文章编号:1004-0609(2007)01-0131-07

块体Mg65Cu22Ni3Y10非晶态合金的制备及在焊接中的应用

陈振华,司乃潮,张扣山,赵 伟

(江苏大学 材料科学与工程学院, 镇江 212013)

摘 要:利用铜模浇铸法制备了厚度为2 mm、成分为Mg65Cu22Ni3Y10块体合金试样,并通过X射线衍射、差热扫描量热仪证实其为完全的非晶态。以镁合金AM60B为母材、2 mm厚的Mg65Cu22Ni3Y10板状非晶态合金为中间层,在420~540 ℃下进行焊接,利用金相显微镜、扫描电镜(SEM)和能谱仪研究了焊接接头的微观形貌和成分分布。结果表明:界面接合良好,未观察到片状夹杂物、气孔及未焊合等缺陷;焊缝区由块状α-Mg相和针状化合物组成,基体中的Al元素通过晶界扩散偏聚到焊缝中,微量Y元素扩散到基体中,有少量的Mn和Cu元素发生偏聚,Ni元素分布均匀,没有发生偏聚现象。

关键词:Mg65Cu22Ni3Y10;非晶态合金;扩散钎焊;相界扩散;非晶态钎料

中图分类号:TG 454 文献标识码:A

Preparation and application in welding of bulk Mg65Cu22Ni3Y10 amorphous alloys

CHEN Zhen-hua, SI Nai-chao, ZHANG Kou-shan, ZHAO Wei

(School of Material Science and Engineering, Jiangsu University, Zhenjiang 212013, China)

Abstract: Bulk Mg65Cu22Ni3Y10 alloy with thickness of 2 mm was fabricated by casting in a traditional copper mould. Full amorphous structure was confirmed by X-ray diffractometry and differential scanning calorimetry (DSC). A welding experiment was performed using Mg-based alloys AM60B as base metal and bulk Mg65Cu22Ni3Y10 amorphous alloy as interlayer between 420 ℃ and 540 ℃. The microstructures and elements distribution of the brazed joints were analyzed by metallographic microscopy, SEM and EDS. The results show that a sound bonded interface is obtained without sheet inclusion, pore and unbinding. The microstructure consists of bulk α-Mg phase and needle compound in the weld metal, element Al diffuses along the grain boundary of the substrate into the welding line. A little Y diffuses into the base metal. A little Mn and Cu segregate and element Ni distributes homogeneously and no segregation appears in weld area.

Key words: Mg65Cu22Ni3Y10; amorphous alloy; diffusion brazing; phase boundary diffusion; amorphous solder alloys

镁合金的密度一般小于2 g/cm3,是目前最轻的金属结构材料,其机械加工能量仅为铝合金的70%,而减振性能、磁屏蔽性能远优于铝合金,被人们誉为“21世纪最具发展潜力和前途的绿色工程材料”[1]。以镁为主要成分的块体金属玻璃具有相对较高的比强 度、比刚度,同时制备成本低、制备工艺简单,因此研究Mg基块体金属玻璃很有意义[2-3]。

非晶钎焊料是20世纪70年代发展起来、利用快冷法制备出的钎料, 由于其成分计量精确、熔化温度范围窄小、化学成分均匀性和显微组织均匀性高、扩散活性及附着活性高、容易流进缝隙、钎焊区无显微偏析和显微缩孔,因而可获得高强度和高耐腐蚀性的焊接接头,是一种非常有前途的钎焊料[4-5]。

由于镁合金的焊接性能较差,很难实现可靠连 接,这成为制约镁合金应用的技术瓶颈和亟待解决的关键技术之一[6]。虽然近10年来人们对镁基非晶态合金研究取得了一些突破性的进展,但目前还未能将Mg基非晶态合金应用到焊接领域。杨春秀[7]采用真空吹铸法研究了Mg65Cu25-xNixY10(x=1, 2, 3, 4, 5)的非晶合金形成能力,结果表明Mg65Cu22Ni3Y10具有最强的非晶形成能力。本文作者利用自制的成分为Mg65Cu22Ni3Y10、厚度为2 mm板状非晶态合金作钎料,采用对接接头的形式对AM60B铸态镁合金进行焊接,对一定保温时间和压力下的焊接接头形貌及组织特征进行了研究,利用光学显微镜、扫描电镜和能谱分析的方法分析了焊接接头的微观组织、元素分布和扩散行为。

