热轧带钢平整机工作辊的不均匀磨损及其降低措施

张杰1,许焕宾1,李洪波1,刘会聪1,周一中2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 武汉钢铁(集团)公司 热轧厂,湖北 武汉,430083)

摘要:以2 250 mm热轧带钢平整机为对象,对工作辊的不均匀磨损进行研究。通过测量发现其工作辊磨损具有“W”形的特征,并分析该磨损与热轧和冷轧平整磨损的异同。结合其磨损特点,构造磨损模式函数,采用遗传算法确定模型参数,得到可满足工程要求的磨损模型。利用该模型计算分析不同窜辊策略时工作辊的磨损情况,针对原策略的不足提出新的窜辊策略并进行工业试验。研究结果表明:不均匀磨损程度减小,工作辊服役期延长。

关键词:热轧;平整机;工作辊磨损;轧辊窜辊

中图分类号:TG333.72 文献标志码:A 文章编号:1672-7207(2011)06-1611-06

Uneven wear of work roll and its reduction measurement on hot strip temper mill

ZHANG Jie1, XU Huan-bin1, LI Hong-bo1, LIU Hui-cong1, ZHOU Yi-zhong2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Hot Rolling Plant, Wuhan Iron & Steel (Group) Corp, Wuhan 430083, China)

Abstract: Taking 2 250 mm hot strip temper mill as a subject, uneven wear of work roll was studied. The difference between wear of hot strip mill and cold strip mill and “W” shape wear of work roll of hot strip temper mill were pointed out after measurement and analysis. Integrating its wear characteristics, the function of wear model, whose parameters were confirmed by using genetic algorithm, was constructed. The wear model which meets the requirements of project was obtained. Using the model, the wear of work roll under the condition of different shifting strategies was simulated. Simulation results show the deficiency of original shifting strategy. Based on the results, new shifting strategy is proposed and applied in industrial test, and the effects are as follows: non uniform wear of work roll is improved and service period of work roll is prolonged.

Key words: hot strip; temper mill; wear of work roll; shifting of work roll

板带轧机的板形及其变化主要与承载辊缝形状及其变化有关。承载辊缝形状主要取决于2个方面[1]:一是工作辊的辊形,二是轧辊的弹性变形。前者由轧辊的初始辊形、轧辊的磨损及轧辊的热变形等决定,后者与轧机所承受的载荷(轧制力、弯辊力等)有关,对于不同的轧机,它们对辊缝的影响程度是不同的。热轧带钢平整机的作用是对冷却到室温的热轧带钢施以很小的变形,以提高力学性能、改善板形(平坦度)[2]。平整机的结构与普通四辊轧机的相同,由于负荷较小,多采用单辊传动。由于热轧带钢平整机既没有冷却,也没有润滑,工作辊出现了比较严重的不均匀磨 损[3-4]。由于平整机的轧制力比较小,引起的弹性变形及其变化也较小,磨损对辊缝及其板形的影响更加突出。所以,研究热轧带钢平整机工作辊的磨损的规律并进行改善十分必要。在生产过程中,工作辊的磨损不可避免,但影响板形的是它的不均匀磨损。工作辊的磨损主要由与轧件的相互作用产生,故磨损主要发生在与轧件接触的部分。由于轧件宽度的变化及轴向窜辊,轧辊与轧件的接触区实际上是变化的,所以,轧辊的磨损程度就会不同。有研究表明,假设接触区不变,在与轧件接触范围内工作辊的磨损也是不均匀的(如“猫耳”形磨损)[5],因此,对工作辊磨损需要关注的一是磨损量,二是磨损的分布,后者用以辊身长度方向的位置为横坐标、以直径(或半径)变化量为纵向坐标的“磨损曲线”来表示。目前,国内外关于带钢热连轧机(以下简称“热轧”)、带钢冷轧机(以下简称“冷轧”)及冷轧带钢平整机(以下简称“冷轧平整”)的工作辊磨损问题的研究比较多,并得到了许多有价值的结果[2,6-8],但关于热轧带钢平整机(以下简称“热轧平整”)工作辊磨损的研究较少。本文作者以具有窜辊功能的某2 250 mm热轧平整机为对象,通过对轧辊辊形的测量和轧制压力分配、窜辊位置、弯辊力等轧制参数的采集,分析工作辊磨损的特点,建立工作辊的磨损模型;利用磨损模型对平整机工艺参数进行优化,以减少工作辊的不均匀磨损,降低对板形的不利影响。

