Trans. Nonferrous Met. Soc. China 25(2015) 622-627

Leaching and recovery of zinc from leaching residue of zinc calcine based on membrane filter press

Zhen-guang RU, Cen-xuan PAN, Gui-hua LIU, Xue-ting WANG, Guang-yu DOU, Ke-song ZHU

Cleaner Production Center, Chinese Research Academy of Environmental Sciences, Beijing 100012, China

Received 18 April 2014; accepted 16 August 2014

Abstract: The feasibility of leaching and recovery of zinc from zinc leaching residue (ZLR) based on a membrane filter press (MFP) was investigated. Experimental results show that zinc calcines with particle sizes of less than 106 μm and chambers of widths of 30 mm are appropriate for establishing uniform filter cakes to obtain acceptable leaching and recovery results. The leaching of zinc from ZLR performed via washing at 90 to 96 °C for 90 min with spent electrolyte using a MFP results in a zinc extraction rate of 97%, and almost all of the zinc leached are recovered after water washing with MFP, thereby avoiding any loss in the ZLR. Compared with the traditional hot concentrated acid leaching process, the process based on MFP as a leaching reactor is able not only to ensure a high extraction rate but also to reduce the leaching time. Moreover, the thickening, pulping, second leaching, washing, filtering and pressing could be integrated and realized using a single MFP.

Key words: zinc; membrane filter press; zinc leaching residue; leaching; recovery

1 Introduction

Zinc sulfide ores are the main source of zinc metal in the world, in which zinc generally exists in forms of sphalerite and marmatite. Currently, more than 80% of the zinc is produced by conventional zinc hydrometallurgical methods, including roasting, leaching and electrowinning processes [1,2]. During the roasting process, ZnS is converted to ZnO, but a significant fraction of ZnO reacts with the iron impurities to form zinc ferrite [3-5]. Zinc ferrite is insoluble in mild acidic conditions. Thus, a considerable amount of leaching residue will be produced in the subsequent leaching process [6,7]. In addition, the leaching reaction rate decreases over time due to the decreasing acid concentration during the traditional leaching process in stirred tank. Consequently, incomplete leaching will occur, thereby further increasing the generation of zinc leaching residue (ZLR), leading to a significant waste of resources and a high environmental risk [8,9].

The high demand for zinc has attracted the interest of industry to utilize the ZLR as a valuable secondary source [1]. Hydrometallurgical processes are widely applied to recycle zinc from ZLR due to their significant advantages of lower capital and operating costs, as well as being less harmful to the environment [1,2]. Currently, the most common hydrometallurgical process is to recover zinc from ZLR in a bath of hot concentrated sulfuric acid [10]. A high extraction rate of zinc can be obtained using this process, but incomplete leaching still occurs due to the leaching in the stirred tank. Moreover, the hot concentrated acid leaching process involves a long reaction time (4-6 h) and consumes an enormous amount of energy and sulfuric acid to process the large amount of ZLRs obtained by thickening. More importantly, in most electrolytic zinc plants, the ZLRs containing water-soluble zinc with a content of less than 5% are directly discharged or heaped, causing a portion of the zinc losses. The water-soluble zinc can cause soil contamination, water pollution and several other serious environmental pollution through the leachate by rainfall [8,9]. Therefore, finding a cost effective and environmental friendly process to recover zinc from ZLR remains a major challenge.

The membrane filter press (MFP), which is a common machine on solid-liquid separation, has advantages of low cost, high solid content and outstanding efficiency that has been widely used in various industries. In recent years, the washing function of MFP has also been attracting attention for use in the titanium dioxide, sugar, pigment and electrolytic manganese metal industries [11-14]. LIU et al [14] recovered 50% of water-soluble manganese from an electrolytic manganese residue (EMR) via a MFP using water. This MFP-based water washing technology could be industrially applied because it solves the problem of “water swelling”, which commonly occurs in previous water washing technologies [14,15]. On the basis of the previous work of LIU et al [14], we attempted to wash the EMR via a MFP using anolyte. In 2009, the MFP-based technology on the leaching and recovery of manganese from EMR via a combination of anolyte washing with water washing was realized and resulted in a patent application being submitted (No. CN1024700A) [16]. Note that several demonstrative operations have also been constructed in China based on this technology. However, the possibility of using this technology in the hydrometallurgical zinc process has never been investigated previously. If this technology could be used in electrolytic zinc plants, the thickening, pulping, second leaching, washing, filtering and pressing would be integrated and realized using a single MFP. In addition, the leaching of zinc from ZLR in the form of spent electrolyte washing would be performed under constant acid concentration via a continuous flow of spent electrolyte.

