应变速率为0.001~1 s-1,压下量为60%的软化机制以动态再结晶为主;万志鹏等[12]依据不同变形参数下的动态软化应力和变形微观组织,揭示GH4720Li合金在温度为1060~ 1120 ℃,应变速率为0.001~10 s-1,真应变为0.8的软化机制为非连续动态再结晶。但目前鲜有从流动应力-应变曲线、加工硬化率、变形激活能和变形微观组织等多角度因素来综合研究和分析合金软化机制的报道。

本文作者以连续SiC纤维增强Ti60基复合材料的热压或热等静压工艺为背景,在变形温度为850~ 950 ℃,应变速率为0.001~10 s-1,真应变为0.51的热变形条件下对Ti60合金进行等温恒应变速率压缩实验,通过分析流动应力-应变曲线,并综合考虑加工硬化率、变形微观组织和变形激活能,对Ti60合金的软化机制进行了系统的研究。研究结果对合理制定SiC纤维增强Ti60基复合材料的热压或热等静压工艺具有重要的指导意义。

1 实验

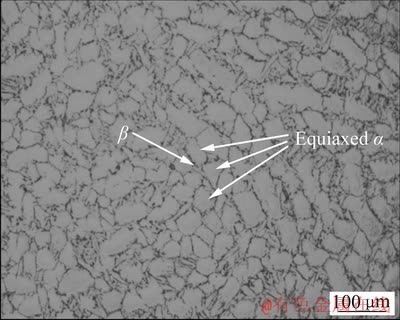

实验材料为经锻造+两相区固溶+时效处理的Ti60合金,图1所示为其原始组织照片。由图1可知,Ti60合金原始微观组织为等轴组织,由近等轴的初生α相和β转变组织组成。通过金相分析软件测得的初生α相的含量约为75%(体积分数)。

图1 Ti60合金原始微观组织

Fig. 1 Initial microstructure of Ti60 alloy

等温恒应变速率压缩实验在Thermecmaster-Z型热模拟试验机上进行,压缩试样为d 8 mm×12 mm的圆柱体。为减小热压缩过程中试样出现鼓肚,在试样两端垫云母片以降低压头与试样之间的摩擦。压缩试样的变形温度分别为850、900、920和950 ℃;应变速率分别为0.001、0.01、0.1、1和10 s-1。在每个变形条件下,以10 ℃/s的加热速度将试样升温到要求的变形温度后保温5 min。保温结束后以实验设定的应变速率对试样进行压缩,压缩至应变为0.51后结束压缩,然后以50 ℃/s的冷却速度(氩气冷却)冷却,以冻结高温变形组织。实验过程中,通过Thermecmaster-Z型热模拟试验机上配置的专用数据采集软件,获得不同热变形条件下的流动应力-应变数据。采用线切割方法,沿压缩试样的轴向对半剖开并制备金相试样,经研磨-抛光-腐蚀(采用HF、HNO3和H2O体积比为1:3:6的HF+HNO3+ H2O腐蚀液)后在XJP-6A型金相显微镜上进行微观组织观察。

2 结果与分析

2.1 流动应力-应变曲线

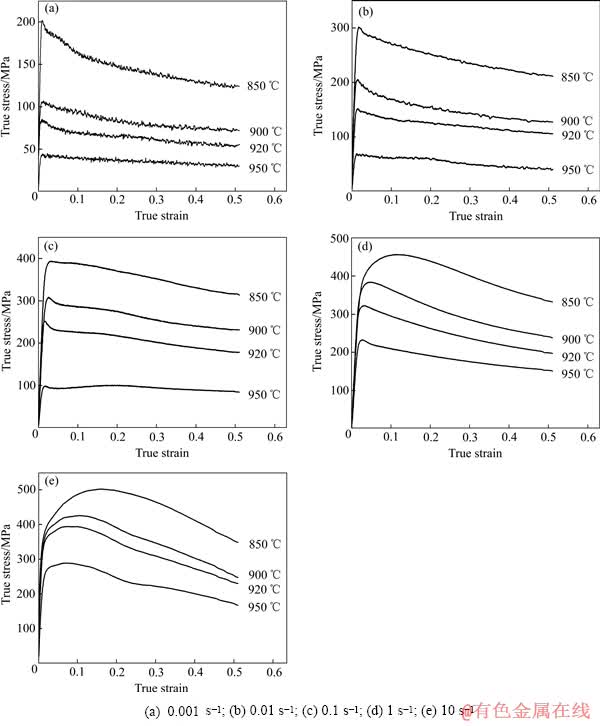

图2所示为Ti60合金在不同热变形条件下的流动应力-应变曲线。由图2可知,热变形初期,流动应力在经历了较明显的加工硬化后迅速达到峰值,然后随着应变量的增加,不同应变速率条件下的流动应力- 应变曲线呈现出不同的流动特征。在低应变速率(0.001~0.1 s-1)条件下变形时,流动应力-应变曲线大致呈现流动稳态型,而在高应变速率(1~10 s-1)条件下变形时,大致呈现流动软化型。

