文章编号:1004-0609(2008)02-0221-05

放电等离子烧结制备WC-Co硬质合金温度分布的数值模拟

刘雪梅,宋晓艳,张久兴,赵世贤,魏 君

(北京工业大学 材料科学与工程学院 新型功能材料教育部重点实验室,北京100022)

摘 要:以WC-Co复合粉末为烧结原料,在实验测定石墨模具和试样的物性参数的基础上,采用有限元法对硬质合金SPS过程中烧结系统的温度分布进行研究。结果表明:试样烧结过程中,烧结系统内的温度分布不均匀,烧结温度较低时,高温区域位于硬质合金试样内,随着烧结温度的升高,高温区域向压头转移,热量由试样和压头向模具传递;试样中心温度高于模具中心的测定温度,它们之间的差值与试样加热速率变化趋势一致。模具中心温度的模拟预测结果与实验测定结果基本吻合。

关键词:WC-Co硬质合金;放电等离子烧结(SPS);温度分布;有限元法

中图分类号:TF 124 文献标识码:A

Simulation of temperature distribution during spark plasma sintering to synthesize WC-Co cermets

LIU Xue-mei, SONG Xiao-yan, ZHANG Jiu-xing, ZHAO Shi-xian, WEI Jun

(College of Materials Science and Engineering, Key Laboratory of New Functional Materials of Educational Ministry of China, Beijing University of Technology, Beijing, 100022, China)

Abstract: By using the WC-Co powders as the sintering material, based on physical parameters of graphite and sintering samples measured by experiments, the temperature distribution during SPS process to synthesize WC-Co cermets is simulated by finite element method. The results show that there is a greatly inhomogeneous temperature distribution in the SPS system. The highest temperature zone lies in the sample at lower sintering temperature, and moves forward to the punch with increasing sintering temperature. The temperature of the center of die is lower than that of the center of sample and the change of its difference is in accordance with the change of heating rate. It is concluded that the heat transfers from the punch to the die. The prediction results show a good agreement with the experimental measurements.

Key words: WC-Co cermet; spark plasma sintering (SPS); temperature distribution; finite element method

WC-Co硬质合金因其极高的硬度和耐磨性、良好的抗弯强度和断裂韧性等独特性能,在切削工具、模具、矿山工具及耐磨零部件等领域得以广泛应用[1-2]。传统的硬质合金烧结是在保护气氛炉或真空炉中加热到液相温度以上进行烧结,由于烧结温度高,保温时间长,经常发生烧结致密体中晶粒长大而引起硬质合金综合性能的降低。近年来发展起来的SPS技术在硬质合金材料的制备方面展现出比以往烧结方法显著的技术优势,最近几年国内外应用SPS技术制备硬质合金材料的研究报道明显增多[3-8]。研究结果表明,利用SPS技术可在明显降低的烧结温度、很短的保温时间、可控的烧结压力下制备出晶粒组织较均匀、致密度高的超细乃至纳米结构的硬质合金。

然而,SPS快速制备硬质合金复合材料的特殊机理至今少有报道。SPS过程中烧结温度是影响材料致密化过程的重要因素,目前,SPS过程中通常采用在模具中插入热电偶或采用红外测温仪对模具的温度进行测量。由于SPS过程升温速度快(可达300 ℃/min),模具和试样温度难以得到均衡,即使试样内部也存在温差[9-10],难以获得试样烧结过程的真正温度。由于试样的温度难以测定,因此数值模拟成为揭示试样烧结过程中温度分布的有效途径,有限元技术也开始用于SPS过程温度场的模拟[11-14]。由于SPS过程的复杂性和特殊性,现有的研究局限于致密的块体材料,或研究结果适用范围有限,对硬质合金的SPS过程研究具有一定的借鉴作用,但无法代表硬质合金SPS致密化过程中烧结系统的温度分布。

本文作者针对WC-Co复合粉体的SPS致密化过程,在一定的假设条件下对烧结系统内的温度分布进行模拟,以期对SPS过程进行更深入的了解,为揭示SPS机理奠定基础,在此基础上,进一步分析影响烧结成形质量的工艺因素,从而为硬质合金粉末SPS烧结的工艺参数优化提供指导。

1 SPS核心系统有限元模型的建立

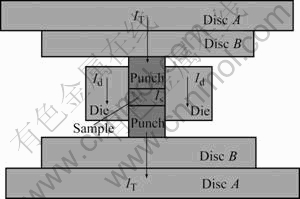

图1所示为试样、模具、压头和垫块组成的SPS核心系统及电流流动方向示意图,模具、垫块和压头均为石墨材料。

图1 试样、模具、压头和垫块(Disc A和Disc B)组成的SPS核心系统和电流流动方向示意图

Fig.1 Schematic sketch of configuration of sample, die, punches and discs and route of current in SPS system

