Trans. Nonferrous Met. Soc. China 22(2012) s68-s73

Solid-state recycling of AZ91D magnesium alloy chips

HU Mao-liang1, 2, JI Ze-sheng1, CHEN Xiao-yu1, WANG Qu-dong2, DING Wen-jiang2

1. School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China;

2. National Engineering Research Center for Light Alloy Net Forming, Shanghai Jiao Tong University, Shanghai 200240, China

Received 9 July 2012; accepted 8 August 2012

Abstract: A method for recycling AZ91D magnesium alloy chips by solid-state recycling was studied. The experiments were carried out adopting the cold-press pressure and hot extrusion. The results indicate that recycled specimens of AZ91D magnesium alloy present better mechanical properties and consist of fine grains due to dynamic recrystallization. The mechanisms of dynamic recrystallization depend on plastic deformation process and change with the deformation temperature. At 300-350 °C, the deformation mechanisms are associated with the operation of basal slip and twinning, and the “necklace” structures are formed. At 350-400 °C, the cross slip results in the formation of new grains and grain refinement. At above 400 °C, the dynamic recrystallization mechanisms are controlled by dislocation climb, and recrystallized grains are homogeneous. The tensile strength of recycled specimens increases with the increase of the strain rate. When the strain rate is overhigh, the cracks and fractures in the surface appear and affect the tensile strength of recycled specimens.

Key words: AZ91D magnesium alloy; alloy chips; solid-state recycling; hot extrusion; extruding temperature; strain rate

1 Introduction

Magnesium alloys are currently the light alloys used as structural metals because of their many advantages such as high specific stiffness, high specific strength, high thermal conductivity, high dimensional stability, superior damping capacity, good electromagnetic shielding characteristic and good machinability [1]. In recent years, magnesium alloy products have been widely applied in automobile and aerospace industry [2]. With the increase of demand, a large amount of waste in the form of chips or scraps is produced in the manufacturing process such as die casting and plastic forming process [3,4].

Common recycling treatments are remelting of chips or scraps. However, these methods are costly because magnesium alloys are susceptible to oxidation. An appropriate reclaiming of these chips or scraps has very important meanings for saving resources, cutting down the cost of magnesium alloy production and environment pollution. MAMORU et al proposed that hot extrusion is an effective processing method for efficiently reclaiming magnesium alloy chips or scraps [5]. The advantage of the recycling process is that the treatment is conducted in the solid state, which does not need a special protective environment or extra caution [6,7]. Recycled magnesium alloys show excellent mechanical properties [8].

In the previous researches, machined chips such as AZ31 chips [8], ZK60 chips [6], AZ80 chips [9] and AZ91 chips [5] were fabricated by solid-state recycling. Since hot extrusion can provide high compressive and shear forces in the recycling process, the oxide film in the surface is broken and original chips exhibit bonding by fresh metal surface. Recycled magnesium alloy shows high tensile strength and high elongation to failure at room temperature [8, 10]. In the solid-state recycling process, the occurrence of dynamic recrystallization must be carefully considered since it has a significant effect on the microstructure and mechanical property of the recycled alloy. The occurrence of dynamic recrystallization is tightly related to extruding temperature and strain rate. In this work, the effect of extruding temperature and strain rate on microstructure and mechanical property of recycled AZ91D magnesium alloy are investigated.

