DOI: 10.11817/j.issn.1672-7207.2015.03.011

TBM盘形滚刀磨损速率研究

谭青1, 2,谢吕坚1, 2,夏毅敏1, 2,朱震寰1,孙鑫键1,王艳宜3

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

3. 常德职业技术学院 工程系,湖南 常德,415000)

摘要:建立考虑接触力和相对滑动速度的滚刀磨损速率模型,在此基础上分析贯入度、刀圈半径变化以及安装半径对滚刀磨损速率的影响,并利用微元法对盘形滚刀的磨损寿命预估方法进行研究,最后进行工程实例验证。研究结果表明:滚刀点磨损速率最大点在最大切深点与破岩前锋点之间;滚刀磨损速率随滚刀安装半径呈线性增大;滚刀磨损速率随贯入度的增大而增大,随滚刀半径减小而增大;贯入度、刀具半径和刀具安装半径三者中贯入度对滚刀磨损速率作用最大。

关键词:盘形滚刀;磨损速率;贯入度;滚刀半径;安装半径;磨损寿命

中图分类号:TH117.1;U455.3 文献标志码:A 文章编号:1672-7207(2015)03-0843-06

Analysis of wear rate of TBM disc cutter

TAN Qing1, 2, XIE Lüjian1, 2, XIA Yimin1, 2, ZHU Zhenhuan1, SUN Xinjian1, WANG Yanyi3

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of High Performance Complex Manufacturing, Central South University,

Changsha 410083, China;

3. Department of Engineering, Changde Vocational and Technical College, Changde 415000, China)

Abstract: The wear rate of tunnel boring machine (TBM) disc cutter based on contact pressure and relative slide velocity was built. Then the effect of penetration, cutter radius change and installation radius on disc cutter wear rate was researched, and the prediction method of disc cutter’s lifetime was studied. The conclusion was proved by engineering practice. The results show that the point with the maximum wear rate is between the deepest penetration point and breaking forward point. The wear rate of disc cutter increases almost linearly with the installation radius, and it increases with the increase of penetration and the decrease of disc cutter radius, and penetration is the most influential factor of wear rate of disc cutter.

Key words: disc cutter; wear rate; penetration; radius of disc cutter; installation radius; lifetime

盘形滚刀是隧道掘进机(tunnel boring machine, TBM)执行开挖工作的核心部件,由于需要承受很大的推进力和与岩石之间的摩擦力,极易产生严重磨损[1]。经统计,在秦岭隧道掘进过程中,刀具消耗的成本占整个工程成本的1/3:因此,对TBM盘形滚刀的磨损进行深入研究,以减少刀具耗损是十分重要的。目前,国内外对TBM盘形滚刀的破岩分析进行了大量研究,如:孙金山等[2]发现在滚刀破岩过程中存在能耗最小的最佳刀间距,并且岩石结构面对岩渣的形成影响重大;谭青等[3]基于离散元探讨了刀具切削顺序对TBM刀具破岩机理的影响;苏鹏程等[4]基于空间力系平衡提出了TBM刀盘滚刀优化设计的方法。而对于滚刀磨损及管理方面,国外研究较多,主要集中在滚刀磨损量预测、滚刀磨损影响因素和岩土的材料磨耗性等。张照煌等[5]给出了TBM刀盘上盘形滚刀破岩弧长及弧长磨损系数的解析表达式,并将其应用于秦岭隧道TBM刀具磨损预测;Wang等[6]通过分析滚刀破岩比能与滚刀半径及其切削参数的关系,得出基于破岩比能的滚刀磨损预测方法;Frenzel等[7-8]通过大量的岩体磨耗性实验,提出TBM掘进参数和围岩地质条件是影响滚刀磨损的关键因素;CAI(Cerchar abrasivity index)是表征岩石磨耗性的比较权威的参数,国外学者进行了大量实验,使CAI规范化、标准化[9-12];Tanimoto等[13]得出掘进地质层中岩石石英含量越高,硬质颗粒越尖锐,掘进机滚刀磨损越严重;Machel[14]通过实验研究得出岩石所受应力越大,磨耗越强。在此,本文作者建立基于接触力和相对滑动速度并考虑各影响因素的滚刀磨损速率模型,研究贯入度、滚刀半径以及安装半径对滚刀磨损速率的影响,并对滚刀磨损寿命的预估方法进行探讨。

