文章编号:1004-0609(2010)05-0813-07

超声孕育处理对AS41镁合金凝固组织的影响

乐启炽,张志强,崔建忠,刘鸿明,高恩保

(东北大学 材料电磁过程研究教育部重点实验室,沈阳110004)

摘 要:采用连续功率超声对AS41镁合金熔体进行孕育处理,研究超声处理功率(强度)、处理时间和处理温度等工艺条件对其凝固组织的影响规律。通过对凝固金相和低倍组织观察以及XRD和Mg2Si相的点阵常数计算,结果表明:连续功率超声孕育处理可以显著细化AS41镁合金的凝固组织,晶粒尺寸仅为无超声处理时的30%~50%;适当提高超声强度和处理温度以及适当延长处理时间均可增强细化效果。优化的处理条件如下:超声强度为30~40 W/cm2,处理时间为50~80 s,处理温度为650~700 ℃。此外,超声处理也使Mg2Si相细化和球化,Mg2Si相的点阵常数也发生明显变化。

关键词:AS41镁合金;熔体;超声孕育处理;凝固组织

中图分类号:TG146.2; TG249.9 文献标志码:A

Effect of ultrasonic inoculation treatment on solidification microstructure of AS41 magnesium alloy

LE Qi-chi, ZHANG Zhi-qiang, CUI Jian-zhong, LIU Hong-ming, GAO En-bao

(Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education,

Northeastern University, Shenyang 110004, China)

Abstract: Continuous power ultrasound was applied to inoculating the AS41 melt, and the effects of inoculating conditions including ultrasonic power (intensity), treating time and treating temperature on the solidification microstructures were investigated. According to the metallographical and macroscopical observation together with the XRD pattern and the calculation of Mg2Si phase lattice constant, the results indicate that the continuous power ultrasonic inoculation treatment can refine the grain size of AS41 magnesium alloy markedly, and the grain size with ultrasonic treatment is only 30%-50% as that without ultrasonic treatment. The grain refinement is improved by enhancing ultrasonic intensity, elevating treating temperature (melt temperature), or prolonging treating time. Its optimum condition is that the ultrasonic field with intensity of 30-40 W/cm2 treats AS41 melt in the temperature range of 650-700 ℃ for 50-80 s. In addition, the ultrasonic treatment also leads to the refinement and spheroidization of Mg2Si and the change of its lattice constant as well.

Key words: AS41 magnesium alloy; melt; ultrasonic inoculation; solidification microstructure

自1925年德国用压铸方法生产镁合金部件以来,镁合金压铸已走过80多年历史。早期压铸镁合金主要是AZ91镁合金,后来德国大众开始使用AZ81和AZ61镁合金进行压铸。由于AZ系镁合金的耐热温度只有150 ℃,因此,Dow和Norsk Hydro等公司开始开发耐热温度可达到175 ℃而其他性能与AZ81相当的镁合金体系。迄今为止,最成功的是NL Industries和Dow公司在1970年代开发的Mg-Al-Si-Mn系合金。该合金有较好的耐热性且比含稀土的耐热镁合金廉价。德国大众在1971年左右逐渐把其超过一半的产品用AS41镁合金替代AZ81镁合金[1]。

AS系镁合金比AZ系镁合金具有更好的耐热性,这可能与其低Al含量和稳定的Mg2Si相析出有关[2-3]。但是,添加Si只在压铸件中有效,在一般的砂型铸造中,由于有粗大的汉字状Mg2Si相析出,导致在析出相与基体之间的界面上容易产生裂纹,最终导致力学性能的显著降低[4-5]。通过在合金中添加Sb、Ca、P或Sr等变质剂或者改变合金中的Si含量[5-8],或者通过快速凝固[9]、机械合金化[10-11]等方法可改变Mg2Si相的形貌,从而提高合金的力学性能。

大量研究表明,镁合金熔体的超声处理可以实现其凝固组织的细化[12-13],且对镁合金熔体中的第二相形貌有显著影响[14]。与其他合金熔体相比,对镁合金熔体进行超声处理的最大优点在于用普通铁质材料制造的变幅杆在熔体中具有很好的耐久性,不存在腐蚀和污染问题。本文作者采用连续功率超声对AS41镁合金熔体进行孕育处理,研究超声功率、处理时间和处理温度等条件对AS41镁合金凝固组织和Mg2Si相形貌的影响规律。