1 热轧带钢平整机工作辊磨损的 特点

按金属的磨损理论,工作辊的磨损主要分为磨粒磨损、疲劳磨损(接触疲劳、热疲劳等)、黏着磨损和腐蚀磨损4类[9-11]。它们的具体作用与轧机或平整机的工作状况有关,如轧件状况(温度、材质、表面)、轧辊状况(材质、硬度、粗糙度)、轧制工艺(轧制力、轧制速度、轧制长度、润滑状况、冷却条件)等。

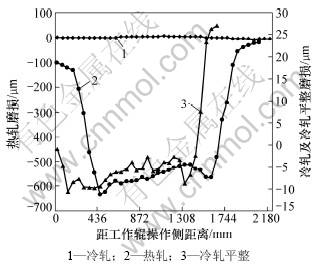

图1所示为武钢2 250 mm热轧、武钢2 180 mm冷轧和冷轧平整等3种轧机具有代表性的工作辊磨损曲线。由图1可以看出:热轧工作辊中部与轧件宽度对应部分磨损较大,呈现了“箱”形磨损,磨损量达600 μm,在“箱”的底部有2个“猫耳”形磨损[5, 12]。冷轧及冷轧平整的工作辊磨损一般小于50 μm,“箱”形磨损没有或很小。

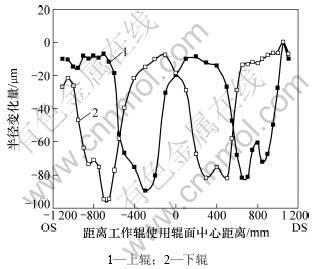

图2所示为武钢2 250 mm热轧平整的工作辊磨损曲线,它的显著特点是不均匀磨损呈“W”形分布。2个峰值磨损达200~300 μm,好似放大了的“猫耳”形磨损;其中部磨损很小,仅有10~30 μm;2个峰值磨损区间的距离为900~1 200 mm,与带钢的宽度范围相近;峰值磨损区的宽度约为400 mm,与工作辊±200 mm窜辊行程相当;由于工作辊初始位置及窜辊均为反对称,故上下工作辊磨损曲线也呈反对称。

图1 热轧、冷轧及冷轧平整的工作辊磨损曲线

Fig.1 Work roll wear contour of hot mill, cold mill and cold temper mill

图2 热轧平整的工作辊磨损曲线

Fig.2 Work roll wear contour of hot temper mill

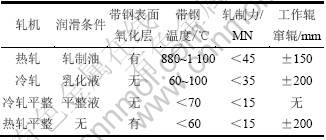

可见:热轧平整的工作辊磨损特征与热轧、冷轧及冷轧平整的工作辊磨损分布形式均有明显的不同,这与它们不同的工作状况有关。以武钢2 250 mm热连轧机、武钢2 250 mm热轧平整机及武钢2 230 mm冷轧联机及平整机为例,表1所示为它们的工作条件。

热轧的特点是:高温,大轧制力,带钢表面有氧化层,高温下的润滑对减轻磨损有一定作用,但效果不如冷轧的明显。4种磨损类型基本上都存在[12],故磨损较大。

冷轧的特点是:常温,大轧制力,带钢表面无氧化层,润滑良好,它的磨损以疲劳磨损和腐蚀磨损为主[8],故磨损很小。

表1 不同轧机和平整机的工作状况

Table 1 Working condition of different mills and tempering mill

冷轧平整的特点是:常温,小轧制力,带钢表面无氧化层,平整液的润滑效果远比冷轧的乳化液效果差。它的磨损也以疲劳磨损和腐蚀磨损为主[2],磨损比冷轧的略大。

与冷轧平整不同的是:热轧平整时没有润滑,带钢表面有严重的氧化层,故应存在磨粒磨损。观察热轧平整的工作辊磨损曲线可以发现:在与带钢中部接触的部分磨损较小,这与冷轧平整的情况接近;在与带钢边部接触的部分磨损很大,这又与热轧的情况相似。可见,热轧平整的工作辊磨损情况介于热轧和冷轧平整之间。这是因为热轧平整工作辊的磨损具有与其他轧机或平整机不同的特征,它的磨损模型也应具有自己的特点。