1 实验

1.1 实验原料

实验原料为块状的Mg、Cu、Ni、Y,其成分分别为(质量分数):Mg 99.99%、Cu 99.95%、Ni 99.97%和Y 99.95%,及商用铸态AM60B镁合金。

1.2 非晶制备

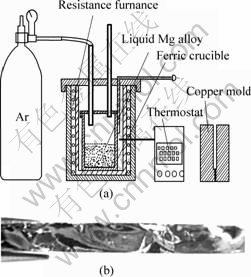

在高纯氩气保护下的非自耗电弧炉中熔炼摩尔比为22?3?10的Cu-Ni-Y中间合金,将中间合金与纯Mg按预定比例配比(为抵消熔炼过程中因镁液蒸发对成分比例的影响,配比时Mg适量增加5%(质量分数)左 右[8])。然后在通有氩气保护的电阻炉中的坩埚(低碳钢)中760 ℃保温1.5 h,最后快速将合金液浇入铜模型腔中获得2 mm厚的板状试样(图1(a)),图1(b)所示为浇铸试样的断面照片,可以看出试样断面呈现非晶态合金特有的断面特征—镜面光泽,呈银白色。采用理学D/max 2400衍射仪进行铸态试样截面的X射线衍射(XRD)分析,Perkin-Elmer DSC-7差示扫描量热计(DSC)表征评价块体金属玻璃的玻璃转变与晶化行为,加热速率为20 K/min。

图1 镁合金熔炼示意图与厚为2 mm的非晶试样

Fig.1 Sketch of prepared amorphous alloys(a) and photo of cross section of amorphous Mg65Cu22Ni3Y10 alloys with thickness of 2 mm(b)

1.3 置中间层AM60B的焊接

AM60B的焊接实验在自制的管试电阻炉中进行。该工艺同时利用了中间层非晶态合金的超塑性现象及其熔化后的液相对界面间空洞的填充作用和液相扩散比固相快的优点,在表面较平整处获得母材之间的直接扩散连接,在粗糙度大的局部主要靠液态中间层的填充与扩散实现母材间的连接,从而加速实现界面间的紧密接触,减小界面残留空洞。在实现界面间紧密接触过程中因有液相填充作用的参与,对母材超塑性变形程度的要求得以降低,也使降低焊接压力和减小变形成为可能[9]。该工艺从其内部金属流动及原子迁移的本质看, 以实现中间层的熔化→润湿母材→填充间隙(具有高温钎焊特征)、并通过使中间层变为易于扩散的液相及母材相变过程中新相与母相间的相界作为短路扩散通道, 促进中间层向母材扩散为目标(具有扩散焊特征)[10],该工艺区别于普通钎焊的地方在于加压而不加任何钎剂。

焊接前用砂纸将非晶态钎料表面打磨干净,镁合金表面用钢刷清理。这种处理一方面破坏了表面的氧化膜,增加钎料的润湿能力,同时在钢刷刷过的表面形成较粗糙的纵横交错的细槽,对钎料起了特殊的毛细管作用,促进钎料沿洁净的母材表面铺展,改善润湿[11]。

加热速率为40~45 K/min。为防止镁合金的燃烧和中间层非晶的氧化,在焊接过程中通氩气保护。

2 结果与分析

2.1 非晶形成能力分析

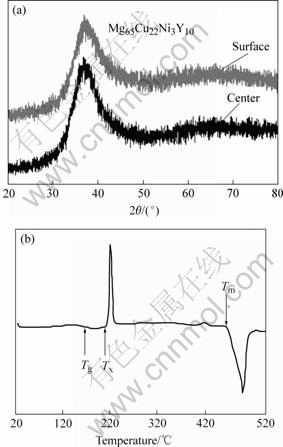

图2(a)所示为铜型浇铸2 mm厚的Mg65Cu22Ni3Y10表面和心部X射线衍射谱。由图可见,在2θ=37?附近两者都表现为典型的非晶相漫散衍射峰,无明显的晶态峰出现,这表明该成分合金可形成2 mm厚的完全非晶相的薄板。

图2 铸态Mg65Cu22Ni3Y10合金的X射线衍射及加热速率20 K/min时在晶化和熔化温度范围的连续加热DSC曲线

Fig.2 XRD patterns of as-cast Mg65Cu22Ni3Y10 alloys with thickness of 2 mm(a) and DSC curve in temperature ranges of crystallization and melting at heating rate of 20 K/min(b)