1 盘形滚刀的磨损速率模型

1.1 盘形滚刀磨损速率理论模型

盘形滚刀刀圈正常磨损是刀具消耗的主要形式[15],而磨粒磨损是滚刀正常磨损的主要形式。影响磨料磨损的主要因素有作用于接触表面的载荷、相对滑动距离、被磨损表面的表面性能。磨料磨损量可由下式求得[16]:

(1)

(1)

将式(1)两边对时间t求导得

(2)

(2)

式中:Q为磨损量;k为量纲1的磨损系数,对于磨料磨损一般取10-1~10-6[16];W为作用载荷;L为磨损行程;H为材料表面硬度;v为摩擦副的相对滑动 速度。

由式(2)可知磨损速率与载荷和摩擦副之间的相对滑动速度的乘积成正比,因此,盘形滚刀刀刃上某点处的磨损速率(以下称为点磨损速率)与该点处的接触力p和该点与岩石的相对滑动速度v的乘积成正比。点磨损速率可由下式计算:

(3)

(3)

式中:Qd为刀刃上某一点的磨损量;p为接触力;Hc为滚刀材料表面硬度。科罗拉多矿冶研究院在大量的岩石切割试验和工程分析基础上提出了考虑岩石力学性质、滚刀几何参数等的等截面盘形滚刀刀圈连续切削岩石时接触力CSM(Colorado school of mincs)模型[17]:

(4)

(4)

其中:

(5)

(5)

为滚刀正下方的破碎区基本压力;

为滚刀正下方的破碎区基本压力; 表示刀刃上某点以及破岩最大切深点与滚刀中心连线的夹角;

表示刀刃上某点以及破岩最大切深点与滚刀中心连线的夹角; 为滚刀与岩石的接触角;

为滚刀与岩石的接触角; 为刀尖压力分布系数,对于等截面滚刀,

为刀尖压力分布系数,对于等截面滚刀, =0~0.2,一般来说,滚刀锋利时取值较大,一般取0.1;

=0~0.2,一般来说,滚刀锋利时取值较大,一般取0.1; 为岩石抗压强度;

为岩石抗压强度; 为岩石抗拉强度;s为刀尖间距;r为滚刀半径;T为滚刀刀刃宽度;h为贯入度。设TBM掘进时刀盘转速为

为岩石抗拉强度;s为刀尖间距;r为滚刀半径;T为滚刀刀刃宽度;h为贯入度。设TBM掘进时刀盘转速为 ,盘形滚刀安装半径为R,刀径为r,则盘形滚刀转速

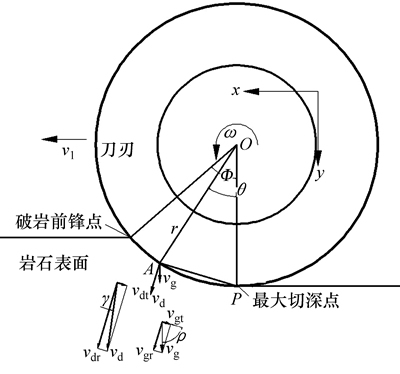

,盘形滚刀安装半径为R,刀径为r,则盘形滚刀转速 。盘形滚刀的运动实际上是盘形滚刀绕自身转轴的转动和绕刀盘的旋转轴线旋转的两定轴运动合成,因此,考虑滚刀运动速度时,一方面,要考虑滚刀沿切削螺旋线对岩石的滚压运动,另一方面,要考虑滚刀绕刀盘中心线转动时的侧滑运动,滚压运动与侧滑运动相互垂直。先考虑对岩石的滚压运动。滚刀沿切削螺旋线的滚压运动又可分为2个运动,如图1所示。

。盘形滚刀的运动实际上是盘形滚刀绕自身转轴的转动和绕刀盘的旋转轴线旋转的两定轴运动合成,因此,考虑滚刀运动速度时,一方面,要考虑滚刀沿切削螺旋线对岩石的滚压运动,另一方面,要考虑滚刀绕刀盘中心线转动时的侧滑运动,滚压运动与侧滑运动相互垂直。先考虑对岩石的滚压运动。滚刀沿切削螺旋线的滚压运动又可分为2个运动,如图1所示。

1) 滚刀在刀盘推动下被动转动。滚刀在掌子面平面以最大切深点P为速度瞬心滚动[16],滚刀刀刃上点A的速度为

其中: 为滚刀转速;l为A点到速度瞬心的距离,l=

为滚刀转速;l为A点到速度瞬心的距离,l= =2rsin

=2rsin 。将vd分解为沿半径OA方向的vdr和垂直于OA方向vdt共2个速度。其中vdt垂直于岩石表面,与岩石表面之间没有相对滑动作用,而vdt与岩石表面相切,因此,滚刀上点A与岩石的相对滑动速度vdt为

