DOI: 10.11817/j.ysxb.1004.0609.2021-36504

脉冲渗氧对工业纯钛表面摩擦磨损性能的影响

张聪惠,刘 颖,肖桂枝,张 津

(西安建筑科技大学 冶金工程学院,西安 710055)

摘 要:采用脉冲渗氧的方法在不同温度、时间下对工业纯钛进行渗氧处理,以改善其在应用过程中的耐磨损性能。采用 X 射线衍射仪(XRD)、扫描电镜(SEM)、纳米压痕仪和摩擦磨损试验机分别对试样表层的特征峰强度、形貌特征、压痕硬度、表面摩擦因数及磨痕截面积进行测试。结果表明:经脉冲渗氧处理在工业纯钛试样表面形成氧化层和氧扩渗层;与连续渗氧试样和原始试样相比,700 ℃脉冲渗氧6 h试样的表面硬度最大,为15.39 GPa,约为同等参数下连续渗氧试样的1.7倍和原始试样的7.3倍;800 ℃脉冲渗氧4.5 h试样的摩擦因数和磨痕截面积最小,分别为0.24和317.44 μm2.。试样的黏着磨损被明显削弱,耐磨损性能得到提高。

关键词:工业纯钛;脉冲渗氧;氧化层;氧扩渗层;摩擦;磨损

文章编号:1004-0609(2021)-04-0945-11 中图分类号:TG156.9 文献标志码:A

引文格式:张聪惠, 刘 颖, 肖桂枝, 等. 脉冲渗氧对工业纯钛表面摩擦磨损性能的影响[J]. 中国有色金属学报, 2021, 31(4): 945-955. DOI: 10.11817/j.ysxb.1004.0609.2021-36504

ZHANG Cong-hui, LIU Ying, XIAO Gui-zhi, et al. Effect of pulse oxidation on surface friction and wear properties of pure titanium properties of industrial pure titanium[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 945-955. DOI: 10.11817/j.ysxb.1004.0609.2021-36504

钛及钛合金材料质量轻,强度高,综合力学性能优异,国内外已广泛应用于航天、船舶、化工等传统工业领域;又因其导热系数小,生物相容性高,近年来也逐步应用于手表手机、钛炊具等生活领 域[1-5]。然而由于表面承载能力低、摩擦因数大,易发生黏着磨损等特点,钛金属的实际应用仍然受到了很大限制[6-9]。如何提高钛金属材料的耐磨损性能已经成为国内外钛金属材料研究的热点。

表面渗氧是一种能有效提高钛金属表面强度及磨损性能的处理方法,BAILEY等[10]和JAMESH等[11]分别在625 ℃、650 ℃条件下对工业纯钛进行了20 h、48 h热氧化处理,结果表明在样品表面均形成了一定厚度的氧化层,样品表面硬度得到明显提高。ANIOLEK等[12]对600~800 ℃热氧化纯钛的磨损性能研究结果表明,600 ℃热氧化后的纯钛由于热氧化形成氧化层,使其抗磨料磨损性能得到大幅提高,体积磨损减少了48%。但热氧化处理的主要渗氧氛围为空气,氧原子在钛金属表面的渗入量有限,纯钛的耐磨损性能仍存在较大的改进空间。

由于脉冲渗氧技术在真空条件下进行,能显著增加纯钛表面活性,提高氧在工件表面的吸附能力,形成结构致密、结合性好的渗氧层。本文用脉冲渗氧的方法在流动的纯氧环境中对工业纯钛进行渗氧处理,并以连续渗氧处理作为对照,探究其对生活钛金属构件强度、磨损性能等方面的改善情况,为进一步发展钛金属材料在生活领域的应用提供实验、理论依据。

1 实验

1.1 实验材料

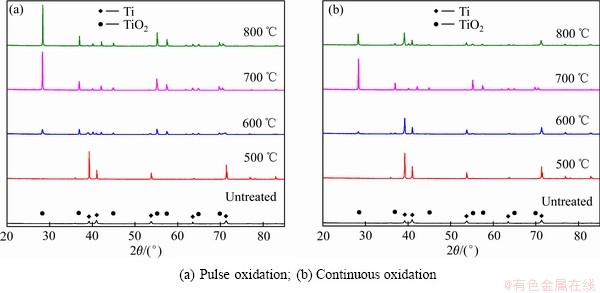

实验材料选择工业纯钛TA2,初始状态为3 mm厚轧制板材,化学成分如表1所示。

表1 实验用TA2的化学成分

Table 1 Chemical compositions of TA2 (mass fraction, %)

1.2 实验方法

1.2.1 样品预处理

实验用TA2钛板经线切割得到40 mm×50 mm尺寸实验试样。所有试样经550 ℃、45 min退火处理以消除或减少内应力和表面的加工硬化,使试样内部组织接近平衡状态。用砂纸打磨掉各试样在退火处理过程中形成的氧化膜,随后将试样在酸溶液(V(HF):V(HNO3):V(H2O)=3:6:11)中酸洗10 min,进一步去除表面杂质,得到纯钛金属样品,最后将各试样在超声波清洗器中先后用去离子水和乙醇清洗,吹干,待用。