在热压缩实验中,合金的流动应力-应变曲线是其微观组织变化的宏观体现。根据合金软化机制的不同,流动应力-应变曲线分别呈现流动稳态型和流动软化型[13]。通常认为,当合金的流动应力-应变曲线呈现流动稳态型时,其软化机制以动态回复(DRV)为主,而当呈现流动软化型时,其软化机制以动态再结晶(DRX)为主。但文献[14]的作者在研究Al-5Zn-2Mg时发现,虽然合金的流动应力-应变曲线呈现流动软化型,但其软化机制仍为DRV,此时流动应力-应变曲线的流动软化行为主要是温升效应所致。

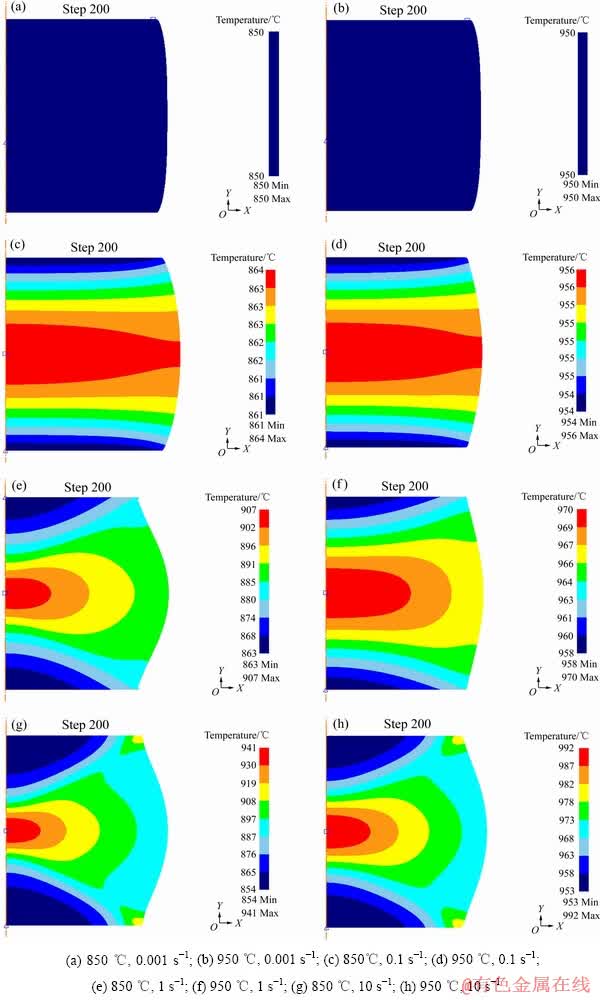

众所周知,钛合金的导热系数较低,故钛合金在高温压缩变形时,变形功产生的热能有可能会因热交换散热不充分而导致试样温度提高。为考察Ti60合金在高温变形过程中的温升情况,现采用DEFORM有限元软件,对该合金在低应变速率区间((850 ℃,0.001 s-1)、(950 ℃,0.001 s-1)、(850 ℃,0.1 s-1)、(950 ℃,0.1 s-1))和高应变速率区间((850 ℃,1 s-1)、(950 ℃,1 s-1)、(850 ℃,10 s-1)、(950 ℃,10 s-1))的压缩变形过程的温度场进行模拟计算,其结果如图3所示。从图3(a)~(d)可知,当合金在低应变速率(0.001~0.1 s-1)条件下变形时,变形试样中的温升不显著,温升范围在0~14 ℃之间,其中,最高温升(14 ℃)发生在(850 ℃,0.1 s-1)条件下(见图3(c));而在(0.001 s-1,850~950 ℃)条件下,试样因变形速率小,有充足时间进行热交换散热而导致基本上没有温升发生(见图3(a)和3(b))。从图3(e)~(h)可知,当合金在高应变速率(1~10 s-1)条件下变形时,变形试样中的温升较显著,温升范围在20~91 ℃之间,且应变速率越高,变形温度越低,温升效应越显著,其中,最高温升(91 ℃)发生在(850 ℃,10 s-1)条件下(见图3(g));而最低温升(20 ℃)发生在(950 ℃,1 s-1)条件下(见图3(e))。

图2 Ti60合金在不同热变形条件下的流动应力-应变曲线

Fig. 2 Flow stress-strain curves of Ti60 alloy under different thermal deformations

