双剪统一强度理论计算塑性金属材料强度的唯一性

刘 光 连

(中南大学 机电工程学院,湖南 长沙,410083)

摘 要:研究了双剪统一强度理论及其有关关系式,得到塑性金属材料双剪统一强度理论参数b的计算式,对某一塑性金属材料,其值为常数,取值范围是b>-1;运用双剪统一强度理论计算某一塑性金属材料的强度时有唯一确定的强度计算值,而不是多个值,不能得出塑性金属材料的τs/σs;分析材料的拉压强度比为1时双剪统一强度理论的2组等价变换式,对b<0的材料,双剪统一强度理论计算表明,材料的破坏不是由中间主剪应力引起,这与双剪统一强度理论的假设矛盾;该理论不适用于三向等值拉应力状态的计算。

关键词:双剪统一强度理论;屈服;塑性;金属

中图分类号:TH114 文献标识码:A 文章编号:1672-7207(2008)06-1280-05

Uniqueness in calculating strength of plastic metals based on twin-shear unified strength theory

LIU Guang-lian

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Twin-shear unified strength theory and its related functions were studied. The formula of parameter b in the twin-shear unified strength theory for a certain plastic metal was developed and its value was determined to be constant for a certain plastic metal and its value range is b>-1; only a certain value can be obtained when the strength of a plastic metal based on the twin-shear unified strength theory was calculated and the value of ts/ss could not be obtained. The results show that based on the analysis of the two equivalent equations of the twin-shear unified strength theory when the ratio of tensile strength to compressive strength equals 1, for materials with b<0, the fracture of materials is not caused by the intermediate principal shear stress, which does not agree with the hypothesis of the twin-shear unified strength theory, and this theory can not be applied in stress state such as equitriaxial tension.

Key words: twin-shear unified strength theory; yield; plastic; metal

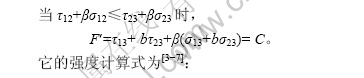

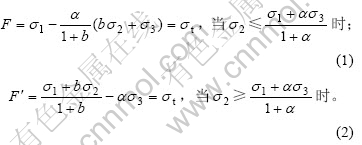

Yu于1961年提出了双剪应力屈服准则[1],1985 年发展为双剪应力强度理论[2],1991年提出了新的双剪统一强度理论[3]。双剪统一强度理论认为:“当作用于双剪单元体上的2个较大剪应力及其面上的正应力影响函数到达某一极限值时,材料开始发生破坏。”它的数学建模方程如下[3-6]:

式中:b为反映中间主剪应力以及相应面上的正应力对材料破坏影响程度的参数; 为材料的拉伸强度极限(

为材料的拉伸强度极限( )与压缩强度极限(

)与压缩强度极限( )的比值,即

)的比值,即 。

。

若认为材料的拉伸、压缩强度极限相等,即 ,则式(1)和(2)就是双剪统一屈服准则的计算式[4];若令

,则式(1)和(2)就是双剪统一屈服准则的计算式[4];若令 ,b=1,则式(1)和(2)就是双剪应力屈服准则的计算式[1-2, 4]。

,b=1,则式(1)和(2)就是双剪应力屈服准则的计算式[1-2, 4]。

自2004年以来,双剪统一强度理论在国内外得到较多的引用[8-10]和应用[11-13]。双剪统一强度理论具有统一的理论模型和统一的数学表达式,适用于金属、岩石、聚合物等多种材料[4-5]。

双剪统一强度理论不断得到发展,在系列剪应力强度理论基础上,出现了“新的普遍形式的统一强度理论”和它的各种特例[14]。在此,本文作者根据双剪统一强度理论推导过程中已经得到的有关关系式,研究双剪统一强度理论参数b的物理意义和该理论的强度计算式,分析参数b的取值范围和该理论的不足,指出新的强度理论仍然值得研究。