1.2.2 脉冲渗氧与连续渗氧处理

渗氧处理在CMT滑轨管式炉中进行,将预处理样品装入炉中,通入高纯O2 10 min,充分排除炉内空气,将炉温升至渗氧温度,保温通O2 60 min后用真空泵抽至真空,真空保温30 min,如此往复脉冲循环到有效渗氧时间,将炉温降至 300 ℃取出样品,得到脉冲渗氧试样。将炉温升至渗氧温度后持续通O2 到渗氧时间后,炉温降至 300 ℃并取出样品,得到连续渗氧试样。

实验设置两组变量:渗氧温度取500 ℃、600 ℃、 700 ℃、800 ℃,有效渗氧时间取3 h、4.5 h、6 h,每组参数条件下分别进行脉冲渗氧和连续渗氧处理并作对比。

1.2.3 实验检测方法

采用Agilent Nano Indenter G200 纳米压痕仪测量试样表面硬度和弹性模量,实验采用一次压入的方式,选取金刚石 Berkovich 压头,半锥角 65.3°。实验固定最大压入载荷为50 mN,测试时试样在15 s内加载到最大载荷并保持10 s,随后卸载10%并保持15 s,最后完全卸载[13]。

磨损实验在 Bruker(CETR)公司生产的UMT-2摩擦磨损试验机上进行,摩擦副为Al2O3球,摩擦轨迹为直径6 mm的圆周运动,摩擦速率224 r/min,各样品均在3 N载荷下对磨20 min,用激光共聚焦显微镜拍摄磨痕形貌。

用S-2700型扫描电镜对样品表面进行背散射电子成像观察;表面物相检测采用D8 Advance多功能X射线衍射仪,靶材选用Cu靶。探针扫描角度范围为20°~80°,步宽0.02°,扫描速度为0.15 s/step,实验管压为40 kV;采用能谱仪(EDS)进行含氧量分析。

2 结果与讨论

2.1 试样表面宏观表征

无论何种加工方法所获得的金属材料表面,只要暴露在空气中,都会立即与吸附分子发生化学反应,而钛作为典型的亲氧金属,氧化层外侧的金属原子与氧原子发生化学反应而生成氧化膜,其厚度随原子扩散过程而增加[14]。氧化膜中的钛元素来源于氧化层,又因氧化层成分不同而透光性不同。氧化膜极薄无法用肉眼观察,但可凭借其在入射光下发生干涉出现的颜色变化辨别其相对厚度[15-17]。当渗氧温度相同时,脉冲渗氧3 h、4.5 h、6 h后,试样表面颜色由深蓝色变为蓝色再到浅蓝色;连续渗氧3 h、4.5 h、6 h后,试样表面颜色由浅蓝色变为淡蓝色再到蓝白色。当渗氧时间相同时,脉冲渗氧分别在500 ℃、600 ℃、700 ℃、800 ℃下进行时,试样表面颜色由深蓝色逐渐变为浅灰色;连续渗氧在不同温度下进行时,试样表面颜色由浅蓝色变为灰白色。试样表面颜色越浅,氧化膜越厚,可以看出随着处理渗氧时间的延长或渗氧温度的升高,试样表面的氧化膜逐渐变厚。

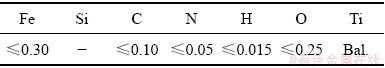

2.2 氧化层横截面形貌表征

实验中通过横截面观察各试样氧化层的组织形貌,结果表明,在低于600 ℃较低的渗氧温度下,两种渗氧方式都能在纯钛表面形成极薄的氧化层,但其厚度随渗氧时间的变化不明显。当渗氧温度提高到700 ℃,试样表面能形成一定厚度的氧化层和氧扩渗层,氧化层随渗氧时间的延长逐渐变厚,脉冲渗氧3 h、4.5 h、6 h试样表面形成的氧化层厚度分别为3.0、4.5、7.4 μm;连续渗氧3 h、4.5 h、6 h试样表面形成的氧化层厚度分别为2.8、3.9、4.9 μm。当渗氧时间延长到6 h后,脉冲试样氧化层依然完整,连续试样氧化层局部区域则出现裂纹,氧化层与基体出现明显分层现象。700 ℃渗氧不同时间纯钛试样的氧化层横截面如图1所示。

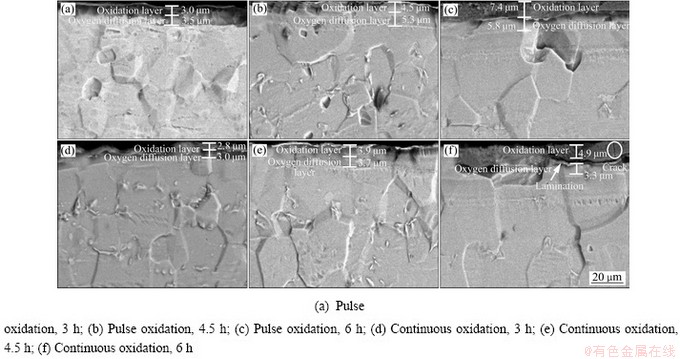

渗氧温度进一步提升至800 ℃,相比于连续渗氧,脉冲渗氧各渗氧时间下的氧化层均较厚且更加致密,氧化层与纯钛基体的结合状况也明显优于连续试样。800 ℃下纯钛试样氧化层的横截面形貌如图2所示,脉冲渗氧3 h、4.5 h、6 h试样表面形成的氧化层厚度分别为3.7、5.4、5.8 μm,连续渗氧3 h、4.5 h、6 h试样表面形成的氧化层厚度分别为3.4、4.5、5.2 μm,可以看到,800 ℃脉冲渗氧4.5 h氧化层与基体之间尚未明显分层,渗氧6 h后氧化层局部出现裂纹,但整体仍然与基体结合紧密,800 ℃连续渗氧6 h试样氧化层严重破碎,分层现象严重,基体表面出现孔洞。