。将vd分解为沿半径OA方向的vdr和垂直于OA方向vdt共2个速度。其中vdt垂直于岩石表面,与岩石表面之间没有相对滑动作用,而vdt与岩石表面相切,因此,滚刀上点A与岩石的相对滑动速度vdt为

(6)

(6)

图1 滚刀与岩石相对滑动速度

Fig. 1 Relative sliding velocity between rock and disc cutter

2) 滚刀垂直于掌子面对岩石的贯入运动。贯入速度vg为掘进机掘进速度, =

= 。同样将vg分解为

。同样将vg分解为

沿半径OA方向的vgr和垂直于OA方向vgt共2个速度,vgt与岩石表面相切,因而与岩石发生相对滑动。vg与岩石切面存在夹角 ;

; =

= ,与vdt方向相同。因此,滚压运动滚刀上点A与岩石的相对滑动速度vs为

,与vdt方向相同。因此,滚压运动滚刀上点A与岩石的相对滑动速度vs为

(7)

(7)

侧滑运动是滚刀整体侧滑,因此,侧滑运动滚刀上点A与岩石的相对运动速度相等,vce=vx[5]。其中,vx为滚刀侧滑速度,

(8)

(8)

滚刀上A点与岩石的相对滑动速度v为vt与vce的合成,vt与vce相互垂直,所以,

(9)

(9)

由式(3),(4)和(9)可得滚刀刀刃上某点处点磨损速率为

(10)

(10)

滚刀单位时间内的磨损量即滚刀磨损速率可由点磨损速率对滚刀与岩石的接触面积分获得:

(11)

(11)

式中:Q为滚刀磨损量;t为作用时间; 为滚刀与岩石的接触面;S为接触面积。

为滚刀与岩石的接触面;S为接触面积。

由CSM接触力模型,可假定刀刃上垂直于滚刀中面的直线上各点的磨损率相等,滚刀磨损速率为

(12)

(12)

式中:T为刀刃宽度。

1.2 盘形滚刀磨损寿命预估

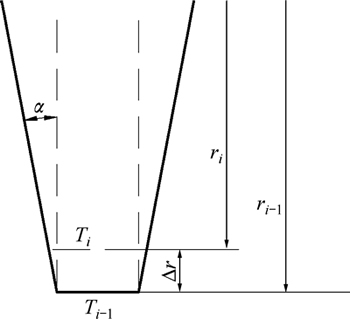

图2所示为等截面滚刀刀圈断面。为便于研究,不考虑过渡圆弧。设刀刃半角为 ,滚刀的初始半径为r,初始刀刃宽为T,以刀圈半径减少

,滚刀的初始半径为r,初始刀刃宽为T,以刀圈半径减少 (

( 为一极小值)为一磨损步长,则第i-1步长时刀圈半径为

为一极小值)为一磨损步长,则第i-1步长时刀圈半径为 ,刀刃宽度为

,刀刃宽度为 ;第i步次时刀圈半径为ri,刀刃宽度为Ti;ri=r-i

;第i步次时刀圈半径为ri,刀刃宽度为Ti;ri=r-i ,

, 。刀圈磨损体积

。刀圈磨损体积 为

为

(13)

(13)

图2 盘形滚刀刀圈断面

Fig. 2 Profile shape of disc cutter ring

此时滚刀磨损速率为 ,因此,第i步磨损所用时间

,因此,第i步磨损所用时间 =

= 。盘形滚刀磨损寿命

。盘形滚刀磨损寿命

。其中:

。其中: ;rmin为盘形滚刀的磨损极限半径。

;rmin为盘形滚刀的磨损极限半径。

2 盘形滚刀磨损速率特性

以滚刀切削某大理岩地层为例,该大理岩力学特性如下:单轴抗压强度为58~64 MPa,抗拉强度为4~6 MPa。滚刀结构参数见表1。

表1 盘形滚刀刀圈结构参数

Table 1 Structural parameters of disc cutter

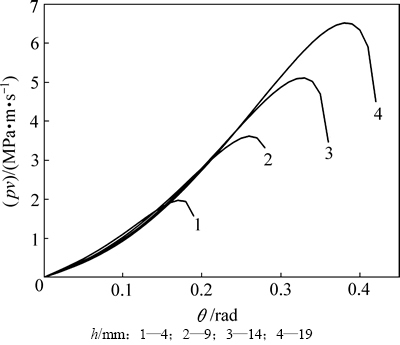

图3所示为盘形滚刀切削岩石时刀刃上点压力 (p)和速度(v)的乘积随 的分布,其中横坐标代表刀刃上点的位置。每条曲线横坐标最大值对应该贯入度时的滚刀与岩石的接触角