1 计算塑性金属材料强度的唯一性

参数b被认为是双剪统一强度理论的破坏准则参数[3-5]。在一般情况下,可取b=0,1/4,1/2,3/4,1,5/4,3/2共7种典型参数[4]。例如,文献[4]中举例计算了某一承受内压的低碳钢薄壁圆筒的壁厚,其拉压强度极限相等,分别取b=0,1/4,1/(1+ ),1/2,3/4和1,经计算得到的壁厚分别为12,10.8,10.4,10,9.43和9 mm。取b=0时算得的壁厚与第三强度理论得出的结果一致;取b=1/(1+

),1/2,3/4和1,经计算得到的壁厚分别为12,10.8,10.4,10,9.43和9 mm。取b=0时算得的壁厚与第三强度理论得出的结果一致;取b=1/(1+ )时,算得的壁厚与第四强度理论的计算结果(10.38 mm)接近。从这个算例看,即使是各向同性材料,在同一应力状态下,参数b可以有多种选择,是不确定的。究竟哪个是最优的取值,该理论似乎并不能确定。

)时,算得的壁厚与第四强度理论的计算结果(10.38 mm)接近。从这个算例看,即使是各向同性材料,在同一应力状态下,参数b可以有多种选择,是不确定的。究竟哪个是最优的取值,该理论似乎并不能确定。

双剪统一强度理论的参数b可以取不同的值进行设计计算,得出没有确定性的结果。事实上,对于一各向同性塑性金属材料的拉伸屈服强度、压缩屈服强度和剪切屈服强度都是材料常数。以此为前提,可以确定参数b。

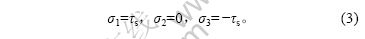

为此,考虑塑性金属材料在纯扭转受力状况下,因材料剪切屈服而发生失效,失效条件为:

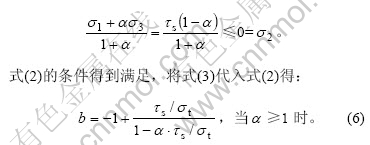

a. 若材料的 ≤1,则由式(3)得:

≤1,则由式(3)得:

b. 若材料的 ≥1,则由式(3)得:

≥1,则由式(3)得:

式(5)和(6)是双剪统一强度理论计算塑性金属材料参数b的表达式。当 =1时,式(5)与(6)的计算结果相等。文献[15]也得到了式(5),但没有区分

=1时,式(5)与(6)的计算结果相等。文献[15]也得到了式(5),但没有区分 ≤1和

≤1和 ≥1的情况。

≥1的情况。

因此,应用双剪统一强度理论计算塑性金属材料的强度时,应先根据塑性金属材料的 ,

, 和

和 计算

计算 和b,并根据

和b,并根据 的取值范围选择b的计算式(5)或(6)。不同的塑料金属材料对应于不同的

的取值范围选择b的计算式(5)或(6)。不同的塑料金属材料对应于不同的 和b,且都为常数,在某一主应力状态下,由式(1)和(2)可知,双剪统一强度理论有唯一确定的强度计算值。

和b,且都为常数,在某一主应力状态下,由式(1)和(2)可知,双剪统一强度理论有唯一确定的强度计算值。

2 分析和讨论

2.1 塑性金属材料参数b的取值范围

在式(5)和(6)中: ,

, ,

, 和

和 都为正数,且

都为正数,且 >0,

>0, >0,由此得:

>0,由此得:

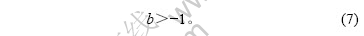

式(7)是塑性金属材料参数b的取值范围。不同塑性金属材料的 ,

, ,

, 和

和 不同,因此,b的数值也不相同。部分塑性金属材料的拉伸屈服强度和压缩屈服强度较接近,在此取

不同,因此,b的数值也不相同。部分塑性金属材料的拉伸屈服强度和压缩屈服强度较接近,在此取 =1,当由式(5)和(6)计算的b相等时,对双剪统一强度理论进行分析。

=1,当由式(5)和(6)计算的b相等时,对双剪统一强度理论进行分析。

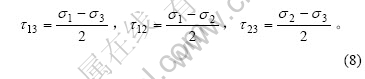

τij为主剪应力,用主应力σ1,σ2和σ3可表示为:

