DOI: 10.11817/j.ysxb.1004.0609.2020-37355

微波反应烧结制备WC-Co硬质合金工艺性能

鲍 瑞1,郭圣达2,易健宏1,陈 颢2,羊建高2,余 飞2

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 江西理工大学 工程研究院,赣州 341000)

摘 要:以W粉、Co粉和碳黑为原料,通过球磨、压制成形及微波反应烧结制备WC-6Co硬质合金。采用XRD、SEM、密度计和维氏硬度计等研究微波反应烧结温度、升温速率、保温时间和W粉粒度4个因素对硬质合金组织与性能的影响。结果表明:选用粒度为1.3 μm的W粉为原料,当温度大于1100 ℃时,W即可被C完全碳化生成WC;当温度为1300 ℃时合金致密性较好,维氏硬度(HV30)与断裂韧性(Wk)分别为1999 N/mm2和8.51 MPa/m1/2,继续提高温度至1400 ℃时合金性能无明显变化。烧结温度越低、升温速率越大、保温时间越短,合金残留孔隙越多,导致维氏硬度与断裂韧性性能下降。当微波反应烧结温度为1300 ℃、升温速率100 ℃/min和保温时间10 min时制备的WC-6Co硬质合金微观组织均匀和综合性能最佳。选用粒度为27.0 μm的W粉为原料按照最佳工艺烧结制备出WC-6Co硬质合金,并与平均粒度1.3 μm的W粉制备的合金进行对比发现粗W粉颗粒制备的合金中存在W2C,微波反应烧结工艺参数与W粉平均粒度相关。

关键词:微波反应烧结;硬质合金;微观组织;性能;烧结参数

文章编号:1004-0609(2020)-08-1828-09 中图分类号:TG135.5 文献标志码:A

WC-Co硬质合金因兼具有高硬度、高强度和良好的断裂韧性而被广泛应用于涉及到国民经济的众多领域,其发展水平直接制约着机床、船舶、工程机械与兵器、汽车、航空航天等工业技术发展水平[1-2]。研究表明[3-4],当WC晶粒细化到超细及纳米级别后粘结相分布的更加均匀,硬质合金的硬度与耐磨性得到提升,同时具有良好的强度与韧性的配合,最终实现高硬度和高韧性的良好结合。烧结是硬质合金制备过程最后也是最主要的一个步骤,目前常用的烧结技术有真空烧结、低压烧结、放电等离子烧结和微波烧结等[5-7]。其中作为新型的烧结技术,微波烧结具有样品同时受热、加热速度快、选择性加热以及非热效应等传统加热方式所不具有的特点[8]。 美国宾州州立大学BREVAL等[9]采用微波烧结技术以WC、Co为原料制备了WC-Co硬质合金,并与传统烧结对比发现两种烧结制备的合金收缩率接近,说明合金致密化程度一致。武汉理工大学周建课题组[10-13]采用微波烧结技术制备了WC-10Co硬质合金。研究发现采用纯微波场加热烧结合金时后期致密化难以进行,烧结温度难以突破1100 ℃;而采用电磁混合场可以有效提升合金的致密化程度,但有少量的W2C出现。中南大学、昆明理工大学易健宏课题组[14-20]系统地研究了微波烧结制备WC-Co类硬质合金技术。研究表明传统的微波烧结技术会使硬质合金表层形成脱碳相W3Co3C等,通过在混料过程中添加碳黑,可有效避免脱碳现象。分析文献发现,目前采用微波烧结技术制备WC-Co硬质合金合金均采用WC粉、Co粉为关键原料,而WC粉末需要将W粉进行高温碳化合成得到,在碳化过程中WC易发生异常长大,不利于制备组织结构均匀的硬质合金。 本文作者所在的课题组发明了一种微波反应烧结制备WC-Co硬质合金的方法[21]。该方法以W、Co和C为原料,采用微波加热粉末使W发生碳化反应,同时还发生粉末的烧结,一步烧结制备出WC-Co硬质合金,避免了WC粉末的制备工序。本发明与传统制备硬质合金相比,具有工艺流程简化、能耗降低等优点。但微波反应烧结工艺的关键参数对硬质合金组织与性能的影响还需更加深入的研究。因此,本文采用微波反应烧结技术,以Co、C和不同粒度的W粉为原料,研究微波反应烧结关键工艺参数、不同粒度的W粉对硬质合金组织与性能的影响,以期为获得综合性能更加优异的WC-Co硬质合金的制备提供可靠的理论依据。

