文章编号:1004-0609(2010)S1-s0881-05

钛在沸腾硝酸介质中腐蚀表面的分析

郭荻子,杨英丽,赵 彬,赵恒章

(西北有色金属研究院,西安 710016)

摘 要:采用8 mol/L沸腾纯硝酸回流腐蚀试验对Ti35、TA2、TA9、TA10和TiNi耐蚀钛材进行均匀腐蚀。腐蚀后多种钛材表面生成氧化层,其结构和成分发生改变。对腐蚀后的材料表面层进行EDS、SEM、XRD和XPS分析。结果表明:TA2,TA9和TA10的表面层完全为TiO2,Ti35合金表面的氧化层组成主要是Ti的各种价态的氧化物,TiNi合金表面由TiNi基体组成;其中,Ti35合金的表面氧化层较其他4种合金更致密,其耐硝酸腐蚀性能最优异。

关键词:钛;腐蚀;氧化层

中图分类号:TF 804.3 文献标志码:A

Analysis on corrosion surface of several titanium alloy in boiled dense nitric acid

GUO Di-zi, YANG Ying-li, ZHAO Bin, ZHAO Heng-zhang

(Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: The anticorrosion titanium alloys Ti35, TA2, TA9, TA10 and TiNi were investigated in detail by the boiling dense nitric acid reflux corrosion. The microstructure and the composition change. The oxidizing layer that appears on the surface of the alloys was characterized using scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS), X-ray diffraction(XRD)experiments and X-ray photoelectron Spectroscopy (XPS). The results show that the surface phase of TA2, TA9, TA10 are completely TiO2. As a contrast, Ti35 are the titanium oxide. In addition, the surface of TiNi alloy is the matrix. The anticorrosion capability of Ti35 oxidizing layer is better that the other alloys.

Key words: titanium; corrosion; oxidation film

随着我国核工业的迅猛发展,核高乏燃料后处理设备的安全性显得更加重要。针对后处理设备选材,国际上的研究主要集中在Zr、Ti和Ti-Ta系合金[1-3]。其中钛及钛合金在氧化性、中性、弱还原性或有氧化剂的某些还原性介质中具有良好的耐腐蚀性[4-6],但在沸腾的浓硝酸介质中,耐腐蚀性大大降低,采用钛合金制造的溶解器对高燃耗乏燃料主要存在沸腾硝酸的加速溶解和点蚀[7]。Ti35合金是西北有色金属研究院自主研制的一种Ti-Ta系α型耐蚀钛合金。该合金具有良好的加工、成形工艺性,焊接性,较好的塑性、韧性和优良的耐腐蚀性能,可长期工作在沸腾状态下高浓度的氧化性酸性溶液环境中[8]。

本文作者选用Ti35、TA2、TA9、TA10和TiNi耐蚀钛合金,研究此5种合金在8 mol/L沸腾浓硝酸溶液中的腐蚀行为,并进行相互比对,同时分析该特殊环境下Ti35钛合金氧化物的结构。

1 实验

1.1 实验材料

选用5种耐蚀钛合金Ti35、TA2、TA9、TA10和TiNi合金,试样分别采用2和3 mm厚的冷轧板材,经过650 ℃,1 h真空热处理,制作成如下尺寸的腐蚀试样:Ti35合金试样尺寸为50 mm×25 mm×3 mm,TA2,TA9和TA10试样尺寸为50 mm×20 mm×2 mm,TiNi合金试样尺寸为50 mm×25 mm×2 mm。

1.2 实验方法与分析

实验前将试样经水砂纸逐级打磨,表面粗糙度小于0.8 μm,对试样进行蒸馏水冲洗、丙酮脱脂,再用蒸馏水冲洗并吹干后在分析天平上称量。根据 JB/T 7901—1999标准要求,实验仪器采用加热蛇形冷凝回流装置、锥形瓶容器、循环水系统等。实验时每一锥形瓶中放置一块试样,溶液保持105.3 ℃的微沸状态,每48 h更换1次溶液,并对试样称量,实验共进行5周期,每周期为48 h。

腐蚀后的试样采用JSM5800型扫描电子显微镜进行表面形貌分析,采用日本理学公司D/max-2550/PC的X射线衍射仪进行试样表面氧化膜的相结构分析,采用美国PE公司的PHI-5400型光电子能谱仪进行XPS分析,以确定试样表面腐蚀氧化膜中的离子价态,分析氧化膜的形成。