对 =1的材料,应用式(8)及τ13=τ12+τ23,式(1)和(2)可以化为:

=1的材料,应用式(8)及τ13=τ12+τ23,式(1)和(2)可以化为:

以上2式是材料参数 =1时,双剪统一强度理论的2组等价变换式。

=1时,双剪统一强度理论的2组等价变换式。

塑性金属材料的剪切屈服强度 、拉伸屈服强度

、拉伸屈服强度 的比

的比 一般为0.250~0.947[4]。若材料的拉压强度比

一般为0.250~0.947[4]。若材料的拉压强度比 =1,取

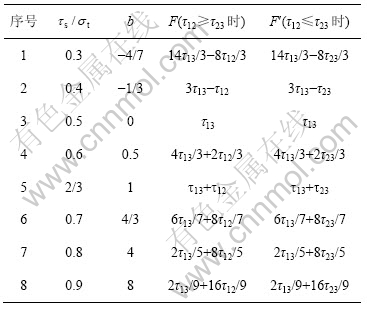

=1,取 的一些典型值0.300,0.400,0.500,0.600,2/3,0.700,0.800和0.900,据式(5)或(6),(9)和(10)可求得相应的参数b、双剪统一强度理论的计算结果F和F?,如表1所示。

的一些典型值0.300,0.400,0.500,0.600,2/3,0.700,0.800和0.900,据式(5)或(6),(9)和(10)可求得相应的参数b、双剪统一强度理论的计算结果F和F?,如表1所示。

表1  =1时不同

=1时不同 塑性金属材料双剪统一强度理论计算得到的b,F和F?

塑性金属材料双剪统一强度理论计算得到的b,F和F?

Table 1 Value of b, F and F? based on Twin-shear unified strength theory for plastic metals with difference  when

when  =1

=1

从式(5)和(6)以及表1可得:对拉压强度比 =1的塑性金属材料,随着材料

=1的塑性金属材料,随着材料 的增大,参数b也增大,并由负数变为正数;当

的增大,参数b也增大,并由负数变为正数;当 <0.5时,b<0;当

<0.5时,b<0;当 =0.5 时,b=0;当

=0.5 时,b=0;当 =2/3时,b=1;当

=2/3时,b=1;当  >2/3时,b>1。

>2/3时,b>1。

文献[4]认为,对各向同性材料,中间主剪应力的作用不会大于最大主剪应力的作用。因此,系数b不会大于1,即b≤1。同理,中间主剪应力也不可能起相反的作用,因此,系数b不应为负值,即b≥0。系数b的变化范围应在0和1之间。显然,0≤b≤1,这与事实不符。

文献[4]还认为,b<0和b>1这2类非凸屈服准则中,前者已有实验结果的报道,后者尚未见有关文献报道这类实验结果,因而,对它的实用意义还不能予以证实。由表1可见,这也与事实不相符。

2.2 双剪统一强度理论的统一性

文献[4,7]认为取参数b的典型数值可得出各种屈服准则:

若b=1, =2m,则式(1)就成为σ1-m(σ2+σ3)= σt,得最大拉应变强度理论;

=2m,则式(1)就成为σ1-m(σ2+σ3)= σt,得最大拉应变强度理论;

若b=0, =1,则得到σ1-σ3=σt,为第三强度理论或单剪强度理论;

=1,则得到σ1-σ3=σt,为第三强度理论或单剪强度理论;

若b=1/2, =1,则得到σ1-(σ2+2σ3)/3=σt,这一结果是第四强度理论(Mises屈服准则)线性逼近,可以作为Mises屈服准则代用的一个新的分段线性准则[4];

=1,则得到σ1-(σ2+2σ3)/3=σt,这一结果是第四强度理论(Mises屈服准则)线性逼近,可以作为Mises屈服准则代用的一个新的分段线性准则[4];

若b=0, ?1,则可得到

?1,则可得到 ,即为莫尔强度理论;

,即为莫尔强度理论;