图2(b)所示为铸态Mg65Cu22Ni3Y10合金完全形成非晶相样品的DSC曲线,该成分合金的Tg、Tx、Tm分别为431.9、488.2和748.2 K,过冷液态温度区间ΔTx(ΔTx=Tx-Tg)为56.3 K。

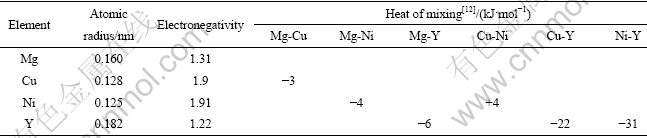

合金凝固速率、合金成分和性质是影响非晶合金形成的主要因素。合金的成分与性质一方面取决于合金系中元素之间的键合特性和混合热,另一方面取决元素原子的相对大小。对Mg65Cu22Ni3Y10中组元元素的基本特性分析表明(见表1),该体系主要组成元素之间具有较大原子尺寸差和较大负混合热,因此,合金间具有较高程度的无序密堆结构及不同于相应晶态平衡相的均匀原子排列方式。由于合金的结晶过程伴随着较大的原子结构的变化,过冷液体具有高的抗结晶热稳定性,所以合金具有高的非晶形成能力。约化玻璃转变温度Trg(Trg=Tg/Tm)作为表征非晶形成能力的参数源于对Tg~Tm或Tg~Tl温度区间内粘度的要求,只有在冷却过程中粘度随温度下降的增长率(dη/dT)足够大,才能使金属原子没有足够时间重排,从而抑制结晶获得非晶态。由对非晶态Mg65Cu22Ni3Y10合金的DSC分析可知,Trg=0.577,因此该成分的合金具有良好的热稳定性和非晶形成能力。

2.2 焊接接头形貌

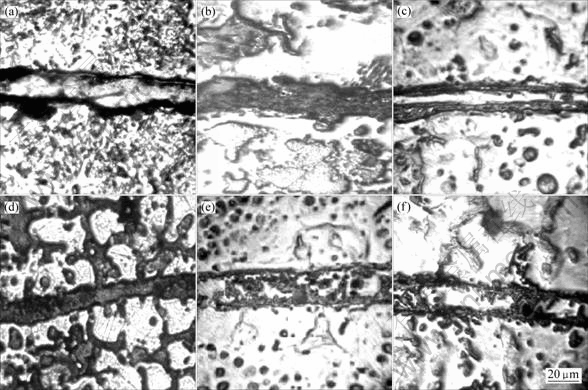

图3(a)~(f)所示是温度为420~540 ℃在光学显微镜下观察到的焊接接头形貌。

图3 焊接接头微观形貌

Fig.3 Microstructures of brazed joints at different temperatures with pressure 0.2 MPa and time of 10 min: (a) 420 ℃; (b) 450 ℃; (c) 480 ℃; (d) 500 ℃; (e) 520 ℃; (f) 540 ℃

表1 Mg65Cu22Ni3Y10组元元素的基本特性

Table 1 Basic properties of Mg65Cu22Ni3Y10 compositional elements

在低倍条件下观察中间层合金与母材界面间的结合效果时,通常看到残留的中间层变为一条线,一些文献称之为界面接合线(Bonding line)。由于本实验中间层采用的是2 mm板状非晶态合金、焊接压力较小,所以与其它采用非晶态薄带作焊接钎料的焊缝相比[10],焊缝较宽,分层更为明显。焊缝宽度随温度的升高变化不大,缝宽都在5~40 μm之间。