1 实验

1.1 原料与设备

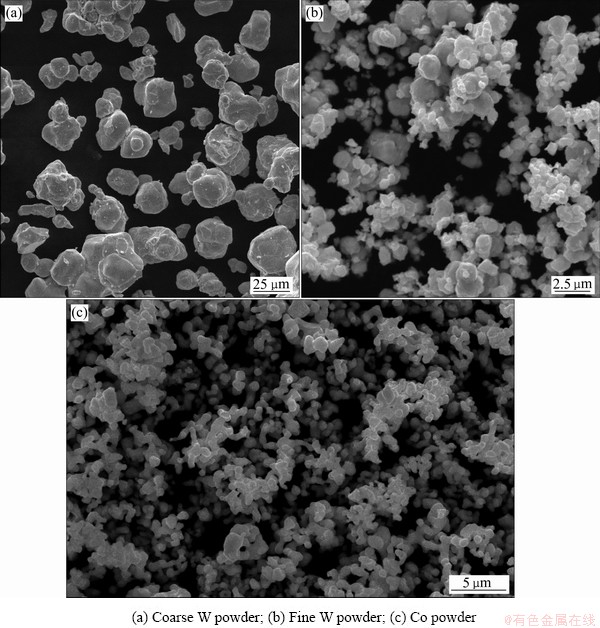

实验使用的原料主要有平均粒度分别为1.3 μm和27.0 μm的W粉、平均粒度为1.0 μm的Co粉,均购自赣州精科科技有限公司,其SEM像如图1所示。所用碳黑纯度为99.9%。实验设备有行星球磨机、真空干燥箱和2.45 GHz 多模腔微波高温炉(MW-L0616V,长沙隆泰公司生产)。

1.2 实验方法

将粒度为1.3 μm细W粉、Co粉和碳黑按质量比称量(WC-6Co),倒入不锈钢球磨罐中,再添加2%(质量分数)石蜡作为成型剂。往球磨罐中填加无水乙醇作为球磨介质,选用牌号为YG6的硬质合金球作球磨球,球直径为6 mm,球料比为5:1。设置球磨转速为300 r/min,球磨时间为10 h;随后将球磨好的料浆置于真空干燥箱中在70 ℃下加热真空干燥4 h。 称量上述混合粉末10 g,置于硬质合金内衬的B类强度条模具中,压强为200 MPa,保压时间10 s;随后将压坯在真空炉中脱脂处理,升温速率10 ℃/min、脱脂温度500 ℃、保温时间2 h;最后再将脱脂后的样品置于微波烧结炉进行烧结。采用如表1所列的烧结工艺分别研究烧结温度、升温速率和保温时间3个关键工艺参数对微波反应烧结制备WC-6Co硬质合金微观组织、性能的影响,优化微波反应烧结工艺参数并与传统低压烧结制备的WC-6Co硬质合金进行对比。随后采用平均粒度为27.0 μm的W粉为原料,经相同的工艺球磨处理后,再采用最佳烧结工艺制备出粗晶粒WC-6Co硬质合金,并与细W粉制备的合金进行对比。

图1 实验用原料的SEM像

Fig. 1 SEM images of experimental materials

采用荷兰帕纳科锐影X射线衍射仪测定合金的物相;用JSM-7001E型场发射扫描电镜观察粉末形貌以及硬质合金微观组织,因硬质合金中W与Co的原子序数相关较大,因此采用背散射模式更有利于观察合金的微观形貌;依据截矩法原理,采用Nano Measure软件计算WC的平均晶粒度;采用排水法测定硬质合金密度;用PHI5000 Versaprobe-II型X射线光电子能谱分析仪对合金元素价态进行测定;采用维氏硬度计测定维氏硬度;利用Palmqvist公式计算合金断裂韧 性[2],如式(1)所示。文中列出的密度、硬度和断裂韧性值均为同一样品测量5次,再计算的平均值。

(1)

(1)

式中:Wk为合金断裂韧性,MPa·m1/2;Hv为维氏硬度,kg·mm-2;P为载荷,N;li为角裂纹长度,mm。

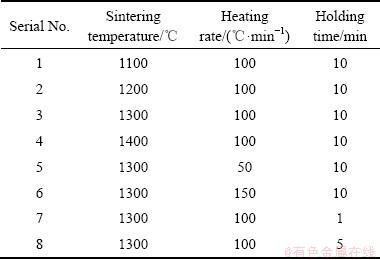

表1 微波反应烧结工艺参数(原料W粉的平均粒度为1.3 μm)

Table 1 Process parameters of microwave reaction sintering (Average particle size of W powder is 1.3 μm)