SPS系统的热传导行为可以用经典导热方程来描述。在三维直角坐标系(x,y,z)中,经典导热方程表示为

式中 α为扩散系数,α=λ/ρc,ρ为材料密度,c为材料比热容,λ为导热系数,T为温度,t为时间,qv为物体内各点的内热源强度, ,JV为单位体积流过的电流密度,RV为单位体积的电阻。

,JV为单位体积流过的电流密度,RV为单位体积的电阻。

采用有限元法对核心系统的SPS过程进行分析,需要确定其边界条件。

1) 初始条件的确定

假设烧结前试样各个部分温度分布均匀,即:

2) 边界条件的确定

SPS过程中,试样通常在一定的真空度(<10 Pa)下进行烧结,可以认为模具、压头、垫块与烧结腔内的烧结气氛之间没有热交换;模具、压头、垫块与烧结腔体之间的热辐射很小,忽略不计;烧结腔体及系统上方的垫块Disc A的上表面和系统下方垫块Disc A的下表面与冷却系统相连,保持常温不变;系统之间的相互接触部位具有接触电阻和碳纸,为便于计算,将接触部位和碳纸的参数均折算到碳纸上,与电流垂直方向的接触电阻为石墨模具的8倍,热导率为石墨模具的1/8,与电流平行方向的接触电阻为石墨模具的14倍,热导率为石墨模具的1/14[12];电流由上垫块的上表面流入,从下垫块的下表面流出,因此,以上垫块上表面的面电流密度(Jsurface)作为电流的输入条件,由下式计算得到:

式中 IT为实际测得的总电流,其大小随烧结温度的变化为:当烧结温度<900 ℃时,IT=1 500 A,烧结温度为900~1 200 ℃时,IT=1 800 A;SB为垫块的横截面积。

3) 材料参数的确定

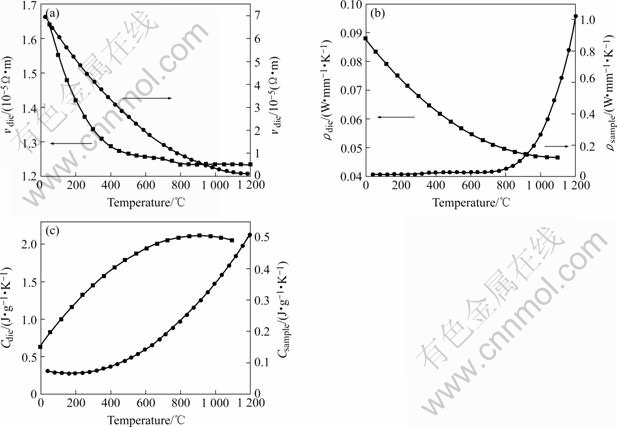

试样和模具的物性参数采用实验测定的方式测得。电阻率、热导率和比热容分别在日本ULVAC ZEM-2 型电阻率测试仪、ULVAC TC7000H 型激光热导仪上进行。假设石墨的物性参数仅与温度有关,可直接测定。

SPS过程中,WC-Co试样不仅发生温度变化,还经历了粉体到致密体的转变,即试样的温度和相对密度均随着烧结过程的进行而发生变化。因此,不能以接近完全致密时的试样的物性参数代表不同烧结阶段试样实际的物性参数。为了定量描述试样在SPS烧结过程中电阻率、热导率、比热容等物性参数的变化,我们对动态烧结过程中试样物性参数的测定进行了实验设计,即:根据不同烧结温度下测定的结果进行拟合得到。SPS过程中采用截断整个烧结过程的方法,以表征不同烧结阶段的烧结特性[15]。首先通过测定代表不同烧结阶段的各烧结温度(如T1,T2,???,Tn-1,Tn)下获得烧结试样在该温度下对应的物性参数(如电阻率n1,n2,???,nn-1,nn),然后对测定的多个散点数据进行拟合,即得到试样的物性参数随烧结温度变化的函数关系(如n(T)=f(T))。应该注意的是,由于仪器测定范围的限定,一些高温烧结的试样,难以直接测定烧结温度下的物性参数。对于此种情况,采用同一烧结温度下获得试样的物性参数随烧结温度的变化曲线进行外推得到。测得的石墨模具和WC-10Co试样SPS过程中物性参数随温度的变化曲线如图2所示。

图2 石墨和WC-Co试样的物性参数随温度的变化

Fig.2 Variations of physical properties of graphite and WC-Co samples at different temperatures: (a) Electric resistivity; (b) Thermal conductivity; (c) Heat capacity