2 结果与讨论

2.1 实验结果

5种钛合金在8 mol/L沸腾硝酸溶液中的腐蚀速率如图1所示。由图1可知,在腐蚀开始阶段,5种钛合金均存在一个快速腐蚀阶段,经历4个周期以后,Ti35和TA10合金腐蚀速率减小并趋于稳定,TA2和TA9合金的腐蚀速率下降,TiNi合金持续保持快速腐蚀行为。

图1 沸腾硝酸中钛合金腐蚀速率与时间的关系

Fig.1 Relationships between corrosion rate and time of titanium alloy in boiling nitric acid

显微组织观察表明,钛合金腐蚀后形成的表面氧化膜和富氧层的厚度都非常小,直接从质量损失值求得腐蚀速率有足够的精确度。其计算式为:

v=365Δm/(Sρt) (1)

式中:v为年腐蚀速率;Δm为平均质量损失;S为试样表面积;ρ为密度;t为腐蚀天数。

根据实验数据计算出Ti35、TA2、TA9、TA10和TiNi的腐蚀速率分别为0.06、0.42、0.30、0.06和27.84 mm/a。

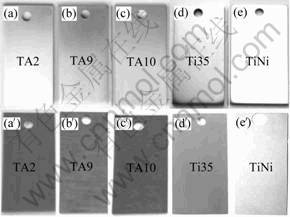

5种钛材在沸腾硝酸环境中均呈现均匀腐蚀的形态(见图2)。Ti35合金挂件随着腐蚀时间的增加,表面的颜色不断加深,2个腐蚀周期后,Ti35合金呈现亮白色并仍保持一定的金属光泽,然后转为淡黄色;5个周期后,Ti35合金变为深黄色。TA2、TA9和TA10挂件在2个腐蚀周期后呈现浅褐色;在5个周期后,表面完全腐蚀为深褐色,不再具有金属光泽;而TiNi合金挂件表面在整个腐蚀周期内一直保持原有的金属光泽,且试片减薄严重,在5个周期后可明显看出边部的腐蚀凹坑。结果表明:Ti35合金出现耐蚀,TA2、TA9和TA10为尚耐蚀,TiNi合金未被耐蚀。

图2 腐蚀5个周期前后的表面宏观形态

Fig.2 Surface macromorphologies of original samples before (a)-(e) and after (a′)-(e′) corroded for 5 periods

2.2 表面微观形貌分析

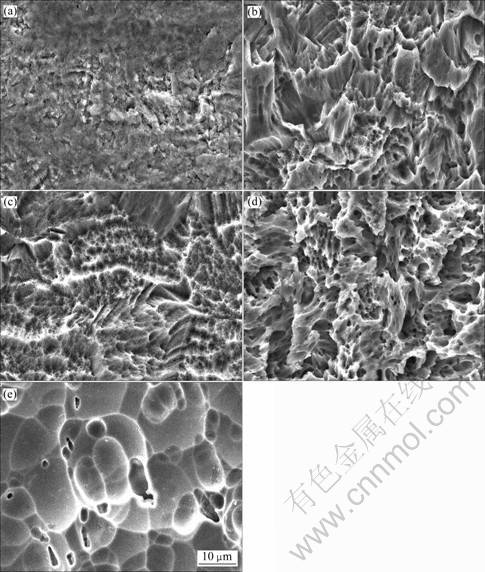

图3所示为腐蚀试样表面形貌。图3(a)表明,Ti35合金即使腐蚀了5个周期后,试样表面平整,表面氧化膜呈现的是均匀致密形态,局部存在少量的凹坑;图3(b)、3(c)和3(d)较为相似,表明TA2、TA9和TA10合金腐蚀试样微观表面氧化膜呈现腐蚀起伏,存在大量凹坑,出现点蚀;图3(c)表明,TiNi合金腐蚀试样微观表面光亮,已完全被腐蚀,能够明显分辨晶界。

图3 腐蚀5个周期后钛合金表面形貌

Fig.3 Surface morphologies of titanium alloys after corroded for 5 periods: (a) Ti35; (b) TA2; (c) TA9; (d) TA10; (e) TiNi

点蚀的产生主要是酸根离子的浸蚀作用使表面钝化膜出现局部破坏而引起的,由于钛点蚀的敏感性与材料表面状态有很大关系[9]。采用同种工艺进行表面砂纸打磨的3种耐蚀合金,通过腐蚀后试样表面显微形貌观察,结果表明Ti35合金的点蚀敏感性较TA2、TA9、TA10和TiNi合金低。

