细晶W-Cu复合FGM制备及其显微组织特征

郭垚峰,范景莲,蒋冬福,刘涛

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:研究喷雾干燥-煅烧还原-球磨工艺对W-10Cu,W-20Cu和W-30Cu复合粉末性能的影响,进而采用低温一步液相烧结制备三层W/Cu梯度功能材料(FGM),并对其进行金相组织、能谱和显微硬度分析。研究结果表明:适当的还原-球磨工艺可以控制W-Cu粉末形貌、粒度,进而提高粉末烧结活性。球磨后的W-10Cu和W-20Cu粉末在1 380 ℃烧结120 min后达到全致密,球磨40 h后的W-10Cu和W-20Cu粉末烧结收缩率比普通状态的W-30Cu粉末的收缩率大。煅烧还原-球磨W-Cu复合粉末进过三层铺粉压制、烧结后,Cu相形成连续网状结构,细小W颗粒均匀分布,材料接近全致密、层间结合完好。材料截面成分和硬度沿梯度方向连续渐变。

关键词:梯度材料;W-Cu合金;喷雾干燥;球磨

中图分类号:TG146.4 文献标志码:A 文章编号:1672-7207(2014)11-3762-07

Fabrication and microstructure of fine grain W-Cu FGM

GUO Yaofeng, FAN Jinglian, JIANG Dongfu, LIU Tao

(State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: An effective process consisting of spray drying, hydrogen reduction and subsequent ball milling was adopted to fabricate W/Cu three-layer functionally gradient material (FGM). The microstructures energy spectrum analysis and micro-penetration hardness were explored. The results show that the size and morphology of the powders can be controlled to improve the sintering activity of the powder by reduction and ball milling process. W-10Cu and W-20Cu can get full density by sintering at 1 380 ℃ for 120 min after milling, and have more shrinkage than W-30Cu at the same sintering process after 40 h milling. The fine tungsten grains uniformly distribute in the matrix Cu phase, and the interfaces of gradient materials are clear without obvious defects. The components and the hardness of the gradient material are gradual changed along the gradient direction.

Key words: gradient material; W-Cu alloy; spray drying; ball milling

偏滤器是现代磁约束核聚变堆试验装置一个非常重要的组成部分[1],其主要功能是屏蔽来自器壁的杂质,减少对中心等离子体的污染,排出来自中心等离子体的粒子流和热流以及核聚变反应过程中所产生的氦灰[2]。偏滤器主要由第一面壁材料、中间适配层、基体热沉材料组成。第一壁材料直接承受来自等离子体的高能粒子流冲击和高热负荷沉积,W合金被认为是最有前景的第一壁材料[3]。热沉材料主要负责传递第一壁产生的热负荷,需要承受5~20 MW/m2的能量密度,目前通常选择CuCrZr[4]作为热沉材料。W-Cu梯度复合材料结合了铜的高热导率、无氢脆性和钨的高熔点、低腐蚀率、低氚滞留的特点,可以通过成分配比制备具有梯度膨胀系数的中间适配层,能够很好地缓释由于第一壁材料与热沉材料热性能不匹配而造成的热应力,是目前制备偏滤器适配层的最佳材料之一[5-7]。由于W和Cu 物理性能差异很大[8],采用传统制备方法很难获得高致密的W-Cu梯度材料[9]。常规的梯度W骨架渗铜工艺,Cu相分布不均匀,易在W坯体内部形成闭孔,降低了材料的热导率[10]。等离子喷涂法由于涂层与基体的结合以机械结合为主,结合强度低,且涂层孔隙率高,容易剥落[11]。激光烧结虽然有可以控制梯度粉末粒度、成分的优点,但激光烧结易形成铜池,从W端烧结可能引起Cu相的大量挥发[12]。本文作者利用传统粉末冶金方法粉末成分、粒度可控的优势,以偏钨酸铵和硝酸铜晶体为原料[13-15],采用溶胶喷雾干燥-煅烧还原-球磨工艺制备W-10Cu,W-20Cu,W-30Cu(质量分数,%,下同)3种复合粉末,研究活化W-Cu粉末的特性,并制备高致密三层梯度W-Cu复合材料。

