激光焊接对块体非晶合金Zr45Cu48Al7晶化行为的影响

李 波1, 李志远1, 熊建钢1, 邢 丽2

(1. 华中科技大学 材料科学与工程学院, 武汉 430074;

2. 南昌航空工业学院 材料系, 南昌 330000)

摘 要: 采用激光焊接技术连接块体非晶合金Zr45Cu48Al7(摩尔分数, %)。 结果表明: 在焊接热循环作用下, 熔化区和热影响区的晶粒形貌和组织具有很大的差异; 焊接速率为2m/min时, 熔化区主要生成τ5(Zr38Cu36Al26)、 ZrCu和一未知相, 热影响区主要生成ZrCu相; 焊接速率为4m/min时, 熔化区保持了非晶特性, 热影响区部分晶化, 其主要生成相为ZrCu相; 热影响区的晶化行为与非晶合金热处理过程的晶化行为有一定的区别, 其主要原因是激光焊接时的高速加热及冷却过程对各晶化相生长速率影响程度不同。

关键词: 块体非晶合金; 激光焊接; 热影响区; 熔化区; 晶化行为; 热循环 中图分类号: TG139

文献标识码: A

Influence of laser welding on crystallization behaviour of Zr45Cu48Al7 bulk metallic glass

LI Bo1, LI Zhi-yuan1, XIONG Jian-gang1, XING Li2

(1. School of Materials Science and Engineering,Huazhong University of Science and Technology, Wuhan 430074, China;

2. Department of Materials Science and Engineering,Nanchang Institute of Aeronautical Technology, Nanchang 330000, China)

Abstract: Using a laser welding method, two pieces of bulk metallic glasses (BMGs)based on Zr45Cu48Al7 (mole fraction, %) were welded. The results indicate that the morphology and the structure in heat-affected zones (HAZs) are different from those in molten zone. When the welding speed is 2m/min, the majority of the crystalline phases in the molten zone are found to be τ5(Zr38Cu36Al26), ZrCu and an unknown phase, those in the HAZs are mainly ZrCu phase. While the welding speed is 4m/min, the molten zone keeps amorphous, HAZ is the discontinuous crystalline zone and the majority of the crystallites in HAZ are ZrCu phase. The crystallization behavior in HAZ is different from that of BMGs during heat-treating process, the main cause is that the effect on the growth speed of crystallization phases is different during the rapid heating and cooling process of laser welding.

Key words: bulk metallic glass; laser welding; heat-affected zone; molten zone; crystallization behavior; thermal cycle

非晶态合金以其高的强度、 韧性、 耐磨性、 耐蚀性、 优良的软磁性、 超导特性和低磁损耗等特点, 开始在电子、 机械、 化工等行业得到应用[1-6]。 块体非晶合金有三个主要问题限制了它的应用: 有限的尺寸、 缺乏可加工性和焊接性能差。 随着块体非晶合金的发展, 科研工作者开始从事块体非晶合金焊接性方面的研究, 主要集中在电子束焊、 摩擦焊和自蔓延连接[7-11]。 块体非晶合金激光焊接过程中, 熔合区附近的基材在焊接热循环作用下, 由非晶态直接晶化, 形成焊接热影响区, 焊缝内熔化的液态金属直接冷却到室温形成熔化区。 研究并克服晶化现象是获得非晶合金焊接接头应做的工作。 本文作者选用了有较好非晶形成能力的块体非晶合金Zr45Cu48Al7, 着重讨论其在激光焊接热循环作用下, 熔化区和热影响区的晶粒形貌和组织结构的差异以及焊接热影响区的晶化行为与非晶合金热处理过程中的晶化行为差异。 有关激光焊接热循环对非晶合金晶化行为的研究尚未见报道。

1 实验

采用电弧熔炼法, 在高纯氩气保护下, 将确定配比的高纯合金组元Zr(99.98%), Al(99.9%)和Cu(99.999%)熔化成成分均匀的合金铸锭, 将其真空密封在石英管内, 待加热至熔化并快冷得到厚度为1mm 的板材。 采用Mac Science MXP2AHF18 X射线衍射仪(Cu Kα辐射)进行X射线衍射实验, 结果证实为完全非晶合金。 采用Perkins Elmer 7 差示扫描量热仪(DSC), 在纯氩气保护下进行热差分析, 其加热速率为 20K/min, 用纯铟和锌对结果进行校正。 根据DSC 曲线测试结果, 可以获得块体非晶合金的玻璃转变温度(Tg) 、 起始晶化温度(Tx) 和晶化峰的峰值温度(Tp), 精度为±1K。