2 模拟结果与分析

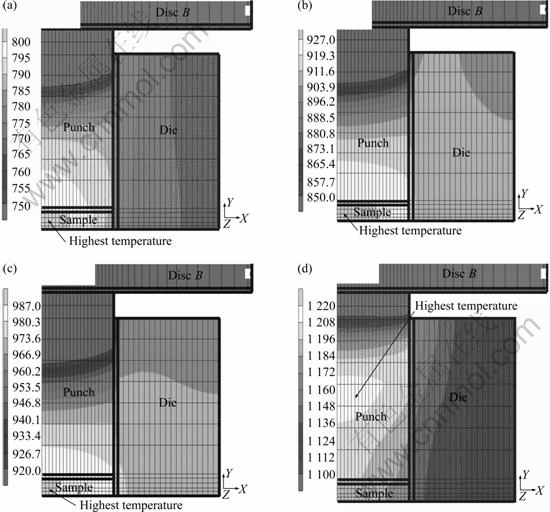

图3所示为采用有限元法对不同烧结阶段SPS核心系统内的温度分布进行模拟的结果。由图可知,系统的轴向和径向均存在明显的温度梯度。由于垫块上端与冷却系统相连,因此低温区是垫块及与之接触的压头,而高温区的位置随着烧结过程的进行而变化:在一定的烧结时间内(如小于566.3 s),高温区位于烧结试样内,当烧结时间继续延长(如达到749.3 s),高温区域则位于压头,原因是随着烧结时间增加,烧结温度升高,试样的电阻率减小,自身产生的能量减少而造成的。系统纵向的温度梯度主要存在于压头和试样中,模具内相对较小。横向的温度分布对了解试样的真正烧结温度影响最大。横向温度梯度随着烧结的进行不断发生变化,例如,当烧结时间为188.8 s时,模具中心与试样中心的温度差不足30 ℃(如图3(a)所示),当烧结时间为749.3 s时,它们之间的温差达到70 ℃(如图3(d)所示)。由上述温度分布可以看出,在WC-Co粉末颗粒的SPS致密化过程中,热量由试样和压头向模具传递。由此可以推断,SPS过程中,硬质合金试样自身就是发热源,产生的热量不仅用于自身加热,还用于模具的加热,完全不同于传统烧结过程中依靠模具传热的加热方式。

图3 不同烧结阶段的温度分布模拟结果

Fig.3 Simulation results of temperature distribution at different sintering stages: (a) 18.8 s; (b) 377.5 s; (c) 566.3 s; (d) 749.3 s

从某一烧结阶段试样的温度分布看,试样内部也存在温度梯度,试样中心的温度高于试样边缘,试样厚度方向(纵向)也存在温度梯度,但相对较小。由此可知,SPS烧结试样的心部和边缘可能存在晶粒尺寸和性能、甚至组成成分的差异。因此,SPS过程中温度分布的模拟对烧结温度的确定和烧结过程的认识具有重要指导意义,特别是对大尺寸试样和发生反应的原位合成烧结更具参考价值。

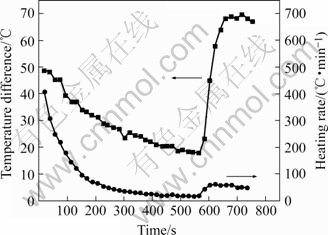

图4所示为试样中心与模具中心温度差值ΔT和烧结过程中加热速率随烧结时间的变化曲线。其中,加热速率由烧结过程中获得的不同时刻测定温度通过计算得到。由图可知,开始烧结时,加热速率超过400 ℃/min,随后加热速率逐渐下降,到560 s左右,下降到16 ℃/min,之后加热速率又逐步升高。ΔT的变化趋势与加热速率的变化趋势相对应:温差由开始时的50 ℃下降到566 s的17.6 ℃,随后又升高到70 ℃。由此可见,试样中心与模具中心的温差ΔT受加热速率的影响很大,加热速率增大,ΔT增加,反之,ΔT减小。因此,SPS过程中,采用低的加热速率,有助于减小模具和试样以及试样内部的温差,得到组织和性能均匀的试样。

图4 试样中心与模具中心温差及加热速率随烧结时间的变化

Fig.4 Variation of temperature difference between center of samples and graphite die and heating rate of samples at different sintering times, using WC-10Co as sintering sample

3 实验验证

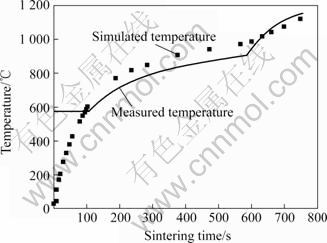

对模具中心温度的模拟预测结果随烧结时间的变化与实测结果进行了比较,如图5所示。由图可见,在t>100 s的阶段两者符合良好,但在烧结的中间阶段,模拟预测结果略高于实测值,主要原因可能是试样内部颗粒间存在孔隙,在烧结过程中气体的排出带走一部分热量,而在模拟过程中未加以考虑,使得实测的烧结温度偏低。由此可以看出,本文建立的关于SPS过程的温度分布及其演变模型和预测结果是合理的。值得注意的是,在烧结开始阶段,实测温度为580 ℃且不发生变化,是由红外测温仪的测定范围所限造成的,并非模具中心的真正温度,因此无法将模拟预测结果与实测值进行比较。正因如此,对实验难以测定范围内的温度分布进行模拟预测,更体现出模拟过程的重要性和使用价值。