因此,结合上述不同变形条件下的温度场的计算结果可以初步判定,Ti60合金在低应变速率(0.001~0.1 s-1)条件下,其流动应力-应变曲线呈稳态流动型的软化机制以DRV为主;而在高应变速率(1~10 s-1)条件下,其流动应力-应变曲线呈流动软化型,有可能是因温升所致,也可能是DRX和温升的综合作用所致,故高应变速率条件下的软化机制还需要补充其他证据来进一步证实和说明。

2.2 加工硬化率

材料的加工硬化率( )定义为流动应力随应变变化的速率,它揭示了微观组织变化的内在特征[15-16],因此可作为判别合金软化机制的重要参量。POLIAK等[17]在考虑不可逆热力学基础上,认为材料发生DRX时,其θ-σ曲线会呈现拐点特征,即

)定义为流动应力随应变变化的速率,它揭示了微观组织变化的内在特征[15-16],因此可作为判别合金软化机制的重要参量。POLIAK等[17]在考虑不可逆热力学基础上,认为材料发生DRX时,其θ-σ曲线会呈现拐点特征,即 =0。为了更清楚地描述加工硬化率的变化,利用偏导数的性质进行推导可得:

=0。为了更清楚地描述加工硬化率的变化,利用偏导数的性质进行推导可得: ,这说明材料发生DRX时,不仅θ-σ曲线呈现拐点特征,而且

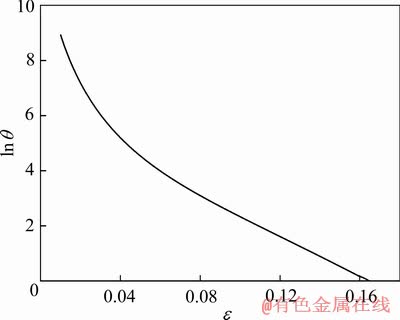

,这说明材料发生DRX时,不仅θ-σ曲线呈现拐点特征,而且 曲线也必然出现相应的拐点特征。由此,可根据lnθ-ε曲线的拐点特征来判断Ti60合金的软化机制中是否存在DRX。

曲线也必然出现相应的拐点特征。由此,可根据lnθ-ε曲线的拐点特征来判断Ti60合金的软化机制中是否存在DRX。

图3 Ti60合金在不同热变形条件下压缩至真应变0.51时的温度场

Fig. 3 Temperature field of Ti60 alloy compressed at 0.51 under different thermal deformation conditions

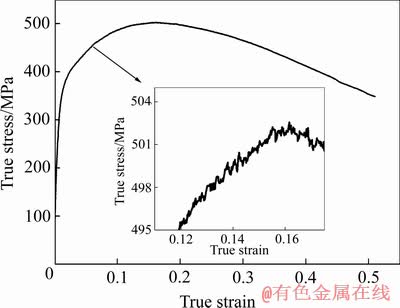

图4所示为 Ti60合金在变形温度850 ℃、应变速率10 s-1时的流动应力-应变曲线。从图4中的局部放大图可知,Ti60合金的流动应力-应变曲线并不是光滑的,因此,难以直接计算流动应力-应变曲线的斜率(加工硬化率θ)。故先对流动应力-应变曲线进行非线性拟合处理,再依据 来求解加工硬化率θ,最后绘制

来求解加工硬化率θ,最后绘制 关系曲线。

关系曲线。

图4 Ti60合金在变形温度850 ℃、应变速率10 s-1时的流动应力-应变曲线

Fig. 4 Flow stress-strain curves of Ti60 alloy under deformation temperature 850 ℃ and strain rate 10 s-1

现以Ti60合金在变形温度850 ℃,应变速率 10 s-1时的流动应力-应变曲线为例来阐述加工硬化率θ的求解过程。先对图4中的流动应力-应变曲线进行非线性拟合,得到式(1)所示的拟合方程:

(1)

(1)