板材经过机械加工后, 切割成尺寸为15mm×5mm×1mm的试样。 采用PRIMA INDUSTRE RAPIDO 5 型激光器进行焊接。 所用焊接规范为: 1) 焊接速率2m/min, 光斑直径0.3mm, 功率1.2kW, 氩气保护; 2) 焊接速率4m/min, 光斑直径0.3mm, 功率1.2kW, 氩气保护。 焊缝经抛光腐蚀后, 在光学显微镜下进行观察, 腐蚀液配比: 50mL HNO3+50mL H2O+3mL HF。 焊缝和热影响区组织结构采用微区X射线衍射进行分析, 衍射光斑直径为50μm。

2 实验结果

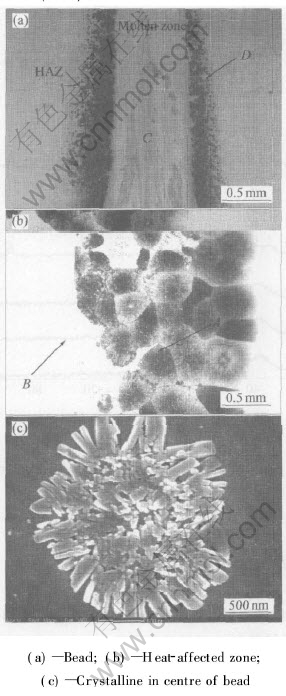

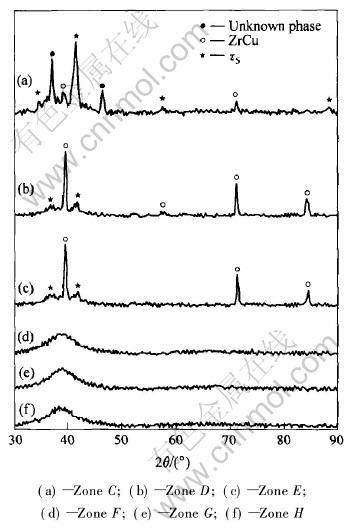

图1所示为焊接速率为2m/min时, 试样沿水平方向的光学显微镜照片。 图1(b)中的晶粒中央明显有晶核长大成圆形等轴晶粒的痕迹(箭头A, B所指), 晶粒长大到一定程度后, 造成成分偏析并再次发生晶化反应。 熔化区晶粒细小, 采用扫描电镜对晶粒形貌进行了观测, 结果如图1(c)所示。 根据Zr-Cu-Al三元合金相图可知, 块体非晶合金Zr45Cu48Al7等温晶化组织主要由τ5相构成[12, 13]。 采用微区X射线衍射技术对熔化区和热影响区的组织进行了分析, 熔化区(C)的X射线衍射结果如图2所示, 熔化区主要生成τ5、 ZrCu和一未知相。 热影响区(D)微区X射线衍射结果证实主要生成ZrCu相(图2)。

图1 焊速为2m/min时试样光学显微镜及扫描电镜照片

Fig.1 Optical microscopy and SEM images of welded Zr45Cu48Al7 at welding speed of 2m/min

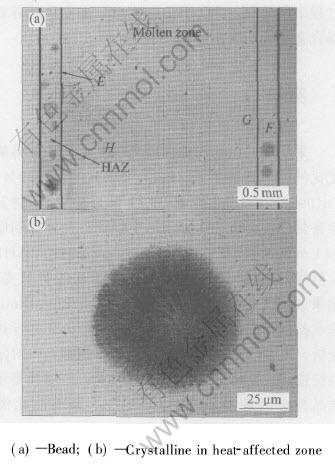

图3所示为焊接速率为4m/min时, 焊缝水平截面和焊接热影响区晶粒光学显微镜照片。 焊接热影响区(E)内分布着不连续的结晶相, 晶粒形貌如图3(b)所示, 经微区X射线衍射证实, 该晶化组织与焊速为2m/min时的热影响区晶化组织基本相同, X射线衍射谱如图2所示。 同时, 分别在焊缝中部H点位置, 焊接热影响区内未发现晶粒的F点位置和熔化区内靠近热影响区的G点位置进行了微区X射线衍射分析, 衍射结果证实, 这些白亮区均保持了非晶特性。