1 实验

AS41镁合金熔体采用电阻坩埚炉熔制。Si以Al-20%Si(质量百分数,下同)中间合金形式加入,Mn以锰剂形式加入。其化学分析结果为Mg-4.1% Al-1.1%Si- 0.22%Mn。把熔制好的合金在锥形坩埚(上口内径d40 mm,底部内径d20 mm)中加热熔化到设定温度后,采用频率为20 kHz、最大功率为2 kW的连续超声进行处理后,最后在坩埚中直接水冷。功率调节误差为±10 W,计时误差为±5 s。处理过程中采用CO2+0.5% SF6混合气体进行保护。

在直接水冷后得到的铸锭中心部位取样进行组织观察。金相观察试样不进行蚀刻,宏观低倍观察和偏振光观察试样分别采用苦味酸3 g+酒精50 mL+蒸馏水5 mL+冰乙酸2.5 mL和苦味酸6.5 g+酒精100 mL+蒸馏水10 mL+冰乙酸5 mL进行蚀刻。利用Leica显微镜的配套图像分析软件对组织进行定量分析。

2 结果与分析

2.1 超声孕育处理对AS41镁合金凝固组织的影响

2.1.1 超声功率对晶粒尺寸的影响

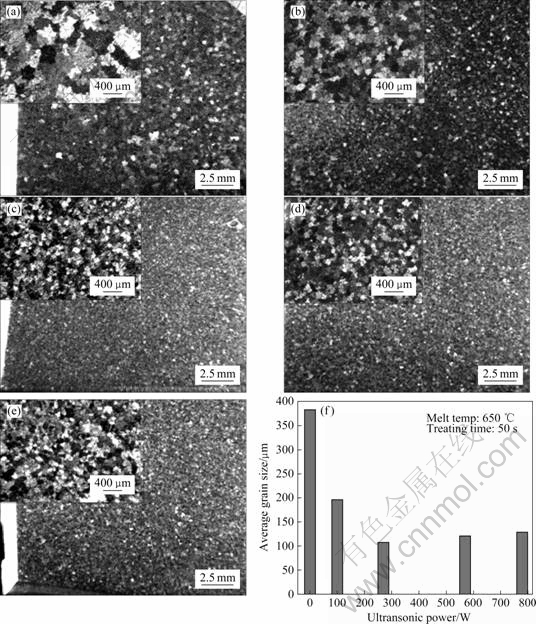

图1所示为未经超声处理和经不同功率超声孕育处理50 s后AS41镁合金凝固组织的宏观低倍照片和显微偏振光照片以及由偏振光照片进行图像分析得到的不同处理条件的平均晶粒尺寸变化。

由图1(a)可见,无超声处理的AS41镁合金凝固组织中的晶粒粗大且尺度不一。根据定量分析,平均晶粒尺寸约为383 μm。由图1(b)~(e)可见,熔体经超声处理后,其凝固组织显著细化且晶粒尺寸的差异明显减小,但细化程度与所施加的超声功率(强度)有关。由图1(f)可见,当超声功率为100 W(超声强度为14 W/cm2)时,平均晶粒尺寸为196 μm,约为无超声处理时的51%;当超声功率为270 W (超声强度38 W/cm2) 时,平均晶粒尺寸为107 μm(为无超声处理时的28%);当功率达到570和780 W (超声强度分别为85和111 W/cm2)时,平均晶粒尺寸分别为121和129 μm(为无超声处理时的31.6%和33.7%)。以上结果表明,超声孕育处理可显著细化AS41镁合金的凝固组织。细化程度与超声功率有关,适当增加超声功率可提高细化效果,但功率过大则细化效果有所减弱。超声功率对AS41镁合金的影响与其对Mg-Ca和AZ80镁合金的影响类似[12-13]。

超声功率对细化效果的影响应与超声非线性空化效应强弱及热效应有关。在较低的超声强度下,超声空化效率较低,细化效果也较差;超声强度增加时,细化程度也提高;但超声强度过大时,超声热效应将部分抵消空化效应对晶粒细化的作用效果。