1 实验方法

结合本课题组原有研究结果[16],按材料成分配制混合溶胶,调节溶胶pH为3~4。调整溶胶喷雾干燥—煅烧还原—球磨工艺分别制备W-10Cu,W-20Cu和W-30Cu 3种复合粉末,其中煅烧工艺为于150~500 ℃煅烧0.5~3 h,还原工艺为H2保护下于120~750 ℃分步还原,球磨工艺为高能球磨0~40 h。使用英国MICRO-PLVS型激光粒度分析仪,统计不同球磨时间下复合粉末的粒度分布。在JSM-5600LV型扫描电子显微镜上观察不同球磨时间下粉末的形貌特征。在25 t液压机上,使用标准抗弯模具,采用分层铺粉、模压成型制备3层梯度材料,每层梯度层铺粉5 g。复合样品梯度层粉末球磨时间如表1所示。将压坯在氢气还原炉中900 ℃预烧,随后在钼丝炉中以氢气为保护气氛于1 380 ℃下烧结120 min,使用德国Leica公司MeF3A金相显微镜观察样品显微组织,美国Buehler公司Micromet5104显微硬度仪检测梯度层维氏硬度,EDAX公司Nova NanoSEM230型能谱仪分析仪检测梯度层成分变化。

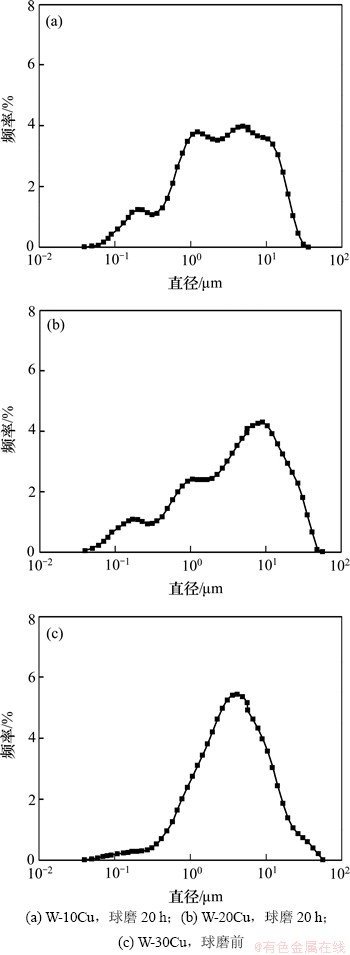

表1 复合样品梯度层粉末球磨时间

Table 1 Milling time of W-Cu powder for composite material samples h

2 结果与讨论

2.1 W-Cu梯度材料成分设计

功能梯度材料是由日本的新野正之等学者于1986年首先提出的,最初设计就是为了减少材料内部应力[8]。由于W-Cu梯度功能材料成分沿Y方向一维连续变化,故采用WAKASHIMA幂函数[17]描述W-Cu梯度成分组成:

φ(Cu)=(y/h)p (1)

式中:φ(Cu)为梯度方向上的Cu体积分数;h为梯度功能材料的厚度;y(h≥y≥0)为相应梯度层的位置;p为成分分布规律指数。由于Cu较W更容易烧结致密,故通常采用p≥1作为成分分布指数。这种梯度结构可以使富W端梯度层成分平稳过渡,利于烧结热应力的减小。为了制备面对等离子W涂层与Cu合金热沉材料间的过渡层,采用W-10Cu,W-20Cu和W-30Cu为成分梯度制备复合材料。

2.2 W-Cu复合粉末性能

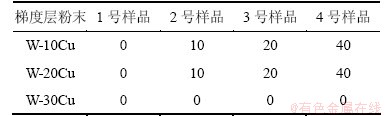

图1所示为不同球磨工艺下W-10Cu粉末SEM形貌。由图1(a)可知:溶胶喷雾法制备的W-Cu复合粉末颗粒细小、均匀,均为近球形,但存在少量团聚。球磨10 h后的W-10Cu粉末明显变形,由近球形变形、破碎为片层状结构(如图1(b)所示)。随着球磨的进行(如图1(c)所示),复合粉末进一步破碎,片层厚度也进一步减小。