由式(1)及 的关系,可求出加工硬化率θ,从而得到如图5所示的

的关系,可求出加工硬化率θ,从而得到如图5所示的 关系曲线。

关系曲线。

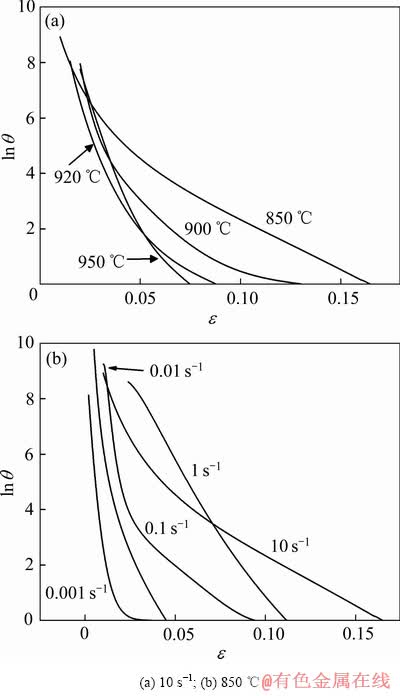

采用上述方法可绘制出Ti60合金在应变速率为10 s-1时不同变形温度下的 关系曲线,以及在变形温度为850 ℃时不同应变速率下的

关系曲线,以及在变形温度为850 ℃时不同应变速率下的 关系曲线,其结果如图6所示。从图6可知,这些变形条件下的

关系曲线,其结果如图6所示。从图6可知,这些变形条件下的 关系曲线均未出现拐点特征,而且,由其它热变形条件下的

关系曲线均未出现拐点特征,而且,由其它热变形条件下的 关系曲线(为避免冗长,文中未给出)也未出现拐点特征。这就表明,Ti60合金在所研究的热变形参数范围内没有发生DRX,因此,图2(d)和(e)中所示的高应变速率(1~10 s-1)区间的流动应力-应变曲线呈流动软化型主要是由温升所致,而非DRX所引起。

关系曲线(为避免冗长,文中未给出)也未出现拐点特征。这就表明,Ti60合金在所研究的热变形参数范围内没有发生DRX,因此,图2(d)和(e)中所示的高应变速率(1~10 s-1)区间的流动应力-应变曲线呈流动软化型主要是由温升所致,而非DRX所引起。

图5 Ti60合金在变形温度850 ℃、应变速率10 s-1时的 关系曲线

关系曲线

Fig. 5 Relationship curves of  for Ti60 alloy under deformation temperature of 850 ℃ and strain rate of 10 s-1

for Ti60 alloy under deformation temperature of 850 ℃ and strain rate of 10 s-1

图6 Ti60合金在不同变形温度和应变速率时的 关系曲线

关系曲线

Fig. 6 Relationship curves of  for Ti60 alloy under different deformation temperatures and different strain rate

for Ti60 alloy under different deformation temperatures and different strain rate

通过上述加工硬化率θ的计算和 关系曲线的无拐点特征可以判定,Ti60合金在低应变速率((0.001~0.1 s-1)区间和高应变速率(1~10 s-1)区间的软化机制均以DRV为主。

关系曲线的无拐点特征可以判定,Ti60合金在低应变速率((0.001~0.1 s-1)区间和高应变速率(1~10 s-1)区间的软化机制均以DRV为主。

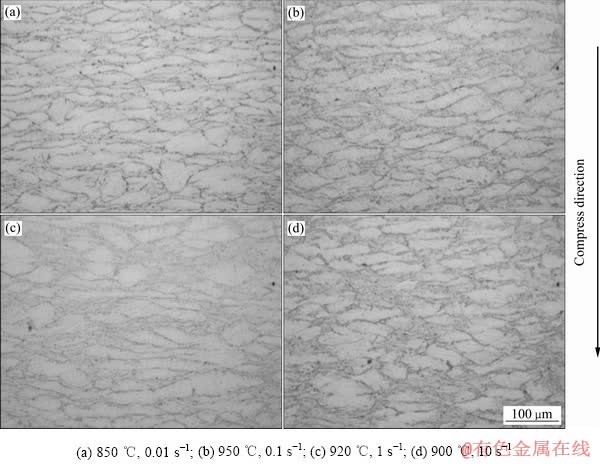

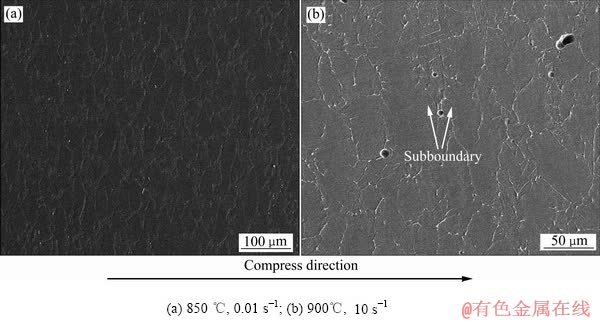

2.3 变形微观组织

图7和8所示分别为Ti60合金在不同热变形条件下微观组织的金相和SEM像。从图7和8中可以看出,在不同的热变形条件下,Ti60合金中的原始等轴状的初生α相(见图1)均沿垂直于压缩轴方向被压扁成短条状,呈现出典型的DRV组织特征,组织中未发现DRX现象,在晶界上也未发现DRX小晶粒的存在,但在晶界附近可以隐约看到亚晶界的存在(见图8(b))。因此,从不同热变形条件下微观组织观察上也进一步证实了Ti60合金在实验参数范围内的软化机制是DRV,而不是DRX。

图7 Ti60合金在不同热变形条件下显微组织的金相照片

Fig. 7 Metallographic images of microstructure of Ti60 alloy under different thermal deformation conditions