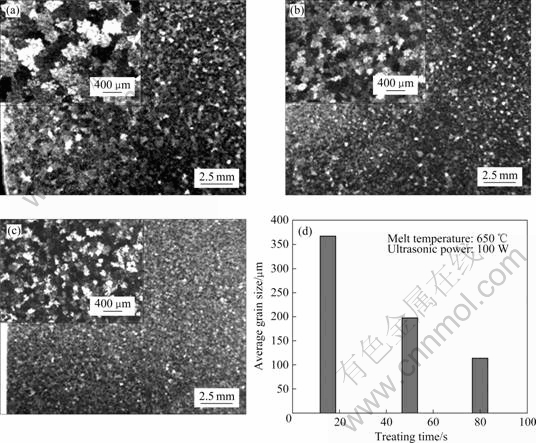

2.1.2 超声孕育处理时间对晶粒尺寸的影响

图2所示为超声功率为100 W时分别孕育处理15、50和80 s后AS41镁合金凝固组织的宏观低倍照片和显微偏振光照片以及对应的平均晶粒尺寸变化。由图2可见,超声孕育时间对AS41镁合金的凝固组织有明显影响,随着处理时间延长,平均晶粒尺寸逐渐减小。处理时间为50和80 s时,平均晶粒尺寸分别达到197和113 μm,是处理时间为15 s时(367 μm)的53.7%和30.8%。这表明延长孕育处理时间可明显提高细化效果。需要指出的是,从超声功率对细化效果的影响可见,延长小功率超声(100 W)的处理时间将有利于熔体中超声非线性效应的积累,达到增强细化效果的目的,但可预见若延长较高功率超声的处理时间,则可能因热效应较大而削弱细化效果。

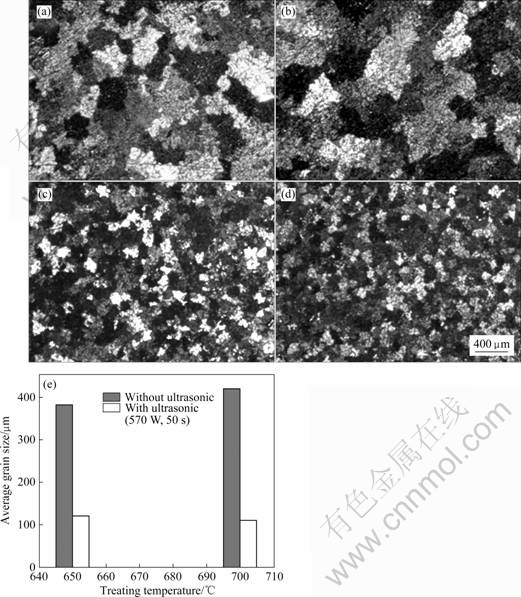

2.1.3 熔体温度对凝固组织的影响

图3所示分别为650和700 ℃的AS41镁合金熔体未施加超声和施加570 W超声处理50 s后凝固组织的显微偏振光照片以及对应的平均晶粒尺寸变化。

图1 650 ℃时超声功率对AS41镁合金凝固组织与平均晶粒尺寸的影响

Fig.1 Effects of ultrasonic power on solidification microstructures and average grain size of AS41 magnesium alloy at 650 ℃: (a) W ithout ultrasonic; (b) 100 W, 50 s; (c) 270 W, 50 s; (d) 570 W, 50 s; (e) 780 W, 50 s; (f) Average grain size

由图3可见,无超声处理时,凝固组织均较粗大,熔体温度为650和700 ℃时,凝固组织平均晶粒尺寸分别为383和420 μm,而经超声处理的凝固组织平均晶粒尺寸分别为121和110 μm。这表明施加超声可显著细化晶粒,更重要的是,无超声处理时高温(700 ℃)熔体因比低温(650 ℃)熔体冷却速率低而晶粒粗大,但经超声处理后,尽管高温熔体也比低温熔体有较低的冷却速率,但其凝固组织反而更细小。因此,对高温AS41镁合金熔体进行超声处理可以获得更好的细化效果。这可能与高温熔体的黏度较低、超声的衰减较少以及空化效率较高有关。