若 ?1,0<b<1,则还可得出许多新强度准则。

?1,0<b<1,则还可得出许多新强度准则。

尽管对参数b和 的不同取值组合,使多个屈服准则成为双剪统一强度理论的特例,然而,分析结果表明,某一塑性金属材料参数b与

的不同取值组合,使多个屈服准则成为双剪统一强度理论的特例,然而,分析结果表明,某一塑性金属材料参数b与 存在确定的函数关系式,它们的值是一一对应的。因此,不考虑材料的强度特性参数,将b与

存在确定的函数关系式,它们的值是一一对应的。因此,不考虑材料的强度特性参数,将b与 分割开来,取b与

分割开来,取b与 的多个组合数进行分析计算的做法是不妥的。

的多个组合数进行分析计算的做法是不妥的。

应用双剪统一强度理论计算塑料金属材料强度时,应先根据材料的拉伸屈服强度、压缩屈服强度、剪切屈服强度等材料特性参数用式(5)或(6)计算参数b。考虑材料3个主要强度参数进行强度计算是双剪统一强度理论的重要特点,也是现在几个经典强度理论所不具备的。据材料特殊的 和

和 ,计算得到特殊的参数b,使得双剪统一强度理论的计算结果与现在的某经典强度理论所得结果一致,这体现了双剪统一强度理论的统一性。如对于低碳钢,

,计算得到特殊的参数b,使得双剪统一强度理论的计算结果与现在的某经典强度理论所得结果一致,这体现了双剪统一强度理论的统一性。如对于低碳钢, =1,

=1, ,由式(5)和(6)得b=0。因此,该算例中,应该取b=0时,壁厚为12 mm的数据,其结果与第三强度理论结果一致。

,由式(5)和(6)得b=0。因此,该算例中,应该取b=0时,壁厚为12 mm的数据,其结果与第三强度理论结果一致。

2.3 塑性金属材料参数b的物理意义

对塑性金属材料,由式(5)和(6)可见,参数b的计算式中没有主应力,这说明参数b与它所受的主应力状态无关。双剪统一强度理论把参数b假设为“中间主剪应力以及相应面上的正应力对材料破坏影响程度的参数” [3-6],对塑性金属材料,这一假设是不成立的。

由双剪统一强度理论计算式(1)和(2)知,参数b是双剪统一强度理论计算材料强度的特征参数。参数b与塑性金属材料的拉伸屈服强度与压缩屈服强度的比值( )、剪切屈服强度(τs)及拉伸屈服强度(σt)有关,且有确定值,是双剪统一强度理论计算塑性金属材料强度的特征参数。参数b可以称为“双剪统一强度理论计算参数”。文献[3-5]认为“参数b是双剪统一强度理论的破坏准则参数”,因某一塑性金属材料的参数b为常数,把参数b作为破坏准则参数是不妥的。

)、剪切屈服强度(τs)及拉伸屈服强度(σt)有关,且有确定值,是双剪统一强度理论计算塑性金属材料强度的特征参数。参数b可以称为“双剪统一强度理论计算参数”。文献[3-5]认为“参数b是双剪统一强度理论的破坏准则参数”,因某一塑性金属材料的参数b为常数,把参数b作为破坏准则参数是不妥的。

2.4 剪应力对材料破坏的影响

在3个主剪应力τ13,τ12和τ23中,τ13为最大主剪应力,τ12和τ13分别为中间主剪应力和最小主剪应力。

当 =1且b<0时,因1+b>0,故存在以下2种情况:

=1且b<0时,因1+b>0,故存在以下2种情况:

a. 当τ12≥τ23时,根据双剪统一强度理论的等价变换式(9)计算,最大主剪应力τ13的系数大于0,中间主剪应力τ12的系数是 <0,即中间(较大)主剪应力的系数为负数,说明中间主剪应力对材料的破坏起了相反的作用;或者,最大主剪应力τ13的系数为2,最小主剪应力t23的系数是

<0,即中间(较大)主剪应力的系数为负数,说明中间主剪应力对材料的破坏起了相反的作用;或者,最大主剪应力τ13的系数为2,最小主剪应力t23的系数是 >0,即最大主剪应力和最小主剪应力的系数为正数,说明影响材料破坏的原因是最大主剪应力和最小主剪应力,而与中间主剪应力无关。这都与双剪统一强度理论认为材料破坏是由最大主剪应力和较大主剪应力引起的假设矛盾。