Hence, the feasibility of leaching and recovery of zinc from leaching residue of zinc calcine based on MFP was investigated, combining spent electrolyte washing with fresh water washing. For this work, the uniformity of filter cakes, which is directly related to the leaching result, was examined. Based on this experimental result, the leaching and washing on extracting zinc from ZLR were subsequently studied.

2 Experimental

2.1 Materials

The experimental study was performed using zinc calcine with a composition of 57% zinc, which was purchased from Hunan Province, China. Spent electrolyte containing 160 g/L of H2SO4 and 50 g/L of Zn2+ was used in all of the leaching experiments. Under all examined conditions, the zinc concentration was determined based on GB/T 14353.3-2010 [17], and the hydrogen ion concentration (H+) was measured based on GB 6498.2-2001 [18]. The membrane filter press (KM470) was from Beijing ZSC Solid-Liquid Separating Technology Co., Ltd. (China), and the membrane plates (470 mm × 470 mm) were from LENSER Filtration GmbH + Co. (Germany).

2.2 Experimental procedure

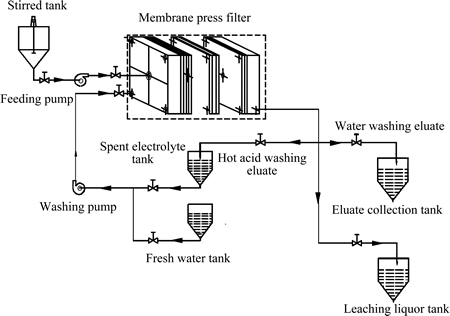

The diagram of leaching and recovery of zinc from zinc calcine is presented in Fig. 1. The proper production process is described briefly as follows. 1) leaching in stirred-tank reactor: Spent electrolyte or sulfuric acid was added to the crushed zinc calcine to leach zinc ions from the ores and to obtain the ZnSO4-contained slurry. 2) filtration: the ZnSO4-contained slurry was pumped into MFP through central feeding hole and filter pressed to obtain the filter cakes (i.e., ZLR); next, the filtrate (leaching liquor) entered the subsequent production process. 3) Re-leaching in MFP: Spent electrolyte at the desired temperature was pumped into the MFP and reacted with filter cakes to leach zinc again and simultaneously recover part of ZnSO4. 4) water washing: The filter cakes were washed again with fresh water to further recover ZnSO4. 5) pressing: Water with a pressure of 1 MPa was pumped into the membrane plates, which was maintained for 20 min to reduce the water content of filter cakes, and the pressed filter cakes were subsequently discharged from the MFP and transported to landfills. The eluate obtained from spent electrolyte washing and fresh water washing steps were collected and returned to spent electrolyte tank and eluate collection tank, respectively.

Fig. 1 Schematic diagram of leaching and recovery process using MFP

3 Results and discussion

3.1 Filter cake formation

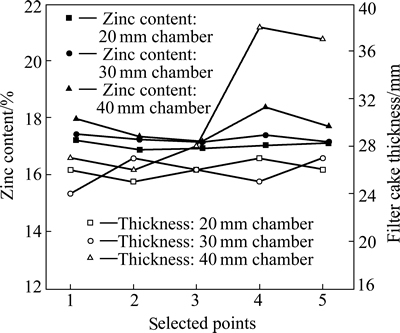

To obtain a high zinc extraction rate and recovery rate using an MFP, the most important step is to obtain uniform filter cakes. The particle size of zinc calcine and sedimentation time, which are directly involved with the width of the filter chambers, are the most important parameters regarding the uniformity of filter cake. Therefore, the particle sizes of zinc calcine, as well as the width of the filter chamber were firstly selected. The five-spot test (upper left, bottom left, center, upper right, bottom right) was used for estimating the uniformity of the filter cakes by measuring the zinc content and thickness of the cakes at these selected points.