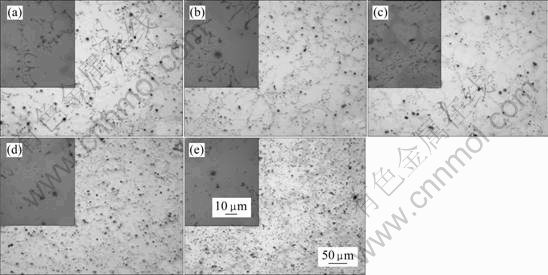

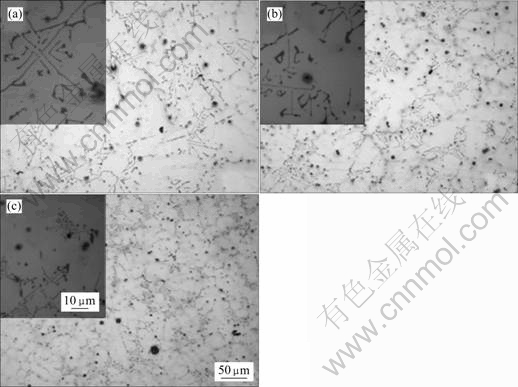

2.2 超声孕育处理对AS41镁合金凝固组织中Mg2Si相形貌的影响

Mg2Si相是AS41镁合金中的主要析出相。图4和5所示分别为超声功率和处理时间对AS41镁合金中Mg2Si相形貌的影响。由图4(a)可见,无超声处理时,Mg2Si相呈现十分粗大的汉字状形态,其骨架线条较宽,此外,还有多边形Mg2Si相析出。由图4(b)~(e)可见,施加超声时,多边形Mg2Si相不再出现,而且随着超声功率增加,汉字状Mg2Si相逐渐细化及不连续化,骨架宽度逐渐减小;在较高的功率(570和780 W)下,多数Mg2Si相转变为弥散的细小球状颗粒。由此可见,超声孕育处理对AS41镁合金中Mg2Si相有显著的细化效果,且其细小弥散化效果随功率增加而增强。以上结果表明,超声功率对AS41镁合金的晶粒细化以及对Mg2Si析出相的影响有不同的规律,因此,在选择超声功率时应综合考虑对两者的影响。由图5可见,在较低超声功率(100 W)下,延长处理时间可以增强Mg2Si相的细化与弥散化效果。这与提高超声功率有相似规律。

图2 650 ℃时处理时间对AS41镁合金凝固组织与平均晶粒尺寸的影响

Fig.2 Effect of treating time on solidification microstructures and average grain size of AS41 magnesium alloy at 650 ℃: (a) 100 W, 15 s; (b) 100 W, 50 s; (c) 100 W, 80 s; (d) Average grain size

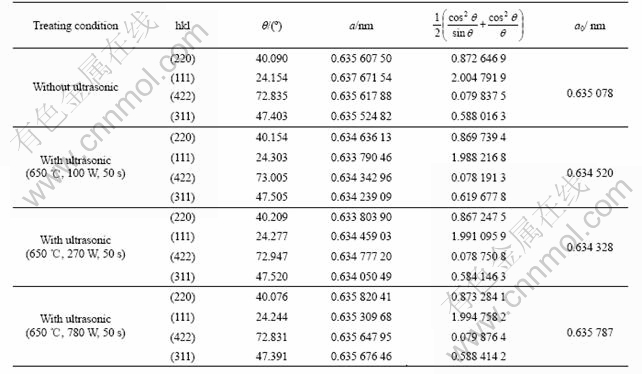

2.3 超声处理条件对AS41镁合金中Mg2Si相晶格常数的影响

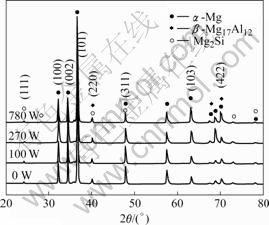

图6所示为熔体未经超声处理和经不同功率超声

处理的AS41镁合金凝固样品的XRD谱。由图6可见,铸态AS41镁合金的相组成为α-Mg基体、β-Mg17A112和Mg2Si析出相,其中β-Mg17A112相以黑色点状随机分布于α-Mg基体内。超声处理功率为100 W时,AS41镁合金中α-Mg的(101)和(103)晶面所对应的衍射峰强度增大,而其(002)和(100)晶面所对应的衍射峰强度减小,说明超声处理使得α-Mg在(101)和(103)晶面形成择优取向,且随超声功率增大,这种趋势更明显。 但超声功率对Mg2Si相在各晶面的衍射强度影响不 明显。

