文章编号:1004-0609(2013)S1-s0217-04

Ti60钛合金的热压缩变形行为

赵子博,王清江,刘建荣,陈志勇

(中国科学院 金属研究所,沈阳 110016)

摘 要:利用Gleeble-3800型热模拟机研究了板条组织Ti60钛合金在温度910~1 085 ℃、应变速率0.001~10 s-1条件下的热压缩变形行为,计算该合金的变形激活能,确立了峰值应力处的流变应力本构方程。结果表明:合金峰值应力随着变形温度的升高和变形速率的降低而降低。应变速率对合金的流变应力的大小有显著影响,在910~970 ℃时该合金的流变应力对变形温度的敏感性大于在1 000~1 085 ℃时的。合金在不同温度区间具有不同的变形激活能与热变形本构关系。

关键词:Ti60合金;热变形;峰值应力;本构关系

中图分类号:TG146.2 文献标志码:A

Hot compression deformation behavior of Ti60 alloy with lamellae microstructure

ZHAO Zi-bo, WANG Qing-jiang, LIU Jian-rong, CHEN Zhi-yong

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The hot compression deformation behavior of near-α titanium alloy Ti60 with lamellar microstructure was investigated at the temperature range of 910-1 085 ℃ and strain rate of 0.001-10 s-1 by compression testing under isothermal hot working. The results show that the peak stress of this alloy decreases with the increase of deformation temperature and the decrease of strain rate. The flow stress is more sensitive to strain rate and influenced by temperature more obvious at the temperature of 910-970 ℃ than 1 000-1 085 ℃. The constitutive equations fitting peak stress state for hot deformation of Ti60 alloy is obtained. Different activation energy and constitutive equations are obtained when the range of deformation temperature are changed.

Key words: Ti60 alloy; hot working; peak stress; constitutive relationship

随着航空工业的不断发展,具有较高比强度的高温钛合金日益受到人们的重视[1]。Ti60钛合金是一种能在600 ℃长期服役的近α钛合金,具有良好的综合力学性能、热稳定性和高温抗氧化性能,可用来制作先进航空发动机的压气机整体叶盘零件。该合金铸锭一般经β单相区开坯、多火次的(α+β)两相区锻造以及热处理过程得到初生α相含量为5%~30%的双态组织,使材料的疲劳以及高温蠕变性能得到良好匹配。但Ti60钛合金的热加工窗口比较窄,导致其组织与性能对热加工过程比较敏感[2-3]。因此,研究Ti60钛合金的热变形行为,对其大型锻件的变形和成形过程的数值模拟以及显微组织的精确控制具有重要的理论指导意义与工程应用价值。

在此,本文作者通过Ti60钛合金的热模拟试验,研究了Ti60在(α+β)两相区以及β单相区的热变形行为,分析材料在高温变形中流变应力、变形速率以及变形温度之间的关系,给出了材料的流变应力本构方程。

1 实验

本实验所用Ti60钛合金为d 32 mm的精锻棒材,合金化学成分为(质量分数):5.6%Al,3.7%Sn,3.2%Zr,0.5%Mo,1.0%Ta,0.37%Si,余量为Ti。合金的β转变温度t(α+β)/β=1 040 ℃,棒材经(1 060 ℃,15 min,FC)热处理得到片层组织。

沿棒材轴向机加成d8 mm×12 mm的热模拟样品。试样以5 ℃/s速度加热至变形温度,保温10 min后开始变形。变形温度为910、940、970、1 000、1 030、1 045、1 065、1 085 ℃;应变速率为0.001、0.01、0.1、1、10 s-1;变形量为75%。

2 结果与分析

2.1 真应力—应变曲线

不同变形温度及速率下的真应力—应变曲线如图1所示,在变形初期,流变应力随着应变量的增加而急剧增加,在应变量约为0.02~0.03时,流变应力达到峰值。然后,随着应变量的增加,不同变形条件下呈现出不同的软化特性,材料流变应力对变形速率的变化比较敏感,相同变形温度下随着变形速率的增加,流变应力急剧增大。应力—应变曲线在不同的温度区间呈现出不同的软化特征。在910~970 ℃,随着变形温度的升高,流变应力降低幅度较大。在变形温度升高至1 000 ℃时,流变应力对温度的敏感性降低。在低温及高温高应变速率变形时,流变应力达到峰值后呈现出持续软化的特性。二者均符合单峰动态再结晶的特点。在高温低应变速率变形时,材料流变应力随着应变的增加迅速降低至以恒定值,进入稳态流变阶段,表现出β晶粒动态回复的特征。