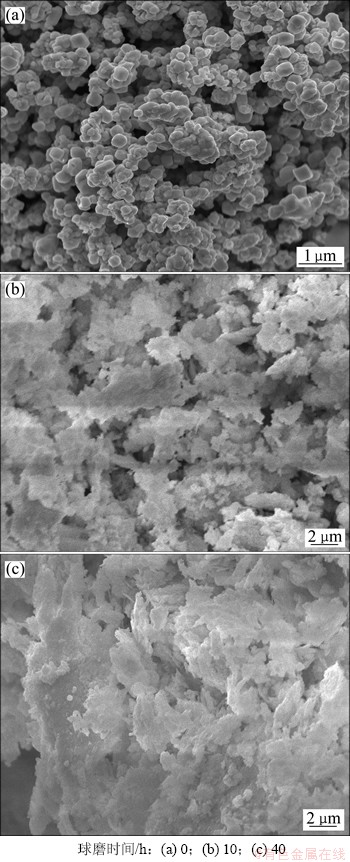

图2所示为3号样品对应的W-Cu复合粉末粒度分布情况。由图2可知:没有球磨的W-30Cu粉末粒度呈正态分布,平均晶粒度为2.05 μm。球磨20 h的W-10Cu和W-20Cu粉末粒度呈现双峰状分布,平均粒径分别为1.03和1.15 μm。这是由于在球磨过程中,颗粒与颗粒间、颗粒与磨球间反复的碰撞、挤压,大尺寸颗粒不断破碎为细小的新颗粒,体现在粒度分布曲线上就是原始正态分布的峰值的降低、细晶区出现新的峰。

粉末的烧结动力主要来自表面能降低带来的系统总能量降低。机械合金化作为一个非平衡过程,可以减小粉末粒度进而增加粉末表面能、增加体系烧结活性。粉末液相烧结初期,固体W颗粒随着Cu相的流动而旋转重排,体系发生致密化。W颗粒的重排主要受液相Cu的毛细管力带动,如式(2)所示[18]:

(2)

(2)

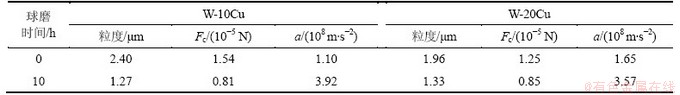

式中:Fc为毛细管力;γlv为液相与气相的界面能(取1.28 J/m2);D为颗粒粒径;m为颗粒质量(近似按照球形计算体积);a为颗粒在毛细管力作用下的重排加速度。通过粒径分布可以计算出W-10Cu和W-20Cu球磨前后毛细管力,见表2。由表2可知:W-10Cu初始粒径比W-20Cu的略大,但球磨10 h后,W-10Cu颗粒细化更明显。这是因为W-20Cu中铜含量较高,喷雾干燥后煅烧还原温度略低,晶粒较细小。同时由于W-10Cu中钨含量高,脆性更强,对球磨过程更敏感,破碎效果更好,故球磨10 h后颗粒反而比W-20Cu的小。对比球磨前后的毛细管力和加速度变化,可以发现:球磨后的粉末颗粒表面积减小,但比表面积却大大增加,故虽然单一颗粒受到的毛细管力减小,但运动加速度a∝D-2反而明显增加,这从颗粒重排毛细管力的角度解释了纳米粉末烧结活性高的原因。