Mg2Si相为体心立方结构,采用直线最小二乘外推法[15]求得经不同超声功率处理后AS41镁合金中Mg2Si相点阵常数的精确值a0如表1所列。由表1可见,超声功率为100 W时,a0由无超声时的0.635 078 nm 减小到0.634 520 nm(减小幅度0.088%);超声功率增大到270 W时,a0减小到0.634 328 nm(减小幅度0.118%);但当超声处理功率进一步增大时,a0反而增大且比无超声时还大。电磁场可以降低Al-5.3Zn

图3 熔体温度对AS41镁合金凝固组织与平均晶粒尺寸的影响

Fig.3 Effects of melt temperature on microstructures and average grain size of AS41 magnesium alloy: (a) 650 ℃, without ultrasonic; (b) 700 ℃, without ultrasonic; (c) 650 ℃, with ultrasonic (570 W, 50 s): (d) 700 ℃, with ultrasonic (570 W, 50 s); (e) Average grain size

图4 650 ℃时超声功率对Mg2Si相形貌的影响

Fig.4 Effect of ultrasonic power on morphology of Mg2Si phase at 650 ℃: (a) Without ultrasonic; (b) 100 W, 50 s; (c) 270 W, 50 s; (d) 570 W, 50 s; (e) 780 W, 50 s

图5 650 ℃时处理时间对Mg2Si相形貌的影响

Fig.5 Effect of treating time on morphology of Mg2Si phase at 650 ℃: (a) 100 W, 20 s; (b) 100 W, 50 s; (c) 100 W, 80 s

表1 不同超声处理条件下AS41镁合金凝固组织中Mg2Si相的点阵参数

Table 1 Lattice constanst of Mg2Si phase in solidification microstructure of AS41 magnesium alloy after different ultrasonic treatments

和Al-1.2Cu的晶格参数,其变化率为0.035%[16]。以上所述表明,超声场对合金晶格常数的影响要远大于电磁场的影响。这可能与超声孕育所致的固溶体的短程有序化或析出相的元素固溶量变化有关。

图6 AS41镁合金凝固样品的XRD谱

Fig.6 XRD patterns of AS41 magnesium alloy solidification samples

3 结论

1) 超声孕育处理可显著细化AS41镁合金的凝固组织,其晶粒尺寸约为无超声处理时的30%~50%,其细化程度与超声功率(强度)、处理时间以及熔体温度密切相关。优化的处理条件如下:超声强度为30~40 W/cm2,处理时间为50~80s,处理温度为650~700 ℃。

2) 超声孕育处理可使AS41镁合金凝固组织中的Mg2Si相显著细化、弥散化,甚至球化,但Mg2Si相细化与AS41镁合金凝固基体组织细化难以同时达到最优效果。

3) 超声处理使α-Mg在(101)和(103)晶面形成择优取向,且随超声功率的增大,趋势更明显,但对Mg2Si相在各晶面的衍射强度影响不大。

4) 超声处理显著改变AS41镁合金中的Mg2Si相的晶格常数,且变化程度远大于施加电磁场的效果。

REFERENCES

[1] KING J F. Development of magnesium diecasting alloys [C]// MORDIKE B L, KAINER K U. Magnesium Alloys and Their Applicatoins. Wolfsburg: Werkstoff-Informationsgesellschaft mbH, 1998: 37-47.

[2] AUNE T K, RUDEN T J. High temperature properties of magnesium die casting alloys[J]. SAE Trans: J Mater Manufacturing, 1992, 105: 1-7.