图1 700 ℃渗氧不同时间试样氧化层的横截面形貌

Fig. 1 Cross-sectional morphologies of oxide layer of sample pulse oxidation at 700 ℃ for different time

图2 800 ℃渗氧不同时间试样氧化层的横截面形貌

Fig. 2 Cross-sectional morphologies of oxide layer of sample pulse oxidation at 800 ℃ for different time

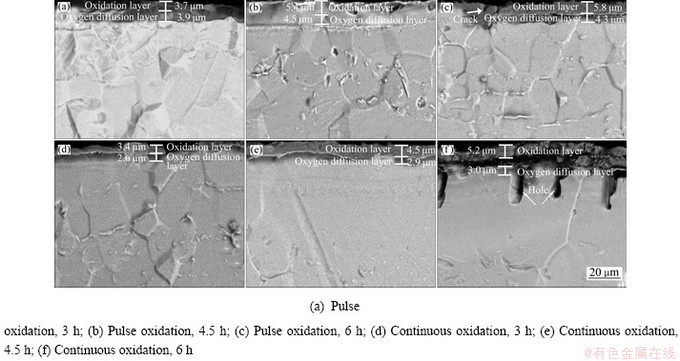

2.3 表面物相分析

渗氧处理4.5 h后试样氧化层致密且与基体结合较好,不同温度下两种渗氧方式渗氧4.5 h纯钛试样的表面特征峰衍射谱如图3所示。

500 ℃的渗氧温度下,两种渗氧方式渗氧后试样表面的物相组成对应一致,均表现出明显的α-Ti相;经600 ℃处理4.5 h纯钛试样连续渗氧试样表面仍然以α-Ti相为主,而脉冲试样表面已出现明显的TiO2相;渗氧温度提高到700 ℃,两种渗氧方式渗氧4.5 h后试样表面均表现出明显的TiO2特征峰,说明经700 ℃处理4.5 h试样表面已被致密氧化层覆盖;进一步提高渗氧温度到800 ℃,连续渗氧试样表面衍射图谱中又重新出现明显的α-Ti相,说明氧化层出现了破裂和脱落的现象,而脉冲试样表面仍然表现出比较完整的TiO2谱,说明氧化层与基体之间结合紧密,氧化层未出现明显破损,脉冲渗氧处理纯钛试样表面得到的氧化层对温度适应性较强,氧化层的热稳定性也更好。

2.4 强化层氧含量分析

渗氧后试样的表面强化层由氧化层和氧扩渗层组成。700 ℃脉冲渗氧6 h的渗氧试样距表面不同深度的元素含量如图4所示。从图4可以看出,渗氧试样表面的氧含量约为38%(质量分数)左右,随着深度的增加,氧含量逐渐降低,在距表面约10 μm的位置,氧含量约为25%,该位置接近氧化层与基体的界面。穿过界面后,氧含量迅速降至14%左右,考虑到氧在纯钛中的最大固溶量为14.5%,可判断纯钛基体表面形成了氧扩渗层,氧扩渗层中的氧随着距表面深度的增加含量继续降低,在距表面约16.5 μm的位置达到最小,说明纯钛基体表层的氧扩渗层厚度大约为6.5 μm,这和通过横截面形貌的测量值大致相同。

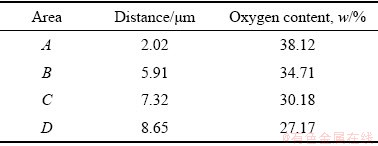

表2所列为700 ℃脉冲渗氧6 h试样氧化层不同深度的氧含量,研究区域如图5所示。图中距表面2.02 μm的A区域,氧的密度为38.12%,与TiO2中氧的密度相近,距表面8.65 μm的D区域氧的密度为27.17%,稍大于TiO中氧含量,说明氧化层不同深度生成了不同的钛氧化物,由表面到内部依次形成TiO2、Ti2O3、TiO等钛氧化物为主成分的氧化物层。过高强度的处理条件下,不同氧化物层之间组成、结构不同,热膨胀系数也存在巨大差异,随着冷却过程的进行,氧化层出现逐层破裂、脱落的现象[18-19]。

图3 不同温度下渗氧4.5 h纯钛试样表面特征峰的XRD谱

Fig. 3 XRD patterns of surface characteristic peak of pure titanium sample pulse oxidation for 4.5 h

图4 700 ℃脉冲渗氧6 h试样表面不同深度的元素含量

Fig. 4 Elements contents at different depths of pulse sample at 700 ℃ for 6 h

表2 700 ℃脉冲渗氧6 h的渗氧试样氧化层不同深度的含氧量

Table 2 Oxygen content at different depths of oxide layer of pulse sample at 700 ℃ for 6 h

