DOI: 10.11817/j.ysxb.1004.0609.2020-39641

活化烧结制备W-Cu复合材料及其性能

任载强1, 2,张 兵1, 2,刘鹏茹1, 2,赵 虎3,赵田丽1, 2,张志娟 1, 2

(1. 西安建筑科技大学 冶金工程学院,西安 710055;

2. 功能材料加工国家地方联合工程研究中心,西安 710055;

3. 金堆城钼业股份有限公司技术中心,西安 710077)

摘 要:研究添加元素Ni对W-Cu复合材料组织和性能的影响。利用预混粉、机械球磨和活化液相烧结法制备不同Ni含量W-Cu复合材料,采用电子扫描显微镜、X射线衍射仪、激光导热仪等对复合材料的显微组织、物相、热导率、热膨胀系数和硬度进行检测与分析。结果表明:当W-Cu复合材料中不添加Ni元素时,W颗粒团聚形成闭合孔隙,液相Cu无法有效填充孔隙,导致W-Cu组织分布不均匀。随着Ni含量逐渐增加,钨颗粒尺寸不断增大,Cu相将W颗粒包覆;当Ni含量增至5%时,Cu相分布呈网状结构,复合材料组织的均匀分布。在性能方面,随着Ni元素含量的增加,W-Cu复合材料的致密度从83.91%提高到95.59%,硬度由229HV提升至304HV,各温度下热导率和热膨胀系数均有所下降。

关键词:W-Cu复合材料;活化烧结;组织结构;物理性能

文章编号:1004-0609(2021)-01-0064-08 中图分类号:TG146.411 文献标志码:A

引文格式:任载强, 张 兵, 刘鹏茹, 等. 活化烧结制备W-Cu复合材料及其性能[J]. 中国有色金属学报, 2021, 31(1): 64-71. DOI: 10.11817/j.ysxb.1004.0609.2020-39641

REN Zai-qiang, ZHANG Bing, LIU Peng-ru, et al. Properties investigation of tungsten-copper composites prepared by activated sintering[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(1): 64-71. DOI: 10.11817/j.ysxb.1004.0609.2020-39641

W-Cu复合材料是由互不相溶的W、Cu两相组成的假合金,其综合了W的高熔点(3410 ℃),高密度(19.32 g/cm3)、低热膨胀系数(4.5×10-6 K)和Cu的高电导率(58.14(MS/m))、高热导率(403 W/(m·K)),以及良好的延展性等优点[1-5],通过调整其成分配比可获得不同的热膨胀系数和导电导热性能[6]以用于与不同材料进行封装。因此W-Cu复合材料在电子封装、航空航天、军事工业等领域具有广泛应用[7-9]。但由于W、Cu两相互不相溶,两者之间润湿角较大,且W的熔点(3410 ℃)与Cu的熔点(1083 ℃)差异较大,难以采用常规的熔炼方法制备,目前最常用的制备方法是熔渗法和液相烧结法[10-13]。

熔渗法通常是将W粉末预压成毛坯,并通过预烧结成多孔W骨架,然后在毛细管力的作用下熔融的Cu相会渗透并填充W骨架的孔洞中,从而获得致密的W-Cu复合材料。熔渗法需要较长时间才能使Cu相在W骨架中分布均匀,但长时间熔渗过程可能会使液相腐蚀材料表面,且熔渗后试样表面存在不均匀残余铜相,因此还需要后续加工处理,增加了加工成本和制备周期[14-15]。传统液相烧结法(预混粉、压制、烧结)虽然工艺简单,但是由于钨、铜元素互不相溶,烧结过程后会存在孔洞,很难达到较高致密度[16-18]。材料的致密度与其导电、导热性能和热膨胀系数等密切相关,并且致密度低,复合材料组织、成分分布不均匀降低其力学性能。因此,一般需要再压制、退火等[19-20]后续工艺来改善样品密度。活化烧结工艺可以提高W-Cu复合材料的烧结性能,即向W-Cu复合粉末中加入小量活化元素(如银、钴、铁、锌等),这些元素会降低W与Cu之间的润湿角,有利于W-Cu复合材料致密化[21]。LI等[22]研究了Ag元素对W-Cu复合材料组织和性能的影响,结果表明当Ag的添加量为2%时W-Cu复合材料致密度可达到98.57%,硬度达到227.6HV,导电率为46.5%IACS。杨晓红等[23]研究了Fe元素对W与Cu之间润湿角的影响,研究表明,添加Fe元素可以降低W与Cu之间的润湿角;在1300 ℃时,当Fe含量为1.2%时,W/Cu间的接触角由107.5°降低到47.5°。孙德国等[24]研究了Co元素对W与Cu之间润湿角的影响,研究表明,添加Co元素很大程度上降低了W-Cu间的接触角,当Co含量为1.5%时,W/Cu间的接触角由110.25°降低到25°。CHEN等[25]研究了Zn添加剂对W-Cu复合材料性能的影响,结果表明,添加2%的Zn后W-Cu复合材料致密度达到97.9%,电导率达到1.44×106 S/m,热膨胀系数由9.58×10-6 K-1降低到8.75×10-6 K-1。如今W-Cu复合材料中添加的活化元素种类越来越多,而Ni元素作为活化元素之一在如今生产过程中应用非常广泛,但Ni元素对W-Cu复合材料组织和性能影响的研究较少。因此,本文采用预混粉、机械球磨和活化液相烧结法制备出不同Ni含量W-Cu复合材料,并对其组织和性能进行了观察分析,研究了Ni含量对W-Cu复合材料组织和性能的影响。