图1 不同球磨工艺下W-10Cu粉末SEM形貌

Fig. 1 SEM images of sol-spray-milling W-10Cu powders

图2 W-Cu复合粉末粒度分布

Fig. 2 Particle size distributions of W-Cu composite powders

表2 喷雾干燥W-Cu粉末球磨前后粒度及烧结毛细管力

Table 2 Relationship between particle size and capillary force of W-Cu

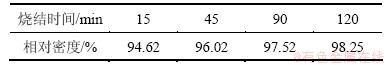

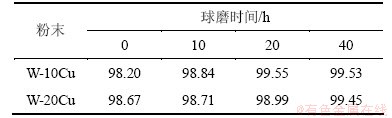

表3所示为溶胶-喷雾干燥W-30Cu复合粉末一步液相烧结致密化情况。由表3可知:超细W-30Cu复合粉末活性很高,在1 380 ℃烧结120 min已接近全致密。考虑到W-10Cu和W-20Cu粉末钨质量分数较高,烧结难度相对较大,故对这2种粉末进行溶胶-球磨处理。2种粉末在1 380 ℃烧结120 min致密化情况如表4所示。由表4可知:溶胶-球磨工艺制备的W-10Cu和W-20Cu烧结活性很高,于1 380 ℃烧结120 min的材料已基本致密,较常规W-Cu粉末致密化温度低。这是由于溶胶-球磨粉末成分混合均匀,在球磨过程中颗粒内部产生大量位错和缺陷,同时晶粒进一步细化。大量的晶格畸变和纳米晶界的形成使粉末活性增大,有利于烧结的进行[19]。

表3 W-30Cu复合粉末1 380 ℃烧结致密化

Table 3 Densification of W-30Cu composite powders at 1 380 ℃

表4 W-10Cu和W-20Cu溶胶-球磨粉末烧结相对密度

Table 4 Relative density of W-10Cu, W-20Cu composite powders after milling %

2.3 W-Cu梯度材料的制备与组织梯度分布特征

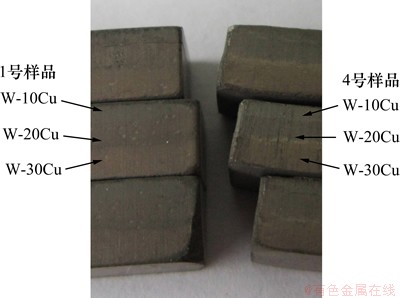

图3所示为梯度材料1号样品和4号样品于900 ℃预烧后的实物照片。由图3可知:未球磨的梯度材料向高铜端(颜色较浅)弯曲变形,与球磨40 h的梯度材料弯曲方向相反。这说明球磨40 h的W-10Cu和W-20Cu粉末处于较高能量状态,烧结收缩率很高,预烧阶段的收缩速度甚至超过了未球磨的W-30Cu粉末。