点蚀的产生主要是酸根离子的浸蚀作用使表面钝化膜出现局部破坏而引起的,由于钛点蚀的敏感性与材料表面状态有很大关系[9]。采用同种工艺进行表面砂纸打磨的3种耐蚀合金,通过腐蚀后试样表面显微形貌观察,结果表明Ti35合金的点蚀敏感性较TA2、TA9、TA10和TiNi合金低。

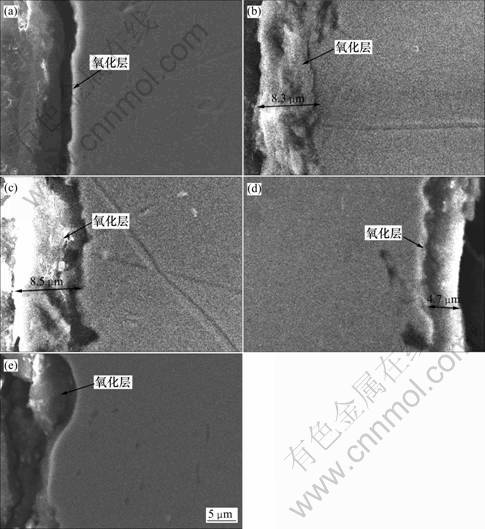

图4所示为5种钛材腐蚀5周期后的试样纵剖面像。由图4可看出,有明显的氧化层存在,但其厚度很小,仅几个微米。Ti35合金具有均匀致密的约1 μm的氧化层;TA2的氧化层较厚,约8.3 μm,TA9约8.3 μm,TA10约4.7 μm;而TiNi合金形成了少量氧化块,试样表面其余部位未形成任何新的覆盖层,仍与腐蚀液体直接接触。试样表面观察不到氧化膜下的富氧层,这是由于腐蚀温度只是略超过100 ℃,在该温度下扩散速度慢,难以形成富氧层。

2.3 表面结构与组分分析

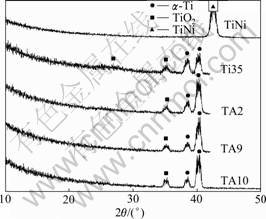

对腐蚀5个周期后的5种钛材试样进行了X线衍射分析(见图5)。由图5可知,Ti35、TA2、TA9和TA10表面腐蚀后,拥有较类似的表面结构,存在生成的TiO2氧化膜,其中主要为金红石型结构,也有部分锐钛矿型结构,这也是钛合金氧化后通常得到的氧化膜结构,具有保护合金免受强烈腐蚀的作用。TiNi合金表面的XRD谱显示,其表面无任何氧化层形成,这也与试样截断面SEM像的结果一致。

图4 钛合金腐蚀5周后纵剖面的形貌

Fig.4 Morphologies of cross section of Ti alloy corroded for 5 periods: (a) Ti35; (b) TA2; (c) TA9; (d) TA10; (e) TiNi

图5 腐蚀5个周期后的XRD谱

Fig.5 XRD patterns of titanium alloys after corroded for 5 periods

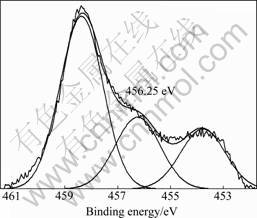

实验5个周期后的腐蚀试样,由于氧化膜非常薄,对其X射线衍射分析未发现其他氧化物的衍射峰,而XRD谱不足以完全解释Ti35合金表面钝化膜的结构。因此,随后对Ti35合金进行XPS分析(图6),在456.25 eV出现了一个明显的Ti2p3/2峰,但没有一种标准物质的2p3/2峰跟此峰对应[10],因为456.25 eV在TiO的Ti2p3/2峰(454.8 eV)和TiO2的Ti2p3/2峰(458.5 eV)之间,可以推测为Tin+(2<n<4),即合金表面具有TiOx的氧化膜,钛以4价、3价和2价存在,主要成分含TiO2、Ti2O3和TiO。

Ti35合金表面生成的钛低价氧化物在继续氧化时又会生成高价钛的氧化物,其反应式(2)和(3)为

2TiO+H2O?Ti2O3+2H++2e (2)

Ti2O3+H2O?2TiO2+2H++2e (3)