2 结果与讨论

2.1 烧结温度的影响

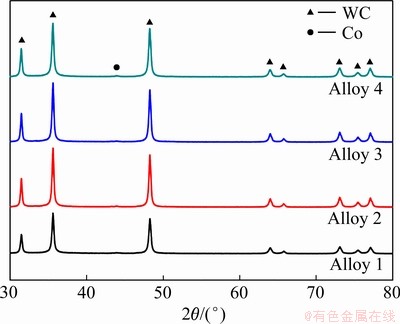

图2所示为1号、2号、3号和4号试样的XRD谱。粉末物相以WC物相为主,还可观察到非常微弱的Co峰,并未见到可能出现的W2C峰。

传统的制备工艺认为W粉需在1300 ℃以上才能被碳化形成WC,而在本实验中当微波反应烧结温度大于1100 ℃时,W即可被C碳化完全生成WC相,微弱的Co峰是由于WC峰太强导致的[20]。分析认为,W的碳化从800 ℃开始,但是传统碳化是依靠热传导使W与C粉末达到一定温度后,热量由外向粉末内部传递使C向W原子内部扩散形成WC的,其反应过程受到动力学限制使其温度需要达到1300 ℃以上时碳化反应才能顺利进行;而微波能够快速进入物体内部并即时转化为热量;另外C是典型的微波吸收体,能够与微波产生很好的耦合作用产生瞬时高温,使C能够快速扩散进入W内部形成WC[22]。

图2 实验制备的1、2、3、4号硬质合金XRD谱

Fig. 2 XRD patterns of cemented carbides (Alloy 1, Alloy2, Alloy 3 and Alloy 4)

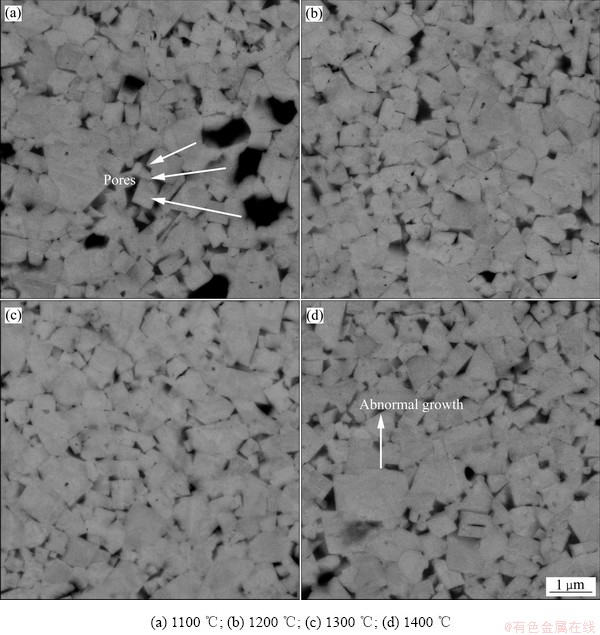

图3所示为1至4号合金在背散射模式下的SEM像。从图3中可以看出,当烧结温度为1100 ℃时,合金中存有大量孔隙,说明在此温度下合金致密性较差;随着烧结温度的升高合金内部孔隙减少;当温度达到1300 ℃以上时,孔隙消失,但是温度过高,合金中出现WC晶粒异常长大的现象,如图3(d)中箭头所示。 WC-Co硬质合金由硬质相WC与粘结相Co组成,在传统的真空或压力烧结过程中为了能尽量消除孔隙、提高合金致密度,烧结温度应保持在1320 ℃的共晶温度以上,使Co熔化为液相,填充孔隙完成致密化过程。由图2可知,W在1100 ℃时可被碳化完全生成WC,但是合金中的孔隙主要通过液相Co的流动与填充来消除的,烧结温度太低,合金中产生不了足够的液相Co来填充孔隙,使合金致密性变差;随着温度的升高(1200 ℃)液相Co数量增加,孔隙被填充得更加充分,合金致密性有所改善,此时可将烧结体看作固相烧结,合金的致密化进程主要受联结和扩散控制,进展缓慢,因此制备的合金存在较多孔隙。当微波反应烧结温度达到1300 ℃时孔隙被填充的较为完全,此时合金的SEM像中较难观察到孔隙;但是当温度达到1400 ℃时,高温会促进WC晶粒的合并长大和溶解-析出长大,此时合金中出现了异常长大的WC晶粒[23-24]。