2.5 渗氧机理分析

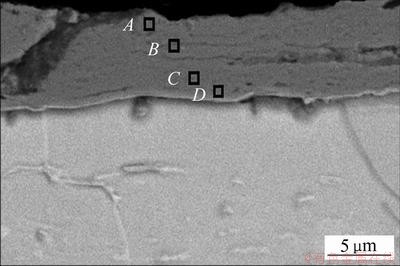

图5 700 ℃脉冲渗氧6 h的渗氧试样氧化层截面形貌

Fig. 5 Cross-sectional morphology of oxide layer of pulse sample at 700 ℃ for 6 h

氧在纯钛中的扩渗机制如图6所示。渗氧处理初期,大量氧原子富集在纯钛试样表面,并通过固溶扩散进入纯钛基体形成氧扩渗层,由于氧钛之间的高浓度差,氧扩渗层迅速转变成为初始氧化层,阻止了外界氧原子的继续渗入;随着渗氧强度的进一步加大及外界氧原子浓度的增大,初始形成的氧化层在氧化层/基体界面处发生如下反应:

TiO2 →Ti+2O (1)

初始氧化层分解产生的氧原子进一步向基体深处扩散,占据基体内钛原子的间隙,形成新的氧扩渗层。外界的高浓度氧占据原来氧化层中氧的空位,形成新的氧化层。在一定的渗氧时间内,随着渗氧强度的持续增大重复进行“氧扩渗层→氧化层→氧化层分解→新氧扩渗层”的过程,直至产生足够厚度的可以彻底阻碍外界氧原子渗入的终止氧化层为止。

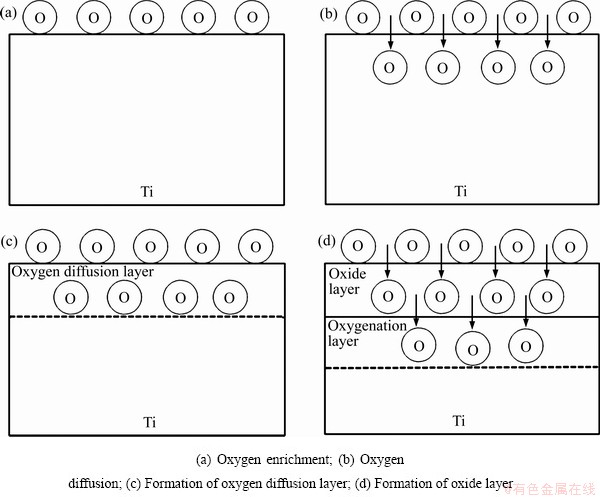

2.6 纳米压痕硬度

不同渗氧参数下纯钛试样表面的显微硬度如图7所示。由图7可看出,原始试样的显微硬度为2.10 GPa,经700 ℃脉冲渗氧6 h后试样的显微硬度最大,达到15.39 GPa,约为原始试样的7.3倍;连续渗氧试样的最大显微硬度同样出现在700 ℃渗氧6 h参数下,显微硬度为9.29 GPa,约为原始试样的4.4倍,但仅为脉冲渗氧最大显微硬度的60%。连续渗氧在空气氛围下进行,由于钛与氧具有很强的亲和力,会迅速在试样表面形成钛的氧化层,氧原子难以向内扩散,形成的氧化层较为疏松,硬度低;脉冲渗氧在真空条件下进行,能有效阻止其他气体在工件表面形成吸附层,增加了纯钛表面对氧的吸附能力,提升氧原子向基体内的扩散速率,形成一定厚度的氧扩渗层,以及致密且与基体结合良好的的氧化层,所以脉冲渗氧试样的氧化层硬度高。

图6 高温下氧原子在纯钛中的扩散机制

Fig. 6 Diffusion mechanism of oxygen atoms in pure titanium at high temperature

图7 不同渗氧参数下纯钛试样的表面显微硬度

Fig. 7 Surface microhardness of pure titanium samples at different pulse oxidation parameters

实验中还对800 ℃脉冲渗氧6 h的纯钛试样进行去氧化皮处理,测量了去皮后的试样基体表面的显微硬度为3.05 GPa,高于原始试样硬度(2.10 GPa),说明在纯钛基体表面有氧扩渗层产生,其硬度大于原始纯钛的表面硬度[20]。因此,图7中800 ℃连续渗氧6 h试样表层氧化层虽近乎完全脱落,但其显微硬度仍然高于原始试样的。

随着温度的升高氧化物颗粒长大,但由于氧化层和基体的热膨胀系数差异较大,氧化膜会对基体产生较大的压应力[21]。膜层内应力得不到释放,就会导致膜层出现裂纹,暴露的基体发生多次氧化,氧化物层数增多,就会出现分层现象,表面硬度降低。所以除脉冲渗氧3 h外,其余渗氧时间下试样都能在700 ℃达到其表面显微硬度的最大值,当温度升高到800 ℃时,连续渗氧6 h试样表面的氧化层与基体分层严重,氧化皮脱落严重,故继续增加渗氧强度将不会显著提高试样的显微硬度,甚至还将对试样造成其他损伤。

