DOI: 10.11817/j.issn.1672-7207.2016.12.031

节理特性对岩体力学性能的影响

张国凯,李海波,夏祥,李娜娜,柴少波

(中国科学院武汉岩土力学研究所岩土力学与工程国家重点实验室,湖北 武汉,430071)

摘要:采用颗粒流模拟研究单轴压缩下节理特性对试件宏观力学参数、能量及波传播规律的影响,揭示裂纹扩展演化机理及破坏模式的变化规律,定义细观节理刚度比和强度比反映节理力学特性。研究结果表明:峰值强度、弹性模量、起裂应力随节理厚度增加、刚度比的下降而不断减小,泊松比随节理厚度增加而大幅度增加,节理强度比直接影响峰值强度;与张开节理相比,节理充填物降低尖端应力集中,导致试件损伤破坏程度及破坏模式的改变,同时引起宏观力学参数增大,并随节理刚度减小,逐渐趋近前者。通过在模型内设置激发源和接收器,对激发源施加速度脉冲模拟剪切波和压缩波的传播过程,节理对波幅影响远大于波速,充填节理透射系数明显大于张开节理透射系数,前者随厚度增加衰减更快,与纵波相比,横波随节理弱化衰减较快。

关键词:颗粒流;单轴压缩;节理特性;岩体力学参数;波传播

中图分类号:TU451 文献标志码:A 文章编号:1672-7207(2016)12-4198-08

Influence of joint features on mechanical properties of rock mass

ZHANG Guokai, LI Haibo, XIA Xiang, LI Nana, CHAI Shaobo

(State Key Laboratory of Geomechanics and Geotechnical Engineering, Institute of Rock and Soil Mechanics,

Chinese Academy of Sciences, Wuhan 430071, China)

Abstract: The uniaxial compression test was performed by particle flow code to study the influence of joint features on the macro mechanical properties, energy and wave propagation. Simultaneously, the mechanisms of crack evolution and failure modes were illustrated. Mesoscopic stiffness ratio and strength ratio were defined to reflect mechanical features of joint. The results show that with the increase of joint thickness and the decrease of joint stiffness ratio, ultimate strength, elastic modulus and crack-initiation stress all decrease. On the contrary, Poisson ratio increases a lot with the increase of joint thickness. However, joint strength ratio only has an effect on ultimate strength. Compared with open joint, joint fillings reduce the stress concentrations at joint tips and increase the macro mechanical parameters of specimens which gradually approach the former with the decrease of joint stiffness. These all lead to the changes of damage degree and failure modes. Numerical simulation of transverse and longitudinal wave propagation was implemented by setting a transmitter and receiver in the model and applying a velocity pulse to the transmitter. The effect of joint on the amplitude attenuation is much larger than wave velocity. The transmission coefficient of filling joint is much bigger than that of open joint. Compared with longitudinal wave, transverse wave produces more amplitude attenuation.

Key words: particle flow code; uniaxial compression; joint features; mechanical properties of rock mass; wave propagation