的分布,其中横坐标代表刀刃上点的位置。每条曲线横坐标最大值对应该贯入度时的滚刀与岩石的接触角 。因刀刃上点磨损率与点的pv成正比,因此,该pv曲线可以表征滚刀与岩石的接触面的点磨损速率分布。从图3可见:点磨损率在最大切深点到破岩前锋点之间,点磨损率先随

。因刀刃上点磨损率与点的pv成正比,因此,该pv曲线可以表征滚刀与岩石的接触面的点磨损速率分布。从图3可见:点磨损率在最大切深点到破岩前锋点之间,点磨损率先随 的增大逐渐增大,到达某

的增大逐渐增大,到达某 =(0.84~0.86)

=(0.84~0.86) 时取得最大值,然后随

时取得最大值,然后随 的增大而减小,点磨损率最大位置相对靠近破岩前锋点。

的增大而减小,点磨损率最大位置相对靠近破岩前锋点。

图3 点磨损速率变化曲线

Fig.3 Variation curves of point wear rate

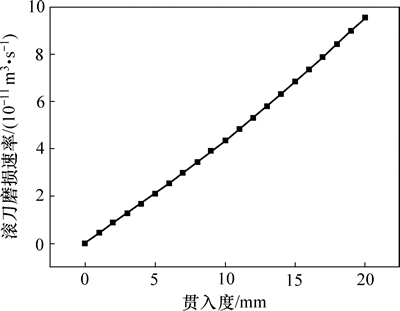

从式(12)可知滚刀的磨损速率与所切削岩石的力学性能、刀具结构参数以及掘进机的切削参数都密切相关。图4所示为由式(12)计算得滚刀磨损速率-贯入度曲线。从图4可看出:滚刀磨损速率随贯入度的增大而增大,在滚刀半径r=216 mm,掘进机贯入度为5 mm时,滚刀磨损速率为2.10×10-11 m3/s;当贯入度增加到10 mm时,滚刀磨损速率增加到4.35×10-11 m3/s,磨损速率增加107.1%。

图4 滚刀半径为216 mm时贯入度对滚刀磨损速率的影响

Fig. 4 Influence of penetration on wear rate of disc cutter when radius of disc cutter is 216 mm

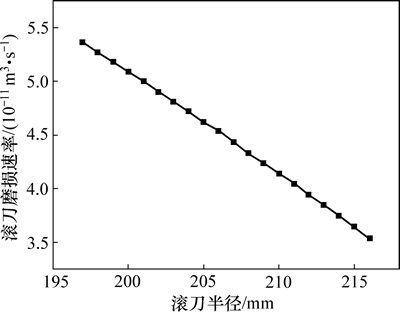

随着掘进机的不停掘进,滚刀磨损后,滚刀半径会逐渐减小,这会反过来影响滚刀的磨损。图5所示为滚刀磨损速率-滚刀半径曲线。从图5可以看到:滚刀磨损速率随滚刀半径的减小而增大,且基本上呈线性关系;当贯入度h=8 mm时,滚刀尚未磨损时的磨损速率为3.53×10-11 m3/s,到滚刀磨损20 mm报废时,滚刀磨损速率为5.36×10-11 m3/s,磨损率增长量为51.8%。这是因为滚刀磨损后,半径减小,刀刃宽度增加,滚刀变钝,维持稳定破岩时需要更大的破岩切削力。

图5 贯入度8 mm时滚刀半径对滚刀磨损速率的影响

Fig. 5 Influence of cutter radius on disc cutter wear rate when penetration is 8 mm

图6所示为滚刀磨损速率-安装半径曲线。从图6可以看出:在刀盘上安装半径较小的区域内,滚刀磨损速率随安装半径的增加基本不变;当安装半径从0 m增加到0.75 m时,磨损速率仅增加4.75%;而当安装半径较大时,滚刀磨损速率随安装半径的增大而迅速增大,当安装半径从0.75 m增加到3.00 m时,磨损速率增加了51.2%,且磨损速率基本上随安装半径的增大而呈线性增大。同时可以看到滚刀安装半径为0 m即处于中心滚刀位置时滚刀也有一定磨损。实际上,安装半径越大,滚刀对岩石的滚压速度越大,因而磨损速率越大;而中心滚刀虽然没有对岩石的滚压运动,但与岩石之间具有很大的侧滑移量,因而,总会有一定的磨损量。