1 实验

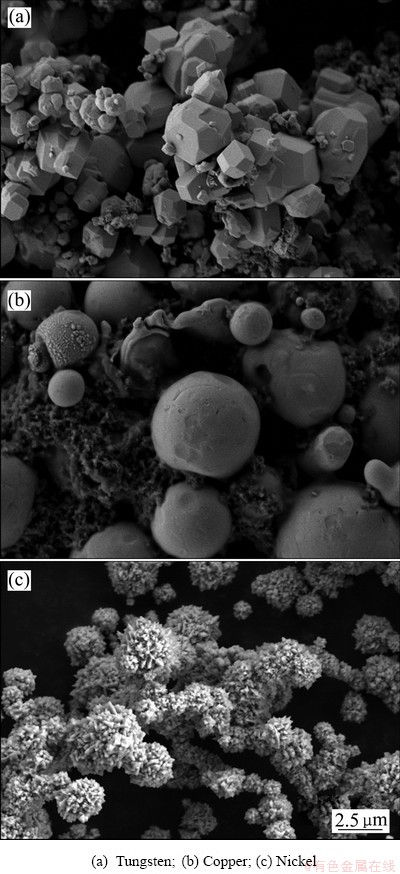

实验材料主要有W粉(粉末粒径2.7 μm,纯度≥ 99.95%)、Cu粉(粉末粒径5 μm,纯度≥99.95%)、Ni粉(粉末粒径5.24 μm,纯度≥99.95%),其粉末形貌如图1所示。

以W-18Cu(质量分数,%)为例,在W、Cu混合粉末中分别添加0%,0.5%,1%,2%,5%的Ni粉末(质量分数),将配比好的粉末装入混料机(混料机型号SBH-5)内混合2 h,再将混合粉末装入球磨罐中,并冲入氦气保护,在球磨机(球磨机型号QM-3SP2)中球磨10 h,球料比为1:1,转速为600 r/min。而后将球磨后的复合粉末装入胶套模具中,采用冷等静压压制成型(冷等静压机型号LDJ320-1500),压制压力为180 MPa,升压速率为18 MPa/min,降压速率为18 MPa/min,经保压10 min后得到d 25 mm的压制坯。然后在马弗炉氢气气氛中由室温升温至1400 ℃保温2 h进行烧结,升温速率为10 ℃/min。为避免降温阶段对烧结件产生不良影响,烧结过程结束后采用随炉冷却,最终得到W-Cu复合材料试样。

图1 原始粉末形貌

Fig. 1 SEM images of original powders

采用扫描电子显微镜(Gemini SEM 300)观察W-Cu复合材料显微组织形貌;采用X射线衍射仪(D8 ADVANCE A25)分析W-Cu复合材料物相成分;采用半自动显微维氏硬度计(401MVD)测量W-Cu复合材料维氏硬度,试验载荷为200 g,加载速度:0.05 mm/s,保压时间20 s;采用激光导热分析仪(LFA 457)测量W-Cu复合材料热导率,根据设备要求制备直径12.7 mm,高度为2 mm的圆片形试样,分别在室温、200、400和600 ℃下测量试样的热导率;采用热膨胀分析仪(NETZSCH DIL402 C)测量W-Cu复合材料热膨胀系数,根据设备要求制备直径5 mm,高度为20 mm的圆柱形试样,由室温加热至600 ℃测量试样的热膨胀系数;采用阿基米德排水法计算试样密度变化。