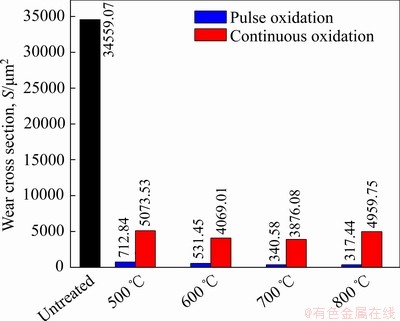

2.7 磨损性能分析

纯钛的磨损机制主要有磨粒磨损、塑性变形以及非常严重的黏着磨损[22],其表面强度与氧化层表面硬度、氧化层厚度及氧化层与纯钛基体的结合情况相关,氧化层硬度越高、厚度越厚、氧化层与基体结合越紧密,试样的表面强度越高[23]。表面磨痕截面积是表征材料摩擦磨损性能的重要指标[24],指被磨材料在单位时间内磨痕的截面面积,不同温度下渗氧4.5 h试样表面磨痕截面积如图8所示。原始试样的表面磨痕截面积为34559.07 μm2,远高于各渗氧试样的。不同温度下脉冲试样的表面磨痕截面积均小于同等参数下连续试样的,这是由于同等参数下,相比于连续渗氧试样,脉冲渗氧在试样表面形成的氧化层硬度更高,厚度更厚,与基体结合更好,脉冲渗氧试样表面强度高。700 ℃时,连续渗氧试样的磨痕截面积最小,为3876.08 μm2,约为原始试样的15.22%,脉冲试样磨痕的最小截面积出现在800 ℃,仅317.44 μm2,为原始试样的0.92%。显著改善了纯钛的表面耐磨损性能。

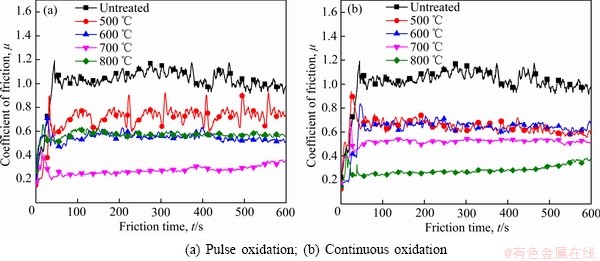

金属表面膜,如氧化膜、吸附气体膜或其他污染膜,会使其摩擦因数降低[25]。图9所示为不同温度下渗氧4.5 h各试样表面摩擦因数随磨损时间的变化曲线。由图9可看出,对相同的摩擦副来说,摩擦因数越小,对磨材料的耐磨损性能越好。各试样表面摩擦因数稳定值均明显低于未处理试样的,试样在700 ℃下连续渗氧4.5 h时,摩擦因数最小,约为0.30,这是由于当温度升高至800 ℃时,连续渗氧形成的氧化膜逐渐疏松,并可出现微小裂痕,与基体出现分层,摩擦因数增大;800 ℃脉冲渗氧4.5 h试样的摩擦因数为0.24,是渗氧处理后试样摩擦因数的最小值,这是由于脉冲渗氧具有良好的真空氛围,能形成硬度高、致密、与基体结合良好的氧化层,800 ℃处理4.5 h时,综合氧化层的厚度以及与基体的结合程度,仍可显著改善纯钛的耐磨损性能。

图9中700 ℃脉冲试样的稳定摩擦因数为0.49,大于同温度下连续试样,但观察图8发现其磨损量更小,这是经700 ℃渗氧4.5 h脉冲试样的硬度大于连续试样的,在对磨初期脱落的磨粒少,由于硬度大,后期的对磨过程中难以碎化,润滑作用有限,故摩擦因数较大[26-27]。

图8 不同温度下渗氧4.5 h试样表面的磨痕截面积

Fig. 8 Wear Sectional area of samples after 4.5 h oxygen treatment

另外,图9中脉冲渗氧试样的稳定磨损阶段比连续试样更早出现,且到达稳定磨损阶段后的摩擦曲线更平滑,这是由于磨损实验中的磨损路径相同,各参数下脉冲试样的硬度均较连续试样高,初始磨擦阶段产生的磨粒不易碎化,磨粒粒径较 大,磨损较严重,摩擦因数增加的速率大,摩擦界面更能快速达到平衡,因此稳定磨损阶段出现得更早[28]。

图9 不同渗氧温度下渗氧4.5 h纯钛试样表面摩擦曲线

Fig. 9 Surface friction curves of pure titanium sample after 4.5 h oxygen treatment