由于漫长的地质作用,工程岩体大多含有不同类型的结构面,结构面密度、张开度、填充物特性、几何产状、连通度等都直接影响岩体的强度和稳定,参数自由组合的多样性,使得岩体的各向异性、复杂性更为突出,节理岩体的变形和力学特性已成为岩石力学的研究热点[1-2]。YOSHINAKA等[1-2]研究了节理粗糙度、摩擦角、几何产状对岩体强度和变形的影响规律,并在工程中得到了验证和推广。任伟中等[3]对闭合断续节理岩体压缩破坏进行了实验研究,裂隙扩展前,节理尖端拉压应力均出现集中,拉应力逐渐消散,压应力集中程度则不断加剧。邵鹏等[4]研究了室内爆破动荷载下充填与非充填试件的疲劳损伤累积,得出充填介质减缓了损伤的累积进程。陈新等[5]对不同产状和连通率张开裂隙石膏进行单轴压缩试验,得出随着连通率增大,试件延性增强,力学参数下降。张波等[6]通过相似材料研究含预制裂隙岩石的破坏过程,采用有限元对试件损伤断裂过程进行了模拟验证。金爱兵等[7]采用颗粒流程序模拟了岩桥长度、节理长度及倾角对试件宏观力学特性的影响,得出试件力学特性受节理长度的影响比受岩桥长度的影响大,初始破裂与倾角密切相关。LEE等[8]对不同倾角张开裂隙花岗岩进行单轴压缩试验,研究了单一和非平行双节理试件裂隙起裂、发展及贯通过程,PFC模拟结果与室内试验基本吻合。黄达等[9]采用颗粒流研究加载速率、倾角对张开非贯通节理试件破坏的影响,随着倾角增大,裂纹尖端切向应力呈增大趋势,法向应力则减小。上述研究多针对张开非充填节理岩体,工程岩体结构面多含充填物,充填物对岩体力学特性影响明显[6]。赵永红[10]采用电镜扫描研究了水泥砂浆充填和张开节理试件的裂纹萌生、扩展及贯通过程,得出充填节理试件起裂应力较大,起裂点向割缝移动。刘红岩等[11-12]研究了单一石膏充填节理岩体的应力-应变过程和变形特性。BAHAADDINI等[13]采用smooth joint模型系统研究了节理几何产状对试件破坏模式的影响,得到了5种不同破坏模式。蒋明镜等[14]根据实验提出无胶结厚度含抗转动能力的岩石微观胶结模型,植入离散元模拟了不同倾角双裂纹岩石的裂纹演化宏微观机理。岩石材料内部预制节理及添加充填物均存在较大困难[6],充填节理岩体的实验及相关研究相对较少,少数研究也基本忽略节理厚度及充填物力学特性的影响。为此,本文作者针对充填节理特性的多变性展开研究,采用PFC数值软件[7-9],从岩石材料的细观结构和力学特性出发,通过设置不同节理厚度、刚度及黏结强度研究节理特性对试件破坏机制的影响规律。同时研究节理对波速和波幅衰减的影响,得出波幅和波速随节理的衰减变化规律。

1 数值试验模型

对于岩石类材料一般选用黏结模型,本次数值试验选用接触黏结模型[9]。试件模型长×宽为100 mm×50 mm,细观参数选取以文献[9]中室内试验结果为基础,并考虑到计算机计算效率和结果稳定性,最终细观参数选取如下:颗粒最小粒径为0.2 mm,粒径比为1.66,密度为2.63 g/cm3,颗粒接触模量Ec为20 GPa,接触刚度比为1.6,颗粒黏结强度服从正态分布,法向和切向黏结强度均值为55 MPa,标准差为15 MPa,颗粒摩擦因数为0.5。

试件模型中节理倾角设置为45°,长度为20 mm,节理几何中心与试件中心重合,在二维情况下,颗粒刚度与接触弹性模量关系[15]为:

kn=2tEc,t=1 (1)

ks=kn/(kn/ks) (2)

式中:kn和ks分别为颗粒法向和切向刚度。

数值模型中张开节理预制采用删除节理范围内颗粒[7-9];充填节理则采用编制fish函数设置处于节理面范围内颗粒或接触的刚度、黏结强度为对应工况下的数值来实现。定义节理刚度比为充填节理颗粒刚度与试件颗粒刚度的比值,节理强度比为节理颗粒黏结强度与试件颗粒黏结强度之比,试验选取节理刚度比分别为0.500,0.100,0.050,0.010和0.001,节理厚度为0.3,0.8,1.3和2.0 mm,节理强度比为0.50,0.20,0.10和0.05。为对比分析,同时对完整试件和张开节理试件进行压缩试验。

2 试验结果及分析

2.1 应力-应变曲线

以上述数值模型为基础,研究不同节理岩石单轴压缩试验的全过程应力-应变曲线如图1所示。由图1可见:随着节理刚度比下降,峰值强度不断减小,充填节理峰值强度均比张开节理试件的大;随着节理厚度增加,峰值强度不断减小,但下降幅度逐渐减小;随节理强度比下降,峰值强度不断下降,强度比小于0.10后逐渐趋于稳定。