图3所示为典型的钎焊接头形貌,从图中可以看出,基体与中间层合金结合界面明显,因钎缝两侧的基体材料相同,故钎缝两侧的界面反应层为对称结构,界面结合紧密,未观察到未钎着部位(界面空洞) 、气孔、裂纹和不焊合等焊接缺陷。焊接接头组织存在化合物相,且出现明显的分层现象,不同温度下的焊缝形貌差别较大。在420 ℃时(图3(a)),焊缝接头分为明显的3层(从中心到两侧依次为:中间层化合物—氧化及夹杂物层—基体),中间层两侧存在较厚的氧化膜和夹杂物,与其他温度下焊接试样形貌相比,焊缝两侧的基体凸凹起伏变化较大,而其他焊缝两侧的基体基本呈现平直化状态。对于结合界面出现平直化的原 因,Takahashi等[16]的计算表明,液相对母材表面的突起部位的溶解较多, 所以使界面趋于平直化;对于既定的中间层,温度越高,母材溶解速率越快,并使液相区宽度迅速达到较大的饱和宽度。可见,结合界面在低温时凸凹、高温时平直化的原因在于温度较低时局部压缩塑性变形及液相中间层对母材的溶解作用贡献小,不能有效溶解母材表面的局部凸凹,而当温度的升高时,母材在钎料中的溶解度升高,溶解速率加快,界面趋于平直化[10]。在450 ℃施焊时(图3(b)),氧化及夹杂物层厚度大大降低;当温度升高到480 ℃时(图3(c)),中间合金两侧接合面开始出现中间合金与基体的反应层;在500 ℃焊接时(图3(d)),可以明显观察到中间层呈树枝状向两侧的基体生长,说明该温度下的液相中间层以基体相界作为短路通道向母材扩散,液态钎料与母材之间存在着激烈的元素互扩散行为;在520 ℃和540 ℃时(图3(e)和(f))焊缝两侧的氧化层和夹杂物完全消失,形成基体与中间层相互扩散后产生的扩散区。

2.3 焊缝组织及元素特征

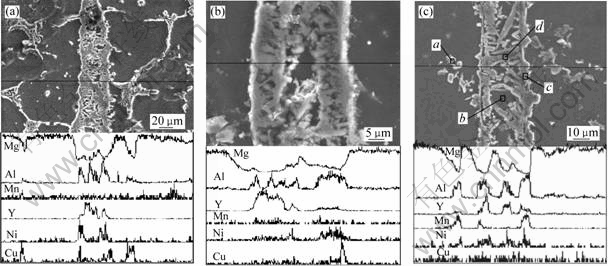

为进一步了解钎焊试样合金元素的分布及扩散行为,用JXA-840A扫描电子显微镜分别分析500 ℃(图4(a))、520 ℃(图4(b))和540 ℃(图4(c))焊接时的焊缝的显微组织及各元素的分布情况。从图4可以清晰地看出,基体为Mg-Al-Mn合金的典型组织,除了存在α-Mg相和在晶界沉淀析出的β-Mg17Al12相外,还存在含Mn的中间相。焊缝两侧没有裂纹、气孔、夹渣等焊接缺陷;基体与中间夹层之间存在明显的界面,与400倍条件下观察的焊接形貌相比,钎缝与母材结合面由直线变成了凹凸起伏的折线,这是由于中间层合金中的原子沿大角度晶界快速扩散的结果。晶粒内部的原子是按一定规律整齐排列的。晶界是不同晶粒相互接触的界面,按两个晶粒之间夹角的大小可分成小角度晶界和大角度晶界。小角度晶界是相邻两个晶粒的原子排列错合的角度很小,约2o~3o,而大角度晶界上质点的排列己接近无序状态。溶质原子在大角度晶界上的扩散激活能小于体扩散时所需的扩散激活能。因此,中间层原子沿大角度晶界渗入深度大,使固/液界面形态为非平面。

图4 钎焊接头的扫描电镜照片及合金元素的线分析

Fig.4 SEM images of brazed joint and linear scanning of elements at different temperatures: (a) 500 ℃; (b) 520 ℃; (c) 540 ℃

中间层由灰色的基体相和细小针状组织构成,且针状组织大部分沿着垂直界面方向生长(图4(c))。在凝固界面及焊缝/母材界面存在着物质的传输、转移,但液态钎料的凝固过程有其特殊性和复杂性。此时焊缝接头区域主要产生两个相对进行的过程,即液态中间层组元向母材的扩散和固态被焊母材向液态中间层的溶解。由于焊缝内液态钎料熔体的量较少,在界面区域将发生强烈的扩散和溶解过程。首先是母材在界面处向液态中间层中溶解,同时中间层中易于母材中的Al、Mn和Mg元素形成共晶体的Cu、Ni和Y元素向母材扩散,使母材与焊缝界面处处于半熔化状态,界面处一些凸缘成为非均质形核的核心,又由于在界面处温度梯度很大,结晶速度却很小( 趋近于零),成分过冷很难形成,等温凝固在界面接头处发生。凝固组织沿最大热流方向低速平面生长,形成垂直母材生长的柱状晶,凝固界面逐渐向焊缝中心移动[17-18]。在柱状晶前沿,焊缝成分发生了巨大变化,出现贫Al和富Mg、Cu微区,在液态中间层中析出α-Mg和亚稳态的Al-Cu、Mg-Cu、Al-Cu-Mg等共晶及化合物晶粒,并不断形核和长大。