2 结果与分析

2.1 Ni含量对W-Cu复合材料显微组织的影响

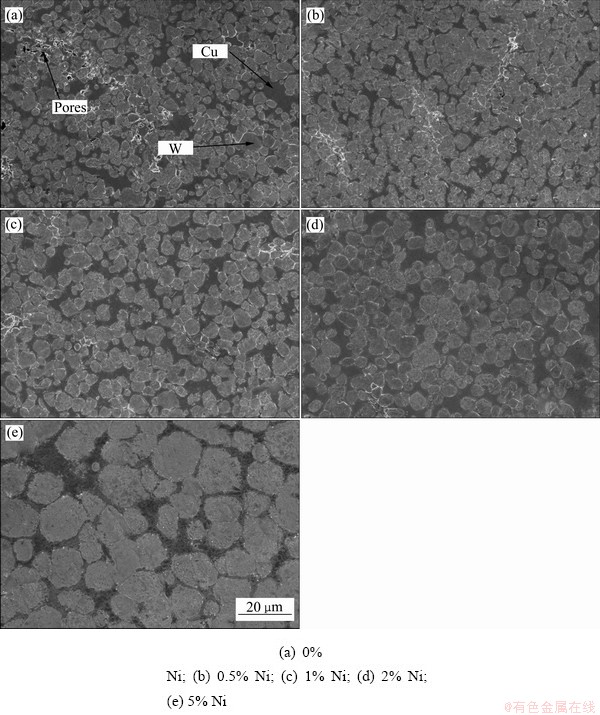

图2所示为添加不同质量分数Ni元素的W-Cu复合材料显微组织。图2中较亮区域为W,较暗区域为Cu或Cu-Ni相。由图2(a)可以看出,当W-Cu复合材料中没有添加Ni元素时,材料组织中存在大量团聚,由于W颗粒团聚后形成闭合孔隙,使得液相Cu无法有效填充孔隙并形成Cu池,导致W-Cu组织分布不均匀,降低W-Cu复合材料致密度和性能。由图2(b)可以看出,当W-Cu复合材料中加入Ni元素后,由于W和Cu界面间润湿角降低,W颗粒重排情况良好,液相Cu开始流入团聚的W颗粒中,Cu池减少,W-Cu复合材料组织更加均匀。从图2(c)~(e)可以看出,随着Ni含量增加,W颗粒的晶粒尺寸增大,颗粒间的间距减少,相互接触增多,复合材料孔隙减少。这是由于Ni溶于Cu中生成Cu-Ni相,改善了W和Cu界面之间的润湿角,提高了液相Cu在W颗粒间的流动性,有助于液相Cu的扩散,减少了W颗粒的聚集。随着W颗粒重排,液相Cu分布更加均匀,有助于液相Cu形成良好网状结构。图2(e)中,当Ni含量为5%时,W-Cu界面在Ni元素作用下润湿角得到改善,铜相形成了连续网状结构,W-Cu组织分布非常均匀。