2.2 试件宏观力学参数

为了充填节理试件力学参数与完整及张开节理试件进行对比分析,将完整试件、张开节理试件节理刚度比分别设为1和1×10-4。

图1 不同节理特性岩体典型的应力-应变曲线

Fig. 1 Typical stress-strain curves for different joint features of rock mass

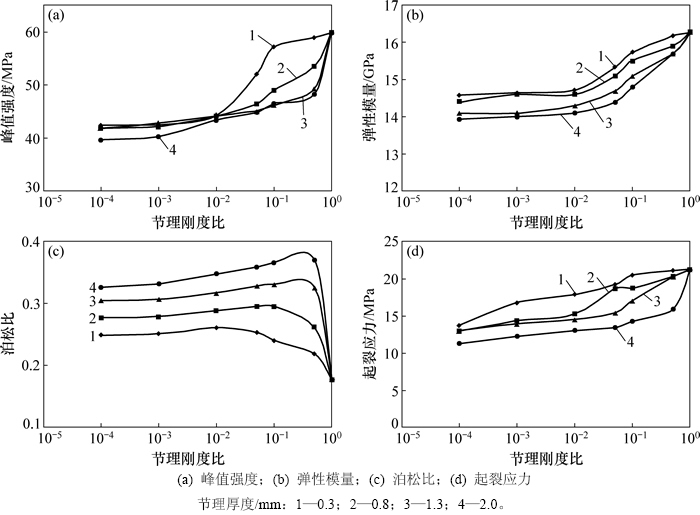

峰值强度变化如图2(a)所示。由图2(a)可见:随着充填节理刚度比下降,峰值强度不断减小,当节理刚度比小于0.010后,逐渐趋于稳定;节理刚度越小其抵抗压剪破坏的作用越弱,尖端附近应力集中程度逐渐增大,强度逐渐下降;充填节理厚度为0.3 mm,当刚度比大于0.100时峰值强度变化较小;随着节理厚度增大,峰值强度对节理刚度比敏感性增强,下降速率突变点对应的刚度比逐渐增大。峰值强度随节理厚度增大而不断减小,但减小幅度逐渐下降。

弹性模量变化规律见图2(b)。由图2(b)可见:弹性模量随节理刚度比减小及节理厚度增大而不断下降,节理刚度比越小、厚度越大则节理可压缩性增加,试件整体刚度下降,相同应力下轴向应变增大,即导致弹性模量下降;当节理刚度比较大时,弹性模量的下降值要远小于峰值强度的下降值,与完整岩石相比,节理厚度为2.0 mm、刚度比为0.500的试件,峰值强度和弹性模量分别下降了19%和3%,充填节理对峰值强度的影响比弹性模量的大;当节理刚度比小于0.010时,充填物对弹性模量的贡献基本为零,与张开节理试件基本一致。

泊松比的变化规律见图2(c)。由图2(c)可见:含节理试件泊松比相比完整试件均大幅度提升,且随节理厚度增加,泊松比不断增大,当节理厚度为2.0 mm时,泊松比相比完整试件增加了1倍左右;随着节理刚度比减小,泊松比先升后降,之后逐渐趋于稳定。软弱节理由于黏结强度降低,局部颗粒间易发生劈裂破坏,加剧了试件的侧向变形,导致试件宏观表现为剪胀破坏。当节理刚度比较小时,节理的可压缩性较高,剪胀作用较小,相同轴向应变下引起的侧向变形相对较小,即泊松比较小;随着节理刚度比增大,节理的剪胀性增强,泊松比增大,完整试件由于不存在软弱结构面,泊松比最小。

起裂应力变化见图2(d)。由图2(d)可见:充填节理起裂应力均大于张开节理起裂应力,随节理刚度比减小、厚度增加,起裂应力不断下降。由于裂纹首先起裂于节理尖端[9],因此,起裂应力主要取决于节理尖端应力集中系数。不同节理厚度下变化存在差异,当节理刚度比为0.100,节理厚度分别为0.3 mm与2.0 mm的试样,起裂应力分别下降3%和33%。

表1所示为节理厚度为0.8 mm在不同节理强度比时的试件力学参数。由表1可知:随节理黏结强度比减小,峰值强度不断下降,起裂应力呈小幅下降,相反泊松比不断增大,弹性模量基本保持不变。

表1 不同节理黏结强度试样宏观力学参数

Table 1 Macro mechanical parameters with different joint bond strengths

图2 试样宏观力学参数随节理厚度和刚度比变化

Fig. 2 Variation curves of macro-mechanical properties of specimen with joint thickness and stiffness ratio

2.3 应力集中及分布

在模型内节理尖端设置测量圆对尖端应力进行监测,定义节理尖端应力集中系数:

(3)

(3)