图6 安装半径对滚刀磨损速率的影响

Fig. 6 Influence of installation radius on wear rate

由贯入度、滚刀半径变化以及滚刀安装半径对滚刀磨损速率的影响分析结果可以看出对滚刀磨损速率变化作用最大的是切削贯入度,因此,选择合适的贯入度对有效地减少刀具消耗有重要意义。

3 工程验证

某隧道工程施工采用1台双护盾式全断面岩石掘进机,隧道沿线地层主要由砂岩、砂砾岩、含砾砂岩、云母石英片岩、大理岩等组成。图7所示为该隧道在7 680~7 714环的滚刀磨损测量值随滚刀安装半径分布图,其中横轴为滚刀刀位号,纵轴为滚刀平均每环磨损量,掘进地质以大理岩为主,掘进时贯入度为8 mm。滚刀中9号刀的安装半径最小,为0.776 m,因此,在本组工程数据中,滚刀安装位置都处于刀盘上较大安装半径区域。图中14号和24号滚刀因在掘进过程中出现异常失效而中途换刀,因此,在数据分析时不考虑这2把滚刀。从图7可以看出:滚刀磨损量随刀位号的增大而增加,也就是说,滚刀磨损量随刀具安装半径的增大而增大;从7 680环到7 696环再到7 714环掘进过程中,滚刀半径随刀具的磨损而减小,因而在7 680~7 696环中滚刀半径比7 696~7 714环要大,显然,图5中7 696~7 714环滚刀平均每环磨损量比7680~7696环的磨损量要大,表明盘形滚刀磨损速率随着滚刀半径的减小而增大。

图7 滚刀平均每环磨损量随刀位号变化

Fig. 7 Variation of average wear of disc cutter per ring with tool number

4 结论

1) 建立了盘型滚刀磨损速率模型,获得TBM盘形滚刀磨损速率与贯入度、刀具半径和刀具安装半径的数学关系表达式,并在此基础上提出了盘形滚刀磨损寿命的预估方法,对TBM现场施工中滚刀的寿命预估具有指导意义。

2) 盘形滚刀磨损速率随滚刀安装半径呈线性增长,随切削贯入度的增大而增大,随滚刀半径因磨损减小而增大。

3) 贯入度、刀具半径和刀具安装半径三者中,贯入度对TBM盘形滚刀磨损速率影响作用最大。

参考文献:

[1] 张珂, 王贺, 吴玉厚, 等. 全断面硬岩TBM滚刀磨损关键技术分析[J]. 沈阳建筑大学学报(自然科学版), 2009, 25(2): 351-354.

ZHANG Ke, WANG He, WU Yuhou, et al. Analysis on key wear technology of the TBM disc cutter[J]. Journal of Shenyang Jianzhu University (Natural Science), 2009, 25(2): 351-354.

[2] 孙金山, 陈明, 陈保国, 等. TBM滚刀破岩过程影响因素数值模拟研究[J]. 岩土力学, 2011, 32(6): 1891-1897.

SUN Jinshan, CHEN Ming, CHEN Baoguo, et al. Numerical simulation of influence factors for rock fragmentation by TBM cutter[J]. Rock and Soil Mechanics, 2011, 32(6): 1891-1897.

[3] 谭青, 徐孜军, 夏毅敏, 等. 2种切削顺序下TBM刀具破岩机理的数值研究[J]. 中南大学学报(自然科学版), 2012, 43(3): 940-946.

TAN Qing, XU Zhijun, XIA Yimin, et al. Numerical study on mode of breaking rock by TBM cutter in two cutting orders[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 940-946.

[4] 苏鹏程, 王宛山, 霍军周, 等. TBM的滚刀布置优化设计研究[J]. 东北大学学报(自然科学版), 2010, 31(6): 877-881.

SU Pengcheng, WANG Wanshan, HUO Junzhou, et al. Optimal layout design of cutters on tunnel boring machine[J]. Journal of Northeastern University (Natural Science), 2010, 31(6): 877-881.

[5] 张照煌, 纪昌明. 全断面岩石掘进机盘形滚刀刃破岩点弧长的解析解及应用研究[J]. 应用基础与工程科学学报, 2009, 17(2): 265-273.