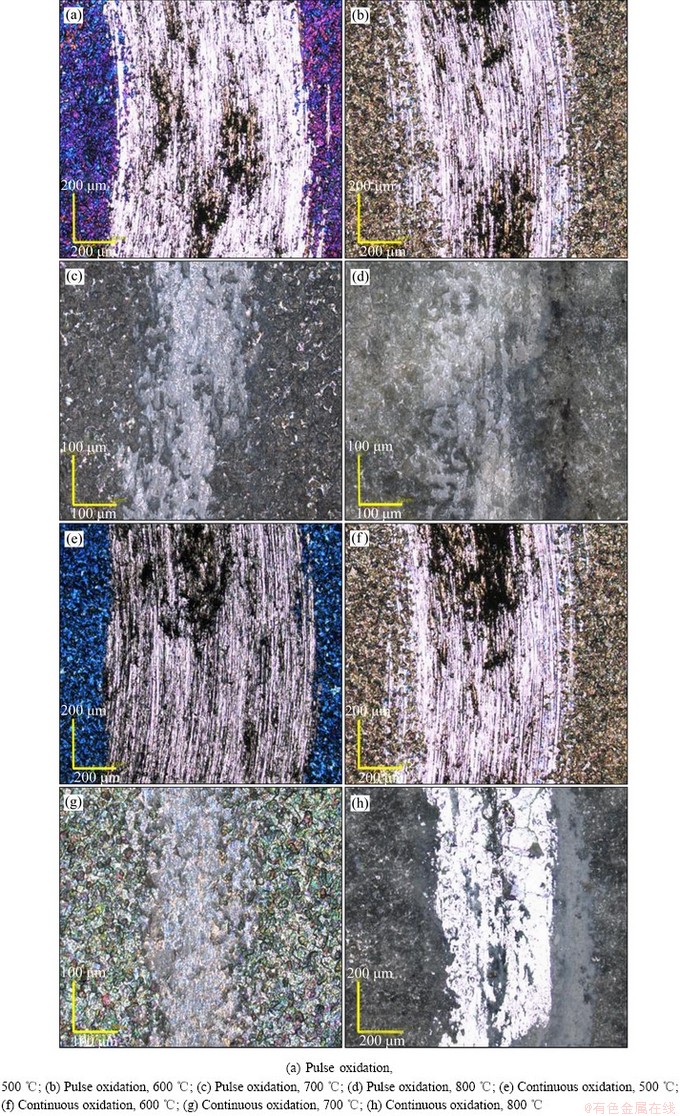

图10 4.5 h渗氧时间下各纯钛渗氧试样的表面磨损形貌

Fig.10 Surface wear morphologies of pure titanium samples under oxygen infiltration time of 4.5 h

图10所示为不同渗氧温度下渗氧4.5 h纯钛试样的表面磨损形貌。由图10可以看出,脉冲渗氧试样表面的黏着磨损效应相比同等渗氧参数下的连续试样更微弱。随着渗氧温度的升高,渗氧试样表面磨痕宽度变小,深度变浅直至逐渐淡化。脉冲渗氧试样的磨痕宽度在700 ℃时比较清晰,磨痕深度很浅,到800 ℃渗氧温度时,已经不能清楚地观察到磨痕,此条件下纯钛试样表面几乎未被磨损,耐磨损性能最好。连续渗氧试样的磨痕宽度在700 ℃时达到最小,当渗氧温度提高到800 ℃后,又显现出明显的磨痕,这是由试样表面的氧化层在对磨过程中脱落成为磨粒所致。

3 结论

1) 渗氧处理后试样表层形成了由TiO2、Ti2O3、TiO多种钛氧化物组成的氧化层。800 ℃脉冲渗氧 6 h试样表面氧化层仍然完整致密,而连续渗氧试样氧化层脱落严重,同等参数条件下,脉冲试样氧化层与基体结合更紧密。

2) 700 ℃脉冲渗氧6 h试样的显微硬度最大,为15.39 GPa,约为原始试样的7.3倍,连续渗氧试样的最大显微硬度为9.29 GPa,约为原始试样的4.4倍,但仅为脉冲渗氧最大显微硬度的60%。

3) 700 ℃连续渗氧4.5 h试样表面摩擦因数最小为0.30,磨痕截面积最小为3876.08 μm2;800 ℃脉冲渗氧4.5 h试样表面摩擦因数最小为0.24,磨痕截面积最小为317.44 μm2,仅为原始试样的0.92%;脉冲渗氧可显著提高纯钛的耐摩擦磨损性能,黏着磨损得到削弱。

REFERENCES

[1] 李 梁, 孙健科, 孟祥军. 钛合金的应用现状及发展前 景[J]. 钛工业进展, 2004, 21(5): 19-24.

LI Liang, SUN Jian-ke, MENG Xiang-jun. Application status and development prospect of titanium alloy[J]. Titanium Industry Progress, 2004, 21(5): 19-24.

[2] 吕冬兰. 钛合金在民用飞机上的应用及发展趋势[J]. 世界有色金属, 2018, 497(5): 230-231

Lü Dong-lan. Application and development trend of titanium alloy in civil aircraft[J]. World Nonferrous Metals, 2018, 497(5): 230-231

[3] 黄张洪, 曲恒磊, 邓 超, 等. 航空用钛及钛合金的发展及应用[J]. 材料导报, 2011, 25(1): 102-107.

HUANG Zhang-hong, QU Heng-lei, DENG-Chao, et al. Development and application of aerial titanium and its alloys[J]. Materials Reports, 2011, 25(1): 102-107.

[4] 冯颖芳. 汽车用钛及钛合金的现状与展望[J]. 中国钛业, 2014(3): 8-14.

FENG Ying-fang. The situation and prospects of titanium and titanium alloys for automobiles[J]. China Titanium Industry, 2014(3): 8-14.