式中:σ1为试件平均应力;σtip为节理尖端应力。

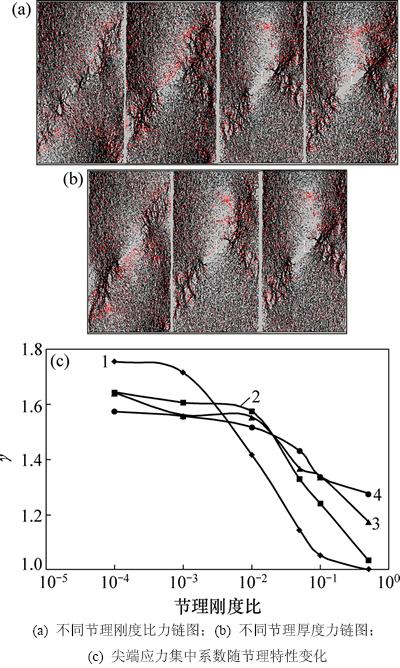

典型的应力分布见图3,图3(a)所示试样从左到右分别是节理厚度为1.3 mm、刚度比分别为0.500,0.010,0.001及张开节理试件,图3(b)所示试样从左至右分别是节理厚度为0.3,0.8和1.3 mm的试件力链图,红色代表张拉作用力,黑色表示压剪作用力,线条粗细程度表示接触力的大小。从图3可以看出:

1) 当节理刚度比较大时,沿节理方向出现轻微的压剪应力集中区,节理承担了较大的压剪作用力,应力集中相对较弱,如节理刚度比为0.500且节理厚度小于等于0.8 mm时,γ均小于1.1;当刚度比大于0.010时,随节理厚度增加,节理承担压剪作用下降,造成γ不断增大。

2) 随节理刚度比减小,γ不断增大,当刚度比小于0.010时γ变化逐渐趋缓,且随节理厚度增加γ呈下降趋势,但变化逐渐减小。由于节理刚度比的下降,节理可压缩性增加,节理处应力分布逐渐减小,节理上部形成“椭圆状”低压剪应力区,该区域出现明显的张拉应力,逐渐由宏观裂隙附近转移到节理尖端附近,并向上发展,向下出现压剪应力集中区,对应图5中反翼裂纹及次生张拉裂纹的扩展路径。

3) 随节理厚度增加,上侧低应力“椭圆区”逐渐增大,当厚度大于0.8 mm时,该区域已接近试件上端,‘椭圆区’张拉应力逐渐向上发展,下部压剪作用力逐渐增强,导致图5中反翼裂纹扩展更彻底。

综上可知:试件内压剪应力分布占主导,随刚度比减小,γ不断增大,节理充填物降低了尖端应力集中,改变了应力分布,导致试件破坏模式的不同。

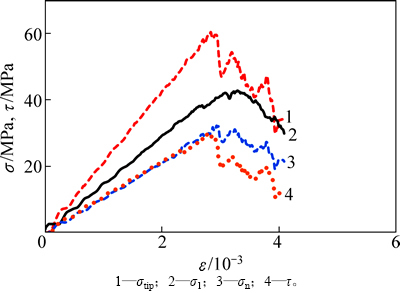

根据应力坐标转换得出节理尖端切向应力和法向应力[9]。图4所示为节理厚度1.3 mm试样各应力变化,峰值强度处γ大于1.5,节理尖端法向、切向应力峰值均早于轴向应力峰值出现,节理尖端损伤破裂发生在整体强度失稳破坏之前。尖端应力出现多个峰值,由于尖端应力集中导致尖端附近局部颗粒链接首先断裂并产生相互滑移,但此时尖端两侧颗粒抗压能力继续增加,表现为尖端应力迅速下降,轴向应力继续增加,之后尖端颗粒相互咬合及库仑摩擦作用使得其抗剪能力继续增加,证明了尖端破坏是渐进式的,尖端应力连续出现循环波动直至试件破坏。

图3 应力集中系数及应力分布随节理特性变化

Fig. 3 Stress concentration factor and stress distribution of rock specimen for different joint features

2.4 微裂纹发展分布

不同节理特性试件裂纹分布见图5,其中图5(b)和5(c)所示试样从左至右节理刚度比逐渐降低,图5(d)所示为节理强度比为0.50和0.05时的试样裂纹分布。图中红色代表剪切裂纹,黑色代表张拉裂纹,对微裂纹进行统计得:各个工况下剪切裂纹与张拉裂纹数量比为1.7~4.9,剪切裂纹占明显优势。

