2250 CVC热连轧机工作辊辊形改进与应用

魏钢城1, 2,曹建国1, 张 杰1, 郝建伟1,陈 刚2

(1. 北京科技大学 机械工程学院,北京 100083;

2. 武汉钢铁(集团)公司,武汉 430083)

摘 要:针对2250热连轧机F5架(CVC)工作辊窜辊行程利用率低、窜辊分布曲线中心偏移,以及CVC工作辊磨损严重且不均匀等问题,建立CVC辊形设计数学模型,结合现场实际应用情况提出武钢2250热连轧机F5架改进的CVC辊形曲线,并给出改进CVC辊形的不同宽度带钢辊缝凸度调节能力的方法;在2250热连轧机下游F5架采用改进的CVC辊形曲线进行工业轧制实验。研究结果表明:CVC轧辊窜辊行程利用率由66%提高到80%,磨损更均匀化。

关键词:热连轧机;带钢;板形;轧辊;CVC; 磨损

中图分类号:TG333.71 文献标识码:A 文章编号:1672-7207(2007)05-0937-06

Optimization and application of CVC work roll contour on 2250 hot strip mills

WEI Gang-cheng1, 2, CAO Jian-guo1, ZHANG Jie1, HAO Jian-wei1, CHEN Gang2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Wuhan Iron and Steel Company, Wuhan 430083, China)

Abstract: Due to some problems of continuously variable crown (CVC) work roll on stand F5 of 2250 hot strip mills, for example, the shifting stroke of the CVC work rolls cannot be shifted well enough, the central position of shifting stroke is deviated and the work rolls is worn very badly and non-uniformly, and based on the developed mathematic model for CVC roll contour design method, the optimized CVC work roll contours and its performance of crown controllability were presented with the rolling operation of the production mills and were applied in downstream stand F5 of 1700 hot strip mill for test. The results show that the percentage of shifting stroke for optimized CVC work roll increases from 66% to 80%, and the wear of optimized CVC work roll is more uniform.

Key words: hot strip mill; strip; profile and flatness; roll; CVC; wear

Continuously variable crown (CVC)是宽带钢热连轧机板形控制的代表性技术之一。武钢2250 CVC热连轧机是目前世界上产量最大、轧制宽度最大的热连轧机,自2003年建成投产以来,年实际产量已逾487万t。该热连轧机组宽度覆盖范围广,达700~2 130 mm,厚度覆盖范围大,达1.2~ 25.4 mm。该轧机投产后,国内又正在建设3套2250热连轧机。在轧机机型确定的情况下,辊形成为带钢板形控制最直接、最有效的手段之一[1-2]。连续可变凸度CVC技术最突出的特点就是可连续改变辊缝凸度,一套轧辊就能满足不同轧制规程的凸度要求,因而在宽带钢冷、热连轧机等得到广泛应用[3-6]。需指出的是,1999年后国内引进的18套热连轧机中,13套热连轧机均为四辊CVC

轧机机型。国内外研究者对CVC的辊形设计方法进行了大量研究[6-10],并对轧制过程CVC辊形的磨损及变化进行了跟踪测试及分析[11-12]。针对CVC辊形窄带凸度控制能力不足问题,国内研究者提出了热连轧机上游机架应用的一种线性变凸度LVC辊形[13]。热连轧机下游机架严重的工作辊磨损使得CVC辊形的自保持性差而难以在服役周期内保持CVC的板形控制特性[2, 11, 14];2050热连轧机中,将F6和F7机架CVC工作辊改为常规平辊[15],但生产实践发现轧制计划内的大多数带钢,其工作辊弯辊和横移量基本上都达到设备能力的最大值,但许多带钢凸度超差严重[16],即轧机板形控制能力明显不足。2250热连轧机上游机架采用CVC机型而下游机架采用SFR机型,即采用平辊可实现长行程窜辊,采用CVC辊形实现连续变凸度,目前使用更多的是CVC工作辊。1700热连轧机进行的工业轧制试验结果表明,采用常规平辊的工作辊窜辊系统通过有节律的窜辊使磨损分散化,不仅局部磨损明显降低,而且在一定程度上减轻了工作辊整体磨损并可增加轧制产量[2],是实现工作辊“磨损控制”的有效方法,其不足之处在于平辊窜辊仍然是低刚度辊缝且平辊窜辊不具有凸度控制功能,这也正是2050热连轧机CVC改常规平辊导致轧机板形控制能力不足的关键原因之一。国内自主开发的ASR工作辊兼有凸度控制与磨损控制的双重能力,可实现边部板形控制[17],不仅适用于工作辊长行程窜辊系统,而且通过采取特定技术手段同样可推广应用于工作辊短行程窜辊系统。因此,研究2250 CVC热连轧机工作辊辊形对稳定发挥超宽轧机轧机板形性能并推广完善热轧板形控制技术具有重要意义。