在惰性气体保护条件下进行保温钎焊时,液态钎料在毛细填缝的同时就与母材发生了相互作用。根据多相扩散理论[19],在扩散系统中,所有元素都必须同时沿各自的活动梯度进行扩散,这一梯度即是每一个元素相互扩散的真正驱动力,母材和钎料中的各元素在连接界面都具有一定的浓度梯度,因而发生相互扩散,即液态钎料组元向母材的扩散和固态被焊母材向液态钎料的溶解。从图中焊缝元素的线分析可知, 500 ℃时,Mg元素扫描线在靠近界面处的过程中急剧下降,通过界面后回升幅度较小,焊缝中Mg元素扫描线为时高时低的曲线波,说明钎缝中Mg元素主要以α-Mg相(灰色块状组织)的形式分散存在,母材中Mg的含量与焊缝中的含量相差较大,基体中的Mg元素只有少量向焊缝中扩散;520 ℃和540 ℃条件下焊接试样的Mg元素扫描线在接近界面的过程中,Mg的含量缓慢降低,穿过界面后迅速升高,在焊缝中部 Mg元素的分布也不均匀,灰色的大面积区域是富 Mg区,而其中的白色条状组织中Mg的含量较少区,这说明在钎焊保温及随后的平衡凝固过程中,在钎料中均匀分布的Mg元素,由于扩散及重新分布变得不均匀,且随着温度的升高焊缝中富集Mg元素的灰色块状组织增多。

由Al的含量分析曲线可知,基体中的Al元素向焊缝发生溶解,在垂直钎缝方向的整个区域内含量明显上升,即钎缝区域内出现了富Al区,而在基体靠近界面很宽的区内出现了Al含量减少现象。产生上述结果的主要原因与金属间化合物Mg17Al12的熔点较 低,易偏析于晶界有关。在AM60B合金中,Al元素主要以β-Mg17Al12的形式沉淀析出于晶界,晶界处扩散激活 能低,是扩散的短路通道,所以在焊接过程中Al原子沿晶界迅速扩散到中间层的液态钎料。偏聚到液态中间层合金中的Al元素在随后的保温及平衡凝固过程中,同Mg元素一样,由于扩散和重新分布变得很不均匀,主要富集于白色的条状组织中。Al元素为中间层的第二主组元,且固态Al向液态中间层中的溶解快于液态中间层中的元素向固态母材中的扩散。浓度的大幅变化及浓度梯度趋向均匀说明中间层与母材间的相互作用(溶解与扩散) 得以顺利发生。这从另一个侧面也反映了界面上的氧化物未能形成接合障碍(如影响润湿或阻碍扩散),即尽管未用任何钎 剂,氧化膜也能在母材溶解过程中被以某种方式破 碎,从而使界面接合良好。

而对于Mn、Y、Cu、Ni元素, Y元素大部分分布于焊缝区、少量扩散到基体中,Mn元素只在部分微小的区出现元素的富聚和贫化,Cu和Ni元素沿垂直焊缝方向分布基本均匀,偏聚现象不是很明显。