图3 不同烧结温度制备的合金SEM像

Fig. 3 SEM images of alloys sintered at different temperatures

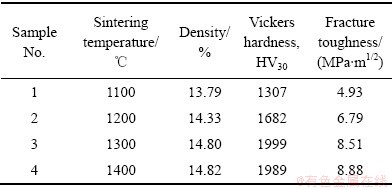

表2所列为4组合金的密度、维氏硬度和断裂韧性平均值。从表2可以看出,合金密度随着微波反应烧结温度的升高而不断增大,当温度大于1300 ℃时,合金密度几乎没有变化,说明温度达到1300 ℃时合金已完全致密化过程,此时继续升高温度合金的致密性无明显变化。当温度为1100 ℃时时,合金中有大量孔隙,维氏硬度值很小,随着温度的升高维氏硬度持续升高;当温度达到1300 ℃以上时,硬度变化较小。硬质合金的硬度主要受到合金致密度、WC晶粒度和粘结相含量等因素的影响。在本次实验中4组合金的Co含量均为6%不变,从图3可知4组合金WC晶粒度也较为接近,因此合金硬度主要受到合金密度的影响,其平均值随着密度的增大而增大[25]。由图3(d)可知当温度为1400 ℃时合金中有异常长大的WC晶粒,依据Hall-Petch关系可知合金硬度随着WC晶粒度的增大而减小,但是表2的结果显示3号与4号合金的维氏硬度相近。分析认为在实验中反应烧结的保温时间仅为10 min,此时尽管合金有异常长大的WC晶粒但整体晶粒尺寸仍然较为均匀,异常长大的WC晶粒数量较少,因此合金硬度减小的并不明显[1]。硬质合金的断裂韧性是指合金内部抵抗裂纹扩展的能力。当合金致密性较差、内部有孔隙时,裂纹扩展受到的阻力小,因此断裂韧性较低;随着密度的增大,韧性增大[1]。当烧结温度达到1300 ℃以上时,合金已接近理论密度值,此时合金内部无明显孔隙,断裂韧性最大。硬质合金的断裂韧性还与WC晶粒度有关,WC晶粒度越大合金断裂韧性越大,但从表2还可看出,3号和4号合金韧性值接近,分析认为这与实验中采用的较短的保温时间有关。综合上述实验结果与分析认为,微波反应烧结温度设置为1300 ℃时合金的微观组织与性能最好。

表2 不同烧结温度制备的合金性能

Table 2 Mechanical properties of cemented carbides sintered at different temperatures

2.2 升温速率的影响

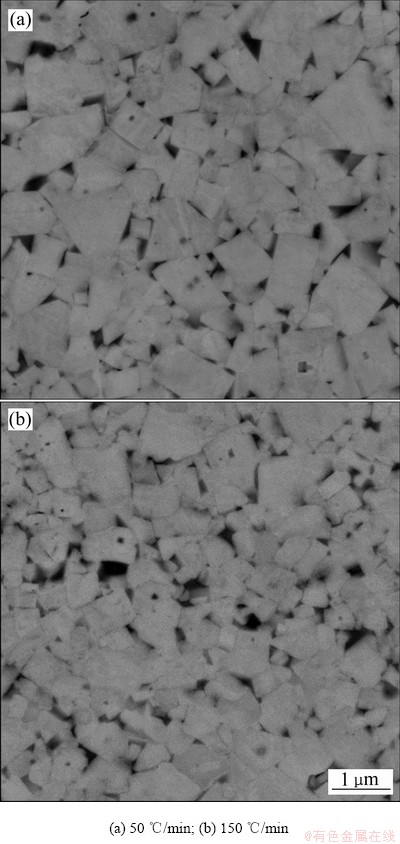

图4所示为固定烧结温度为1300 ℃、保温时间为10 min时,升温速率为50 ℃/min和150 ℃/min合金微观组织。从图4中可以看出,3号和5号合金的微观组织无明显变化,但是6号合金中有少量孔隙存在。分析认为升温速率越大,则合金烧结时间越短,内部孔隙来不及被填充完全,因此合金中有孔隙存在;此外升温速率越大,合金内部的气体来不及排出到样品外面,在内部也会留下孔隙。从SEM像的结果分析认为,控制微波反应烧结升温速率为100 ℃/min较为合适。

图4 不同升温速率制备的硬质合金SEM像

Fig. 4 SEM images of cemented carbides prepared at different heating rates

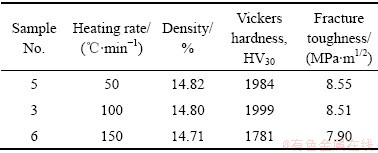

表3所列为3号、5号和6号合金的性能结果,可以看出3号与5号合金的密度、硬度与韧性较为接近。三组合金对比发现6号合金的密度、硬度和韧性最低,分析认为是由于升温速率太快,合金致密性变差导致的。