1 2250 CVC工作辊磨损与窜辊问题

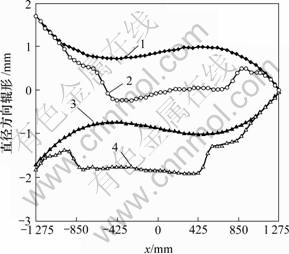

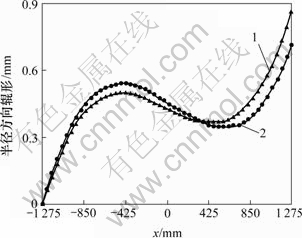

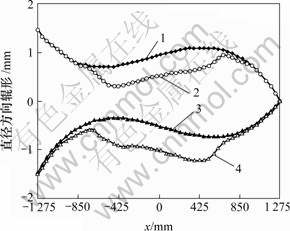

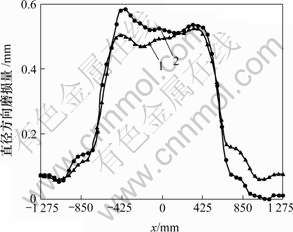

宽带钢热连轧机由于存在明显轧辊磨损和热凸度导致轧制单位内工作辊辊形发生显著变化[11-12]。为了研究2250热连轧机CVC工作辊辊形变化规律,对136支CVC工作辊服役前后辊形进行跟踪测试,其中跟踪采集分析24支F5机架CVC工作辊辊形数据。热轧下游机架尤其是F4和F5机架工作辊磨损最显著, 2250热连轧机F5机架CVC工作辊实测服役前后辊形和磨损辊形如图1和图2所示。其中,x为辊身长度方向各点与辊身中点的距离。

1—上辊上机前;2—上辊下机后;3—下辊上机前;4—下辊下机后

图1 2250热连轧机F5架1个轧制单位服役期的CVC工作辊辊形

Fig.1 CVC work roll contours for stand F5 of 2 250 hot strip mill with a rolling campaign

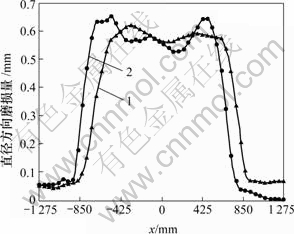

1—上辊;2—下辊

图2 2250热连轧机F5架CVC工作辊辊身长度方向磨损量

Fig.2 CVC work roll wear contours for stand F5 of 2 250 hot strip mill

通过现场实测数据分析发现,F5架CVC工作辊磨损具有如下特点:

a. F5机架CVC工作辊磨损比较严重,直径磨损量达到700 mm;

b. 上下工作辊磨损量不同,一般是下工作辊比上工作辊磨损量大;

c. 工作辊磨损形状呈“箱形”,上下工作辊“箱形”磨损中心位置不对称,磨损位置各有偏移,上辊偏向传动侧大约50 mm,下辊偏向操作侧50 mm;

d. 磨损的“箱形”底部不均匀,一般上辊的“箱形”底部均匀程度稍高于下辊“箱形”底部的均匀程度,一般“箱形”开口处宽度为1 600 mm,底部宽度仅1 100 mm左右,“箱形”的形状与轧制单位编排有关。