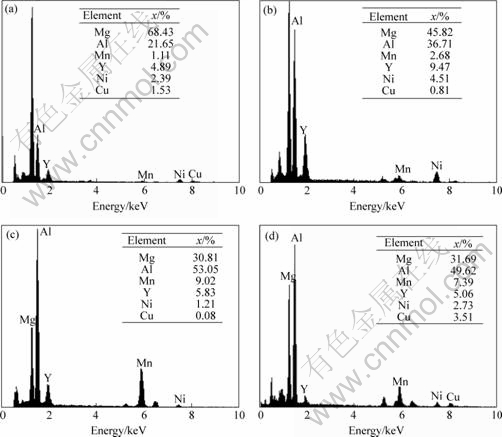

对540 ℃焊接试样焊缝区不同组织的能谱点分析(图5(a)~(d)能谱点分析分别对应图4(d)上的4个点a、b、c和d)结果表明,基体上的白色粒状化合物中除了含有Mg、Al和Mn元素外,中间层合金中的Y、Cu和Ni元素通过晶界向基体中也有一定量的扩散并且偏聚形成复杂的球状金属间化合物(图5(a)),其中Y元素的摩尔分数为4.89%,比Cu、Ni元素的含量多,但远小于元素Al的摩尔分数21.65%。焊缝中间灰色块块基体主要由Mg、Al、Y、Ni和Mn元素构成(图5(b)),其中Al元素的摩尔分数高达36.71%,含量远高于Y和Ni元素,而Cu元素的含量仅为0.81%,母材与钎料之间的相互扩散非常充分;与灰色块状组织中Mg元素含量相比,灰白色的板条状组织中Mg元素的含量大幅度下降,Al和Mn元素的含量大幅度提高,Y、Ni和Cu元素含量不同程度降低,成分接近于Al6Mn型金属间化合物与Mg的固溶体(图5(c))。对钎缝与基体结合面的能谱分析表明(图5(d)),与b、c点相比,此处Cu元素的含量有较大幅度提高, Mg和Al元素含量变化不大, Mn和 Y元素含量略有下降,这是由于非晶态合金成分和组织单一均匀,在钎焊温度下,发生熔化、流动和铺展,同时由于基体与中间层之间Al、Mn和Y元素浓度差别很大,因此在界面前沿浓度梯度的增大导致扩散系数增大,基体中溶解的Al、Mn元素和焊缝中熔解的Y、Cu元素分别迅速向焊缝扩散和基体中扩散,在界面区附近形成了一个Al、Mn、Y和Cu元素富集的区域。

图5 焊缝的能谱点分析

Fig.5 Quantitative analysis of brazing joint by EDS: (a) Spot a in Fig.4(c); (b) Spot b in Fig.4(c); (c) Spot c in Fig.4(c); (d) Spot d in Fig.4(c)

3 结论

1) 在大气环境下用铜模浇铸法制备了厚度为2 mm、成分为Mg65Cu22Ni3Y10(摩尔分数,%)的板状块体非晶态合金试样。分析试样可知,其表面和心部为完全的非晶态,玻璃转化温度(Tg)、晶化温度(Tx)和熔点(Tm)分别为431.9,488.2和748.2 K,约化玻璃转变温度(Trg)为0.577,Mg65Cu22Ni3Y10非晶态合金具有良好的热稳定性和非晶形成能力。

2) 利用制备的板状Mg65Cu22Ni3Y10非晶态合金作钎料在温度为420~540 ℃、压力为0.2 MPa、保温时间为10 min条件下焊接的AM60B合金,试样界面结合紧密,无未钎着部位(界面空洞)、气孔、裂纹、不焊合等焊接缺陷,焊缝宽度在5~40 μm之间。

3) 焊缝由块状的α-Mg相和垂直于界面生长的针状组织组成。

4) 500和520 ℃条件下焊接时Mg元素没有发生明显的扩散现象,在540 ℃时有了从基体向中间层扩散的现象。Al元素以晶界为短路通道向焊缝溶解并偏聚到焊缝中。Y元素大部分分布于焊缝区、少量扩散到基体中,Mn元素有少量的偏聚,Cu和Ni元素沿垂直焊缝方向分布基本均匀,只有少量的Cu元素偏聚于界面区附近。

REFERENCES

[1] 王迎新, 关绍康, 王建强. RE对Mg-8Zn-4Al-0.3Mn合金组织的影响[J]. 中国有色金属学报, 2003, 13(6): 6-19.

WANG Ying-xin, GUAN Shao-kang, WANG Jian-qiang. Effects of RE on microstructures of Mg-8Zn-4Al-0.3 magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 6-19.

[2] Inoue A, Kohinata M, Tasi An-ping. Mg-Ni-La amorphous alloys with a wide supercooled liquid region[J]. Mater Trans JIM, 1989, 10: 378-381.

[3] Kim G G, Inoue A, Masumoto T. High mechanical strengths of Mg-Ni-Y and Mg-Cu-Y amorphous alloys with significant super cooledliquid region [J]. Mater Trans JIM, 1990, 11: 929-934.

[4] 邹家生,许志荣,初雅杰,陈 光. 非晶态焊接材料的特性及其应用[J]. 材料导报, 2004, 18(4): 17-26.

ZOU Jia-sheng, XU Zhi-rong, CHU Ya-jie, CHEN Guang. Characteristics and application of amorphous wedding materials[J]. Materials Review, 2004, 18(4): 17-26.