1) 节理改变了试件的破坏轨迹,完整试样整体损伤破坏程度更大,裂纹数量多且端部效应显著,节理试样为翼裂纹主导的拉剪破坏,微裂纹以节理尖端为突破口,发展为翼裂纹,并逐渐向试件外侧扩展[9],节理厚度较小时起裂角约20°。随节理厚度增加,起裂角逐渐增大,端部效应逐渐消失。

图4 典型节理尖端应力变化曲线

Fig. 4 Typical variation curves of stress at joint tip

2) 节理厚度为0.3 mm且刚度比较大时,节理下尖端产生贯穿试件底部的反翼裂纹,随节理刚度比减小,反翼裂纹逐渐消失,但上端逐渐出现起裂角大于100°的张剪复合型反翼裂纹,向外部贯穿试件,节理两侧微裂纹逐渐减少,与低应力“椭圆区”相关。当节理厚度大于0.3 mm且刚度比较小时,节理上尖端产生张拉次生裂纹,向上发展逐渐与主应力方向平行,这是“椭圆区”内张拉应力造成的。

3) 相比充填节理,张开节理试件反翼裂纹贯通更彻底,微裂纹分布更集中。随节理黏结强度比减小,试件损伤破坏程度减轻,端部效应减弱。

综上可知:试件以剪切破坏为主,随节理刚度比减小,张拉裂纹所占比例逐渐增大,裂纹扩展与应力分布直接相关,试件由翼裂纹贯通破坏向翼裂纹主导与反翼裂纹共同作用变化,随节理弱化,整体损伤破坏程度及端部效应逐渐减弱,局部破坏加剧。

2.5 能量变化分析

能量变化是岩石各物理力学参数变化的诱因和本质特征[16],各能量变化规律见表2。

图5 试件微裂纹发展分布

Fig. 5 Distribution of micro cracks in specimen

表2 能量随节理特性的变化规律

Table 2 Variation of energy for different joint features

边界能即试件破坏所需做的功,由表2可知:边界能随节理刚度比减小而下降,逐渐趋近张开节理试件,相比完整试件下降43%;随节理厚度增加、黏结强度减小,边界能不断减小,后者对边界能影响相对较小。边界能越小试件越容易失稳破坏,因此,随节理特性弱化,试件越容易失稳破坏。

应变能即试件在加载过程中所积累的可释放的能量,与应力应变乘积呈正比。应变能极值一般发生在峰值强度附近,是驱动峰后裂隙扩展的源动力,反映了试件峰后损伤破坏的剧烈程度及为岩爆的评估提供依据[16]。应变能极值随节理特性弱化不断下降,且下降幅度较大;随节理厚度增加其敏感性逐渐减弱,下降幅度放缓,节理厚度大于1.3 mm时敏感性基本保持不变;相比完整试样,含节理试样应变能均较小,尤其是张开节理试样,决定了节理试样峰后损伤破坏程度要比完整试样的小。

摩擦能是黏结颗粒在外力作用下相互滑移的结果,摩擦能相对边界能和应变能较小,总体随节理弱化不断下降。颗粒动能波动性较大,变化规律性较差,相比其他能量,颗粒动能极小,可认为对试件的破坏过程影响相对较小。

2.6 波传播规律研究

颗粒流通过颗粒相互作用模拟波传播反映岩石材料的本质特性,是基于离散介质力学从细观尺度上认识离散介质的波动过程[17-18]。TRENT等[17-18]通过离散元模拟了胶结材料波的传播过程。SADD等[19]采用椭圆形颗粒研究了波的传播和衰减规律。

在模型内设置激发源和接收器如图6(a)所示,通过对激发源内颗粒施加剪切振动或压缩正弦速度脉冲,利用颗粒扰动来模拟P波、S波传播。不同时刻剪切波速度分布见图6(b)~(d),当t=1.25 μs,激发源速度达到首个峰值;当t=19.1 μs,波前到达节理下端;t=37.5 μs时剪切波首次到达接收器,由于节理阻碍波能量的传播,节理上部速度场分布明显较小,接收器速度幅值下降。在剪切波的传播过程中,试件中部速度场基本沿x轴传播,但靠近试件两侧速度场基本沿y轴方向,使速度场呈旋涡状分布。

图6 试样模型及波的传播过程

Fig. 6 Model of specimen and wave propagation

波在节理处发生反射和透射,定义透射系数为

T=Ajoint/A (4)