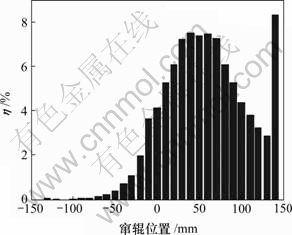

与2 050热连轧机CVC工作辊磨损[5, 12]相比,2250热连轧机CVC工作辊磨损形式具有相似性,但磨损更严重,且“箱形”磨损中心位置发生明显偏移。为此,进一步分析了2250热连轧机工作辊窜辊分布规律。对现场采集到的2005年12月11日至2006年3月20日所轧41 547个钢卷实际窜辊位置的数据进行分析,得到F5架CVC工作辊实际窜辊位置分布比率,如图3所示。图3中,横坐标为窜辊位置分布,纵坐标η为在窜辊分布各位置所轧钢卷数占统计轧钢总卷数的百分比。

图3 2250热连轧机F5架CVC工作辊窜辊位置分布图(41 547卷)

Fig.3 Distribution of shifting stroke position percentage of CVC work roll for stand F5 of 2 250 hot strip mill (41 547 coils)

由图3可知,F5架CVC工作辊窜辊位置分布明显不均匀,窜辊中心位置基本集中在+50 mm左右,与实测的轧辊“箱形”磨损中心位置偏移距离正好吻合;同时,正向窜辊达到极限位置150 mm的概率高达7%,此极限位置表明在窜辊达到极限位置时对凸度控制能力依然不够;窜辊主要分布在[-50, 150]范围内,在[-150, -50]段利用率非常低,而轧机设计窜辊范围为[-150, 150],实际窜辊行程利用率只有66%左右。

通过以上测试分析可知:2250热连轧机F5架CVC工作辊负凸度偏大,正凸度较低,使得2250热连轧机CVC工作辊窜辊行程利用率降低,因而,导致轧辊磨损严重、不均匀,且“箱形”磨损中心位置发生偏移。

2 CVC工作辊辊形设计与改进

宽带钢热连轧生产中,边浪和中浪是主要的板形缺陷,对四次板形的调节能力要求较小,因此,在生产实践中,CVC轧机大都以二次板形为主要控制目标,2250热连轧机CVC工作辊采用的是3次辊形曲线。根据连续变凸度技术基本原理 [6-10],对于轧机的上工作辊,3次CVC辊形函数(半径函数)yt0(x)可用通式表示为:

。 (1)

。 (1)

式中:a3, a2, a1和a0为辊形设计待定常数。

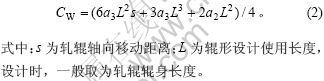

辊缝凸度CW为:

由式(2)可知,辊缝凸度与a1无关(a1可以轧辊轴向力最小[10]或轧辊辊径差最小确定,生产实践中多以轧辊辊径差最小作为设计判据[6-9]),且辊缝凸度与轧辊轴向移动量s呈线性关系。设轧辊轴向移动的行程范围为 ,相应的辊缝凸度范围为

,相应的辊缝凸度范围为 ,分别代入式(2)有

,分别代入式(2)有

; (3)

; (3)

。 (4)

。 (4)

解得:

; (5)

; (5)

。 (6)

。 (6)