[3] LUO A, PEKGULERYUZ M O. Cast magnesium alloys for elevated temperature applications[J]. J Mater Sci, 1994, 29: 5259-5271.

[4] SRINIVASAN A, PILLAI U T S, SWAMINATHAN J, DAS S K, PAI B C. Observations of microstructural refinement in Mg-Al-Si alloys containing strontium[J]. J Mater Sci, 2006, 41: 6087-6089.

[5] SRINIVASAN A, PILLAI U T S, PAI B C. Microstructure and mechanical properties of Si and Sb added AZ91 magnesium alloy[J]. Metall Mater Trans A, 2005, 36: 2235-2243.

[6] KIM J J, KIM D H, SHIN K S, KIM N J. Modification of Mg2Si morphology in squeeze cast Mg-Al-Zn-Si alloys by Ca or P addition[J]. Scripta Materialia, 1999, 41: 333-340.

[7] NAM K Y, SONG D H, LEE C W, LEE S W. Modification of Mg2Si morphology in as-cast Mg-Al-Si alloys with strontium and antimony[J]. Materials Science Forum, 2006, 510/511: 238-241.

[8] DARGUSCH M S, BOWLES A L, PETTERSEN K, BAKKE P, DUNLOP G L. The Effect of silicon content on the microstructure and creep behavior in die-cast magnesium AS alloys[J]. Metall Mater Trans A, 2004, 35(6): 1905-1909.

[9] RAGHUNATHAN N, SHEPPARD T. Fabrication and properties of rapidly solidified magnesium and Mg-Si alloys[J]. Mater Sci Technol, 1990, 6: 629-640.

[10] LU L, LAI M O, HOE M L. Formation of nanocrystalline Mg2Si and Mg2Si dispersion strengthened Mg-Al alloy by mechanical alloying[J]. Nanostructured Mater, 1998, 10(4): 551-563.

[11] FROMMEYER G, BEER S, von OLDENBURG K. Microstructure and mechanical properties of mechanically alloyed intermetallic Mg2Si-Al alloys[J]. Z Metallkde, 1994, 85(5): 372-376.

[12] ZHANG Zhi-qiang, LE Qi-chi, CUI Jian-zhong. Microstructures and mechanical properties of AZ80 alloy treated by pulsed ultrasonic vibration[J]. Trans Nonferrous Met Soc China, 2008, 18: s113-s116.

[13] 张志强, 乐启炽, 崔建忠. 高强超声对Mg-Ca合金凝固组织的影响[J]. 稀有金属材料与工程, 2008, 37(3): 436-439.

ZHANG Zhi-qiang, LE Qi-chi, CUI Jian-zhong. Effect of high-intensity ultrasonic on solidification structure of Mg-Ca alloy[J]. Rare Metal Materials and Engineering, 2008, 37(3): 436-439.

[14] 张志强, 乐启炽, 崔建忠. 超声处理对Mg-9Al二元镁合金Mg17Al12相形貌影响[J]. 稀有金属材料与工程, 2008, 37(1): 173-175.

ZHANG Zhi-qiang, LE Qi-chi, CUI Jian-zhong. Influence of ultrasonic treatment on the morphology in Mg17Al12 of Mg-9Al binary magnesium alloy[J]. Rare Metal Materials and Engineering, 2008, 37(1): 173-175.

[15] 周 玉. 材料分析方法[M]. 北京: 机械工业出版社, 2000: 45.

ZHOU Yu. Analytical method of materials[M]. Beijng: China Machine Press, 2000: 45.

[16] 班春燕. 电磁场作用下铝合金凝固理论基础研究[D]. 沈阳: 东北大学, 2001: 89.

BAN Chun-yan. Fundamental study on solidification of Al alloys under electromagnetic fields[D]. Shenyang: Northeastern University, 2001: 89.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2007CB613702);国家自然科学基金资助项目(50974037, 50904018);教育部新世纪优秀人才支持计划资助项目(NCET-08-0098);中央高校基本科研业务专项资金资助项目(N090209002)

收稿日期:2009-09-13;修订日期:2009-12-20

通信作者:乐启炽,副教授,博士;电话:024-83683312;传真:024-83681758;E-mail: qichil@mail.neu.edu.cn