式中:Ajoint为节理透射波波幅;A为无节理波幅。

波传播参数变化规律统计见表3。随着节理特性变化,纵横波速变化较小。波在节理处发生反射,导致透射波幅下降。相比纵波,横波透射系数受节理变化较敏感,变化幅度较大,如节理刚度比为0.500试样,纵横波透射系数分别为0.61和0.44。与张开节理相比,充填节理透射系数明显较大,但随节理厚度增加,充填物对节理透射系数贡献逐渐减小,与张开节理相比,当节理厚度为0.3 mm时,充填节理P波、S波透射系数分别增加0.34和0.29;当节理厚度为2.0 mm时,充填节理P波、S波透射系数分别增加0.12和0.02;充填节理透射系数受节理厚度影响较大,随厚度增加变化幅度较大,节理厚度从0.3 mm增加到2.0 mm,充填节理P波、S波透射系数分别减小0.27和0.34,张开节理P波、S波透射系数分别减小0.05和0.07。

图7所示为完整试件、节理厚度为0.3 mm试件P波透射波时程曲线,充填节理、张开节理透射系数分别为0.67和0.41,张开节理透射波频率要比充填节理试件和完整试件的小,因此,颗粒流模拟能同时反映频率的变化。对于张开节理,P波透射波前半周期幅值较大,S波则后半周期幅值较大;充填节理P波和S波幅值均是后半周期较大。

表3 波速与衰减随节理特性的变化规律

Table 3 Ultrasonic velocity and wave attenuation for different joint features

图7 不同状态下透射波

Fig. 7 Transmitted waves under different conditions

总体而言,非贯通节理对波幅的影响远比对波速的影响大。与张开节理相比,充填节理透射系数较大,且随节理厚度增加衰减更快。与纵波相比,横波透射系数受节理变化更敏感,波幅随节理弱化衰减更快。

3 结论

1) 峰值强度、弹性模量、起裂应力随节理厚度增加、刚度比减小而不断下降,泊松比随节理厚度增加而大幅度上升,黏结强度对弹性模量、起裂应力影响较小,峰值强度受节理的影响比受弹性模量和起裂应力的影响大。

2) 与张开节理相比,由于充填物降低了尖端应力集中系数,导致充填节理试样宏观力学参数均较大,并随节理刚度比下降,其力学参数不断减小,应力集中系数增大,应力集中随节理厚度变化受节理刚度比影响。

3) 随节理弱化,试件整体损伤破坏程度降低,局部破坏加剧,破坏模式发生改变,张拉裂纹所占比例逐渐增大,试件破坏所需能量均减小,反映了力学参数弱化的本质特征。

4) 节理对波幅影响远比对波速的影响大,与张开节理相比,充填节理透射系数较大,且随节理厚度增加衰减幅度较大。与纵波相比,横波透射系数对节理更加敏感,随节理弱化衰减更快。

参考文献:

[1] YOSHINAKA R, YAMABE T. Joint stiffness and the deformation behavior of discontinuous rock[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1986, 23(1): 19-28.

[2] BARTON N, BANDIS S, BAKHTAR K. Strength, deformation and conductivity coupling of rock joints[J]. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 1985, 22(3): 121-140.

[3] 任伟中, 白世伟, 丰定祥. 平面应力条件下闭合断续节理岩体力学特性试验研究[J]. 实验力学, 1999, 14(4): 521-527.

REN Weizhong, BAI Shiwei, FENG Dingxiang. An experimental study on the mechanical characteristics of rock mass containing close intermittent joints under plane stress condition[J]. Journal of Experimental Mechanics, 1999, 14(4): 521-527.

[4] 邵鹏, 张勇, 贺永年, 等. 应力波反复作用下断续节理岩体疲劳破坏实验研究[J]. 岩石力学与工程学报, 2005, 24(22): 4180-4184.

SHAO Peng, ZHANG Yong, HE Yongnian, et al. Experimental study on fatigue failure of intermittent jointed rock masses subjected to repeated stress wave[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(22): 4180-4184.

[5] 陈新, 廖志红, 李德建. 节理倾角及连通率对岩体强度、变形影响的单轴压缩试验研究[J]. 岩石力学与工程学报, 2011, 30(4): 781-789.

CHEN Xin, LIAO Zhihong, LI Dejian. Experimental study of effects of joint inclination angle and connectivity rate on strength and deformation properties of rock masses under uniaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(4): 781-789.