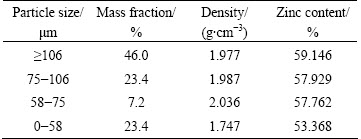

Through observation of the filter cakes formed in the MFP, it is found that triangle cakes were easily formed using raw zinc calcine. The particle size distribution of raw zinc calcines was measured and the corresponding result is presented in Table 1. The presence zinc calcine of large particle size inhibits the formation of uniform cakes due to its good settleability; thus, small size particles should be selected. Choosing the particle size of zinc calcine less than 106 μm (Table 1), which could be obtained in actual production, a series of experiments regarding the filter cake formation were conducted, and the results are presented in Fig. 2.

From Fig. 2, using zinc calcines with particle sizes less than 106 μm, the zinc content and filter cake thickness vary clearly at the five tested points when the filter chamber width is 40 mm, suggesting that the cake uniformity is poor under this condition, which might be due to long sedimentation time. When the filter chamber width is 30 mm, the cake uniformity is improved significantly relative to the chamber width of 40 mm. When the filter chamber width is 20 mm, the cake uniformity is similar to the results obtained as the chamber width is 30 mm. Thus, it can be clearly observed that the uniform filter cakes could be formed by choosing the particle size of zinc calcine to be less than 106 μm for filter chamber widths of 20 mm and 30 mm. As a result, the zinc calcines with particle size less than 106 μm were used in the following experiments. The processing capacity of MFP with 20 mm width chamber is lower than that with 30 mm width chamber. Therefore, combining the results of processing capacity and cake uniformity, the chamber width of 30 mm was selected in the following experiments.

Table 1 Particle size distributions of raw zinc calcines

Fig. 2 Zinc content and thickness of filter cakes at five selected points

3.2 Leaching of zinc from zinc calcine

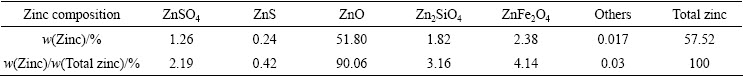

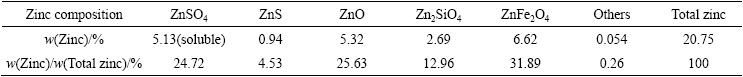

In this leaching process, 100 L of spent electrolyte solution was added to a 300 L stainless steel drum equipped with a variable speed stirrer and then stirred for approximately 1 h at a speed of 60 r/min. Next, the leaching solution was adjusted by adding zinc calcine or sulfate acid until the final Zn2+ concentration of electrolyte was in the range of 130-140 g/L and the final H2SO4 concentration was in the range of 1-2 g/L. Subsequently, the ZnSO4-contained slurry was filtered using a MFP. The analysis results of zinc calcine and ZLR are presented in Tables 2 and 3, respectively.

Table 2 Primary zinc compositions of zinc calcine

Table 3 Primary zinc compositions of ZLR

As presented in Table 2, the grade of zinc calcine is 57.52%, in which ZnO approximately accounts for 90.06% of total zinc in mass. Table 3 indicates that in this process of leaching, most of the ZnO is converted to ZnSO4, resulting in the dramatic decrease of the content of ZnO. After solid-liquid separation using the MFP, many insoluble materials are concentrated in the residue. The content of zinc in the leaching residue is higher than 20%, causing the extraction rate of zinc in this process to be less than 90%. Analysis of ZLR indicates that zinc is mainly presented in the forms of ZnFe2O4, ZnO and ZnSO4, which in total account for up to 80% of the zinc (Table 3). Thus, a secondary leaching process is required to recover the remaining zinc.

3.3 Leaching of zinc from ZLR

In this leaching process, the zinc was extracted from ZLR obtained in Section 3.2 in the form of spent electrolyte washing using MFP. To dissolve ZnFe2O4, strict leaching conditions, such as high temperature (above 90 °C) and high concentration of acid solution (100-200 g/L), are required. Under high temperature and high acid concentration conditions, the extraction rate of zinc can increase to approximately 97% [19,20]. To enable a comparison with the extraction rate obtained in the traditional route, the leaching conditions in the present work are under a temperature in the range of 90 to 96 °C and an acid concentration in the range of 100 to 200 g/L. Because the leaching residues of zinc calcine were fixed in the chamber of the MFP, the high reaction temperature condition was realized through heating of the spent electrolyte.