2 Experimental

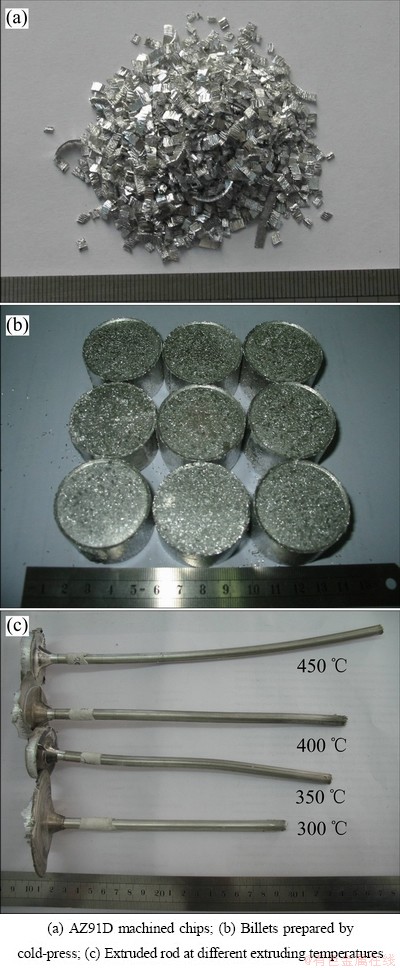

The material used in this work was commercial AZ91D magnesium alloy. Machined chips of this alloy were prepared by machining an ingot in a lathe. Machined chips were kept clean in the turning process. Machined chips of the alloy are shown in Fig.1 (a) and their sizes are 2-8 mm in length, 1.5-2.5 mm in width and 0.5-1 mm in thickness. They were loaded into a 40 mm cylindrical mould in diameter and cold-pressed. The mould surface roughness should reach 0.8 to reduce the friction which affected the experiment results. Pressure equipment was the WE-60 hydraulic-pressed universal testing machine. The pressure and holding time were 300-310 MPa and 3-5 s, respectively. Following the cold-press process, the mould with the formed billet was heated at a setting temperature for 20 min. Finally, hot extrusion was carried out at an extrusion ratio of 25:1 to produce an 8 mm bar in diameter, shown in Fig. 1(c).

Fig. 1 Obtained object pictures prepared by solid-state recycling

AZ91D magnesium alloy is the typical HCP structure and presents low symmetrical character. Its c/a is 1.623, which approaches that (1.633) of perfectly close packing, and its slip systems are few at room- temperature. Below 225 °C, the plastic yield of polycrystalline Mg is only achieved by slipping of basal plane {0001} and twinning of pyramidal plane {

and twinning of pyramidal plane { }

}  . Above 225 °C, the difference between the closest packing planes and closer packing planes becomes small, and the additional pyramidal planes of magnesium alloys start because the amplitude of atomic vibration increases [11]. Therefore, magnesium alloys present an explicit transition in the hot extrusion process, which makes the recycling process easy. So the extruding temperatures in this work are 300, 350, 400 and 450 °C, respectively.

. Above 225 °C, the difference between the closest packing planes and closer packing planes becomes small, and the additional pyramidal planes of magnesium alloys start because the amplitude of atomic vibration increases [11]. Therefore, magnesium alloys present an explicit transition in the hot extrusion process, which makes the recycling process easy. So the extruding temperatures in this work are 300, 350, 400 and 450 °C, respectively.

Standard tensile specimens oriented plane perpendicular to the extrusion direction were prepared to test the tensile strength at room temperature. The extruded samples were machined into tensile specimens of 5 mm in gauge diameter and 25 mm in gauge length. Tensile tests were performed at room temperature on a WDW-200 computer-controlled electron universal tester. Microstructures of the recycled specimens were observed by OLYMPUS-GX71-6230A optical microscope (OM). The specimens were etched in a 4% (volume fraction) aqueous nitric acid solution. Fractures were characterized on a FEI-SIRION scanning electron microscope (SEM). The grain size was determined using a linear intercept method from a large number of non-overlapping measurements.

3 Results and discussion

3.1 Extruding temperature

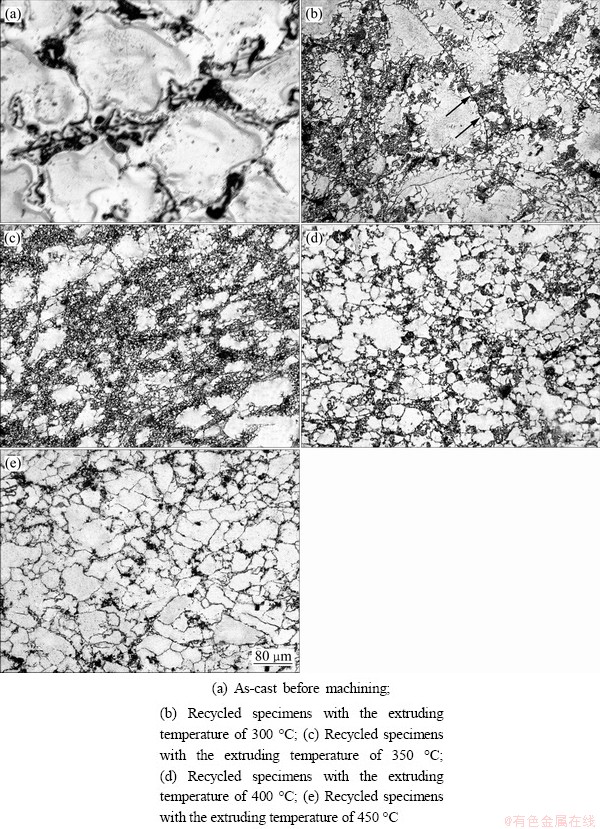

Figure 2 shows the microstructures of as-cast specimen before machining and four kinds of recycled specimens at different extruding temperatures. The commercial AZ91D magnesium alloy microstructure consists of α-Mg solid solution and β-Mg17Al12 phase, shown in Fig. 2(a). The β-Mg17Al12 phase is distributed discontinuously along the grain boundaries [12]. The mean grain size is about 200 μm.