[5] 王敬生, 夏耀勤, 崔耀国. 钛合金在汽车上的应用和展 望[J]. 金属学报, 2002, 38(z1): 533-535.

WANG Jing-sheng, XIA Yao-qin, CUI Yao-guo. The application and prospects of titanium alloy in the automobile[J]. Acta Metallurgica Sinica, 2002, 38(z1): 533-535.

[6] 秦建峰, 王馨舶, 邹娇娟, 等. 热氧化提高钛及钛合金表面性能的研究进展[J]. 表面技术, 2017, 46(1): 1-8.

QIN Jian-feng, WANG Xin-bo, ZOU Jiao-juan, et al. Research progress of thermal oxidation effect on improving surface properties of titanium and titanium alloy[J]. Surface Technology, 2017, 46(1): 1-8.

[7] 张春艳, 李春天, 张 津. 热氧化处理对钛合金表面耐磨性能影响的研究[J]. 表面技术, 2008, 37(6): 18-20, 23.

ZHANG Cun-yan, LI Chun-yian, ZHANG Jin. Study on effect of thermal oxidation treatment on wear resistance of titanium alloy[J]. Surface Technology, 2008, 37(6): 18-20, 23.

[8] 叶雪梅, 孙 斐, 王 燕, 等. 热氧化处理对纯钛耐腐蚀性能影响的研究[J]. 钛工业进展, 2014, 31(1): 21-24.

YE Xue-mei, SUN Fei, WANG Yan, et al. Study on the effect of thermal oxidation on cp-ti corrosion resistance[J]. Titanium Industry Progress, 2014, 31(1): 21-24.

[9] 王娅婷, 林乃明, 唐 宾. 钛及钛合金热氧化工艺的研究现状[J]. 腐蚀与防护, 2014, 35(10): 965-970.

WANG Ya-ting, LIN Nai-ming, TANG Bin. Development of thermal oxidation of titanium and titanium alloys[J]. Corrosion & Protection, 2014, 35(10): 965-970.

[10] BAILEY R, SUN Y. Corrosion and tribocorrosion performance of thermally oxidized commercially pure titanium in a 0.9% NaCl solution[J]. Journal of Materials Engineering & Performance, 2015, 24(4): 1669-1678.

[11] JAMESH M, KUMAR S, NARAYANAN T S N S. Effect of thermal oxidation on corrosion resistance of commercially pure titanium in acid medium[J]. Journal of Materials Engineering & Performance, 2012, 21(6): 900-906.

[12] ANIOLEK K, KUPKA M, BARYLSKI A, et al. Mechanical and tribological properties of oxide layers obtained on titanium in the thermal oxidation process[J]. Applied Surface Science, 2015, 357: 1419-1426.

[13] 张聪惠, 于 飞, 王耀勉, 等. 表面机械研磨工业纯锆的疲劳性能研究[J]. 稀有金属, 2017, 41(3): 284-289.

ZHANG Cong-hui, YU Fei, WANG Yao-mian, et al. Fatigue property of commericial pure zirconium subjected to surface nanocrystallization[J]. Chinese Journal of Rare Metals, 2017, 41(3): 284-289.

[14] 侯文英. 摩擦磨损与润滑[M]. 北京: 机械工业出版社, 2012: 13-22.

HOU Wen-ying. Friction and wear and lubrication[M]. Beijing: China Machine Press, 2012: 13-22.

[15] 梁立业. TC4钛合金阳极氧化着色工艺研究[D]. 沈阳: 沈阳理工大学, 2013.

LIANG Li-ye. Study on anodizing and coloring process of TC4 titanium alloy[D]. Shenyang: Shenyang Institute of Technology, 2013.

[16] MUNGOLE M N, SINGH N, MATHUR G N. Oxidation behaviour of Ti6Al4V titanium alloy in oxygen[J]. Metal Science Journal, 2013, 18(1): 111-114.

[17] 张玲玲, 袁丽萌, 陈 媛, 等. 激光诱致不锈钢彩色标识工艺研究[J]. 应用激光, 2017(1): 115-121.

ZHANG Ling-ling, YUAN Li-meng, CHEN Yuan, et al. Research of the process of laser induced color marking on stainless steel[J]. Applied Laser, 2017(1): 115-121.

[18] HAUFFE K. Oxidation of metals[M]. New York: Plenum Press, 1965: 201.

[19] 杨 闯, 王 亮, 彭先文, 等. TC4钛合金真空脉冲渗氧腐蚀性能的研究[J]. 热加工工艺, 2014, 43(2): 144-146.

YANG Chuang, WANG Liang, PENG Xian-wen, et al. Study on corrosion behavior of vacuum pulse oxidation for TC4 titanium alloy[J]. Hot Working Technology, 2014, 43(2): 144-146.

[20] 张聪惠, 高 鹏, 王耀勉, 等. 高能喷丸对TA2表面TiN薄膜生长和力学性能的影响[J]. 稀有金属, 2018, 42(8): 841-849.

ZHANG Cong-hui, GAO Peng, WANG Yao-mian, et al. Growth and mechanical properties of TiN thin deposited on HESP TA2 substrate[J]. Chinese Journal of Rare Metals, 2018, 42(8): 841-849.