图5 以WC-10Co为烧结试样的模具中心温度的模型预测结果与实际测定结果的比较

Fig.5 Measured temperature and simulated temperature in center of graphite die at different sintering times, using WC-10Co as sintering sample

REFERENCES

[1] PETERSSON A, ?GREN J. Constitutive behaviour of WC-Co materials with different grain size sintered under load[J]. Acta Materialia, 2004, 52: 1847-1858.

[2] SCHUBERT W D, BOCK A, LUX B. General aspects and limits of conventional ultrafine WC powder manufacture and hard metal production[J]. International Journal of Refractory Metals & Hard Materials, 1995, 13: 281-296.

[3] CHA S I, HONG S H, KIM B K. Spark plasma sintering behavior of nanocrystalline WC-10Co cemented carbide powders[J]. Mater Sci Eng A, 2003, A351: 31-38.

[4] JIA C C, TANG H, MEI X Z, YIN F Z, QU X H. Spark plasma sintering on nanometer scale WC-Co powder[J]. Materials Letters, 2005, 59: 2566-2569.

[5] KIM H T, KIM J S, KWON Y S. Mechanical properties of binderless tungsten carbide by spark plasma sintering[C]//The 9th Russian-Korean International Symposium on Science and Technology, Korus, South Korea, 2005: 458-461.

[6] SEEGOPAUL P, MCCANDLISH L E, SHINNEMAN F M. Production capability and powder processing methods for nanostructured WC-Co powder[J]. International Journal of Refractory Metals & Hard Materials, 1997, 15: 133-138.

[7] XIE Y F, WANG X Q, CHEN L D, LI X D, GUO H L. Research on preparation of nano-grained cemented carbide by spark plasma sintering[J]. Materials Research Innovation, 2005, 9(3): 82-83.

[8] SHI X L, SHAO G Q, DUAN X L. Mechanical properties, phases and microstructure of ultrafine hardmetals prepared by WC-6.29Co nanocrystalline composite powder[J]. Mater Sci Eng A, 2005, A392(1/2): 335-339.

[9] MCWILLIAMS B, ZAVALIANGOS A, CHO K C, DOWDING R J. The modeling of Electric-Current-Assisted sintering to produce bulk nanocrystalline tungsten[J]. Nanostructured Materials, 2006, 4: 67-71.

[10] MATSUGI K, KURAMOTO H, HATAYAMA T, YANAGISAWA O. Temperature distribution at steady state under constant current discharge in spark plasma sintering process of Ti and Al2O3 powders[J]. Journal of Materials processing Technology, 2003, 134: 225-252.

[11] 杨俊逸, 李元元, 李小强, 郭 亮, 杨 超. 电场活化烧结温度场的数值模拟[J]. 机械工程材料, 2006, 30(11): 73-76, 80.

YANG Jun-yi, LI Yuan-yuan, LI Xiao-qiang, GUO Liang, YANG Chao. Numerical simulation of temperature distribution during electric field activated sintering[J]. Materials for Mechanical Engineering, 2006, 30(11): 73-76, 80.

[12] VANMEENSEL K, LAPTEV A, HENNICKE J, VLEUGELS J, BIEST O V. Modelling of the temperature distribution during field assisted sintering[J]. Acta Materialia, 2005, 53: 379-388.

[13] ZAVALIANGOS A, ZHANG J, KRAMMER M, GROZA J R. Temperature evolution during field activated sintering[J]. Mater Sci Eng A, 2004, A379: 218-228.

[14] ANSELMI-TAMBURINI U, GENNARI S, GARAY J E, MUNIR Z A. Fundamental investigations on the spark plasma sintering/synthesis process Ⅱ: Modeling of current and temperature distributions[J]. Materials Science and Engineering A, 2005, A394: 139-148.

[15] 宋晓艳, 刘雪梅, 张久兴. SPS过程中导电粉体的显微组织演变规律及机理[J]. 中国科学E辑, 2005, 35(5): 459-469.

SONG Xiao-yan, LIU Xue-mei, ZHANG Jiu-xing. Study on mechanism of conductive powder micro-structure evolution in the process of SPS[J]. Science in China Ser E, 2005, 35(5): 459-469.

基金项目:国家自然科学基金资助项目(50401001; 50671001)

收稿日期:2007-07-06;修订日期:2007-11-04

通讯作者:宋晓艳,教授,博士;电话:010-67392311; E-mail:xysong@bjpu.edu.cn

(编辑 陈爱华)