2 热轧带钢平整机工作辊的磨损 模型

计算轧辊磨损的数学模型可以用来分析影响磨损的因素以及对轧辊的磨损进行预报。由于轧辊的磨损过程比较复杂,目前还不能根据金属磨损理论进行纯机理建模,只能结合生产实际通过大量的实测与分析,建立半经验半理论的磨损预报模型[12-14],即先根据轧辊的磨损特征建立一个包括待定系数的磨损函数,然后对轧辊使用情况如轧辊磨损曲线、轧制参数(轧制力、变形量、轧制长度等)、轧辊参数(材质、轧辊位置等)等进行测量,最后采用回归的方法确定待定系数。

由于热轧平整机工作辊磨损的分布情况与热轧有相似的地方,故参照文献[14]中的方式构造工作辊的磨损函数,即认为平整第i卷带钢后轧辊直径磨损量沿轧辊轴向的分布为:

(1)

(1)

式中:k0为与带钢材质、工作辊材质、带钢温度等有关的系数;LZ为带钢长度,mm;FR为轧制压力,kN;B为带钢宽度,mm;LS为工作辊与轧件的接触弧长,mm;k1为单位轧制压力影响系数;f(x)为不均匀磨损模式函数;w1为轴向磨损分布模式基础量,mm;DW为工作辊直径,mm;x为原点在轧辊端部的轴向坐标,mm。

工作辊磨损的测量结果显示,在与带钢接触的范围内,即使轧制长度、单位轧制力等相同,轧辊的磨损也不相同,突出的是前面提到的“猫耳”形磨损,这里用f(x)表示这种不均匀磨损。何安瑞[14]提出了热轧工作辊的不均匀磨损模式,如图3所示。

图3 工作辊不均匀磨损模式

Fig.3 Uneven distribution mode of work roll

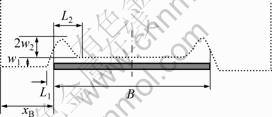

尽管热轧带钢平整机的磨损与热轧的磨损模式相似,但由图1和图2也可以看出二者还是有很大的差别,特别是表征“猫耳”形磨损的L2和w2。通过分析和计算,确定了适合该热轧带钢平整机工作辊不均匀磨损的模式函数:

f(x)=

(2)

(2)

该模式是将长度为Lw的辊身按磨损特征分为7段:带钢宽度B以外较远的2段没有磨损,wi=0;发生磨损的5段可以用模式函数表示:在带钢2个边外很小区段L1(一般为15~20 mm)内有磨损,用线性函数表示;与文献[14]的显著不同在于:新模式用正弦函数描述了2个“猫耳”形磨损段L2的磨损,幅值分别为w2和k2w2,k2是考虑了2个“猫耳”磨损量一般并不相同的局部不均匀系数,带钢边部的位置坐标xB按下式计算:

(3)

(3)

式中:s为工作辊的窜辊量,mm。

若工作辊服役期间共平整n卷带钢,则它的总磨损量W(x)为:

(4)

(4)

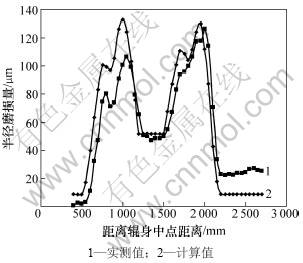

以上磨损模型中,轧制压力、带钢宽度等轧机和轧制工艺参数可以从生产中直接获取,其他6个待定系数k0,k1,k2,w1,w2和L2可采用回归的方法确定。不过,由于模型的结构比较复杂,且只能测到轧辊的最终磨损值W(x),一般的回归方法并不能解出这些待定参数,故本文以测量值与模型计算值差别最小为目标,按参数优化的思想,采用遗传算法对待定参数进行求解,从而建立2 250 mm热轧带钢平整机工作辊的磨损模型。图4所示为采用该模型对现场按某轧制计划生产时对应工作辊磨损的计算结果与实测结果的对比,可见:使用正弦函数并加入局部不均匀系数的新模型可以更准确的描述热轧带钢平整机工作辊的磨损特性。

图4 磨损计算值与实测值对比(上辊)

Fig.4 Contrast of wear between calculated roll wear contour and measured one

3 改善磨损的窜辊新策略

2 250 mm热轧平整机的工作辊具有±200 mm的窜辊能力,其作用是使轧辊的磨损不过分集中在某些区间,以减少因不均匀磨损导致的辊形变化和对板形的影响[15-16]。从前面讨论的磨损模型也可以看出:在带钢规格、轧辊尺寸、平整量等因素确定的条件下,唯一可控的参数是工作辊的窜辊量s。可见:改变窜辊策略即可改变工作辊的磨损。