图2 1400 ℃添加不同含量Ni元素的W-Cu复合材料的SEM像

Fig. 2 SEM images of W-Cu alloy with different Ni contents at 1400 ℃

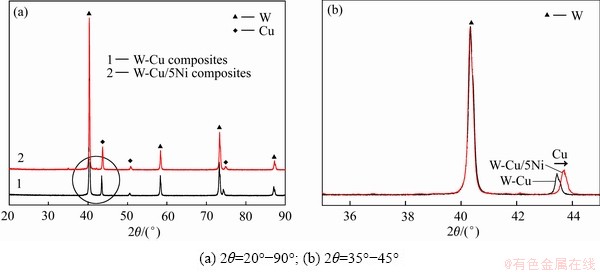

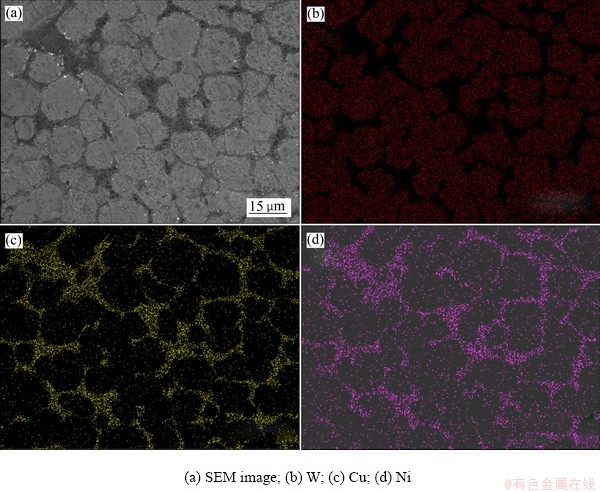

图3所示为W-Cu复合材料和W-Cu-5%Ni复合材料的XRD谱。从图3(a)可以清晰识别出W峰和Cu峰。随着Ni元素加入,由于Ni与Cu可以形成无限固溶体,且Ni元素的晶格常数小于Cu元素的晶格常数,所以图3(b)中Cu衍射峰向高角度移动且更加尖锐。因此,W-Cu-5%Ni复合材料具有均匀组织与Cu和Ni的固溶体密切相关。图4所示为W-Cu-5%Ni复合材料的EDS结果。由图4可以看出,W颗粒重排后分布非常紧密,Cu相将W颗粒包裹且形成均匀的网状结构,Ni相的EDS图像与Cu相的重合,说明Ni元素全部溶入Cu相中,组织分布更加均匀。

2.2 Ni含量对W-Cu复合材料性能的影响

图3 W-Cu复合材料和W-Cu-5%Ni复合材料的XRD谱

Fig. 3 XRD patterns of W-Cu composite and W-Cu-5%Ni composite

图4 W-Cu-5%Ni复合材料的SEM像及EDS谱

Fig. 4 SEM image and EDS patters of W-Cu-5%Ni composites

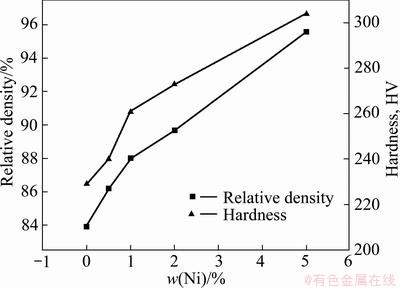

图5所示为不同Ni含量试样的致密度与硬度测量结果。从图5中可以看出,W-Cu复合材料致密度与硬度随着Ni含量增加逐渐上升,不含Ni时复合材料致密度仅为83.91%,当Ni含量为5%时可达到95.59%。这说明Ni含量的提高一定程度上可以提升W-Cu复合材料致密度。这是因为随着Ni含量增加,W和Cu界面间润湿角减少,在液相Cu表面张力作用下,W颗粒向更加紧凑的方向移动,使复合材料中孔隙尺寸和数量迅速减少,毛细管力增大,在强烈毛细管力作用下促使液相Cu迅速分散,形成均匀组织结构,所以致密度急剧上升。W-Cu复合材料的硬度随着Ni含量逐渐提高由229HV上升至304HV,相较不含Ni元素提高了约32.8%,这说明Ni元素对W-Cu复合材料的硬度有较大提升作用。Ni元素对W-Cu复合材料硬度的提升可以归结于致密度的提高和Ni元素对Cu相的固溶强化作用。W-Cu复合材料中加入Ni元素后,一方面来说,提高了W-Cu复合材料致密度,促进复合材料形成更加均匀的组织结构。另一方面,Ni元素会融入Cu相中,形成无限固溶体从而造成晶格畸变,进一步提高W-Cu复合材料的强度。