图8 Ti60合金在不同热变形条件下显微组织的SEM像

Fig. 8 SEM images of microstructure of Ti60 alloy under different thermal deformation conditions

此外,从图7还可以看出,Ti60合金在不同变形条件下的微观组织大致相同,这对稳定连续SiC纤维增强Ti60基复合材料的热压或热等静压工艺,获得组织性能稳定一致的连续SiC纤维增强Ti60基复合材料构件是有益的,由于连续SiC纤维增强Ti60基复合材料构件在实际热压或热等静压制备过程中,变形温度和应变速率总是存在一定的波动范围,而这种波动不会引起变形组织的明显变化。

2.4 热变形激活能

在热变形过程中,材料的流动应力与热变形参数之间的关系可用式(2)~(4)所示的Arrhenius方程来表示[18, 20]:

式中: 为应变速率(s-1);

为应变速率(s-1); 为应力水平参数(m2/N);

为应力水平参数(m2/N); 为流动应力(MPa);

为流动应力(MPa); 为应力指数;

为应力指数; 为变形激活能(J/mol);R为理想气体常数,取R=8.314 J/(mol·K);T为热力学温度(K);

为变形激活能(J/mol);R为理想气体常数,取R=8.314 J/(mol·K);T为热力学温度(K); 为结构因子(s-1),且

为结构因子(s-1),且 ,

, 。

。

由式(2)、(3)和(4)可得

当温度恒定时,由式(5)可得

(8)

(8)

当应变速率恒定时,由式(5)可得

(9)

(9)

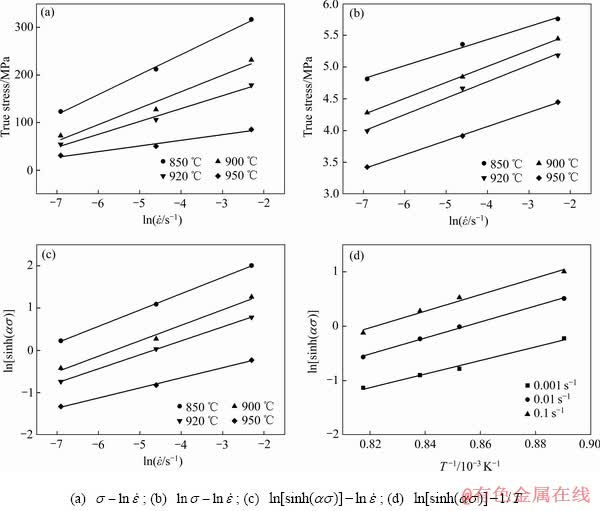

考虑到Ti60合金的流动应力-应变曲线在低应变速率区间(0.001~0.1 s-1)和高应变速率区间(1~10 s-1)分别呈现出不同的流动特征,故应用式(9)计算该合金变形激活能Q时,将分低应变速率区间和高应变速率区间来计算。

图9(a)和(b)所示分别为Ti60合金在低应变速率区间时不同温度下的 和

和 关系图,图9(a)和 (b)中各直线斜率的倒数分别为不同温度下的

关系图,图9(a)和 (b)中各直线斜率的倒数分别为不同温度下的 和n值,取其平均值可得

和n值,取其平均值可得 =0.043,n=4.29,由此可得

=0.043,n=4.29,由此可得 =0.012。图9(c)和(d) 所示分别为Ti60合金在低应变速率区间时不同温度下的

=0.012。图9(c)和(d) 所示分别为Ti60合金在低应变速率区间时不同温度下的 和不同应变速率下的

和不同应变速率下的 关系图,图9(c)中各直线斜率的倒数为不同温度下的n值,图9(d)中各直线的斜率为不同应变速率下的k值,分别取其平均值可得n=4.12,k=14.14,再代入式(9)中可得Ti60合金在低应变速率区间时的Q=484.35 kJ/mol。

关系图,图9(c)中各直线斜率的倒数为不同温度下的n值,图9(d)中各直线的斜率为不同应变速率下的k值,分别取其平均值可得n=4.12,k=14.14,再代入式(9)中可得Ti60合金在低应变速率区间时的Q=484.35 kJ/mol。

同样地,通过上述过程可求得Ti60合金在高应变速率区间的n=4.35,Q=500.76 kJ/mol。由此可知,Ti60合金在低应变速率区间和高应变速率区间的变形激活能Q相差不大,这说明该合金在低应变速率区间和高应变速率区间应为相同的软化机制。