>0,即最大主剪应力和最小主剪应力的系数为正数,说明影响材料破坏的原因是最大主剪应力和最小主剪应力,而与中间主剪应力无关。这都与双剪统一强度理论认为材料破坏是由最大主剪应力和较大主剪应力引起的假设矛盾。

b. 当τ12≤τ23时,根据双剪统一强度理论的等价变换式(10)计算分析,同样可以得到与理论假设矛盾的结论。

当 =1且b>0时,由式(9)和(10)及表1可知,双剪统一强度理论的计算结果F或F?是最大主剪应力和次大主剪应力的加权平均值,且权系数之和等于2;随着材料参数b的增大,F和F?计算式中最大主剪应力τ13的权重系数减少,次大主剪应力的权重系数增加,当b>1时,强度计算式中次大主剪应力的权重系数大于最大主剪应力的权重系数。这与“对各向同性材料,中间主剪应力的作用不会大于最大主剪应力的作用[4]”的观点矛盾。

=1且b>0时,由式(9)和(10)及表1可知,双剪统一强度理论的计算结果F或F?是最大主剪应力和次大主剪应力的加权平均值,且权系数之和等于2;随着材料参数b的增大,F和F?计算式中最大主剪应力τ13的权重系数减少,次大主剪应力的权重系数增加,当b>1时,强度计算式中次大主剪应力的权重系数大于最大主剪应力的权重系数。这与“对各向同性材料,中间主剪应力的作用不会大于最大主剪应力的作用[4]”的观点矛盾。

2.5 塑性金属材料τs/σt

式(4)虽然是塑性金属材料抗剪强度和抗拉强度的比值关系式,但因参数b不确定,因此,不能得出塑性金属材料的抗剪强度和抗拉强度的比值。相反,要根据塑性金属材料抗剪强度和抗拉强度的比值(τs/σt)来确定该材料双剪统一强度理论计算参数b。

2.6 三向等值拉应力状态

在三向等值拉应力状态下,σ1=σ2=σ3=s,因此,双剪统一强度理论式(1)或(2)的计算值为:

式(11)对 =1的塑性金属材料显然是不适用的,说明双剪统一强度理论不适用于分析三向等值拉应力状态。当然,Treasca最大剪应力屈服准则(第三强度理论)、von Mises屈服准则(第四强度理论)等经典强度理论也不适用于分析三向等值拉应力状态。

=1的塑性金属材料显然是不适用的,说明双剪统一强度理论不适用于分析三向等值拉应力状态。当然,Treasca最大剪应力屈服准则(第三强度理论)、von Mises屈服准则(第四强度理论)等经典强度理论也不适用于分析三向等值拉应力状态。

3 结 论

a. 根据材料的拉伸和压缩屈服强度比 的取值情况,得出双剪统一强度理论参数b的计算式:

的取值情况,得出双剪统一强度理论参数b的计算式:

,当

,当 ≤1 时;

≤1 时;

,当

,当 ≥1时。

≥1时。

该理论计算塑料金属材料强度时有唯一确定的强度计算值。

b. 双剪统一强度理论与材料的拉伸、压缩、剪切等强度参数有关,这是它的重要特点,是现在几个经典强度理论所不具备的,但它不能得出塑性材料的τs/σt值或剪切强度。

c. 双剪统一强度理论应用于 =1的塑性金属材料存在的问题:当材料的τs/σt<0.5时,-1<b<0,双剪统一强度理论计算材料的破坏不是由中间主剪应力引起,这与该理论认为材料破坏是由最大主剪应力和较大主剪应力引起的假设矛盾;当b>1且增加时,较大主剪应力对材料破坏的影响会超过最大主剪应力对材料破坏的影响;双剪统一强度理论不适用于分析三向等值拉应力状态。