[5] Bolslein O, Schwarzman A, Rabinlcin A. Induction brazing of Ti-6Al-4V alloy with amorphous 25Ti-25Zr-50Cu brazing filler metal[J]. Mater Sci Eng A, 1996, 206(2): 14-23.

[6] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 6-19.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 6-19.

[7] 杨春秀. 镁基块体非晶合金的制备及性能研究[M]. 兰州: 兰州理工大学出版社, 2005: 49.

YANG Chun-xiu. Study on the Fabrication and Property of Mg-based Bulk Amorphous[M]. Lanzhou: Lanzhou University Technology Press, 2005: 49.

[8] 申泽骥,李宝东. 铸造镁合金熔炼技术进展[J]. 中国铸造装备与技术, 2001(6): 1-3.

SHEN Ze-ji, LI Bao-dong. Technical advancement in magnesium melting[J]. China Foundry Machinery & Technology, 2001(6): 1-3.

[9] 张贵锋, 张建勋, 张 华, 裴 怡, 王士元. 预置中间层的相变超塑性焊接新工艺及其接头组织[J]. 金属学报, 2003, 39(6): 655-660.

ZHANG Gui-feng, ZHANG Jian-xun, ZHANG Hua, PEI Yi, WANG Shi-yuan. A new process of transformation superplastic bonding with interlayer and its joint microstructure[J]. Acta Metallurgica Sinica, 2003, 39(6): 655-660.

[10] 张贵锋, 张建勋, 裴 怡, 牛 靖.“相变-扩散钎焊(T/DB)”新工艺及其接头界面形貌[J]. 热加工工艺, 2004(6): 39-42.

ZHANG Gui-feng, ZHANG Jian-xun, PEI Yi, NIU Jing. New bonding process of transformation/diffusion brazing and the interfacial morphology in its joints[J]. Hot Working Technology, 2004(6): 39-42.

[11] 邹家生. 材料连接原理与工艺[M]. 哈尔滨: 哈尔滨工业大学出版社, 2005: 276-279.

ZOU Jia-sheng. Material Joining and Welding Principle and Technology[M]. Harbin: Harbin Institute of Technology Press, 2005: 276-279. (in Chinese)

[12] Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element[J]. Materials Transactions, 2005, 46(12): 2817-2829.

[13] Inoue A. Slowly-cooled bulk amorphous alloys [J]. Mater Sci Forum, 1995, 179-181: 691-700.

[14] Turnbull D. Under what conditions can a glass be formed [J]. Contemporary Physics, 1969, 10: 473-488.

[15] Shirzadi A A, Wallach E R. Analytical modeling of transient liquid phase (TLP) diffusion bonding when a temperature gradient is imposed[J]. Acta Materialia, 1999, 47(13): 3551- 3560.

[16] Takahashi Y, Morimoto K, Inoue K. Numerical analysis of liquid solid interface migration during transient liquid phase bonding[J]. Transaction of JWRI, 2001, 30(Special Issue): 535-541.

[17] 张贵锋,张建勋,王士元,邱凤翔. 瞬间液相扩散焊与钎焊主要特点之异同[J]. 焊接学报, 2002, 23(12): 92-96.

ZHANG Gui-feng, ZHANG Jian-xun, WANG Shi-yuan, QIU Feng-xiang. Similarities and differences in main characteristics between transient liquid phase bonding and brazing process[J]. Transactions of the China Welding Institution, 2002, 23(12): 92-96.

[18] 王彦芳, 王存山, 高 强, 霍树斌, 王佳杰. TiAl基合金的非晶钎焊[J]. 焊接学报, 2004, 25(2): 111-114.

WANG Yan-fang, WANG Cun-shan, GAO Qiang, HUO Shu-bin, WANG Jia-jie. Brazing of a TiAl-based alloy with Zr65Al7.5Cu27.5 amorphous ribbon[J]. Transactions of the China Welding Institution, 2004, 25(2): 111-114.

[19] Lee S J, Wu S K, Lin R Y. Infrared joining of TiAl intermetallics using Ti-15Cu-15Ni foil-the microstructural evolution at high temperature[J]. Acta Materialia, 1998, 46(4): 1297-1305.

收稿日期:2006-06-13;修订日期:2006-09-30

通讯作者:司乃潮,教授;电话:0511-8780882;E-mail: snc@ujs.edu.cn

(编辑 龙怀中)