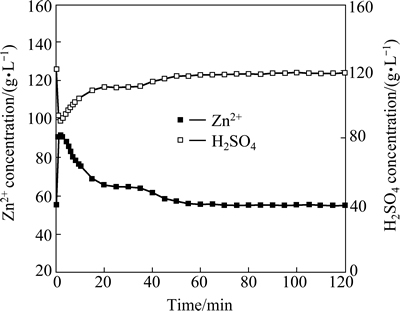

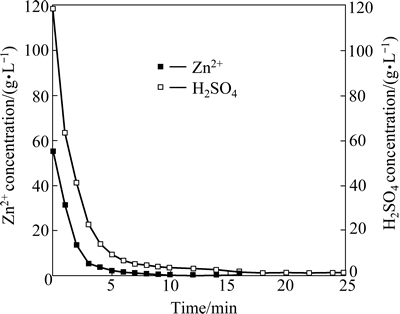

Figure 3 shows the Zn2+ and H2SO4 concentrations with leaching time under a temperature in the range of 90 to 96 °C during the leaching process based on MFP.

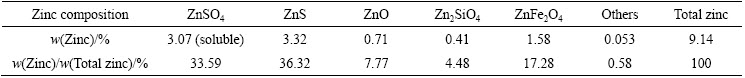

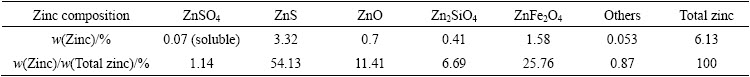

From Fig. 3, the Zn2+ concentration is observed to obviously increase during the initial 5 min, followed by a decrease to 55 g/L after washing for 60 min and only a slight change around the level of 55 g/L in the following 30 min. Conversely, the H2SO4 concentration obviously decreases during the initial 5 min, followed by an increase to 117 g/L after washing for 60 min and then slight changes around the level of 120 g/L in next 30 min. Based on these above results, it can be concluded that the violently reaction of the leaching residue with the hot spent electrolyte only lasts for approximately 60 min. The analysis result of the residue after hot concentrated acid leaching for 90 min is presented in Table 4. Clearly, the zinc content in the residue reduces significantly from over 20% (Table 3) to less than 10% (Table 4). As a consequence, the zinc extraction rate increases to 97%. Thus, this result obviously demonstrates that using a MFP as a leaching reactor could not only ensure a high extraction rate but also reduce the leaching time compared with the traditional hot concentrated acid leaching. The short leaching time using a MFP might be due to the constant reaction conditions of high temperature and high acid concentration during the whole process when using a MFP.

Fig. 3 Zn2+ and H2SO4 concentrations of eluate with hot spent electrolyte (90-96 °C) washing

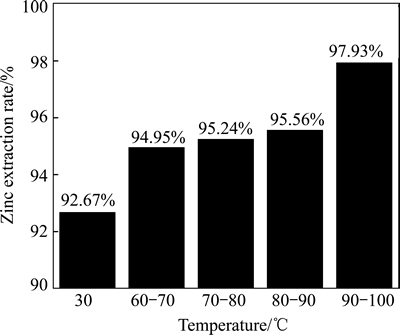

Based on the above results, additional experiments on the leaching of zinc from ZLR were also conducted under low temperatures, such as at 30 °C, 60 to 70 °C, 70 to 80 °C and 80 to 90 °C, to reduce the energy consumption further. The corresponding results are presented in Fig. 4.

The zinc extraction rate at 30 °C is 92.67%, and increases to 94.95% at 60 to 70 °C. When the leaching temperature is further increased to 80 to 90 °C, the extraction ratio increases to 95.56%. The temperature of spent electrolyte has an obvious effect on the zinc extraction ratio. High zinc extraction could be obtained by increasing the temperature of leaching, which is consistent with the results of Ref. [19]. Under low temperatures, the energy consumption is lower, the extraction ratio can not reach the traditional result of 97%. In conclusion, the hot acid leaching only at 90 to 96 °C or above can achieve the ideal result (i.e., more than 97%).

3.4 Recovery of water-soluble zinc

The water-soluble zinc approximately accounts for 3% of the total zinc in the residue after hot acid leaching with MFP (Table 4). To recover this part of the zinc, the leaching residue was further washed with water. Figure 5 shows that both the Zn2+ and H2SO4 concentrations of eluate decrease with increasing washing time, especially in the initial 5 min. These results indicate that Zn2+ and H2SO4 in the zinc residue could be quickly washed out by water using the MFP. After washing for 25 min, the final Zn2+ and H2SO4 concentrations of eluate decrease to 0.05 g/L and 1.25 g/L, respectively.