=1的塑性金属材料存在的问题:当材料的τs/σt<0.5时,-1<b<0,双剪统一强度理论计算材料的破坏不是由中间主剪应力引起,这与该理论认为材料破坏是由最大主剪应力和较大主剪应力引起的假设矛盾;当b>1且增加时,较大主剪应力对材料破坏的影响会超过最大主剪应力对材料破坏的影响;双剪统一强度理论不适用于分析三向等值拉应力状态。

d. 双剪统一强度理论和传统强度理论一样存在不足,新的强度理论有待进一步研究。

参考文献:

[1] YU Mao-hong. Twin shear stress yield criterion[J]. International Journal of Mechanical Science, 1983, 25(1): 71-74.

[2] 俞茂宏, 何丽南, 宋凌宇. 双剪应力强度理论及其推广[J]. 中国科学: A, 1985(12): 1113-1120.

YU Mao-hong, HE Li-nan, SONG Ling-yu. Twin-shear theory and its generalization[J]. Science in China: Series A, 1985(12): 1113-1120.

[3] YU Mao-hong, HE Li-nan. A new model and theory on yield and failure of materials under complex stress state[M]. United Kingdom: Pergamon Press, 1991: 841-846.

[4] 俞茂宏. 双剪理论及其应用[M]. 北京: 科学出版社, 1998: 60-113, 254-262, 299-308.

YU Mao-hong. Twin-shear theory and its applications[M]. Beijing: Science Press, 1998: 60-113, 254-262, 299-308.

[5] YU Mao-hong. Advances in strength theories for materials under complex stress state in the 20th century[J]. Applied Mechanics Reviews, ASME, 2002, 55(3): 169-218.

[6] 俞茂宏, Yoshimine M, 强洪夫, 等. 强度理论的发展与展望[J]. 工程力学, 2004, 21(6): 1-20.

YU Mao-hong, Yoshimine M, QIANG Hong-fu, et al. Advances and prospects for strength theory[J]. Engineering Mechanics, 2004, 21(6): 1-20.

[7] 苟文选. 材料力学:Ⅰ[M]. 北京: 科学出版社, 2005: 296-309.

GOU Wen-xuan. Material mechanics:Ⅰ[M]. Beijing: Science Press, 2005: 296-309.

[8] YU Mao-hong. Unified strength theory and its applications[M]. Berlin: Springer, 2004.

[9] YUAN Shi-jian, XIAO Da-zhi, HE Zhu-bin. A generalized yield criterion[J]. J Mater Sci Technol, 2004, 20(6): 800-802.

[10] YAO Yang-ping, LU De-chun, ZHOU An-nan, et al. Generalized non-linear strength theory and transformed stress space[J]. Science in China Series E: Engineering & Materials Science, 2004, 47(6): 691-709.

[11] Zhang Y Q, Liua G R, Han X. Analysis of strain localization for ductile materials with effect of void growth[J]. International Journal of Mechanical Sciences, 2004, 46: 1021-1034.

[12] WANG Yan-bin, YU Mao-hong, XIAO Yun, et al. Dynamic plastic response of a circular plate based on unified strength theory[J]. International Journal of Impact Engineering, 2005, 31: 25-40.

[13] XU Shuan-qiang, YU Mao-hong. Shakedown analysis of thick-walled cylinders subjected to internal pressure with the unified strength criterion[J]. International Journal of Pressure Vessels and Piping, 2005, 82: 706-712.

[14] 俞茂宏. 线性和非线性的统一强度理论[J]. 岩石力学与工程学报, 2007, 26(4): 662-669.

YU Mao-hong. Linear and nonlinear unified strength theory[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(4): 662-669.

[15] Fan S C, Yu M H, Yang S Y. On the unification of yield criteria[J]. Journal of Applied Mechanics, 2001, 68(3): 341-343.

收稿日期:2007-12-05;修回日期:2008-03-10

通信作者:刘光连(1964-),男,湖南双峰人,博士研究生,副研究员,从事机械设计与理论、高等教育管理的研究;电话:0731-8836906;E-mail: glliu@mail.csu.edu.cn