窜辊策略主要是确定3个参数:步长(每次的窜辊量)、节奏(2次窜辊之间平整的钢卷数)和行程(1次窜辊循环内的轧辊始末窜辊量)。

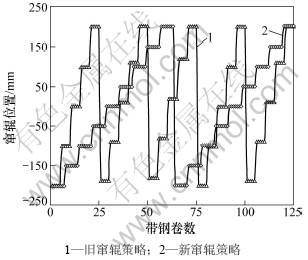

2 250 mm热轧平整机原来采用如图5所示的等步长、变节奏、等行程的窜辊策略,且步长较大,它的不均匀磨损比较严重,如图6所示。

图5 新、旧窜辊策略对比

Fig.5 Contrast between new shift strategy and original one

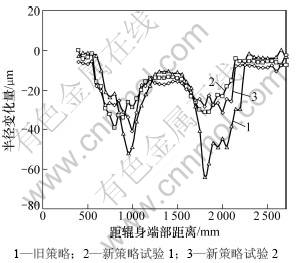

图6 新、旧窜辊策略下的工作辊磨损曲线对比

Fig.6 Contrast of work roll wear between new shift strategy and original one

利用所建模型,对4种窜辊策略(等步长等节奏、等步长变节奏、变行程等步长等节奏、变行程变步长等节奏)进行磨损计算,对于每种策略,选取不同的窜辊参数。

计算结果表明:窜辊的步长和节奏对磨损的影响很大;在一般情况下,步长和节奏越小,局部不均匀磨损越小。不过在设计窜辊策略时,还要考虑设备的能力和生产的便利性。例如,过小的步长实际上难以实现;过小的节奏使得窜辊过于频繁;变步长和变节奏使生产难以组织且失去了窜辊操作的灵活性。综合计算分析及实现的可能性,提出等步长等节奏变行程单向窜辊的新策略,如图6所示,其主要特点是减小步长、适当增加2次窜辊之间平整的钢卷数,减少窜辊循环次数。

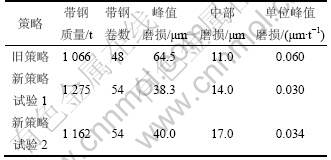

4 新策略的生产试验及效果

按新的窜辊策略进行了生产试验,并与旧策略下的情况进行对比。表2所示为2次新策略试验及1次旧策略试验结果。图6所示为试验的工作辊磨损曲线。从图6可以看到:

(1) 在新策略下,单位平整量的工作辊峰值磨损量为0.030~0.034 μm/t,比旧策略的0.060 μm/t降低了43%以上。与此同时,新策略下中部磨损增加,故整体上表现出工作辊的不均匀磨损得到明显降低。

(2) 新策略下的带钢平整量高于旧策略,说明因不均匀磨损减轻使得对板形的影响减小,工作辊的服役时间延长。

表2 新、旧策略试验下的磨损量比较

Table 2 Contrast of wear between new strategy test and original one

5 结论

(1) 具有工作辊窜辊功能的热轧带钢平整机工作辊的磨损呈现出与其他轧机和平整机不同的“W”形磨损特征,边部的磨损量与热轧的磨损量相近,中部的磨损量与冷轧平整的磨损量相近。

(2) 根据热轧带钢平整机工作辊磨损分布的特点,确定了磨损模型的七段式函数结构;鉴于模型比较复杂、参数难以确定的情况,提出了基于遗传算法的参数优化方法。考虑到热轧带钢平整机工作辊磨损的特殊性,与传统磨损预报模型不同的是:新模型使用正弦函数对局部猫耳状磨损进行描述,并加入局部不均匀系数以准确描述磨损的不对称性。试验结果表明:新模型可以更准确地描述热轧带钢平整机工作辊的磨损特性,更加满足工程需求。

(3) 利用得到的模型,对不同的窜辊策略进行仿真计算和对比分析,结合设备及生产的可行性,提出了新的窜辊策略并进行生产试验,取得了磨损均匀、工作辊服役期延长的良好效果。

参考文献:

[1] CHEN Xian-lin, YANG Quan, ZHANG Qing-dong, et al. Varying contact back-up roll for improved strip flatness[C]// Steel Technology International. London, 1995: 174-178.