表3 不同升温速率制备的合金性能

Table 3 Mechanical properties of cemented carbides prepared by different heating rates

2.3 保温时间的影响

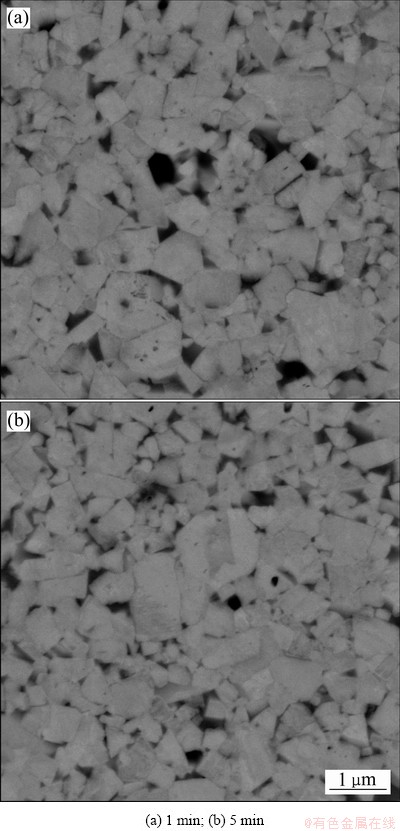

图5所示为保温时间1 min的7号合金和保温时间5 min的8号合金微观组织。从图5可以看出,当保温时间为1 min和5 min时,合金中有较多孔隙;当保温时间延长到10 min时,合金中无明显孔隙,也未观察到异常长大的WC晶粒(见图3(c))。在研究保温时间的实验中,烧结温度固定为1300 ℃,在此温度下合金内部产生了较多的液相Co,其在毛细管力的作用下向孔隙内部发生迁移并填充合金孔隙,使合金密度升高[26]。但是从图5的结果可以发现,当保温时间低于5 min时,合金中存有较多孔隙,说明尽管液相Co向孔隙处迁移,但由于时间太短,使孔隙不能被填充完全,导致合金内部残留有孔隙;当保温时间延长至10 min时,合金内部孔隙可被填充完全,密度提高。

图5 不同保温时间制备的硬质合金SEM像

Fig. 5 SEM images of cemented carbides with different holding time

表4所列为不同保温时间制备的合金密度、维氏硬度和断裂韧性的检测结果。随着保温时间的延长合金密度、硬度和韧性均不断增大。在本文实验范围内设置保温时间为10 min时烧结效果最好。 综合上述实验结果与分析,认为微波反应烧结的烧结温度设置为1300 ℃、升温速率为100 ℃/min、保温时间为10 min时合金的微观组织与性能最好。

表4 不同保温时间制备的合金性能

Table 4 Mechanical properties of cemented carbides with different holding time

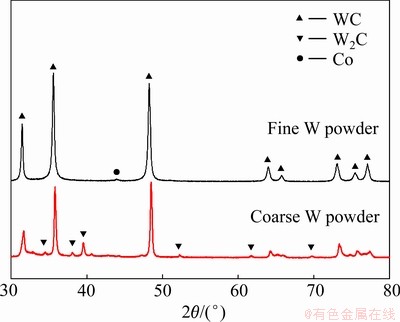

2.4 W粉粒度的影响

固定微波反应烧结温度为1300 ℃、升温速率为100 ℃/min、保温时间为10 min,采用粒度为27.0 μm粗W粉为钨源,经相同球磨、脱脂和烧结工艺制备出WC晶粒度更大的WC-6Co硬质合金,并与3号合金进行对比。 图6所示为两组合金的XRD谱。从图6中可以看出,采用细颗粒W粉为原料制备的硬质合金中仅检测出WC与Co两种物相,而粗颗粒W粉制备的合金中还有W2C。W粉的碳化过程主要是通过C与W表面反应以及C向W内部逐渐扩散来实现的,碳化反应除了需要满足热力学的要求,还要受到动力学的制约[22, 27]。分析认为当烧结温度为1300 ℃时,C与微波发生强烈的耦合作用产生高温,其活性得到大幅提升,因此可以与W反应生成WC,但由于保温时间太短(10 min),粗颗粒的W粉又会增加C元素的扩散路径,因此当保温结束后C并未完全扩散进入W颗粒内部参与反应,导致合金中残留W2C[28]。

图6 不同粒度W粉制备的硬质合金XRD谱

Fig. 6 XRD patterns of cemented carbides prepared by W powders with different average size

