Trans. Nonferrous Met. Soc. China 22(2012) 1387-1392

In-situ synthesis of Al3Ti particles reinforced Al-based composite coating

NIU Li-bin, ZHANG Ju-mei, YANG Xiao-lan

College of Materials Science and Engineering, Xi’an University of Science and Technology, Xi’an 710055, China

Received 22 June 2011; accepted 5 September 2011

Abstract: Using titanium wires (99.5%, 200 μm in diameter) as a reactive source, an Al-based composite coating reinforced by titanium tri-aluminide (Al3Ti) particles was fabricated by infiltration plus in-situ methods. According to the differential thermal analysis (DTA) curve, the reactive temperature between Ti wires and Al matrix can be determined at 890 ℃. The obtained composite coatings were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), and microhardness and wear test. The experimental results show that when holding period is 20 min at 890 ℃, the titanium wires react completely to in-situ synthesize Al3Ti particles, which presents blocky and strip-like states. The microhardness of in-situ synthesized Al3Ti particles is about 4.5 times that of the Al-matrix. Under the condition of dry sliding at 10 N load, compared with the unreinforced Al matrix, the composite coating fabricated with 20 min offers unique wear resistance behavior, and its wear mechanism is that the adhesive wear and abrasive wear coexist.

Key words: intermetallics; in-situ reaction; composite coating; wear resistance

1 Introduction

Compared with ceramic particles, the intermetallics have not only low density, high hardness and melting temperature, but also much closer coefficient of thermal expansion (CTE) to Al matrix [1-4]. So, intermetallic particles reinforced Al-based composites have been extensively investigated [5,6]. Among the transition-metal intermetallics, tetragonal Al3Ti has good theromdynical stability in Al matrix and good compatibility with α(Al) having FCC crystal structure, so, it tends to be used as reinforcement for Al-based composites, and have a wide range of industrial applications. The processing of the composites includes two domains, namely, ex-situ and in-situ methods, due to the surface contamination of the reinforcements. The composites obtained by ex-situ method present poor wettability between the reinforcements and the matrices, and the thickness of the reinforcing phases is limited by the starting powder size. However, in-situ method can overcome these shortcomings. For example, the reinforcements are synthesized directly in a metallic matrix by chemical reactions between elements or between an element and a compound during the composite fabrication. In previous works, NAYAKA et al [6] have successfully in-situ synthesized and studied nanocomposites with Al3Ti particles in Al–Ti alloys by mechanical alloying over 20 h and subsequent annealing at 673 K for 2 h. KARABI and NARNAWARE [7] prepared in-situ Al3Ti/Al-4.5%Cu matrix composites with varying amount of Al3Ti particles by induction melting aluminum, titanium and master alloy and following by solidification method. WATANABE et al [8,9] fabricated the Al3Ti platelet particles reinforced Al-based function grad composites using centrifugal casting technique and studied anisotropy of wear resistance of the composites. Besides, the other appropriate fabrication methods have been brought forward, such as hot pressing (HP), hot extrusion, and hot isostatic pressing (HIP) at temperatures close to the melting point of Al [10,11].

As mentioned above, these literatures mainly focused on preparing bulk composites, it is well known that the life-span of the component in industry depends on its surface and no its bulk characteristics. If the surface of the component is enhanced, the life-span of the component can be also prolonged. Up to today, only few works aimed at the investigation on in-situ Al3Ti particles reinforced Al-based composite coating, as well as some studies on its wear resistance.

In the study, a combined technique was put forward, namely, infiltration plus in-situ method, which can extremely short reactive time, simplify processing, as well as reduce cost of composite coating. By means of the combined method, using titanium wires and Al ingot as reactive sources, Al-based composite coatings reinforced by in-situ Al3Ti particles were prepared at certain temperature for various time, and the microstructures and wear-resistant properties of the composite coatings were investigated.

2 Experimental

The initial materials used in the experiments were titanium wires (99.5%, 200 μm in diameter) and Al ingot. The chemical composition (mass fraction, %) of the Al ingot was 90.18Al-7.6Si-1.3Cu-0.27Mg-0.65Mn. Before fabrication, titanium meshes were weaved by machine and the pore size of the meshes was about 0.5 mm. The titanium meshes can ensure the uniform distribution of in-situ Al3Ti reinforcements in Al matrix. The fabricating process can be described as follows.

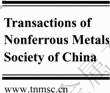

Firstly, titanium meshes were cut into small patches with the dimensions of 190 mm×80 mm, and Al ingots were machined into Al blocks with dimensions of 190 mm×90 mm×80 mm. Secondly, patches and Al blocks were etched in 10%HF and 15%NaOH solution, respectively, then alcohol cleaned, water flushed and dried. Thirdly, three layers of the patches were overlapped together and tightly covered to the bottom of the graphite crucible with dimensions of 200 mm×100 mm×80 mm, Al block was placed above the patches, then an assembly fixture was obtained, as shown in Fig. 1. Fourthly, three same assembly fixtures were heated to 890 ℃ at 8 ℃/min and maintained for 2, 10 and 20 min, respectively, in quartz tubes under Ar atmosphere, and furnace cooled to room temperature. Finally, the samples were removed from the graphite crucibles.