变形激活能Q代表了原子跃迁所需要克服的能垒大小,是反映合金变形难易程度的重要参量[21-22]。通常认为,当钛合金的变形激活能Q接近于纯钛中α相的自扩散激活能(242 kJ/mol)[23]时,其软化机制以DRV为主;当变形激活能远高于纯钛中α相自扩散激活能时,其软化机制以DRX为主[24]。这是由于DRV过程中, 材料内部空位、位错等缺陷的迁移、重排和湮灭都是通过扩散机制来实现的,因此,其激活能与纯钛中α相的自扩散激活能相近;而DRX过程是通过晶粒的形核和长大来实现的,且需要比空位扩散过程更多的能量,因此DRX过程所需的激活能要远高于纯钛中α相的自扩散激活能。

如前所述,综合前面流动应力-应变曲线的流动特征、加工硬化率的无拐点特征以及变形微观组织的观察可知,Ti60合金的软化机制以DRV为主。这说明,虽然Ti60合金在低应变速率区间的变形激活能(484.35 kJ/mol)和高应变速率区间的变形激活能(500.76 kJ/mol)均比纯钛中α相自扩散激活能要高出不少,但其软化机制仍是以DRV为主。这可能与如下几个因素有关:1) 所研究的Ti60合金中,初生α相含量高(体积比约为75%),而α相属密排六方结构,与体心立方的β相相比,其具有较少的滑移系,属于脆性相,从而导致变形激活能较高;2) 本文研究的变形温度较低,属于(α+β)两相区变形(Ti60的β转变温度为1050 ℃),较低的变形温度会使合金塑性变形的难度增加,这也会导致变形激活能提高;3) Ti60合金因具有高的层错能[25],故其扩展位错宽度窄、易集束,这有利于位错的交滑移和攀移,使异号位错相互抵消,

图9 Ti60合金的关系图

Fig. 9 Relationship diagram of Ti60 alloy

位错密度下降,畸变能降低,从而难以达到DRX所需的能量,故其软化机制以DRV为主。

变形激活能明显高于纯钛中α相自扩散激活能时,软化机制仍以DRV为主的现象在其它钛合金中也有出现。例如,BAO等[26]在研究Ti-1023合金的变形行为和变形机制时发现,该合金在(α+β)两相区(650~800 ℃),应变速率为0.001~0.1 s-1,真应变为0.6条件下的变形激活能为322 kJ/mol,但其软化机制为DRV;文献[27]中IMI550合金的高温流动应力分析结果表明,该合金在(α+β)两相区(900~950 ℃),应变速率为4.2×10-4~4.2×10-2 s-1,压下量为50%条件下的变形激活能高达637 kJ/mol,但其软化机制仍然是DRV。这些研究结果也间接地说明了本文研究结果的合理性和准确性。

3 结论

1) Ti60合金的流动应力-应变曲线在低应变速率(0.001~0.1 s-1)条件下呈现流动稳态型,在高应变速率(1~10 s-1)条件下呈现流动软化型。

2) Ti60合金在低应变速率(0.001~0.1 s-1)区间由塑性功产生的温升较小,而在高应变速率(1~10 s-1)区间由塑性功产生的温升较大。高应变速率区间的流动应力-应变曲线呈流动软化型主要是由温升所致,而不是因动态再结晶所致。

3) 通过分析流动应力-应变曲线的流动特征,并综合考虑加工硬化率、变形微观组织和变形激活能,确定了Ti60合金在实验参数范围内的软化机制以动态回复为主。

4) Ti60合金在不同变形条件下的微观组织大致相同,这对稳定连续SiC纤维增强Ti60基复合材料的热压或热等静压工艺,获得组织性能稳定一致的连续SiC纤维增强Ti60基复合材料构件是有益的。

REFERENCES

[1] 张 军, 汪 洋, 王 宇. TC11钛合金应变率相关力学行为的实验和本构模型[J]. 中国有色金属学报, 2017, 27(7): 1369-1375.

ZHANG Jun, WANG Yang, WANG Yu. Experiment and constitutive model of rate-dependent behavior of titanium alloy TC11[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(7): 1369-1375.

[2] 王克鲁, 鲁世强, 李 鑫, 董显娟. Ti-5.6Al-4.8Sn-2.0Zr- 1.0Mo-0.35Si-0.85Nd合金α+β两相区变形行为及工艺参数优化[J]. 中国有色金属学报, 2017, 27(4): 724-731.

WANG Ke-lu, LU Shi-qiang, LI Xin, DONG Xian-juan. Deformation behavior and process parameter optimization of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd alloy in α+β forging process[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(4): 724-731.

[3] 罗文忠, 孙 峰, 赵小花, 张晓园, 雷锦文. 固溶处理对Ti60合金组织及拉伸性能的影响[J]. 稀有金属材料与工程, 2017, 46(12): 3967-3971.