图2 试样各微区的X射线衍射谱

Fig.2 XRD patterns of different zones in sample

3 结果讨论

3.1 焊接热影响区与熔化区晶粒形貌的差异

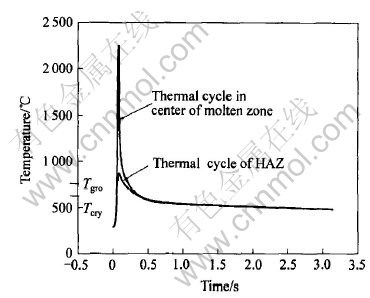

焊接热影响区的晶化是关于块体非晶合金的热稳定性问题, 而焊接熔化区冷却过程的非晶化是液态合金在冷却过程中的非晶形成能力的问题, 当冷却速率不够快时, 熔化区也可以发生晶化。 非晶合金在加热和冷却过程中, 其最大形核率所处温度值(Tcry)小于其晶核最大生长速率所处温度值(Tgro), 阻止晶化反应发生的临界升温速率远远大于形成非晶的临界冷却速率[14]。 因此, 焊接过程中, 焊接热影响区比熔化区更容易晶化。 本文采用有限元分析技术, 就激光焊接过程的温度场变化进行了分析, 并在图中示意地标出了最大形核率温度值(Tcry)和晶核最大生长速率温度值(Tgro), 计算时所用的物理参数, 采用文献[15-17]给出的相近成分的Zr基块体非晶合金的物理参数, 模拟结果如图4所示。

焊接热影响区在加热过程中首先加热到Tcry温度, 此时以形核反应为主, 易生成晶核。 随后的加热和冷却过程均经过Tgro温度, 在该温度附近主要以晶核长大为主, 先期晶化的晶核得以快速长大。

图3 焊速为4m/min时焊缝的光学显微照片

Fig.3 Optical microscope photos of welded Zr45Cu48Al7 at welding speed of 4m/min

图4 焊速为2m/min时焊缝中部及焊接热影响区热循环曲线

Fig.4 Thermal cycle curves in center of bead and HAZ at welding speed of 2m/min

所以, 焊接热影响区在焊接热循环作用下易于在非晶合金中大量晶化。

熔化区由液态冷却到室温的过程中, 由于冷却速率快, 迅速凝固成固态金属, 并保持了非晶特性。 刚形成的固态非晶合金冷却过程中, 首先冷却到Tgro温度值, 但此时由于非晶合金中所存在的晶核较少, 晶核长大反应对熔化区内非晶合金的晶化体积贡献较少。 随后的冷却过程中, 熔化区内的非晶合金冷却到Tcry温度值时, 在此温度附近主要以形核反应为主, 熔化区内容易形成细小的晶粒且晶化体积相对较少。 所以, 焊接热影响区比熔化区更容易晶化, 且热影响区晶粒尺寸大于熔化区晶粒尺寸。

其次, 随液态过冷度的增加, 晶核的临界尺寸不断的减小。 固态非晶合金的母材中存在一些尺寸大于晶核临界尺寸的晶核以及小于临界晶核尺寸的原子团簇。 固态非晶合金加热过程中, 这些晶核以及原子团簇的存在降低了非晶合金的热稳定性, 大大促进了焊接热影响区在加热过程中的晶化。 在受热过程中, 晶核快速的长大, 造成焊接热影响区和熔化区晶粒形貌的差异。

基于以上分析: 当焊接速率为2m/min时, 由于焊接热影响区比熔化区更容易晶化, 且Tgro温度值对晶化过程贡献较大, 所以焊接热影响区的晶粒尺寸大于熔化区晶化的晶粒尺寸; 当焊接速率为4m/min时, 由于熔化区的冷却速率大于形成该非晶合金的临界冷却速率, 阻止了晶化反应的发生, 使熔化区保持了非晶特性。 由于热影响区中含有加热前就存在着的晶核, 小于临界晶核尺寸的原子团簇以及加热过程中生成的晶核, 造成了非晶合金热影响区的部分晶化。