[2] LI Xiao-yan, ZHANG Jie, CHEN Xian-lin, et al. Improvement on the strip flatness of cold temper mill by modifying roll contour shape[J]. Journal of University of Science and Technology Beijing, 2004, 11(3): 252-255.

[3] 蔡丽芳, 张杰, 曹建国, 等. 热轧带钢平整机工作辊磨损问题研究[J]. 冶金设备, 2007, 4(2): 38-41.

CAI Li-fang, ZHANG Jie, CAO Jian-guo, et al. Study on the wear of the working roll in temper rolling mill for hot strip[J]. Metallurgical Equipment, 2007, 4(2): 38-41.

[4] 刘会聪. 热轧带钢平整机工作辊磨损和弯窜辊特性的研究[D]. 北京: 北京科技大学机械工程学院, 2008: 22.

LIU Hui-cong. Study on work roll wear and strip shape control of hot strip temper mill[D]. Beijing: University of Science and Technology Beijing. School of Mechanical Engineering, 2008: 22.

[5] 牟善文. 硅钢板热轧过程中工作辊磨损及其控制方法的研究[D]. 北京: 北京科技大学机械工程学院, 2002: 26.

MU Shan-wen. Research on work roll wear and its control methods in silicon steel hot rolling[D]. Beijing: University of Science and Technology Beijing. School of Mechanical Engineering, 2002: 26.

[6] 邹家祥. 工作辊磨损预报计算[J]. 钢铁, 1986, 21(7): 23-27.

ZOU Jia-xiang. The calculation of work roll wear prediction[J]. Iron and Steel, 1986, 21(7): 23-27.

[7] Ginzburg V B. High-quality steel rolling: Theory and practice[M]. New York: Marcel Dekker, 1993: 33.

[8] 鲁海涛, 曹建国, 张杰, 等. 冷连轧机变接触支承辊板形控制性能研究与应用[J]. 钢铁, 2007, 42(5): 42-46.

LU Hai-tao, CAO Jian-guo, ZHANG Jie, et al. Shape control with varying contact backup rolls on tandem cold rolling mill[J]. Iron and Steel, 2007, 42(5): 42-46.

[9] Mascia J C, Marini O C, Ubici E. Reduction of work roll wear by controlling tertiary scale growth[J]. Iron and Steel Engineer, 1998, 75(6): 48-51.

[10] Sven-Erik L, Therfse G. The influence of rolling temperature on roll wear, investigated in a new high temperature test rig[J]. Journal of Materials Processing Technology, 1994, 42: 239-291.

[11] Sachs G. Roll wear in finishing trains of hot strip mills[J]. Iron and Steel Engineer, 1961, 38(12): 71-92.

[12] 何安瑞, 张清东, 曹建国, 等. 热轧精轧机组工作辊磨损分析及预报[J]. 冶金设备, 1999(3): 23-26.

HE An-rui, ZHANG Qing-dong, CAO Jian-guo, et al. Wear analysis and its pattern prediction of work rolls in finishing trains of hot strip mills[J]. Metallurgical Equipment, 1999(3): 23-26.

[13] 曹建国, 张杰, 甘健斌, 等. 无取向硅钢热轧工作辊磨损预报模型[J]. 北京科技大学学报, 2006, 28(3): 286-289.

CAO Jian-guo, ZHANG Jie, GAN Jian-bin, et al. Work roll wear prediction model of non-oriented electrical steel sheets in hot strip mills[J]. Journal of Science and Technology Beijing, 2006, 28(3): 286-289.

[14] 何安瑞. 宽带钢热轧精轧机组辊形的研究[D]. 北京:北京科技大学机械工程学院, 2000: 22.

HE An-rui. Study on roll contour in finishing trains of hot wide strip mills[D]. Beijing: University of Science and Technology Beijing. School of Mechanical Engineering, 2000: 22.

[15] Nakanishi T. Application of work roll shift mill to hot strip and plate rolling[J]. Hitachi Review, 1983, 32(2): 59-64.

[16] Kitahama M, Yarita I, Abe H, et al. Profile control of hot rolled strip by work roll shifting (K-WRS) mill[J]. Iron and Steel Engineer, 1987, 64(11): 34-43.

(编辑 杨幼平)

收稿日期:2010-05-25;修回日期:2010-08-12

基金项目:国家自然科学基金重点资助项目(59835170)

通信作者:张杰(1960-),男,上海人,博士,教授,从事冶金机械及板带轧制方向的研究;电话:010-62334723;E-mail:zhangjie@ustb.edu.cn