图3 W-Cu梯度材料900 ℃预烧实物照片

Fig. 3 Images of W-Cu gradient materials after pre-sintering at 900 ℃

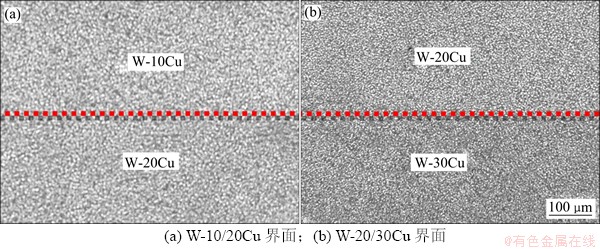

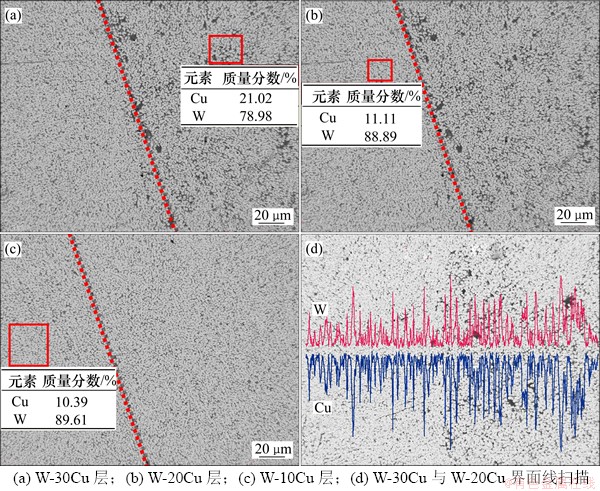

研究表明,W-Cu梯度适配层中气孔的存在会降低材料热导率和涂层自身的结合强度,而且对核聚变燃料气体的滞留有影响[20],故制备高致密、低变形的W-Cu梯度材料有十分现实的意义。考虑到1号样品和4号样品的烧结变形情况相反,实验采用球磨时间适中的3号样品进行高温液相烧结,以降低梯度材料的烧结变形。图4所示为3号样品1 380 ℃液相烧结120 min后的金相组织。由图4可知:分层铺粉—压制—烧结后的梯度材料接近全致密、层间结合完好,细小W颗粒均匀分布在Cu相形成的连续网状结构中。进而对梯度层进行能谱分析,如图5所示。图5(a),(b),(c)所示分别为设计前的W-30Cu,W-20Cu,W-10Cu层的面扫描照片,由能谱分析可知每层成分均与原始设计存在偏差:W-30Cu层和W-20Cu层铜含量降低,W-10Cu层铜含量略有增加。这是因为实验采用1 380 ℃液相烧结,Cu相熔化并带动W颗粒流动,三层梯度材料随着Cu相的黏性流动而完整的结合在一起。同时,液相烧结过程中,梯度材料表面的Cu相有部分溢出。检测取样时,对梯度烧结坯进行了表面抛光处理,导致检测结果中材料整体铜含量偏低。图5(d)所示为W-30Cu与W-20Cu界面附近的线扫描。由于本研究制备的W-Cu梯度材料,晶粒细小,二次颗粒的粒度为微米级,与能谱入射斑为同一数量级,故线扫描呈现锯齿状连续谱线。由图5(d)可知:W-30Cu(右部分)白色的W颗粒周围包覆着较多的深色Cu基体,对应的线扫描中Cu谱线较密集,强度也较高。由右向左进入W-20Cu区域,Cu峰密集度明显减小,W峰密集度和强度则逐渐增加。液相Cu流动导致的均匀化带来了梯度材料整体的高致密和梯度成分的渐变,在实际生活中有一定应用价值。考虑到梯度成分有所偏离,后续研究中将采用缩短烧结时间、降低烧结温度、加压烧结等措施,对Cu相流失问题进行控制。

图4 梯度复合材料3号样品金相组织

Fig. 4 Microstructures of gradient material sample 3

图5 梯度复合材料3号样品能谱分析

Fig. 5 Energy spectrum analysis of W-Cu gradient material sample 3

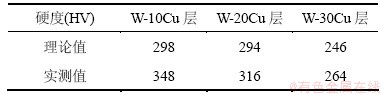

W-Cu复合材料的硬度取决于W的质量分数以及W和Cu间的结合强度,可以间接反映梯度材料的烧结状况。对经球磨工艺的W-Cu梯度材料3号样品进行显微硬度分析,每个梯度层均取4个硬度再求平均值,结果见表5。由表5可知:由于Cu质量分数的差异,3层梯度材料沿梯度方向存在着硬度梯度,W-10Cu层硬度最大,W-10Cu层与W-20Cu层的硬度差小于W-20Cu与W-30Cu层的硬度差。这与前面的能谱分析结果一致,即W-10Cu层与W-20Cu层的成分差异小于W-20Cu与W-30Cu层的成分差异。表中的W-Cu理论硬度由下式计算得到[4]:

(3)

(3)

式中:Hc,Hw和HCu分别为W-Cu复合材料的硬度、纯W的硬度(HV为362)和纯Cu的硬度(HV为44); 为 W的体积分数。此混合定律适用于双组元、组元间无交互作用(或作用可忽略)的复合材料。W-Cu复合材料成分间固溶度较低[21],可用式(3)估算其理论硬度。对比理论值与实测结果发现,本实验制备的三层梯度复合材料每层的硬度均大于理论硬度。这是因为梯度材料沿厚度方向成分梯度渐变,实测硬度为数组数据的平均值。同时,球磨带来的粉末变形和加工硬化十分明显,这导致烧结后的梯度材料显微硬度较理论硬度普遍偏高。

为 W的体积分数。此混合定律适用于双组元、组元间无交互作用(或作用可忽略)的复合材料。W-Cu复合材料成分间固溶度较低[21],可用式(3)估算其理论硬度。对比理论值与实测结果发现,本实验制备的三层梯度复合材料每层的硬度均大于理论硬度。这是因为梯度材料沿厚度方向成分梯度渐变,实测硬度为数组数据的平均值。同时,球磨带来的粉末变形和加工硬化十分明显,这导致烧结后的梯度材料显微硬度较理论硬度普遍偏高。