在两相区,随着变形温度的升高,α相含量逐渐减少(图2)。在低温变形时,α为主要变形相,变形机制主要为α板条的变形与再结晶,变形过程中,α板条转化为等轴α相。随着温度的升高,较软的β相逐渐成为主要变形相;在高温高应变速率变形时,β相能积累起足够的位错密度使得再结晶的发生。而在较低应变速率时,具有较高层错能的β相[4]在高温变形过程中因动态回复造成的软化与加工硬化作用趋于平衡,表现为稳态流变的特点。

2.2 本构方程的建立

金属材料的热变形主要是一种热激活的过程,为了进一步确定Ti60板条组织流变应力、变形温度以及变形速率之间的关系,对其高温变形行为进行动力学分析。目前在金属的热变形过程中,变形温度与变形速率对流变应力的影响均可用Arrhenius 方程来表述,这些动力学方程主要有以下3种形式[5-9]:

(1)

(1)

(2)

(2)

(3)

(3)

式中: 为应变速率;A1、A2、A3、β和α为材料常数;n为应力指数;δ为流变应力;Q为合金表观变形激活能(kJ/mol);R为气体常数;T为热力学温度。式(3)中α可由式(1)和式(2)中n和β求得(α=β/n)。

为应变速率;A1、A2、A3、β和α为材料常数;n为应力指数;δ为流变应力;Q为合金表观变形激活能(kJ/mol);R为气体常数;T为热力学温度。式(3)中α可由式(1)和式(2)中n和β求得(α=β/n)。

图1 Ti60钛合金真应力—应变曲线

Fig. 1 True stress—true strain curves of Ti60 alloy

图2 两相区α相含量随温度的变化

Fig. 2 Change of α phase content with temperature in (α+β) region

图3 峰值应力与变形速率对数的关系

Fig. 3 Relationship between σp and ln at different temperatures

at different temperatures

根据3种动力学关系,分别计算Ti60钛合金的本构方程,发现式(2)与实验结果符合得最好,故研究采用与实验结果相关系数最好的幂指数关系描述应变速率、变形温度以及流变应力之间的关系。

对式(2)两边取对数得:

(4)

(4)

其中:

A4=lnA2-Q/(RT)。 (5)

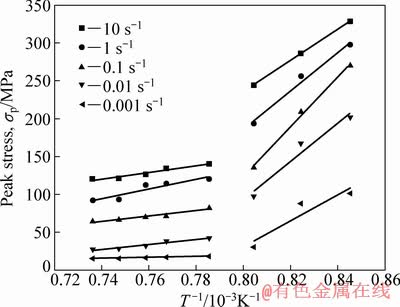

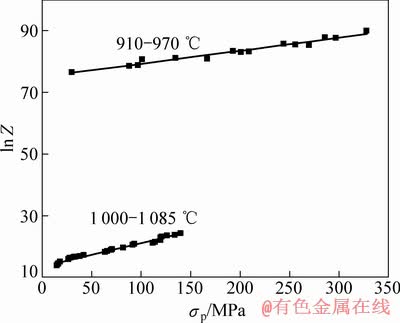

图3所示材料峰值应力与应变速率的对数在不同的温度区间分别符合各自的线性关系。经计算在910~970 ℃,材料的β值较接近平均值,为0.042 586;在1 000~1 085 ℃,材料的β值平均为0.076 35。

在一定的应变速率下取峰值应力对式(2)取自然对数并求导得:

(6)

(6)

由式(6)以及图4峰值应力与温度的倒数的关系可知,在910~970 ℃,Ti60合金中α板条的变形激活能为862.277 kJ/mol;在1 000~1 085 ℃,材料的变形激活能为232.835 kJ/mol。为概括变形温度和应变速率对热加工参数的综合影响,通常用Zener-Hollomon 表示,即

Z= exp[Q/(RT)] (7)

exp[Q/(RT)] (7)

将式(7)带入式(2)得图4 峰值应力与温度倒数的关系

Z=A2exp(βδ) (8)

图4 峰值应力与1/T的关系

Fig. 4 Relationship between σp and 1 000/T at different strain rates

图5 峰值应力与参数Z的关系

Fig. 5 Relationship between peak stress and Zener-Hollomon parameter

将不同温度区间对应的表观变形激活能Q值代入式(7)计算不同温度与应变速率条件下的Z值,根据ln Z与应峰值应力σ的关系曲线(图5)求得材料常数A2,得到Ti60钛合金在不同温度区间对应的热力学方程,如式(9)所示:

ε=3.914 5×1032exp(0.042 586δ)exp[-862 277/(RT)] (9)