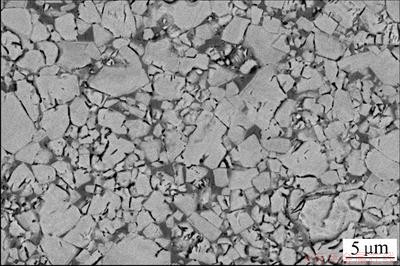

图7所示为粗颗粒W粉制备的硬质合金微观组织。与图3(b)进行对比发现,粗颗粒W粉制备的合金中存在较多粗大的WC晶粒,但两组合金的晶粒形貌非常相近。这是由于WC与W2C均是六方结构,因此SEM像上看无明显差别。

图7 平均粒度27.0 μm W粉制备的硬质合金微观组织

Fig. 7 Microstructure of cemented carbide prepared by W powders with 27.0 μm size

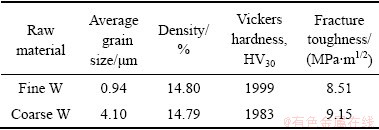

表5所列为两组合金的力学性能结果。可以看出合金密度较为接近,尽管合金WC晶粒度相差较大,但维氏硬度差距较小。由Hall-Petch关系可知合金硬度随着WC晶粒度的增大而减小,但由于粗颗粒W粉制备的合金中存在较多W2C,其硬质要高于WC的[29],因此粗颗粒W粉制备的合金硬度与细颗粒W粉制备的接近。从表5还可看出,两组合金的断裂韧性也相差很小,由文献可知韧性随着合金WC晶粒度的增加而增加,但由于粗颗粒W粉制备的合金中存在硬脆相W2C,使其韧性下降,导致其韧性与细颗粒W粉制备的合金相近[29]。

表5 不同W粉制备的合金性能

Table 5 Mechanical properties of cemented carbides with different W powder

3 结论

1) 在微波作用下,约1100 ℃时细颗粒W即可被碳化生成WC粉,远低于传统的1300 ℃。烧结温度低于1300℃时,尽管W可被碳化为WC,但由于温度太低,合金仅发生固相烧结,因此合金内部存留有较多孔隙。2) 升温速率太快(大于150 ℃/min)或者保温时间太短均会使合金内部孔隙来不及被填充完全,导致制备的合金致密性差。综合分析认为微波反应烧结温度设置为1300 ℃、升温速率为100 ℃/min和保温时间10 min时制备的合金组织与性能最佳。 3) 粗颗粒W粉在1300 ℃时碳化10 min后仍然有W2C,其会增加合金的硬度但会对断裂韧性产生不利影响。此外,微波反应烧结制备工艺参数还受到W粉平均粒度的影响。

REFERENCES

[1] 郭圣达, 鲍 瑞, 易健宏, 羊建高, 刘 亮, 杨 平. SPS制备含钼WC-6Co硬质合金的工艺性能[J]. 中国有色金属学报, 2018, 28(3): 556-564.

GUO Shend-da, BAO Rui, YI Jian-hong, YANG Jian-gao, LIU Liang, YANG Ping. Effects of SPS sintering parameters on microstructure and properties of WC-6Co cemented carbides with Mo addition[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(3): 556-564.

[2] GUO S D, BAO R, YANG J G, CHEN H, YI J H. Effect of Mo and Y2O3 additions on the microstructure and properties of fine WC-Co cemented carbides fabricated by spark plasma sintering[J]. International Journal of Refractory Metals and Hard Materials, 2017, 69: 1-10.

[3] RAIHANUZZAMAN R M, HAN ST. Conventional sintering of WC with nano-sized Co binder: Characterization and mechanical behavior[J]. International Journal of Refractory Metals and Hard Materials, 2015, 53: 2-6.

[4] XIE H, LIU Y, YE J, LI M, ZHU Y F, FAN H J. Effect of (Cr0.8V0.2)2(C,N) addition on microstructure and mechanical properties of WC-8Co cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2014, 47: 145-149.

[5] HUANG Z, REN X R, LIU M X, XU C, ZHANG X H, GUO S D, CHEN H. Effect of Cu on the microstructures and properties ofWC-6Co cemented carbides fabricated by SPS[J]. International Journal of Refractory Metals and Hard Materials, 2017, 62: 155-160.

[6] FABIJANIC T A, ALAR Z, CORIC D. Influence of consolidation process and sintering temperature on microstructure and mechanical properties of near nano- and nano-structured WC-Co cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2016, 54: 82-89.

[7] DEMIRSKYI D, BORODIANSKA H, AGRAWAL D, RAGULYA A, SAKKA Y, VASYLKIV O. Peculiarities of the neck growth process during initial stage of spark-plasma, microwave and conventional sintering of WC spheres[J]. Journal of Alloys and Compounds, 2012, 523: 1-10.