表5 三层W-Cu梯度材料显微硬度

Table 5 Micro-penetration hardness of W-Cu three layers gradient material

3 结论

1) 适当的溶胶喷雾—煅烧还原—球磨工艺可以控制W-Cu粉末形貌、粒度,进而增加高W含量W-Cu粉末烧结活性。球磨20 h的W-10Cu和W-20Cu粉末晶粒细小、均匀,在1 380 ℃一步液相烧结120 min便基本致密化。球磨40 h后的W-10Cu和W-20Cu粉末收缩率比未球磨的W-30Cu粉末的收缩率大。

2) 球磨20 h的溶胶-球磨W-Cu复合粉末(3号样品)经过3层铺粉压制,于1 380 ℃液相烧结120 min后,梯度材料接近全致密、层间结合完好。能谱分析和显微硬度分析表明,3层梯度材料截面成分和硬度沿梯度方向连续渐变,与原始设计存在偏移,这是液相铜均匀化、流失的结果。

参考文献:

[1] Barabash V, Peacock A, Fabritsiev S, et al. Materials challenges for ITER-Current status and future activities[J]. Journal of Nuclear Materials, 2007, 370(367): 21-32.

[2] 郭双全, 冯云彪, 燕青芝, 等. 偏滤器中钨与异种材料的连接技术研究进展[J]. 焊接技术, 2010, 39(9): 3-7.

GUO Shuangquan, FENG Yunbiao, YAN Qingzhi, et al. Development of joining technologies on tungsten with dissimilar materials for divertor[J]. Welding Technology, 2010, 39(9): 3-7.

[3] 朱大焕, 王坤, 王先平, 等. 偏滤器第一壁W/Cu FGM的热应力模拟与优化设计[J]. 稀有金属材料与工程, 2011, 40(9): 1658-1661.

ZHU Dahuan, WANG Kun, WANG Xianping, et al. Thermal stress simulation and optimization design for the W/Cu FGM of divertors[J]. Rare Metal Materials And Engineering, 2011, 40(9): 1658-1661.

[4] 汪峰涛, 吴玉程, 王涂根, 等. W-Cu面对等离子体梯度热沉材料的制备和性能[J]. 复合材料学报, 2008, 25(2): 25-30.

WANG Fengtao, WU Yucheng, WANG Tugen, et al. Fabrication and properties of the W-Cu gradient heat sink materials for plasma facing materials[J]. Acta Materiae Compositae Sinica, 2008, 25(2): 25-30.

[5] Kitamura K, Nagata K, Shibui M, et al. Effects of interface edge configuration on residual stress in the bonded structures for a divertor application[J]. Journal of Nuclear Materials, 1998, 263: 275-280.

[6] Zhou Z J, Tan J, Qu D D, et al. High heat loading performance of actively cooled W-Cu FGM-based components[J]. International Journal of Minerals, Metallurgy and Materials, 2011, 18(4): 467-471.

[7] 范景莲, 刘涛, 朱松, 等. W-Cu复合材料制备新技术与发展前景[J]. 硬质合金, 2011, 28(1): 56-65.

FAN Jinglian, LIU Tao, ZHU Song, et al. New processing technology and prospective application of high performance W-Cu composites[J]. Cemented Carbide, 2011, 28(1): 56-65.

[8] Ling Y H, Li J T, Zhou Z J, et al. Fabrication and microstructure of W/Cu functionally graded material[J]. Journal of University of Science and Technology Beijing, 2001, 8(3): 198-202.

[9] Zhang F B, Wang Z D, Cai H P, et al. The Characterization of W-Cu Composite Coating Prepared by Double-Glow Discharge[J]. Rare Metal Materials and Engineering, 2012, 41(S1): 323-326.

[10] 刘秋香, 谢仕芳, 陆德平. W-Cu梯度热沉材料的研究进展[J]. 江西科学, 2012, 30(4): 499-502.

LIU Qiuxiang, XIE Shifang, LU Deping. Research progress of tungsten/copper heat-sink gradient materials[J]. Jiangxi Science, 2012, 30(4): 499-502.