Table 4 Main zinc compositions of residue after hot acid leaching (90-96 °C)

Table 5 Main zinc compositions of residue after fresh water washing

Fig. 4 Zinc extraction rate under various temperatures

The final residue obtained after being washed and pressed merely contains 6% of zinc, in which the water-soluble zinc only accounts for 0.07% (Table 5), suggesting that the majority of water-soluble zinc is recovered during the water washing process. Compared with the traditional hot concentrated acid leaching process, the water-soluble zinc lost in the leaching residue is very low.

Fig. 5 Zn2+ and H2SO4 concentrations of eluate with water washing time

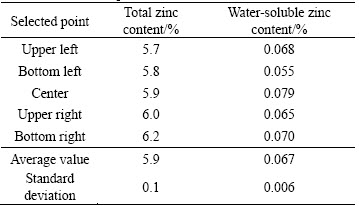

3.5 Washing uniformity

To estimate the washing results, the washing uniformity of MFP was examined by measuring both the total zinc and the water-soluble zinc contents in the final residue. As presented in Table 6, both the total zinc and the water-soluble zinc contents change slightly at five selected points (upper left, bottom left, center, upper right, and bottom right) in the residue, indicating that the hot spent electrolyte and water washing are quite uniform. Therefore, the zinc that can be extracted in zinc calcine and the water-soluble zinc that can be recovered in the residue are completely extracted and recovered by using the MFP.

Table 6 Total zinc and water-soluble zinc contents of final filter cake at selected five points

4 Conclusions

1) The use of a MFP is found to be completely feasible and effective to leach and recover zinc from leaching residues of zinc calcine.

2) The zinc calcines with particle size of less than 106 μm and MFP chambers with a width of 30 mm are proper for establishing uniform filter cakes to obtain acceptable leaching and recovery results.

3) The zinc extraction rate reaches 97% at 90 to 96 °C, with the leaching time of only 90 min for the case of washing ZLR with spent electrolyte based on MFP.

4) Almost all zinc leached is recovered after water washing using a MFP, thereby avoiding any loss in ZLR.

5) Compared with the traditional hot concentrated acid leaching process, the process based on the MFP as a leaching reactor could ensure not only a high extraction rate but also a reduced leaching time.

6) The thickening, pulping, second leaching, washing, filtering and pressing could be integrated and performed using a single MFP, thereby dramatically reducing the cost, land and time.

References

[1] JHA M K, KUMAR V, SINGH R J. Review of hydrometallurgical recovery of zinc from industrial wastes [J]. Resources Conservation and Recycling, 2001, 33(1): 1-22.

[2] LI Mi, PENG Bing, CHAI Li-yuan, PENG Ning, YAN Huan, HOU Dong-ke. Recovery of iron from zinc leaching residue by selective reduction roasting with carbon [J]. Journal of Hazardous Materials, 2012, 237-238: 323-330.

[3] DIMITROV R I, MOLDOVANSKA N, BONEV I K,  Oxidation of marmatite [J]. Thermochimica Acta, 2000, 362(1-2): 145-151.

Oxidation of marmatite [J]. Thermochimica Acta, 2000, 362(1-2): 145-151.

[4] PENG Ning, PENG Bing, CHAI Li-yuan, LI Mi, WANG Ji-ming, YAN Huan, YUAN Yuan. Recovery of iron from zinc calcines by reduction roasting and magnetic separation [J]. Minerals Engineering, 2012, 35: 57-60.

[5] VAHIDI E, RASHCHI F, MORADKHANI D. Recovery of zinc from an industrial zinc leach residue by solvent extraction using D2EHPA [J]. Minerals Engineering, 2009, 22 (2): 204-206.

[6] LI Xuan-hai, ZHANG Yan-juan, PAN Liu-ping, WE Yan-song. Effect of mechanical activation on dissolution kinetics of neutral leach residue of zinc calcine in sulphuric acid [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1512-1519.

[7] YAN Huan, CHAI Li-yuan, PENG Bing, LI Mi, PENG Ning, HOU Dong-ke. A novel method to recover zinc and iron from zinc leaching residue [J]. Minerals Engineering, 2014, 55: 103-110.

[8]  A, ERDEM M. Environmental risk assessment and stabilization/solidification of zinc extraction residue: I. Environmental risk assessment [J]. Hydrometallurgy, 2010, 100(3-4): 103-109.