在通常情况下,CVC轧机应在目标凸度控制范围内尽量增加其窜辊的行程,但2250 CVC热连轧机窜辊行程利用率较低。由图3可知,CVC工作辊窜辊主要分布在正向范围内,而且经常窜辊到正的极限位置。2250热连轧机CVC工作辊轴向移动范围为-150~150 mm,即sm=150 mm,对应的轧辊凸度范围为-0.5~0.5 mm。通过带钢轧制数据分析和轧制试验,取改进后的凸度范围为-0.3~0.7 mm,由此确定改进前后的CVC工作辊辊形见图4。在辊缝凸度变化范围一定的情况下,辊形设计使用长度越大,辊径差越大[10, 18-19]。因此,应当选取适宜的辊形设计使用长度,以尽可能减小辊径差。由于板带轧制都在中部,以最大板宽2 130 mm计算,工作辊两端各有一段(35 mm)在任何情况下均不与轧件接触,因此,可取L=2 430 mm,得到辊形曲线。在实际生产中按最大宽度轧制的情况很少,因此,若按实际轧制宽度进行辊形设计,可以进一步降低辊径差,如取实际轧制宽度为1 850 mm,可取L=2 150 mm,得到实际辊形曲线。

1—改进前; 2—改进后

图4 2250热连轧机F5架改进前后的CVC工作辊辊形对比

Fig.4 Roll contour comparison between CVC and optimized CVC for stand F5 of 2 250 hot strip mill

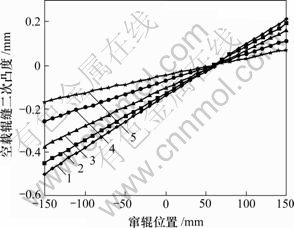

空载辊缝调节范围反映辊型在不施加弯辊力和轧制力情况下,由窜辊改变辊缝凸度的能力[13],图5所示为改进后CVC工作辊对于不同宽度B带钢的空载辊缝凸度调节能力。

带钢宽度/mm: 1—2 150; 2—2 050; 3—1 850; 4—1 550; 5—1 250

图5 2250热连轧机F5架改进后CVC工作辊的空载辊缝凸度

Fig.5 Roll gap profile controllability of optimized CVC work roll for stand F5 of 2 250 hot strip mill

3 改进的CVC工作辊工业试验及应用

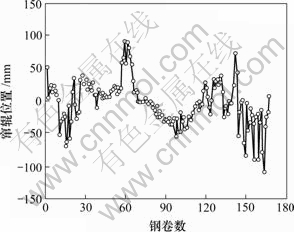

2006年4月14~25日在对2250热连轧机二级计算机控制模型进行相应的修改,进行 4轮F5机架改进CVC工作辊的上机轧制实验。轧制单位内CVC工作辊窜辊位置分布见图6,服役前、后的轧辊辊形变化见图7和图8。

图6 2250热连轧机改进的F5架CVC工作辊轧制单位内窜辊位置分布图

Fig.6 Distribution of shifting stroke position of optimized CVC work roll with a rolling campaign for stand F5 of 2 250 hot strip mill

1—上辊上机前;2—上辊下机后;3—下辊上机前;4—下辊下机后

图7 2250热连轧机改进的F5架CVC工作辊服役前后辊形变化

Fig.7 Optimized CVC work roll contours for stand F5 of 2 250 hot strip mill with a rolling campaign

1—上辊;2—下辊

图8 2250热连轧机F5架改进的CVC工作辊辊身长度方向磨损量

Fig.8 Optimized CVC work roll wear contours for stand F5 of 2 250 hot strip mill

经对比分析可知,改进后的辊形整个轧制单位窜辊分布基本均匀,窜辊行程利用率达到整个行程的80%,改进的CVC工作辊严重磨损有所减小,且上下工作辊“箱形”磨损底部趋于均匀,“箱形”磨损中心位置基本位于轧辊中间位置未再发生偏移,有利于带钢凸度和楔形控制的适度提高。取得稳定效果后,F5架改进的CVC工作辊已投入大型工业轧机应用。