图5 不同Ni含量W-Cu复合材料的致密度与硬度

Fig. 5 Density and hardness of W-Cu composites with different Ni contents

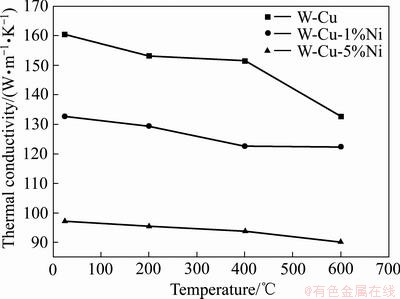

图6所示为不同Ni含量W-Cu复合材料的热导率变化曲线。从图6可以看出,Ni元素对W-Cu复合材料热导率有较大影响,随着Ni含量增高W-Cu复合材料热导率不断降低,当Ni元素含量达到5%时,室温下W-Cu复合材料的热导率由160.34 W/(m·K)减少至97.35 W/(m·K),相较不含Ni元素降低了约39.3%。W-Cu复合材料中的导热表现为W颗粒被液相Cu包覆后Cu相形成了网状结构,自由电子通过在Cu相中运动来传热。当W-Cu复合材料中加入Ni元素后,Ni元素融入Cu相中构成无限固溶体,促进复合材料逐渐形成均匀的网状结构,然而Ni元素的加入同时会使网状结构中晶格畸变程度提高,对内部自由电子运动起到阻碍作用,并且Ni元素的存在对电子运动的阻碍作用大于网状结构对电子运动的促进作用,因此,随着Ni含量增高W-Cu复合材料热导率降低。

图6 不同Ni含量的W-Cu复合材料的热导率

Fig. 6 Thermal conductivity of W-Cu composites with different Ni contents

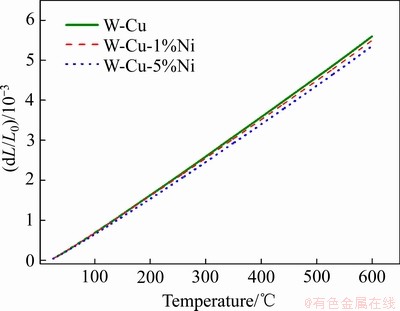

不同Ni含量W-Cu复合材料的热膨胀系数如图7所示。从图7可以看出,W-Cu复合材料的热膨胀系数随着温度升高而不断增大,在相同温度下随着Ni含量升高W-Cu复合材料热膨胀系数会减小。已有研究表明,热膨胀系数受复合材料相对密度和组分的影响。当W-Cu复合材料中不含Ni时,在组织中会存在许多孔洞,从而增加W-Cu复合材料的热膨胀系数,此时孔洞是影响W-Cu复合材料热膨胀系数的主要因素。将Ni添加到W-Cu复合材料中后,相对密度增加,导致复合材料中的孔洞减少。当Ni含量达到5%时,复合材料致密度较高,此时成分是影响复合材料热膨胀系数的主要因素。随着Ni元素不断固溶到Cu相中,Cu相中晶格畸变增加,导致Ni、Cu两相间的相互结合力逐渐增加,复合材料受热后颗粒震动幅度减少,同时Ni元素的热膨胀系数也小于Cu相的热膨胀系数,所以宏观上表现为热膨胀系数减少。因此,当W-Cu复合材料的相对密度较低时,复合材料孔隙中的缺陷会导致热膨胀系数增加;当W-Cu复合材料相对密度较高时,热膨胀系数由复合材料的成分决定,这与CHEN等[25]研究结果相似。

图7 不同Ni含量的W-Cu复合材料的热膨胀系数

Fig. 7 Thermal expansion coefficient of W-Cu composites with different Ni contents

3 结论

1) 利用机械球磨法结合液相烧结法可以制备出一种具有均匀的组织结构和良好力学性能的W-Cu复合材料。通过对比研究得出当复合材料中Ni元素添加量为5%时,W-Cu复合材料组织最为均匀,致密度能够达到95.59%。

2) 活化液相烧结过程中Ni元素通过融入Cu相中来调整W-Cu界面间润湿角,促进液相Cu形成连续的网状结构,进而使W-Cu复合材料组织均匀,这表明Ni元素对复合材料的界面组织有积极作用。

3) 随着Ni元素含量增加,W-Cu复合材料密度由83.91%增加到95.59%,硬度由229HV提高至304HV,各个温度下热导率和热膨胀系数均有所减少。

REFERENCES

[1] LIN D, HAN J S, KWON Y S, et al. High-temperature compression behavior of W-10wt.%Cu composite[J]. International Journal of Refractory Metals & Hard Materials, 2015, 53: 87-91.

[2] ZHOU Qiang, CHEN Peng-wan. Fabrication of W-Cu composite by shock consolidation of Cu-coated W powders[J]. Journal of Alloys and Compounds, 2016, 657: 215-223.