At the extruding temperature of 300 °C, as shown in Fig. 2(b), the specimen exhibits partial dynamic recrystallization. Dynamic recrystallization takes place at original grain boundaries in the hot extruding process. New grains nucleate and grow at the recrystallization boundaries, and then the “thickening bands” of recrystallization are formed [13]. Recrystallization grain size is smaller than that of original grains when the deformation degree is lower. It is easy to form the microstructures consisting of the coarse deformed grains and thin dynamic recrystallized grains. The distribution of the grains is nonuniform. Therefore, the “necklace” structures are formed. In addition, some long crooked black lines can be seen in the metallurgical microstructures, as shown with the black arrow. These black lines are the bonding interface of the original chips. This indicates that the chips are not completely broken into pieces by compressive and shear forces with the extruding temperature of 300 °C. Increasing the extruding temperature to 350 °C, coarse grains and thin dynamically recrystallized grains coexist, shown in Fig. 2(c). The volume fraction of dynamically recrystallized grains progressively increases. In particular, the long crooked black lines disappear. By continuing to increase the extruding temperature to 400 °C and 450 °C, the recrystallized grains are homogeneous and forms high angle boundaries. In particular, an equiaxed micro- structure with an average grain size of 45 μm is presented, shown in Fig. 2(e).

The mechanisms of dynamic recrystallization depend on plastic deformation process and change with the deformation temperature [14]. At low-temperature in the range of 300-350 °C, shown in Figs. 2(a) and (b), the deformation mechanisms of magnesium alloys are associated with the operation of basal slip and twinning. The twinning and progressive lattice rotation in areas of high dislocation density near twin boundaries results in the formation of fine grains with non-equilibrium grain boundaries [14]. At 350-400 °C, the critical shear stress of prismatic slid plane decreases rapidly with the increase of the extruding temperature, which makes the cross-slip of the dislocations start easy [15]. Cross-slip of the dislocations changes the orientation from spiral to angle. The angle dislocations are located in the non-basal and easy to climb [16]. Cross-slip is predominantly activated near original grain boundaries, where the stresses are highly concentrated and the dislocation rearrangements by cross-slip and climb generate low-angle boundary Fig. 2 Microstructures of AZ91D magnesium alloy specimens: (a) As-cast before machining; (b) Recycled specimens with the extruding temperature of 300 °C; (c) Recycled specimens with the extruding temperature of 350 °C; (d) Recycled specimens with the extruding temperature of 400 °C; (e) Recycled specimens with the extruding temperature of 450 °C network. Continuous absorption of the dislocations in the low-angle boundaries results in the formation of new grains [14, 17]. Generally, the cross-slip of the dislocations controls the plastic flow and the nucleation of dynamic recrystallization. At above 400 °C, the activation energy of plastic deformation approaches the volume diffusion energy of magnesium alloys, which leads to producing mass dislocation climb. Mass dislocation climb leads to producing low-angle grain boundaries. The moving dislocations are wound by sub-boundaries and gradually change into big-angle grain boundaries [16-17]. The dynamic recrystallization mechanisms are controlled by dislocation climb.

Fig. 2 Microstructures of AZ91D magnesium alloy specimens

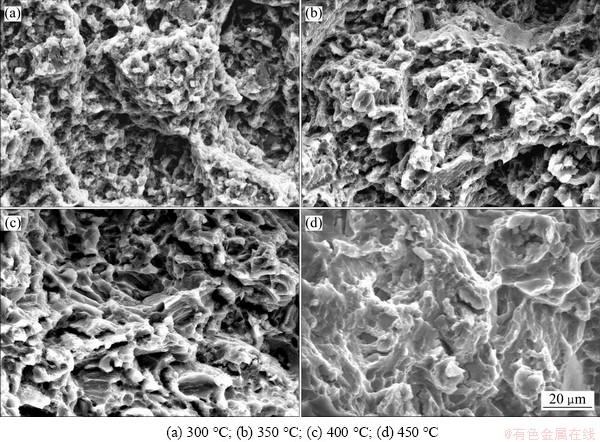

Figure 3 shows the fractographs of four kinds of recycled specimens at different extruding temperatures. With the extruding temperature of 300 °C, as shown in Fig. 3(a), some long crooked-cracks can be seen in the fracture surface, shown by the white arrow. These cracks are the bonding interface of the original chips, indicating that adopting the extruding temperature of 300 °C does not form the fine consolidation of the chips. With the extruding temperature of 350 °C and 400 °C, as shown in Figs. 3(b) and (c), the failure surfaces are composed of a lot of cleavage planes and small dimples. In particular, with the extruding temperature of 450 °C shown in Fig. 3(d), the cleavage planes and cleavage steps increase obviously. The fractures exhibit the characteristics of quasi-cleavage.