LUO Wen-zhong, SUN Feng, ZHAO Xiao-hua, ZHANG Xiao-yuan, LEI Jin-wen. Influence of solution treatment on the microstructure and mechanical property of Ti60 alloy[J]. Rare Metal Materials and Engineering, 2017, 46(12): 3967-3971.

[4] ZHAO Z L, LI H, FU M W, GUO H Z, YAO Z K. Effect of the initial microstructure on the deformation behavior of Ti60 titanium alloy at high temperature processing[J]. Journal of Alloys and Compounds, 2014, 617: 525-533.

[5] 成小乐, 尹 君, 屈银虎, 符寒光, 赵 冰. 连续碳化硅纤维增强钛基(SiCf/Ti)复合材料的制备技术及界面特性研究综述[J]. 材料导报, 2018, 32(3): 796-807.

CHENG Xiao-le, YIN Jun, QU Yin-hu, FU Han-guang, ZHAO Bing. Areview of the state-of-art preparation technology and interface characteristics of continuous-silicon-fiber-reinforced titanium matrix (SiC f/Ti) composites[J]. Materials Review, 2018, 32(3): 796-807.

[6] 孔 旭, 王玉敏, 张 旭, 杨 青, 张国兴, 杨丽娜, 杨 锐. SiCf/Ti60复合材料的热稳定性[J]. 稀有金属材料与工程, 2017, 46(增刊): 71-75.

KONG Xu, WANG Yu-ming, ZHANG Xu , YANG Qing, ZHANG Guo-xing, YANG Li-na, YANG Rui. Thermal stability of SiCf/Ti60 composites[J]. Rare Metal Materials and Engineering, 2017, 46(Supple): 71-75.

[7] 黄 浩, 王敏涓, 李 虎, 李四青, 张书铭, 李臻熙, 黄 旭, 解 川. 连续SiC纤维增强钛基复合材料研制[J]. 航空制造技术, 2018, 61(14): 26-36.

HUANG Hao, WANG Min-Juan, LI Hu, LI Si-qing, ZHANG Shu-ming, LI Zhen-xi, HUANG Xu, XIE Chuan. Preparation of SiC fibers reinforced titanium matrix composites[J]. Aerospace Manufacturing Technology, 2018, 61(14): 26-36.

[8] LUO J, LI M Q. Strain rate sensitivity and strain hardening exponent during the isothermal compression of Ti60 alloy[J]. Materials Science and Engineering A, 2012, 538: 156-163.

[9] 赵子博, 王清江, 刘建荣, 陈志勇. Ti60钛合金的热压缩变形行为[J]. 中国有色金属学报, 2013, 23(1): 217-220.

ZHAO Zi-bo, WANG Qing-jiang, LIU Jian-rong, CHEN Zhi-yong. Hot compression deformation behavior of Ti60 alloy with lamellae microstructure[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 217-220.

[10] 徐文臣, 单德彬, 李春峰, 吕 炎. TA15钛合金的动态热压缩行为及其机理研究[J]. 航空材料学报, 2005, 25(4): 10-15.

XU Wen-chen, SHAN De-bin, LI Chun-feng, Lü Yan. Study on the dynamic hot compression behavior and deformation mechanism of TA15 Titanium alloy[J]. Journal of Aeronautical Materials, 2005, 25(4): 10-15.

[11] 蔡 赟, 孙朝阳, 万 李, 阳代军, 周庆军, 苏泽兴. AZ80镁合金动态再结晶软化行为研究[J]. 金属学报, 2016, 52(9): 1123-1132.

CAI Yun, SUN Chao-yang, WAN Li, YANG Dai-jun, ZHOU Qing-jun, SU Ze-xing. Study on the dynamic recrystallization softing behavior of AZ80 magnesium alloy[J]. Acta Metallurgica Sinica, 2016, 52(9): 1123-1132.

[12] 万志鹏, 王 涛, 孙 宇, 胡连喜, 李 钊, 李佩桓, 张 勇. GH4720Li合金热变形过程动态软化机制[J]. 金属学报, 2019, 55(2): 213-221.

WAN Zhi-peng, WANG Tao, SUN Yu, HU Lian-xi, LI Zhao, LI Pei-huan, ZHANG Yong. Dynamic softening mechanisms of GH4720Li alloy during hot deformation[J]. Acta Metallurgica Sinica, 2019, 55(2): 213-221.

[13] MCQUEEN H J, RYAN N D. Constitutive analysis in hot working[J]. Materials Science & Engineering A, 2002, 322(1): 43-63.

[14] LI Luo-xin, WANG Guan, LIU Jie, YAO Zai-qi. Flow softening behavior and microstructure evolution of Al-5Zn-2Mg aluminum alloy during dynamic recovery[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 42-48.

[15] 王忠堂, 霍 达, 于晓林. 基于新加工硬化率方法的AZ80镁合金动态再结晶临界条件[J]. 中国有色金属学报, 2018, 28(10): 30-37.