[21] KHALIL N. Quantum chemical approach of corrosion inhibition[J]. Electrochimica Acta, 2003, 48(18): 2635-2640.

[22] 李朝志, 付彬国, 刘金海, 等. 钛合金干滑动摩擦行为与磨损机理研究进展[J]. 材料导报, 2018, 32(S1): 410-414.

LI Chao-zhi, FU Bin-guo, LIU Jin-hai, et al. Research progress of wear behavior and mechanism of titanium alloys under sliding condition[J]. Materials Reports, 2018, 32(S1): 410-414.

[23] 谢莹莹. 网状结构TiBw/TC4复合材料TiAl3涂层制备及氧化性能[D]. 哈尔滨: 哈尔滨工业大学, 2015.

XIE Ying-ying. Preparation and oxidation properties of TiAl3 coatings on TiBw/TC4 composites[D]. Harbin: Harbin Institute of Technology, 2015.

[24] 孙 跃, 马欣新, 徐淑艳, 等. 轴承钢等离子体基升温注渗层耐磨性研究[C]// 中国机械工程学会摩擦学分会. 第七届全国摩擦学大会论文集(二). 兰州: 工程科技Ⅰ辑, 2002.

SUN Yue, MA Xin-xin, XU Shu-yan, et al. Study on wear resistance of plasma based temperature increasing layer for bearing steel[C]// Tribology Branch of Chinese Society of Mechanical Engineering. Proceedings of the 7th National Tribology Congress (2). Lanzhou: Journal of Engineering Science and Technology Ⅰ, 2002.

[25] 贾毅朝. 摩擦与摩擦因数的分析[J]. 运城学院学报, 2006, 24(2): 60-61.

JIA Yi-zhao. Analysis of friction and friction coefficient[J]. Journal of Yuncheng University, 2006, 24(2): 60-61.

[26] 张 健. 电弧喷涂Ni-Ti涂层的组织结构及其耐磨性能研究[D]. 西安: 西安石油大学, 2012.

ZHANG Jian. Study on microstructure and wear resistance of arc sprayed Ni-Ti coating[D]. Xi’an: Xi’an Petroleum University, 2012.

[27] 张燕平. ZGMn13高锰钢耐磨性与磨削加工硬化机理的研究[D]. 福州: 福州大学, 2013.

ZHANG Yan-ping. Study on wear resistance and grinding hardening mechanism of ZGMn13 high manganese steel[D]. Fuzhou: Fuzhou University, 2013.

[28] 熊其玉, 王 伟, 贾文兵, 等. 面接触多体摩擦过程界面特性试验研究[J]. 应用力学学报, 2015, 32(2): 226-232.

XIONG Qi-yu, WANG Wei, JIA Wen-bin, et al. Experimental study on interface characteristics of surface contact multi-body friction process[J]. Chinese Journal of Applied Mechanics, 2015, 32(2): 226-232.

Effect of pulse oxidation on friction and wear properties of industrial pure titanium surface

ZHANG Cong-hui, LIU Ying, XIAO Gui-zhi, ZHANG Jin

(College of Metallurgy Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China)

Abstract: In order to improve the wear resistance of industrial pure titanium in the process of application, the method of pulse oxidation was used under different temperatures and time. X-ray diffractometer (XRD), scanning electron microscope (SEM), nano indentation tester and friction and wear tester were used to test the characteristic peak strength, morphology characteristics, indentation hardness, surface friction coefficient and wear scar cross-sectional area of the wear mark. The results show that oxidation layer and oxygen diffusion layer form on the surface of industrial pure titanium samples by pulse oxidation. Compared with the continuous oxidation samples and the original samples, the surface hardness of the pulse oxidation sample at 700 ℃ for 6 h is the largest, being 15.39 GPa, which is about 1.7 times of that of the continuous oxidation sample, 7.3 times of that of the original sample. The friction coefficient and wear scar cross-section area of the pulse oxidation sample at 800 ℃ for 4.5 h are the smallest, which are 0.24 and 317.44 μm2, respectively. The adhesive wear of the samples is significantly weakened and the wear resistance is improved.

Key words: industrial pure titanium; pulse oxidation; oxidation layer; oxygen diffusion layer; friction; wear

Foundation item: Project(2016JM5032) supported by the Shaanxi Natural Science Basic Research Program, China; Project(51804241) supported by the National Natural Science Foundation of China; Project(17JS065) supported by the Key Laboratory Research Project of Shaanxi Provincial Department of Education, China; Project(2016004) supported by the Open Project of State Key Laboratory of Rolling Technology and Continuous Rolling Automation of Northeastern University, China

Received date: 2019-11-04; Accepted date: 2020-06-26

Corresponding author: ZHANG Cong-hui; Tel: +86-29-82201862; E-mail: jiandazhang2010@hotmail.com

(编辑 李艳红)

基金项目:陕西省自然科学基础研究计划资助项目(2016JM5032);国家自然科学基金资助项目(51804241);陕西省教育厅重点实验室研究资助项目(17JS065);东北大学轧制技术及连轧自动化国家重点实验室开放课题基金资助项目(2016004)

收稿日期:2019-11-04;修订日期:2020-06-26

通信作者:张聪惠,教授,博士;电话:029-82201862;E-mail:jiandazhang2010@hotmail.com