值得指出的是,为了完善推广热轧板形控制技术,不仅要根据生产实际改进CVC板形控制技术,更要逐步应用CVC工作辊改平辊和ASR工作辊新技术。

4 结 论

a. 2250热连轧机下游机架尤其是F4和F5机架工作辊磨损最显著,与2050热连轧机CVC工作辊磨损相比,2250超宽热连轧机CVC工作辊磨损更严重,直径磨损量达到700 μm;磨损形状呈“箱形”,上下工作辊“箱形”磨损中心位置不对称,磨损位置各有偏移,上辊偏向传动侧大约50 mm,下辊偏向操作侧50 mm。

b. 2250热连轧机普遍存在CVC工作辊窜辊行程利用率低、窜辊分布位置中心偏移,F5架CVC工作辊负凸度偏大,正凸度不足等问题,使得2250热连轧机CVC工作辊窜辊行程利用率降低,导致前述轧辊磨损严重,不均匀且“箱形”磨损中心位置发生偏移。

c. 建立了CVC辊形设计数学模型,结合现场实际提出了F5架改进的2250 CVC辊形曲线,完善了工作辊凸度控制要求,并给出了改进后CVC辊形曲线的对于不同宽度带钢的空载辊缝凸度调节能力。工业试验结果表明,CVC辊辊窜辊行程利用更充分,磨损更均匀化的明显效果。

参考文献:

[1] 陈先霖. 宽带钢冷连轧机的机型设计问题[C]//2005年中国钢铁年会论文集. 北京: 冶金工业出版社, 2005: 511-514.

CHEN Xian-lin. Strip mill configuration design of cold tandem mills[C]// CSM 2005 Annual Meeting Proceedings. Beijing: Metallurgical Industry Press, 2005: 511-514.

[2] 曹建国, 张 杰, 陈先霖, 等. 宽带钢热连轧机选型配置与板形控制[J]. 钢铁, 2005, 40(6): 40-43.

CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Selection of strip mill configuration and shape control[J]. Iron and Steel, 2005, 40(6): 40-43.

[3] Klockner J. CVC technology for hot rolling mills[J]. Metallurgical Plant and Technology, 1987, 10(1): 54-60.

[4] Bald W, Klamma K. CVC technology for cold rolling mills[J]. Iron and Steel Engineer, 1988, 65(5): 24-28.

[5] 杨 广, 金学俊, 解建平. 现代化的宝钢2 050 mm热轧机组[J]. 轧钢, 2002, 19(2): 41-43, 52.

YANG Guang, JIN Xue-jun, XIE Jian-ping. The modern 2 050 mm hot strip mill of Baosteel[J]. Steel Rolling, 2002, 19(2): 41-43, 52.

[6] XU Le-jiang, XU Yao-huan, ZHANG Yong, et al. CVC technology in China’s largest cold strip mill[J]. Steel Technology International, 1994(1): 203-208.

[7] 张 杰, 陈先霖, 徐耀寰, 等. 轴向移位变凸度四辊轧机的辊型设计[J]. 北京科技大学学报, 1994, 16(S2): 98-101.

ZHANG Jie, CHEN Xian-lin, Xu Yao-huan, et al. Roll contour design of 4-high mill with variable crown by axial shifting[J]. Journal of University of Science and Technology Beijing, 1994, 16(S2): 98-101.

[8] 陈 杰, 周鸿章, 钟 掘. CVC四辊铝冷轧机工作辊辊型设计[J]. 轻合金加工技术, 2000, 28(3): 12-13.

CHEN Jie, ZHOU Hong-zhang, ZHONG Jue. Design of the work roll shape of 4-h CVC mill[J]. Light Alloy Fabrication Technology, 2000, 28(3): 12-13.

[9] LU Cheng, Kiet A K, JIANG Zheng-yi. A design of a third-order CVC roll profile[J]. Journal of Material Processing Technology, 2002, 125/126: 645-648.

[10] 曹建国, 张 杰, 陈先霖, 等. 1700冷连轧机连续变凸度辊形的研究[J]. 北京科技大学学报, 2005, 25(S6): 1-3.

CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Research on CVC roll contour in 1 700 mm tandem cold mill[J]. Journal of University of Science and Technology Beijing, 2005, 25(S6): 1-3.