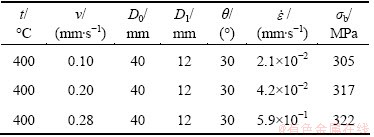

3.2 Strain rate

The recrystallization grain size is related to not only temperature but also strain rate. When the extruding temperature increases, the increasing of grain boundary diffusion and migration makes the grains grow easily, which leads to grain coarsening. When the strain rate increases, the generated dislocations in the deformation process can’t eliminate completely. The dislocations increase and the recrystallization nucleation increase, which improve the mechanical properties. The extrusion strain rate  is determined by using the following equation [5]:

is determined by using the following equation [5]:

(1)

(1)

where v is the ram velocity, D0 is the container diameter, D1 is the extrusion diameter, Re is the extrusion ratio and θ is the semi-angle of conical die. The calculated extrusion strain rate is listed in Table 1. The tensile strength of recycled specimens increases with increase of the strain rate.

Table 1 Extrusion conditions and corresponding tensile strength

Fig. 3 Fractographs of recycled AZ91D magnesium alloy with different extruding temperatures

The relation between the Zener-Hollomon (i.e.,  ) and the grain size may be given in the following form [18]:

) and the grain size may be given in the following form [18]:

(2)

(2)

where Q is the activation energy; R is the gas constant; T is the deformation temperature (Absolute temperature);  is the strain rate; d is the grain size and p is the grain size exponent. From the relation, the grain size can be given:

is the strain rate; d is the grain size and p is the grain size exponent. From the relation, the grain size can be given:

(3)

(3)

It is found that the grain size decreases with the increase of Zener-Hollomon (Z) parameter. The relationship between the deformation temperature and Z parameter is the exponential form, but the relationship between the strain rate and Z parameter is the linear equation. Therefore, the deformation temperature is the principal influential factor for the recycled magnesium alloy.

The above theoretical analysis shows that the higher the strain rate, the better the tensile strength. But the temperature in the extruding process will rise because of the calorific effect produced by deformation when the strain rate is overhigh and flow stress decrease obviously. When the strain rate continues to increase, the flow stress obviously increases because the work-hardening velocity becomes faster than the softening velocity generated by recrystallization. The surface of recycled AZ91D magnesium alloy extruded at strain rate of 1.2 mm/s at 400 °C is shown in Fig. 4. The cracks and fractures in the surface appear. Therefore, the extrusion velocity should be properly chosen.

Fig. 4 Cracks and fractures of recycled AZ91D magnesium alloy extruded in 1.2 mm/s at 400 °C

4 Conclusions

1) Recycled specimens of AZ91D magnesium alloy show better mechanical properties. The interfaces of individual chips of recycled materials are not identified when adopting appropriate parameters. Solid-state recycling is an efficient method for magnesium alloy chips recycling.

2) The mechanisms of dynamic recrystallization depend on plastic deformation process and change with the deformation temperature. At 300-350 °C, the deformation mechanisms are associated with the operation of basal slip and twinning, and the “necklace” structures are formed. At 350-400 °C, the cross slip results in the formation of new grains and grain refinement. At above 400 °C, the dynamic recrystallization mechanisms are controlled by dislocation climb, and recrystallized grains are homogeneous.

3) The tensile strength of recycled specimens increases with the increase of the strain rate. When the strain rate is overhigh, the cracks and fractures in the surface appears and affects the tensile strength of recycled specimens.

References

[1] HSIANG S H, KUO J L. An investigation on the hot extrusion process of magnesium alloy sheet [J]. Journal of Materials Processing Technology, 2003, 140(2): 6-12.

[2] ZHAO H L, GUAN S K, ZHENG F Y, LI Q K, WANG L G. Microstructure and properties of AZ31 magnesium alloy with rapid solidification [J]. Transactions of Nonferrous Metals Society of China, 2005, 15(1): 144-148.