[3] SHI Xiao-liang, YANG Hua, WANG Sheng, et al. Characterization of W-20Cu ultrafine composite powder prepared by spray drying and calcining-continuous reduction technology[J]. Materials Chemistry & Physics, 2007, 104(2/3): 235-239.

[4] JOHNSON J L, PARK S J, KWON Y S, et al. The effects of composition and microstructure on the thermal conductivity of liquid-phase-sintered W-Cu[J]. Metallurgical & Materials Transactions (Part A), 2010, 41(7): 1871-1871.

[5] HAMIDI A G, ARABI H, RASTEGARI S. Tungsten-copper composite production by activated sintering and infiltration[J]. International Journal of Refractory Metals & Hard Materials, 2011, 29(4): 538-541.

[6] 姜国圣, 王志法, 何 平, 等. W-15Cu电子封装材料导热性能的研究[J]. 粉末冶金技术, 2009, 27(6): 438-441.

JIANG Guo-sheng, WANG Zhi-fa, HE Ping, et al. The reasearch on the property of thermal conductivity of W-15Cu heat sink[J]. Powder Metallurgy Technology, 2009, 27(6): 438-441.

[7] ZHOU Zhang-jian, DU Juan, SONG Shu-xiang, et al. Microstructural characterization of W/Cu functionally graded materials produced by a one-step resistance sintering method[J]. Journal of Alloys and Compounds, 2007, 428(1/2): 0-150.

[8] PINTSUK G, SMID I, DORING J E, et al. Fabrication and characterization of vacuum plasma sprayed W/Cu- composites for extreme thermal conditions[J]. Journal of Materials Science, 2007, 42(1): 30-39.

[9] MANESHIAN M H, SIMCHI A. Solid state and liquid phase sintering of mechanically activated W-20 wt.% Cu powder mixture[J]. Journal of Alloys & Compounds, 2008, 463(1/2): 0-159.

[10] DORE F, MARTIN C L, ALLIBERT C H. Apparent viscosity of W-Cu powder compacts during sintering[J]. Materials Science & Engineering A (Structural Materials:, Properties, Microstructure and Processing), 2004, 383(2): 390-398.

[11] KINGERY W D, NARASIMHAN M D. Densification during sintering in the presence of a liquid phase. Ⅱ. Experimental[J]. Journal of Applied Physics, 30(3): 307.

[12] BOLLINA R, GERMAN R M. Heating rate effects on microstructural properties of liquid phase sintered tungsten heavy alloys[J]. International Journal of Refractory Metals & Hard Materials, 2004, 22(2/3): 117-127.

[13] HWANG K S, HUANG H S. Identification of the segregation layer and its effects on the activated sintering and ductility of Ni-doped molybdenum[J]. Acta Materialia, 2003, 51(13): 3915-3926.

[14] 刘 舒, 谢敬佩, 马窦琴, 等. 纳米钨铜复合粉末的制备及其烧结行为研究[J]. 稀有金属与硬质合金, 2014, 42(5): 34-38.

LIU Shu, XIE Jing-pei, MA Dou-qin, et al. Preparation and sintering behavior of nanometer tungsten copper composite powder[J]. Rare Metals and Cemented Carbide, 2014, 42(5): 34-38.

[15] 王德志, 张宇晴, 段柏华. 微波快速熔渗制备钼铜复合材料[J]. 有色金属科学与工程, 2018, 47(3): 15-20.

WANG De-zhi, ZHANG Yu-qing, DUAN Bai-hua. Molybdenum-copper composites prepared by microwave infiltration[J]. Nonferrous Metals Science and Engineering, 2018, 47(3): 15-20

[16] DONG Long-long, AHANGARKANI M, CHEN Wen-ge, et al. Recent progress in development of tungsten-copper composites: Fabrication, modification and applications[J]. International Journal of Refractory Metals & Hard Materials, 2018, 75: 30-42.

[17] ZHENG Ling-ling, LIU Jin-xu, LI Shu-kui, et al. Investigation on preparation and mechanical properties of W-Cu-Zn alloy with low W–W contiguity and high ductility[J]. Materials & Design, 2015, 86: 297-304.

[18] QIU Wen-ting, PANG Yong, XIAO Zhu, et al. Preparation of W-Cu alloy with high density and ultrafine grains by mechanical alloying and high pressure sintering[J]. International Journal of Refractory Metals and Hard Materials, 2016, 61: 91-97.