[8] 鲍 瑞, 易健宏. 微波烧结技术在硬质合金制备中的应 用[J]. 中国有色金属学报, 2014, 24(6): 1544-1561.

BAO R, YI J H. Application of microwave sintering technology in cemented carbide preparation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1544-1561.

[9] BREVAL E, CHENG J P, AGRAWAL D K, GIGL P, DENNIS M, ROY R, PAPWORTH A J. Comparison between microwave and conventional sintering of WC/Co composites[J]. Materials Science and Engineering A, 2005, 391: 285-295.

[10] 周 建, 程吉平, 袁润章, 张韵瑾, 邱进宇. 微波烧结WC-Co细晶硬质合金的工艺与性能[J]. 中国有色金属学报, 1999, 9(3): 465-468.

ZHOU Jian, CHENG Ji-ping, YUAN Run-zhang, ZHANG Yun-jin, QIU Jin-yu. Property and technology of WC-Co fine grain cemented carbide in microwave sintering[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 465-468.

[11] 全 峰, 周 建, 刘伟波, 刘桂珍. VC/Cr3C2对微波烧结超细WC-10Co性能的影响[J]. 武汉理工大学学报, 2007, 29(12): 49-51.

QUAN Feng, ZHOU Jian, LIU Wei-bo, LIU Gui-zhen. Effects of VC/Cr3C2 additions on microwave sintering properties of ultrafine WC-10Co hard alloys[J]. Journal of Wuhan University of Technology, 2007, 29(12): 49-51.

[12] 全 峰. 微波烧结WC-10Co硬质合金的结构与性能研究[D]. 武汉: 武汉理工大学, 2007: 1-100.

QUAN Feng. Structure and properties of WC-10Co cemented carbide sintered by microwave sintering[D]. Wuhan: Wuhan University of Technology, 2007: 1-100.

[13] ZHOU J, SHI C, MEI B, YUAN R, FU Z. Research on the technology and the mechanical properties of the microwave processing of polymer[J]. Journal of Materials Processing Technology, 2003, 137(3): 156-158.

[14] 鲍 瑞. WC-Co硬质合金的微波烧结制备研究[D]. 长沙: 中南大学, 2013: 1-115.

BAO Rui. Studies on microwave sintering of WC-Co hard metals[D]. Changsha: Central South University, 2013: 1-115.

[15] BAO R, YI Jian-hong, PENG Yuan-dong, ZHANG Hao-zhe. Effects of microwave sintering temperature and soaking time on microstructure of WC-8Co[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 372-376.

[16] BAO R, YI Jian-hong, PENG Yuan-dong, ZHANG Hao-zhe, LI Ai-kun. Decarburization and improvement of ultra fine straight WC-8Co sintered via microwave sintering[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 853-857.

[17] BAO R, YI Jian-hong. Densification and alloying of microwave sintering WC-8wt.%Co composites[J]. International Journal of Refractory Metals and Hard Materials, 2014, 43: 269-275.

[18] BAO R, YI Jian-hong. Effect of sintering atmosphere on microwave prepared WC-8wt.%Co cemented carbide[J]. International Journal of Refractory Metals and Hard Materials, 2013, 23: 372-376.

[19] BAO R, YI Jian-hong, ZHANG Hao-zhe, PENG Yuan-dong. A research on WC-8Co preparation by microwave sintering[J]. International Journal of Refractory Metals and Hard Materials, 2012, 32: 16-20.

[20] 娄 静, 易健宏, 周承商. 微波烧结WC-Co硬质合金致密化与晶粒生长[J]. 中国有色金属学报, 2012, 22(7): 1976-1983.

LOU Jing, YI Jian-hong, ZHOU Cheng-shang. Densification and grain growth of microwave sintered WC-Co cemented carbide[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1976-1983.

[21] 鲍 瑞, 易健宏, 李凤仙, 谈松林, 张家敏, 游 昕. 一种用微波反应烧结制备WC-Co硬质合金的方法. 中国, CN103695685A[P]. 2014-04-02.

BAO Rui, YI Jian-hong, LI Feng-xian, TANG Song-lin, ZHANG Jia-ming, YOU Xing. A method for preparing WC-Co cemented carbide by microwave reaction sintering. China, CN103695685A[P]. 2014-04-02.

[22] 吴爱华, 唐建成, 叶 楠, 李 婷, 吴 桐, 雷纯鹏. 微波碳化法制备纳米WC粉末及其机理[J]. 粉末冶金材料科学与工程, 2014, 19(6): 862-866.