[6] 张波, 李术才, 张敦福, 等. 含充填节理岩体相似材料试件单轴压缩试验及断裂损伤研究[J]. 岩土力学, 2012, 33(6): 1647-1652.

ZHANG Bo, LI Shucai, ZHANG Dunfu, et al. Uniaxial compression mechanical property test, fracture and damage analysis of similar material of jointed rock mass with filled cracks[J]. Rock and Soil Mechanics, 2012, 33(6): 1647-1652.

[7] 金爱兵, 李兵, 邓富根. 断续节理对岩体力学性能的影响[J]. 北京科技大学学报, 2012, 34(12): 1359-1363.

JIN Aibing, LI Bing, DENG Fugen. Effect of intermittent joints on the mechanical properties of rock mass[J]. Journal of University of Science and Technology Beijing, 2012, 34(12): 1359-1363.

[8] LEE H, JEON S. An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression[J]. International Journal of Solids and Structures, 2011, 48(6): 979-999.

[9] 黄达, 岑夺丰, 黄润秋. 单裂隙砂岩单轴压缩的中等应变率效应颗粒流模拟[J]. 岩土力学, 2013, 34(2): 535-545.

HUANG Da, CEN Duofeng, HUANG Runqiu. Influence of medium strain rate on sandstone with a single pre-crack under uniaxial compression using PFC simulation[J]. Rock and Soil Mechanics, 2013, 34(2): 535-545.

[10] 赵永红. 受单轴压缩大理岩填充割缝周围的微裂纹生长[J]. 岩石力学与工程学报, 2004, 23(15): 2504-2509.

ZHAO Yonghong. Mini-crack development from a cemented fracture in marble specimen under uniaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(15): 2504-2509.

[11] 刘红岩, 邓正定, 王新生, 等. 节理岩体动态破坏的SHPB相似材料试验研究[J]. 岩土力学, 2014, 35(3): 659-665.

LIU Hongyan, DENG Zhengding, WANG Xinsheng, et al. Similar material test study of dynamic failure of jointed rock mass with SHPB[J]. Rock and Soil Mechanics, 2014, 35(3): 659-665.

[12] 刘欣宇, 刘爱华, 李夕兵. 充填柱状节理类岩石材料的试验研究[J]. 岩石力学与工程学报, 2014, 33(4): 772-777.

LIU Xinyu, LIU Aihua, LI Xibing. Experimental study of columnar jointed sandstone-like material with preset filling[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(4): 772-777.

[13] BAHAADDINI M, SHARROCK G, HEBBLEWHITE B K. Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression[J]. Computers and Geotechnics, 2013, 49(20): 206-225.

[14] 蒋明镜, 陈贺, 张宁, 等. 含双裂隙岩石裂纹演化机理的离散元数值分析[J]. 岩土力学, 2014, 35(11): 3259-3268.

JIANG Mingjing, CHEN He, ZHANG Ning, et al. Distinct element numerical analysis of crack evolution in rocks containing pre-existing double flaw[J]. Rock and Soil Mechanics, 2014, 35(11): 3259-3268.

[15] Itasca Consulting Group Inc. PFC 2D (particle flow code in 2 dimensions) theory and background[M]. Minneapolis, USA, Itasca Consulting Group Inc, 2002: 12-23.

[16] 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则[J]. 岩石力学与工程学报, 2005, 24(17): 3003-3010.

XIE Heping, JU Yang, LI Liyun. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003-3010.

[17] TRENT B C, MARGOLIN L G. A numerical laboratory for granular solids[J]. Engineering Computations, 1992, 9(2): 191-197.

[18] HOLT R M, KJOLAAS J, LARSEN I, et al. Comparison between controlled laboratory experiments and discrete particle simulations of the mechanical behavior of rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2005, 42(7/8): 985-995.

[19] SADD M H, GAO J, SHUKLA A. Numerical analysis of wave propagation through assemblies of elliptical particles[J]. Computers and Geotechnics, 1997, 20(3/4): 323-343.

(编辑 杨幼平)

收稿日期:2015-12-30;修回日期:2016-04-20

基金项目(Foundation item):国家自然科学基金资助项目(51439008, 41572307, 51209200)(Projects(51439008, 41572307, 51209200) supported by the National Natural Science Foundation of China)

通信作者:张国凯,博士研究生,从事岩石动力学实验和数值模拟研究;E-mail:zhangguokai12@163.com