[11] Zhou Z J, Song S X, Du J, et al. Performance of W-Cu FGM based plasma facing components under high heat load test[J]. Journal of Nuclear Materials, 2007, 365(363): 1309-1314.

[12] Pintsuk G, Brunings S E, Doring J E, et al. Development of W/Cu functionally graded materials[J]. Fusion Engineering and Design, 2003, 68(66): 237-240.

[13] 范景莲, 刘涛, 成会朝. 一种超细钨铜复合粉末的制备方法: CN1846908[P]. 2005-04-14.

FAN Jinglian, LIU Tao, CHENG Huichao. A way to manufacture super fine W-Cu powder: CN1846908[P]. 2005-04-14.

[14] 范景莲, 朱松, 刘涛, 等. 超细/纳米W-20Cu复合粉末的液相烧结机制[J]. 中国有色金属学报, 2011, 21(7): 1587-1593.

FAN Jinglian, ZHU Song, LIU Tao, et al. Mechanism of ultrafine/nano W-20Cu composite powder during liquid sintering[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(7): 1587-1593.

[15] Fan J L, Liu T, Zhu S, et al. Synthesis of ultrafine/ nanocrystalline W-(30-50)Cu composite powders and microstructure characteristics of the sintered alloys[J]. Int Journal of Refractory Metals and Hard Materials, 2012(30): 33-37.

[16] 刘涛, 范景莲, 田家敏, 等. 超细/纳米W-10%Cu复合粉末制备与烧结工艺[J]. 中南大学学报(自然科学版), 2009, 40(5): 1235-1239.

LIU Tao, FAN Jinglian, TIAN Jiamin, et al. Synthesis and sintering of ultra-fine/nanometer W-10%Cu composite powder[J]. Journal of Central South University (Science and Technology), 2009, 40(5): 1235-1239.

[17] 刘彬彬, 谢建新. W-Cu梯度功能材料的设计、制备与评价[J]. 粉末冶金材料科学与工程, 2012, 15(5): 413-420.

LI Binbin, XIE Jianxin. Design, fabrication and evaluation of W-Cu functionally graded materials[J]. Materials Science and Engineering of Powder Metallurgy, 2012, 15(5): 413-420.

[18] Johnson J L, Brezovsky J J, German R M. Effect of liquid content on distortion and rearrangement densification of liquid-phase-sintered W-Cu[J]. Metallurgical and Materials Transactions A, 2005, 36(6): 1557-1565.

[19] 田颖, 李运刚, 焦阳. 超细W-Cu复合粉末的制备现状[J]. 粉末冶金技术, 2011, 29(4): 296-299.

TIAN Ying, LI Yungang, JIAO Yang. Current situation of ultrafine W-Cu composite powders preparation[J]. Powder Metallurgy Technology, 2011, 29(4): 296-299.

[20] 种法力. 适配层对钨铜第一壁材料热负荷性能的影响[J]. 特种铸造及有色合金, 2010, 30(12): 1096-1098.

ZHONG Fali. Effects of different compliant layers on the heat performance of W/Cu PFC (plasma facing component)[J]. Special Casting & Nonferrous Alloys, 2010, 30(12): 1096-1098.

[21] 范景莲, 刘涛, 田家敏, 等. 喷雾干燥-氢还原制备W-50Cu纳米复合粉末过程中的相转变[J]. 稀有金属材料与工程, 2008, 37(11): 1919-1923.

FAN Jinglian, LIU Tao, TIAN Jiamin, et al. Phase transformation during synthesis of W-50Cu nanocomposite powder by spray-drying and hydrogen reduction process[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1919-1923.

(编辑 赵俊)

收稿日期:2013-12-20;修回日期:2014-03-13

基金项目(Foundation item):国家磁约束核聚变能发展研究专项(2014GB115000);教育部博士点基金重点项目(20130162130002) (Project(2014GB115000) supported by the Key Project of National Magnetic Confinement Fusion Program;Project(20130162130002) supported by the Key Project of Doctoral Program of the Ministry of Education)

通信作者:范景莲(1967-),女,湖南澧县人,教授,从事难熔金属研究;电话:0731-88836652;E-mail: fjl@csu.edu.cn