在1 000~1 085 ℃温度区间内有:

ε=7.812 26×105exp(0.076 35δ)exp[-232 835/(RT)] (10)

结果表明,Ti60钛合金在不同的变形温度区间有着不同的变形机制。在910~970 ℃时,在热变形过程中主要涉及板条α相球化再结晶。钛合金在两相区变形时的表观激活能高于其自扩散能(310~720 kJ/mol)主要与α板条的再结晶有关[10] 。在1 000~1 085 ℃时的热力学激活能比β相的自扩散能(153 kJ/mol)[11]略高,表明在高两相区(1 000~1 030 ℃)与β变形速率的不同而表现出不同的规律。在单相区(1 045~1 085 ℃),其主要变形机制一致。这一现象与另一种高温钛合金Ti600的研究规律基本一致[12]。

3 结论

1) Ti60钛合金在910~970 ℃以及1 000~1 085 ℃以较高应变速率变形时,合金应力—应变曲线在变形初期迅速达到峰值后流变应力持续降低,表现出动态再结晶的特性;而在高温较低应变速率时,达到峰值应力后出现一小范围软化便进入稳态流变阶段,表现出动态回复的特性。

2) Ti60钛合金的流变应力对变形速率比较敏感,在不同的温度区间,变形温度对流变应力的的影响大小存在差异,在910~970 ℃,流变应力对温度的敏感性远高于1 000~1 085 ℃时的。

3) 建立了不同温度区间的流变应力本构方程,合金在不同的温度区间变形机制不同。

REFERENCES

[1] 张振祺, 洪 权, 杨冠军, 罗国珍. Ti600 高温钛合金蠕变前后的组织变化[J]. 材料工程, 2000, 10(4): 18-21.

ZHANG Zhen-qi, HONG Quan, YANG Guan-jun, LUO Guo-zhen. Research on microstructure of Ti600 alloy after creep test[J]. Journal of Materials Engineering, 2000, 10(4): 18-21.

[2] LI Miao-quan, XIONG Ai-ming, HUANG Wei-chao, WANG Hai-rong, SU Shao-bo, SHEN Li-chuang. Microstructural evolution and modelling of the hot compression of a TC6 titanium alloy[J]. Materials Characterization, 2002, 49(3): 203-209.

[3] GEY N, BOCHER P, UTA E, GERMAIN L, HUMBERT M. Texture and microtexture variations in a near-α titanium forged disk of bimodal microstructure[J]. Acta Materialia, 2012, 60(6): 2647-2655.

[4] GOURDET S, MONTHEILLET F. Effects of dynamic grain boundary migration during the hot compression of high stacking fault energy metals[J]. Acta Materialia, 2002, 50(11): 2801-2812.

[5] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Materials Science and Engineering A, 2002, 325(1): 112-125.

[6] RAO K P, PRASAD Y. High temperature deformation kinetics of Al-4Mg alloy[J]. Journal of Mechanical Working Technology, 1986, 13(1): 83-95.

[7] PRASAD Y, SESHACHARYULU T. Modelling of hot deformation for microstructural control[J]. International Materials Reviews, 1998, 43(6): 243-258.

[8] SHI H, MCLAREN A J, SELLARS C M, SHAHANI R, BOLINGBROKE R. Constitutive equations for high temperature flow stress of aluminium alloys[J]. Materials Science and Technology, 1997, 13(3): 210-216.

[9] MILLETT J C F, BROOKS J W, JONES I P. Assessment and modelling of isothermal forging of intermetallic compounds Part 1—TiAl[J]. Materials Science and Technology, 1999, 15(6): 697-704.

[10] WANJARA P, JAHAZI M, MONAJATI H, YUE S, IMMARIGEON J P. Hot working behavior of near-α alloy IMI834[J]. Materials Science and Engineering A, 2005, 396(1): 50-60.

[11] BALASUBRAHMANYAM V V, PRASAD Y. Deformation behaviour of beta titanium alloy Ti-10V-4.5Fe-1.5Al in hot upset forging[J]. Materials Science and Engineering A, 2002, 336(1): 150-158.

[12] 戚运连, 曾卫东, 赵永庆. Ti600 合金的高温本构方程[J]. 热加工工艺, 2006, 35(17): 5-8.

QI Yun-lian, ZENG Wei-dong, ZHAO Yong-qing. Constitutive equations for hot deformation of Ti600 alloy[J]. Hot Working Technology, 2006, 35(17): 5-8.

(编辑 杨 华)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:王清江,研究员;电话:024-83978830;E-mail:qjwang@imr.ac.cn