[19] LI Zhi-gang, JIA Cheng-chang, SUN Lan, et al. Pressure sintering of W-15wt.%Cu alloys prepared by mechanical alloying as a subsequent densification treatment method[J]. Rare Matels, 2006, 25(2): 124-128.

[20] 刘 舒, 谢敬佩, 李继文, 等. 退火工艺对W-20%Cu复合材料组织与性能的影响[J]. 材料热处理学报, 2015, 36(4): 34-38.

LIU Shu, XIE Jing-pei, LI Ji-wen, et al. Effect of annealing process on microstructure and properties of W-20% Cu composites[J]. Journal of Materials and Heat Treatment, 2015, 36(4): 34-38.

[21] JOHNSON J L, GERMAN R M. Phase equilibria effects on the enhanced liquid phase sintering of tungsten- copper[J]. Metallurgical Transactions A (Physical Metallurgy and Materials, Science), 1993, 24(11): 2369-2377.

[22] LI Yuan, ZHANG Jian, LUO Guo-qiang, et al. Densification and properties investigation of W-Cu composites prepared by electroless-plating and activated sintering[J]. International Journal of Refractory Metals and Hard Materials, 2018, 71: 255-261.

[23] 杨晓红, 范志康, 梁淑华, 等. Fe元素对Cu/W间润湿行为和界面特性的影响[J]. 中国有色金属学报, 2009, 19(1): 153-159.

YANG Xiao-hong, FAN Zhi-kang, LIANG Shu-hua, et al. Effect of Fe element on wetting behavior and interface characteristics between Cu/W[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 153-159.

[24] 孙德国, 肖 鹏, 梁淑华, 等. 元素Co对Cu/W间润湿性的影响[J]. 稀有金属材料与工程, 2008, 37(12): 2134-2138.

SUN De-guo, XIAO Peng, LIANG Shu-hua, et al. Effect of element Co on wettability between Cu/W[J]. Rare Metal Materials and Engineering, 2008, 37 (12): 2134-2138.

[25] CHEN Ping-an, LUO Guo-qiang, SHEN Qiang, et al. Thermal and electrical properties of W-Cu composite produced by activated sintering[J]. Materials & Design, 2013, 46: 101-105.

Properties investigation of tungsten-copper composites prepared by activated sintering

REN Zai-qiang1, 2, ZHANG Bing1, 2, LIU Peng-ru1, 2, ZHAO Hu3, ZHAO Tian-li1, 2, ZHANG Zhi-juan1, 2

(1. College of Metallurgy Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China;

2. National and Local Engineering Researching Center for Functional Materials Processing, Xi’an 710055, China;

3 Technical Center, Jinduicheng Molybdenum Co., Ltd., Xi’an 710077, China)

Abstract: The effects of Ni addition on the microstructure and properties of W-Cu composites were researched. W-Cu composites with different contents of Ni element were fabricated by powder mixing, mechanical ball milling and activated liquid phase sintering. The microstructures were observed, and the thermal conductivity, thermal expansion coefficient and hardness of composite materials were measured. The results show that without the addition of Ni element, W particles agglomerate to form closed pores and liquid Cu can not fill the pores, leading to the unbalanced distribution of W-Cu structure. With the increase of Ni element, the W particles grow and were coated with Cu. In particular, when the Ni content increases to 5%, Cu presents a network structure, and the microstructure of the composite is uniform. In addition, with the increase of Ni content, the density and the hardness of the composites increase, and the thermal conductivity and the thermal expansion coefficient decrease.

Key words: W-Cu composites; activated sintering; organizational structure; physical property

Foundation item: Project(51874226) supported by the National Natural Science Foundation of China; Project (2012KTCQ01-08) supported by the Science and Technology Research Program of Shaanxi Province, China; Project(201805033YD11CG17(8)) supported by Xi’an Science and Technology Plan, China

Received date: 2020-01-06; Accepted date: 2020-07-10

Corresponding author: ZHANG Bing; Tel: +86-13691363825; E-mail: r.zhang1112@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51874226);陕西省科技统筹科技攻关项目(2012KTCQ01-08);西安科技计划资助项目(201805033YD11CG17(8))

收稿日期:2020-01-06;修订日期:2020-07-10

通信作者:张 兵,教授,博士:电话:13691363825;E-mail:r.zhang1112@163.com