根据尤海格(Uhig)配位场理论,钝化态的过渡金属,一般具有较强的氧吸附层,其次,外d层的电子空位作为接受体,而溶存氧作为供体,d层的电子空

图6 Ti35合金钝化膜的XPS谱

Fig.6 XPS spectra of Ti35 alloys passive film

位与氧结合形成钝化膜[6]。而Ti35合金中的Ta元素由于具有d层的电子空位,在沸腾硝酸形成的热动力环境中加速促进钛合金失去电子形成氧化物。而钛在硝酸中的腐蚀产物Ti4+对腐蚀起缓蚀作用[6],Ta使钛合金钝化膜得到强化,因而阻止了硝酸的进一步腐蚀,其耐腐蚀性能也随之增强。

3 结论

1) Ti35、TA2、TA9、TA10和TiNi 5种钛合金的腐蚀速率分别为0.06、0.42、0.30、0.06和27.84 mm/a,Ti35合金的耐腐蚀性能最优。

2) TA2、TA9和TA10的表面层完全为TiO2,Ti35合金表面的氧化层组成主要是Ti的各种价态的氧化物,TiNi合金表面无氧化层覆盖。

3) Ti35合金腐蚀后表面生成的氧化膜较其他4种钛合金均匀致密,主要成分为TiO2、Ti2O3和TiO,这3种成分阻止腐蚀的进一步发展,该合金的点蚀敏感性低,可直接在耐蚀环境中使用。

REFERENCES

[1] MARDARE A I, SAVAN A, LUDWIG A, WIECK A D, HASSEL A W. A combinatorial passivation study of Ta-Ti alloys[J]. Corrosion Science, 2009, 51(7): 1519-1572.

[2] MUDALI U K, DAYAL R K, GNANAMOORTHY J B. Corrosion behavior of weldments of Ti and Ti-5Ta for nuclear fuel reprocessing plants[J]. Journal of Mater Engineering and Performance, 1995, 4(6): 756-760.

[3] ZHOU Ying-long, NIINOMI M, AKAHORI T, FUKUI H, TODA H. Corrosion resistance and biocompatibility of Ti-Ta alloys for biomedical applications[J]. Materials Science and Engineering A, 2005, 398(1/2): 28-36.

[4] 李争显, 杜继红, 高广睿, 徐 重, 周 廉. 用双层辉光等离子法在钛合金表面制备的Ti-Pd合金性能研究[J]. 稀有金属材料与工程, 2006, 35(8): 1239-1242.

LI Zheng-xian, DU Ji-hong, GAO Guang-rui, XU Zhong, ZHOU Lian. Performances of Ti-Pd coating on titanium surface prepared by double glow plasma technology[J]. Rare Metal Materials and Engineering, 2006, 35(8): 1239-1242.

[5] 徐增华. 金属耐蚀材料——钛合金[J]. 腐蚀与防护, 2002, 28(1): 42-48.

XU Zeng-hua. Corrosion resistant materials—Ti alloy[J]. Corrosion & Protection, 2002, 28(1): 42-48.

[6] 余存烨. 耐蚀钛合金的发展[J]. 钛工业进展, 2003, 1: 12-17.

YU Cun-ye. Developing of corrosion resistant titanium[J]. Titanium Industry Progress, 2003, 1: 12-17.

[7] 徐潇潇, 邱少宇. Ti合金在核燃料后处理设备中的应用研究进展[J]. 材料导报, 2005, 19(11): 57-62.

XU Xiao-xiao, QIU Shao-yu. Research progress in the application of titanium alloy to nuclear fuel reprocessing facility[J]. Materials Review, 2005, 19(11): 57-62.

[8] 杨英丽, 赵 彬, 林 桥, 殷京瓯, 苏航标. 加工率对Ti-35合金组织性能的影响[J]. 钛工业进展, 2004, 21(6): 22-25.

YANG Ying-li, ZHAO Bin, LIN Qiao, YIN Jing-ou, SU Hang-biao. Effect of processing rate on structure and mechanical properties of Ti-35 alloy[J]. Titanium Industry Progress, 2004, 21(6): 22-25.

[9] 刘道新. 金属的腐蚀与防护[M]. 西安: 西北工业大学出版社, 2005: 317-318.

LIU Dao-xin. Corrosion and protection of metals[M]. Xi’an: Northwestern Polytechnical University Press, 2005: 317-318.

[10] Perkin Elmer Corp, Eden Prairie. Handbook of X-ray photoelectron spectroscopy[M]. Minnesota: Physical Electronics Division, Perkin Elmer Corporation, 1979: 38-39.

(编辑 陈爱华)

通信作者:郭荻子;电话:029-86231078; E-mail: gd17036@163.com