ZHANG Zhaohuang, JI Changming. Analytic solution and it’s usage for arc length of rock breaking point on TBM disc cutter[J]. Journal of Basic Science and Engineering, 2009, 17(2): 265-273.

[6] WANG Lihui, KANG Yilan. The energy method to predict disc cutter wear extent for hard rock TBMs[J]. Tunneling and Underground Space Technology, 2012(28): 183-191.

[7] Frenzel C, K A Sling H, Thuro K. Factors influencing disc cutter wear[J]. Geomechanics and Tunneling, 2008, 1(1): 55-60.

[8] Nilsen B, Dahl F E, Holzhauser J, et al. Abrasivity of soils in TBM tunneling[J]. Tunnels & Tunneling International, 2006, 38(3): 1-4.

[9] Dahl F, Bruland A, Jakobsen P D, et al. Classifications of properties influencing the drillability of rocks based on the NTNU/SINTEF test method[J]. Tunneling and Underground Space Technology, 2012, 28(3): 150-158.

[10]  M, Maidl U, Martak L. Abrasiveness and tool wear in shield tunnelling in soil.

M, Maidl U, Martak L. Abrasiveness and tool wear in shield tunnelling in soil.  Werkzeugversc-

Werkzeugversc-  Schildvortriebim Lockergestein[J]. Geomechanics and Tunneling, 2011, 4(1): 36-54.

Schildvortriebim Lockergestein[J]. Geomechanics and Tunneling, 2011, 4(1): 36-54.

[11] Dahl F,  E, Breivik T. Development of a new direct test method for estimating cutter life, based on the Sievers’ J miniature drill test[J]. Tunneling and Underground Space Technology, 2007, 22(1): 106-116.

E, Breivik T. Development of a new direct test method for estimating cutter life, based on the Sievers’ J miniature drill test[J]. Tunneling and Underground Space Technology, 2007, 22(1): 106-116.

[12] Plinninger R J,  H, Thuro K. Wear prediction in hardrock excavation using the CERCHAR abrasiveness index (CAI)[C]// Schubert W. Rock engineering theory and practice, Proceedings of the ISRM Regional Symposium EUROCK 2004 & 53rd Geomechanics Colloquy. Berlin: Germany, 2004: 599-604.

H, Thuro K. Wear prediction in hardrock excavation using the CERCHAR abrasiveness index (CAI)[C]// Schubert W. Rock engineering theory and practice, Proceedings of the ISRM Regional Symposium EUROCK 2004 & 53rd Geomechanics Colloquy. Berlin: Germany, 2004: 599-604.

[13] Tanimoto C, Yamanaka S, Tsusaka K, et al. A study on cutter wear and mechanical properties of rocks in tunneling with a TBM[J]. Zairyo/Journal of the Society of Materials Science, 2006, 55(1): 29-36.

[14] Michael A. Stress dependency of the Cercharabrasivity index (CAI) and its effects on wear of selected rock[J]. Tunneling and Underground Space Technology, 2012, 23(4): 351-359.

[15] 万治昌, 沙明元, 周雁领. 盘形滚刀的使用与研究(1): TB880E型掘进机在秦岭隧道施工中的应用[J]. 现代隧道技术, 2002, 39(5): 1-11.

WANG Zhichang, SHA Mingyuan, ZHOU Yanling. Study on disk cutters for hard rock: Application of TB880E TBM in Qinling tunnel[J]. Modern Tunneling Technology, 2002, 39(5): 1-11.

[16] 张明富, 袁大军, 黄清飞, 等. 砂卵石地层盾构刀具动态磨损分析[J]. 岩土力学与工程学报, 2008, 27(2): 397-402.

ZHANG Mingfu, YUAN Dajun, HUANG Qingfei, et al. Analysis of dynamic abrasion of shield cutter in sandy cobble stratum[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(2): 397-402.

[17] Rostami J. Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters[J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 57: 172-186.

(编辑 陈灿华)

收稿日期:2014-04-10;修回日期:2014-06-22

基金项目(Foundation item):国家重点基础研究发展计划(973计划)项目(2013CB035401);国家自然科学基金资助项目(51274252);湖南省战略新兴产业重大科技攻关项目(2012GK4068) (Project(2013CB035401) supported by the National Basic Research Development Program(973 Program) of China; Project(51274252) supported by the National Natural Science Foundation of China; Project(2012GK4068) supported by Strategic Emerging Industries of Science and Technology Key Project of Hunan Province)

通信作者:谭青,博士,教授,从事机械设计方法与理论、机械电子等教学与科研工作;E-mail: jds-share@163.com