WU Ai-hua, TANG Jian-cheng, YE Nan, LI Ting, WU Tong, LEI Chun-peng. Fabrication and mechanism of WC nano-powders prepared by microwave carbonization[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(6): 862-866.

[23] 郭圣达, 易健宏, 鲍 瑞. 放电等离子烧结制备钨钴硬质合金的研究现状[J]. 中国钨业, 2015, 30(6): 35-41.

GUO Sheng-da, YI Jian-hong, BAO Rui. Research status of WC-Co cemented carbide prepared by spark plasma sintering[J]. China Tungsten Industry, 2015, 30(6): 35-41.

[24] SIVAPRAHASAM D, CHANDRASEKAR S B, SUNDARESAN R. Microstructure and mechanical properties of nanocrystalline WC-12Co consolidated by spark plasma sintering[J]. International Journal of Refractory Metals and Hard Materials, 2007, 25: 144-52.

[25] LIN N, WU C H, HE Y H, ZHANG D F. Effect of Mo and Co additions on the microstructure and properties of WC-TiC-Ni cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2012, 30: 107-113.

[26] KONYASHIN I, HLAWATSCHEK S, RIES B, MAZILKIN A. Co drifts between cemented carbides having various WC grain sizes[J]. Materials Letters, 2016, 167: 270-273.

[27] LIU B X, SHI A H, YANG G L, SU Q, CHEN G J, ZHANG L N, YANG B. Recovery of tungsten carbides for preparing ultrafine WC-Co composite powder using core-shell structured precursor synthesized by CVD[J]. International Journal of Refractory Metals and Hard Materials, 2017, 67: 74-81.

[28] GUO S D, BAO R, YANG P, LIU L, YI J H. Morphology and carbon content of WC-6%Co nanosized composite powders prepared using glucose as carbon source[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(4): 722-728.

[29] 羊建高, 谭敦强, 陈 颢. 硬质合金[M]. 长沙: 中南大学出版社, 2012: 1-490.

YANG Jian-gao, TANG Dun-qiang, CHEN Hao. Cemented carbides[M]. Changsha: Central South University Press, 2012: 1-490.

Microwave reaction sintering on WC-Co cemented carbides fabrication

BAO Rui1, GUO Sheng-da2, YI Jian-hong1, CHEN Hao2, YANG Jian-gao2, YU Fei2

(1. School of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Project Research Institute, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: Tungsten powder, cobalt powder and carbon black were invoked as raw materials.WC-6Co cemented carbides were prepared by ball-milling, compression moulding and microwave reaction sintering. The effects of sintering factors (Sintering temperature, heating rate and holding time) and the average particle size of W powders on the microstructure and properties of cemented carbides were investigated by XRD, SEM, Vickers hardness tester, et al. The results show that W powders with an average size of 1.3 μm can be carbonized to WC by C when the temperature is greater than 1100 ℃. The high densification of cemented carbide can be achieved when the temperature is 1300 ℃. The Vickers hardness (HV30) and fracture toughness (Wk) are 1999 N/mm2 and 8.51 MPa·m1/2, respectively. No obvious property changes occur when sintering temperature increases to 1400 ℃. The residual pores in the alloy increase with reducing the sintering temperature, increasing the heating rate and reducing the holding time, which would result in the decrease of HV30 and Wk. It is considered that the microstructure is uniform and the comprehensive properties is the best when the microwave reaction sintering temperature is 1300 ℃, the heating rate is 100 ℃/min, and the holding time is 10 min. Subsequently, coarse grained WC-6Co cemented carbides are prepared from W powders with an average size of 27.0 μm and compared with fine grained WC-6Co cemented carbides. The results show that W2C exists in the alloy prepared from coarse W powders. The parameters of microwave reaction sintering are also affected by the average size of W powders.

Key words: microwave reaction sintering; cemented carbides; microstructure; properties; sintering parameters

Foundation item: Project(51464013) supported by the National Natural Science Foundation of China; Project (2015FB127) supported by the Natural Science Foundation of Yunnan Province, China; Project(20181BBE58001) supported by the Natural Science Foundation of Jiangxi Province, China

Received date: 2018-07-12; Accepted date: 2020-06-22

Corresponding author: GUO Sheng-da; Tel: +86-797-8312705; E-mail: enga@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51464013);云南省科技厅面上项目(2015FB127);江西省科技厅项目(20181BBE58001)

收稿日期:2018-07-12;修订日期:2020-06-22

通信作者:郭圣达,讲师,博士;电话:0797-8312705;E-mail:enga@163.com