[3] CHEN Zhen-hua. Deformation magnesium alloy [M]. Beijing: Chemical Industry Press, 2005: 372-375. (in Chinese)

[4] HU Mao-liang, JI Ze-sheng, CHEN Xiao-yu, ZHANG Zhen-kao. Effect of chip size on mechanical property and microstructure of AZ91D magnesium alloy prepared by solid state recycling [J]. Materials Characterization, 2008, 59(4): 385-389.

[5] MAMORU M, KOHEI K, KENJI H. New recycling process by extrusion for machined chips of AZ91 magnesium and mechanical properties of extruded bars [J]. Materials Transactions, 1995, 36(10): 1249-1254.

[6] NAKANISHI M, MABUCHI M, SAITO N, NAKAMURA M. Tensile properties of the ZK60 magnesium alloy produced by hot extrusion of machined chip [J]. Journal of Materials Science Letters, 1998, 17: 2003-2005.

[7] LEE J S, CHINO Y, HOSOKAWA H, SHIMOJIMA K, YAMADA Y, MABUCHI M. Deformation characteristics at elevated temperature in recycled 5083 aluminum alloy by solid state recycling [J]. Materials Transactions, 2005, 46(12): 2637-2640.

[8] YASUMASA C, TETSUJI H, MAMORU M. Mechanical and corrosion properties of AZ31 magnesium alloy repeatedly recycled by hot extrusion [J]. Materials Transactions, 2006, 47(4): 1040-1046.

[9] LIU Ying, LI Yuan-yuan, ZHANG Da-tong, NAGI T W L, CHEN Wei-ping. Microstructure and properties of AZ80 magnesium alloy prepared by hot extrusion from recycled machined chips [J]. Transactions of Nonferrous Metals Society of China, 2002, 12(5): 882-885.

[10] YASUMASA C, RYUJI K, KOJI S, HIROYUKI H, YASUO Y, CUI E W, HAJIME I, MAMORU M. Superplasticity and cavitation of recycled AZ31 magnesium alloy fabricated by solid recycling process [J]. Materials Transactions, 2002, 43(10): 2437-2442.

[11] CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium alloy [M]. Beijing: Chemical Industry Press, 2004: 202-205. (in Chinese)

[12] JIANG Ju-fu, LUO Shou-jing. Reheating microstructure of refined AZ91D magnesium alloy in semi-solid state [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(6): 1074-1081.

[13] CAHN R W. Processing of Metal and Alloys (Materials Science and Technology, Vol.15) [M]. Beijing: Science Press, 1999: 408-414. (in Chinese)

[14] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60 [J]. Acta Materialia, 2001, 49(7): 1199-1207.

[15] COURET A, CAILLARD D, PUSCHL A, SCHOECK G. Prismatic glide in divalent h. c. p. metals [J]. Philosophical Magazine A, 1991, 63(5): 1045-1057.

[16] GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Hot compression deformation behavior of AZ31 magnesium alloy at elevated temperature [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 900-906. (in Chinese)

[17] GALIYEV A, SITDIKOV O, KAIBYSHEV R. Deformation behavior and controlling mechanisms for plastic flow of magnesium and magnesium alloy [J]. Materials Transactions, 2003, 44(4): 426-435.

[18] ZENER C, HOLLOMON J H. Effect of strain rate upon the plastic flow of steel [J]. Journal of Applied Physics, 1994, 15(1): 22-27.

AZ91D镁合金屑的固相再生

胡茂良1, 2, 吉泽升1, 陈晓瑜1, 王渠东2, 丁文江2

1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040;

2. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200240

摘 要:利用固相再生技术回收利用AZ91D镁合金屑,具体工艺为先冷压再热挤。结果表明:制备的AZ91D镁合金具有较好的力学性能且晶粒明显细化。在热挤出过程中发生了动态再结晶,且动态再结晶组织受到热挤温度和应变速率的影响,在300-350 °C下基面滑移和孪晶协调变形导致动态再结晶晶粒产生,形成“项链”组织;在350-400 °C下位错的交滑移控制动态再结晶形核;高于400 °C时位错攀移控制了整个动态再结晶过程,形成均匀的再结晶组织。随着应变速率增加AZ91D镁合金力学性能增大,改善了材料的力学性能,但应变速率过大,制备试样表面出现裂纹,影响材料的力学性能。

关键词:AZ91D镁合金;合金屑;固相再生;热挤压;挤压温度;应变率

(Edited by CHEN Can-hua)

Foundation item: Projects (50674038, 50974048) supported by the National Natural Science Foundation of China; Project (200802140004) supported by Doctoral Fund of Ministry of Education of China

Corresponding author: HU Mao-liang; Tel: +86-451-51644189; E-mail: humaoliang309@yahoo.com.cn