A, ERDEM M. Environmental risk assessment and stabilization/solidification of zinc extraction residue: I. Environmental risk assessment [J]. Hydrometallurgy, 2010, 100(3-4): 103-109.

[9] MIN Xiao-bo, XIE Xian-de, CHAI Li-yuan, LIANG Yan-jie, LI Mi, KE Yong. Environmental availability and ecological risk assessment of heavy metals in zinc leaching residue [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 208-218.

[10] GRAYDON J W, KIRK D W. The mechanism of ferrite formation from iron sulfides during zinc roasting [J]. Metallurgical Transactions, 1988, 19 (5): 777-785.

[11] ZHANG Dan. Application of membrane filter press in pigment industry [J]. Chemical industry and engineering progress, 2009, 28(1): 342-345. (in Chinese)

[12] WANG Jia-lin, LIU Jiang-liang, LI Jian-jun, JIANG Suan. The application improvement of membrane filter press in the post treatment of titanium dioxide production [J]. Yunnan Metallurgy, 2012, 41(1): 48-52. (in Chinese)

[13] YU Bin, WANG Zhao-qiang. The applicatoin of auto membrane filter press in sugar Industry (I) [J]. Sugarcane and Canesugar, 2004(1): 33-36. (in Chinese)

[14] LIU Gui-hua, PAN Cen-xuan, ZHU Ke-song, RU Zhen-guang, WEI Jian. Manganese extraction from slag with membrane filter press [J]. China’s Manganese Industry, 2010, 28(2): 36-38, 42. (in Chinese)

[15] DUAN Ning, DAN Zhi-gang, WANG Fan, PAN Cen-xuan, ZHOU Chang-bo, JIANG Lin-hua. Electrolytic manganese metal industry experience based China’s new model for cleaner production promotion [J]. Journal of Cleaner Production, 2011, 19(17-18): 2082-2087.

[16] DUAN Ning, PAN Cen-xuan, WANG Fan, LIU Gui-hua, ZHOU Chang-bo, DAN Zhi-gang, PENG Xiao-cheng, ZHU Chun-lei. The double-stage acid leaching with integrated washing-filtering process for production of manganese from manganese ore: China, CN1024700A [P]. 2009. (in Chinese)

[17] GB/T 14353.3-2010. Methods for chemical analysis of copper ores, lead ores and zinc ores—Part 3: Determination of zinc content [S]. (in Chinese)

[18] GB/T 6489.2-2001. Phthalate esters for industrial use -Methods of test and determination of acidity [S]. (in Chinese)

[19]  KOCAKERIM M M. Optimization study of the leaching of roasted zinc sulphide concentrate with sulphuric acid solutions [J]. Chemical Engineering and Processing: Process Intensification, 2004, 43(8): 1007-1014.

KOCAKERIM M M. Optimization study of the leaching of roasted zinc sulphide concentrate with sulphuric acid solutions [J]. Chemical Engineering and Processing: Process Intensification, 2004, 43(8): 1007-1014.

[20] LECLERC N, MEUX E, LECUIRE J M. Hydrometallurgical extraction of zinc from zinc ferrites [J]. Hydrometallurgy, 2003, 70(1-3): 175-183.

利用隔膜压滤机从电解锌浸出渣中浸出与回收锌

汝振广,潘涔轩,刘闺华,王雪婷,窦广玉,朱克松

中国环境科学研究院 清洁生产中心,北京100012

摘 要:研究利用隔膜压滤机从锌浸渣中浸出和回收锌的可行性。实验结果表明:选择粒度小于106 μm的锌焙砂和宽度30 mm的压滤腔室时滤饼的均匀性及洗涤效果较佳。以废电解液洗涤锌浸渣的形式浸出锌,在90~96 °C条件下洗涤90 min获得的锌浸出率为97%,且水洗后几乎所有浸出的锌被回收,避免了锌渣中锌的损失。与传统热酸浸出工艺相比,以隔膜压滤机为浸出反应器的浸出工艺不仅能保障浸出率又能缩短浸出时间。并且还可将浓缩、化浆、二段浸出和洗涤与过滤、压滤集成在一台隔膜压滤机上完成。

关键词:锌;隔膜压滤机;锌浸渣;浸出;回收

(Edited by Yun-bin HE)

Corresponding author: Cen-xuan PAN; Tel: +86-10-84915298; Fax: +86-10-84932378; E-mail: pancenx@sina.com

DOI: 10.1016/S1003-6326(15)63645-7