3.2 焊接热影响区与熔化区晶化组织的差异

当焊接速率为2m/min时, 熔化区的晶化组织经微区X射线衍射谱证实主要由τ5相构成。 根据Zr-Cu-Al三元合金相图可知, 块体非晶合金Zr45Cu48Al7冷却过程中的主要晶化相为τ5相[12, 13]。 这与实际观测的结果相一致。 但微区X射线衍射谱也显示, 焊接热影响区主要生成ZrCu相。 激光焊接块体非晶合金过程中, 热影响区内存在着淬态保留的以及加热过程中生成的ZrCu和τ5相晶核。 但在该成分的非晶合金中(Zr与Cu的含量接近1∶1), ZrCu相的生长不需要Cu原子做长距离的扩散。 其次, τ5相(Zr38Cu36Al26)在长大过程中, 需要Cu原子和Al原子同时做长距离扩散, 所需参与的原子较多。 因此, 焊接热影响区在加热过程中, ZrCu相比τ5相更容易长大。 在高速加热和冷却的过程中, 焊接热影响区中ZrCu相得以快速长大, 而τ5相含量相对较少, 造成焊接热影响区和熔化区组织上的差异。

3.3 焊接热影响区晶化行为与非晶合金热处理过程中晶化行为的差异

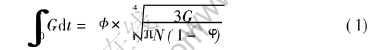

非晶合金的晶化温度与加热速率也存在着一定的关系, 随加热速率的增加, 晶化温度有向高温移动的趋势[18]。 非晶合金晶化时, 在绝对发生晶化温度点以上温度区间内发生晶化反应, 遵循形核与核长大的扩散机理, 进行加热晶化时, 有下列关系式成立[19]:

式中 φ为晶化体积分数; 为加热速率; t为等温晶化时绝对发生晶化温度与实际晶化温度之差, 即过热度; G为晶核的线生长速率; N为单位时间单位体积内形核次数。

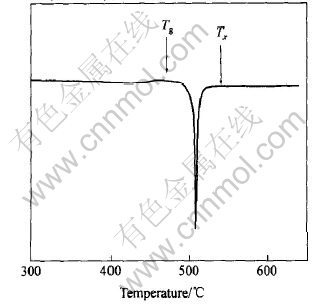

一般热处理过程, 虽然ZrCu和τ5等各相比值有一定的差别, 但由于加热速率比较低(大约100K/min以下), 形成相同晶化体积分数时(β相同), 各晶化相在式(1)右边的积分值差别不大, 经历相同的受热过程时, 各相晶核线生长速率相差不大。 各相的晶化反应放热峰几乎同时被DSC实验所检测到, 具体表现为在DSC曲线中仅有一个放热峰存在(如图5所示)。 激光焊接非晶合金过程中, 由于加热速率可以达到104K/s [17], 形成相同晶化体积分数时(φ相同), 各相比值的差别通过加热速率

图5 加热速率为2K/min时的DSC曲线

Fig.5 DSC curve at heating rate of 20K/min

显著放大, 造成式(1)右边各晶化相积分值的显著差异。 经历相同的激光焊接受热过程时, 造成这种差别的主要因素是快速加热和冷却过程中, 各相的线生长速率(G)存在很大差别, 即形成相同的晶化体积分数, 它们所需时间差别很大。 具体表现为在某个加热速率条件下, 由于线生长速率大, 易生长相能够迅速长大并造成成分偏析, 随后其他生成相在成分偏析的有利条件下相继长大。 正因为高速加热过程对各晶化相线生长速率影响程度不同, 造成了焊接热影响区的晶化行为与一般热处理过程的晶化行为的不同, 也造成了焊接热影响区中ZrCu相的增加。

4 结论

1) 焊接热影响区比熔化区更容易发生晶化, 实现非晶合金的焊接的难点在于克服热影响区的晶化。

2) 在焊接热循环作用下, 焊接热影响区和熔化区的晶化组织和晶粒形貌有很大的差异。 焊接速率为2m/min时, 熔化区主要生成τ5(Zr38Cu36-Al26)、 ZrCu和一未知相, 热影响区主要生成ZrCu相; 焊接速率为4m/min时, 熔化区保持了非晶特性, 热影响区部分晶化, 其主要生成相为ZrCu相。

3) 在焊接热循环作用下, 热影响区中的非晶合金Zr45Cu48Al7的晶化行为与热处理过程的晶化行为有一定的不同。

REFERENCES

[1]何圣静, 高梨如. 非晶态材料及其应用[M]. 北京: 机械工业出版社, 1987. 61.