[11] CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Control of roll contour for strip profile and flatness in hot rolling[C]//44th Mechanical Working and Steel Processing Conference Proceeding & 8th International Steel Rolling Conference Proceeding. Florida, 2002: 1001-1010.

[12] 连家创, 黄传清, 陈连生. 2050CVC热连轧机精轧机组轧辊磨损的研究[J]. 钢铁, 2002, 37(3): 24-27.

LIAN Jia-chuang, HUANG Chuan-qing, CHEN Lian-sheng. Roll wear on finishing train of 2050 CVC hot strip mill[J]. Iron and Steel, 2002, 37(3): 24-27.

[13] 王仁忠, 何安瑞, 杨 荃, 等. LVC工作辊辊形的板形控制性能研究[J]. 钢铁, 2006, 41(5): 41-44.

WANG Ren-zhong, HE An-rui, YANG Quan, et al. Profile control capability of LVC work roll contour[J]. Iron and Steel, 2006, 41(5): 41-44.

[14] 严洪凯, 杜素周, 张清东. CVC工作辊磨损和热凸度对轧机板形控制性能的影响[J]. 冶金设备, 2000(3): 1-4.

YAN Hong-kai, DU Su-zhou, ZHANG Qing-dong. Influence of wear and hot crown of CVC work roll on the behaviors of strip shape control[J]. Metallurgical Equipment, 2000(3): 1-4.

[15] 孔祥伟, 徐建忠, 龚殿尧, 等. 采用平辊实现自由程序轧制最优横移方案新方法[J]. 东北大学学报: 自然科学版, 2002, 23(12): 1166-1169.

KONG Xiang-wei, XU Jian-zhong, GONG Dian-yao, et al. Optimum shift scheme of SFR realized by adopting flat roll[J]. Journal of Northeastern University: Natural Science, 2002, 23(12): 1166-1169.

[16] 孔祥伟, 徐建忠, 王国栋, 等. 精轧F7机架采用平辊实现自由程序轧制的研究[J]. 钢铁, 2002, 37(11): 26-29.

KONG Xiang-wei, XU Jian-zhong, WANG Guo-dong, et al. Study on schedule free rolling with flat roll on F7 finish stand[J]. Iron and Steel, 2002, 37(11): 26-29.

[17] 曹建国, 张 杰, 宋 平, 等. 无取向硅钢热轧板形控制的ASR技术[J]. 钢铁, 2006, 41(6): 43-46.

CAO Jian-guo, ZHANG Jie, SONG Ping, et al. ASR technology for controlling profile and flatness of non-oriented electrical steel strip in hot rolling[J]. Iron and Steel, 2006, 41(6): 43-46.

[18] 杨光辉, 曹建国, 张 杰, 等. SmartCrown四辊冷连轧机工作辊辊形[J]. 北京科技大学学报, 2006, 28(7): 669-671.

YANG Guang-hui, CAO Jian-guo, ZHANG Jie, et al. SmartCrown work roll contour of a 4-hi tandem cold rolling mill[J]. Journal of University of Science and Technology Beijing, 2006, 28(7): 669-671.

[19] 杨光辉, 曹建国, 张 杰, 等. SmartCrown冷连轧机板形控制新技术改进研究与应用[J]. 钢铁, 2006, 41(9): 56-59.

YANG Guang-hui, CAO Jian-guo, ZHANG Jie, et al. Optimization of application of SmartCrown on tandem cold rolling mill[J]. Iron and Steel, 2006, 41(9): 56-59.

收稿日期:2006-11-16;修回日期:2007-01-08

基金项目:北京科技大学科技发展专项基金资助项目(20050311890)

作者简介:魏钢城(1962-),男,湖北武汉人,博士研究生,从事板形控制、板带轧制技术及自动化研究

通信作者:曹建国,男,博士,副教授;电话: 010-62332835;E-mail: geocao@me.ustb.edu.cn