WANG Zhong-tang, HUO Da, YU Xiao-lin. Critical conditions of dynamic recrystallization of AZ80 magnesium alloy based on a new method of work hardening rate[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(10): 30-37.

[16] PRASAD G V, GOERDELER M, GOTTSTEIN G. Work hardening model based on multiple dislocation densities[J]. Materials Science and Engineering A, 2005, 400/401: 231-233.

[17] POLIAK E I, JONAS J J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization[J]. Acta Materialia, 1996, 44(1): 127-136.

[18] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[19] 万 帆, 运新兵, 毕 胜, 裴久杨. 铝锶合金高温塑性变形行为及本构方程[J]. 中国有色金属学报, 2018, 28(5): 888-896.

WAN Fan, YUN Xin-bing, BI Sheng, PEI Jiu-yang. Pyroplastic deformation behavior and constitutive equation of Al-Sr alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(5): 888-896.

[20] CAHNG Li-li, ZHENG Li-wei. Isothermal compression behavior and constitutive modeling of Ti-5Al-5Mo-5V- 1Cr-1Fe alloy[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(6): 1114-1122.

[21] LIU Lei, WU Xun-xin, GONG Hai, WANG Kai. Modification of constitutive model and evolution of activation energy on 2219 aluminum alloy during warm deformation process[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(3): 448-459.

[22] 熊尚武, 潘清林, 张 豪, 范 曦, 王向东, 刘丽丽. 喷射成形7055铝合金的热变形行为及显微组织演变[J]. 中国有色金属学报, 2018, 28(5): 863-871.

XIONG Shang-wu, PAN Qing-lin, ZHANG Hao, FAN Xi, WANG Xiang-dong, LIU Li-li. Hot deformation behavior and microstructure evolution of spray formed 7055 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(5): 863-871.

[23] VO P, JAHAZI M, YUE S, BOCHER P. Flow stress prediction during hot working of near-α titanium alloys[J]. Materials Science and Engineering A, 2007, 447(1/2): 99-110.

[24] XU Xin, DONG Li-min, BA Hong-bo, ZHANG Zhi-qiang, YANG Rui. Hot deformation behavior and microstructural evolution of beta C titanium alloy in β phase field[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(11): 2874-2882.

[25] PARTRIDGE P G. The crystallography and deformation modes of hexagonal close-packed metals[J]. Metallurgical Reviews, 1967, 12(1): 169-194.

[26] BAO Ru-qiang, HUANG Xu, CAO Chun-xiao. Deformation behavior and mechanisms of Ti-1023 alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(2): 274-280.

[27] ROBERTSON D G, MCSHANE H B. Analysis of high temperature flow stress of titanium alloys IMI 550 and Ti-10V-2Fe-3Al during isothermal forging[J]. Materials Science and Technology, 1998, 14(4): 339-345.

Softening mechanism of Ti60 alloy during hot deformation

WANG Tian-xiang1, LU Shiq-iang1, WANG Ke-lu1, OUYANG De-lai2, YAO Quan1

(1. School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The isothermal compression tests of Ti60 alloy were conducted on the Thermecmaster-Z thermal simulator, through analyzing the flow stress-strain curve characteristics, calculating work hardening rate, observing deformation microstructure of alloy and the deformation activation energy, the softening mechanism is that deformation temperature of 850-950 ℃, the strain rate of 0.001-10 s-1 and true strain of 0.51. The results show that flow stress-strain curve of Ti60 alloy presents the flow steady state under low stain rate (0.001-0.1 s-1) and flow softening state under high stain rate (1-10 s-1), respectively. The curve of work hardening rate shows no inflection point. The microstructure of deformation is dynamic recovery microstructure without dynamic recrystallization. The activation energy of deformation is 484.35 kJ/mol under low stain rate and 500.76 kJ/mol under high stain rate, with little difference between them. Comprehensively based on these results, it can be concluded that the softening mechanism of Ti60 alloy is mainly dynamic recovery.

Key words: Ti60 alloy; work hardening rate; deformation microstructure; deformation activation energy; softening mechanism

Foundation item: Projects(51964034, 51761029) supported by the National Natural Science Foundation of China; Project(YC2018-S365) supported by the Graduate Student Innovation Foundation of Jiangxi Province, China

Received date: 2019-04-26; Accepted date: 2019-11-02

Corresponding author: LU Shi-qiang; Tel: +86-13870819637; E-mail: niatlusq@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51964034,51761029);江西省研究生创新基金资助项目(YC2018-S365)

收稿日期:2019-04-26;修订日期:2019-11-02

通信作者:鲁世强,教授,博士;电话:13870819637;E-mail:niatlusq@126.com