HE Sheng-jing, GAO Li-ru. The Amorphous Alloy and Its Application[M]. Beijing: China Machine Industry Press, 1987. 61.

[2]Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys[J]. Acta Mater, 2000, (48): 279-285.

[3]Peker A, Johnson W L, Schafer. Amorphous Metal/Diamond Composite Material[P]. US 5567532, 1996-10-15.

[4]Peker A, Johnson W L. Beryllium Bearing Amorphous Metallic Alloys Formed by Low Cooling Rates[P]. US 5288344, 1994-02-22.

[5]Dandliker R B, Conner R D, Tenhover M A. Composite Penetrator[P]. US 6010580, 2000-01-04.

[6]Peker A, Johnson W L. Torsion-ally Reacting Spring Made of a Bulk-solidifying Amorphous Metallic Alloy[P]. US 5772803, 1998-06-30.

[7]Kawamura Y, Kagao S, Ohno Y. Electron beam welding of Zr-based bulk metallic glass to crystalline Zr metal[J]. Mater Trans, 2001, 42(12): 2649-2651.

[8]Kawamura Y, Ohno Y. Successful electron-beam welding of bulk metallic glass[J]. Mater Trans, 2001, 42(11): 2476-2478.

[9]Yokobuyuki Y, Abe N, Fukaura K, et al. Electron beam welding of Zr50Cu30Ni10Al10 bulk glassy alloys[J]. Mater Trans, 2002, 43(10): 2509-2515.

[10]Wong C H, Shek C H. Friction welding of Zr41Ti14-Cu12.5Ni10Be22.5 bulk metallic glass[J]. Scripta Materialia, 2003, 49(5): 393-397.

[11]Kawamura Y, Shoji T, Ohno Y. Welding technologies of bulk metallic glasses[J]. Journal of Non-Crystalline Solids, 2003, 317(1-2): 152-157.

[12]Villas P, Prince A, Okamato H. Handbook of Ternary Alloy Phase Diagrams[M]. ASM International, 1995. 3540.

[13]Petzow G, Effenberg G. Ternary Alloys: A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams[M]. New York: VCH, 1998. 133.

[14]Schroers J, Masuhr A, Johnson W L. Pronounced asymmetry in the crystallization behavior during constant heating and cooling of a bulk metallic glass-forming liquid[J]. Physical Review B, 1999, 60(17): 11854-11858.

[15]Inoue A. Bulk Amorphous Alloys Preparation and Fundamental Characteristics[M]. NH: Trans Tech Publications, 1998. 87.

[16]Yamasaki M, Kagao S, Kawamura Y. Thermal diffusivity and conductivity of Zr55Al10Ni5Cu30 bulk metallic glass[J]. Scripta Materialia, 2005, 53(1): 63-67.

[17]Duley W W. Laser Welding[M]. New York: A Wiley-interscience Publication, 1998. 67.

[18]Liu L, Wu Z F, Zhang J. A kinetic study of the non-isothermal crystallization of a Zr-based bulk metallic glass[J]. Journal of Alloys and Compounds, 2002, (339): 90-95.

[19]刘江龙, 邹至荣. 高能束热处理[M]. 北京: 机械工业出版社, 1997. 46-48.

LIU Jiang-long, ZHOU Zhi-rong. Heat Treatment with High Energy Beam[M]. Beijing: China Machine Industry Press, 1997. 46-48.

(编辑陈爱华)

基金项目: 江西省材料科学和工程研究中心资助项目(ZX200401004)

收稿日期: 2005-03-28; 修订日期: 2005-07-04

作者简介: 李 波(1974-), 男, 博士研究生.

通讯作者: 李志远, 教授; 电话: 027-87557449; 传真: 027-87557449; E-mail: hbkmkw@mail.hust.edu.cn