The specimens were cut, mounted, ground, and polished with a diamond paste for metallographic characterization. Microstructures of the composite coatings were examined using a scanning electron microscope equipped with an energy dispersive X-ray spectroscope (EDS). Phases were analyzed on a PW 1730 X-ray diffractometer with monochromated Cu Kα radiation at 40 kV and 40 mA. The micro-hardness values for both matrix and reinforcement were performed on a Tukon 2100B Vickers/Knoop hardness tester. Friction and wear tests were carried out using a ball-on-disc type friction and wear tester. The testing conditions were as follows: the upper ball with 3 mm in diameter made of AISI52100 steel (62HRC), normal load 10 N, test duration 10 min, the rotation diameter 6 mm and the rotation velocity 200 r/min. The wear tests were repeated at least three times for each sample, and the mass losses of the specimens were measured in an electronic balance with an accuracy of 0.0001 g. The unreinforced Al matrix was considered the reference specimen.

Differential thermal analysis (DTA) was performed using the NETZSCH STA449C equipment. The schematic diagram of the DTA specimen is shown in Fig. 2(a). The specimen was heated from 400 ℃ to 1000 ℃ and then cooled to 400 ℃ at 8 ℃/ min. The entire test process was conducted in the high-purity argon gas using a flow rate of 150 mL/min.

Figure 2(b) shows the DTA curve of the specimen prepared from titanium wires and Al ingot. As can be seen, in the stage of heating, there are two endothermic peaks and one exothermic peak. The first endothermic peak centered at 503.1 ℃ is weak due to the interfacial reactions between TiO2 and Al [12]. The second endothermic peak with the maxima at 639.9 ℃ is attributed to the melting of Al matrix. The significant exothermic peak exists at 891.3 ℃, which is the possible reactive temperature between Al melt and Ti wires. When the curve of the cooling temperature was also maintained, there was only one evident exothermic peak at 620.6 ℃ which should be attributed to the solidification of the molten Al. Therefore, in this work, we can consider that the experiment temperature is approximately 890 ℃.

Fig. 1 Schematic illustration of assembly fixture in experiments

Fig. 2 Schematic diagram (a) and DAT curve (b) of specimen

3 Results and discussion

3.1 XRD phase analysis

Figure 3 shows that when the holding time is 2 min at 890 ℃, there are only two Al and Ti peaks, and no new phases are observed. When extending the holding time to 20 min, almost no Ti peak can be found. Beside the significant Al peaks, several Al3Ti peaks can be detected, and the most intensive peak is corresponded with Al3Ti (113) at 2θ=39.340°. This means that the titanium wires are totally transferred into Al3Ti, and no other intermetallic compounds such as Ti2Al5 and AlTi2 are formed.

Fig. 3 XRD patterns of composite coatings heated at 890 ℃ for different time

3.2 Microstructure

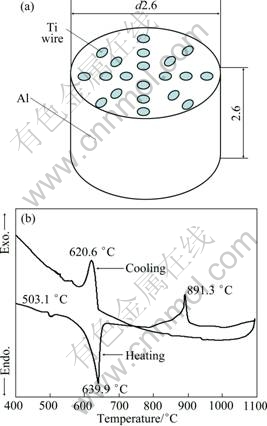

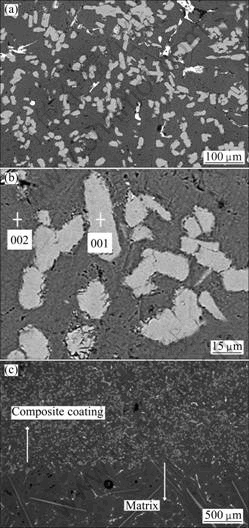

Figure 4(a) shows the back scattered electron image of the composite coating fabricated at 890 ℃ for 2 min, regardless of horizontal and vertical directions. The white sections (like as silkworm chrysalis) are uniformly embedded in the black sections, and the distance between both centers is 0.5 mm, which agrees with the scale of original mesh pores size. According to the area scanning results in Figs. 4(b) and (c), it is confirmed that the white sections are of Ti element and the black sections are of Al matrix. Based on the interface analysis (as shown in Fig. 4(d)), it can be detected that interface bonding between Al matrix and Ti wires is continuous and free of pores, indicating that no reactive products are formed when the holding time is short.

Fig. 4 SEM image of composite coating for 2 min (a), results of map scanning Ti (b) and Al (c), interface between Ti wire and Al matrix (d)

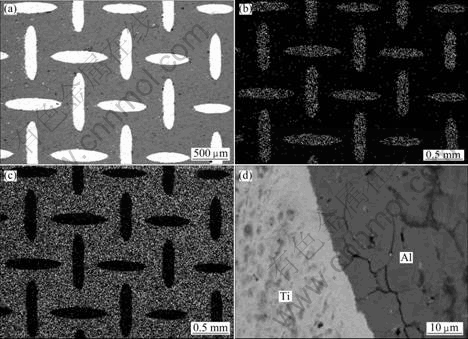

Figure 5(a) shows the microstructure of the composite coating heated at 890 ℃ for 10 min, the original regular arrangement for Ti wires can be still observed. Some reactive products present blocky and strip-like states around the white sections (see Fig. 5(b)). According to the EDS, the chemical compositions of point A are 24.79% Ti and 75.21% Al (mole fraction). It can be concluded that the reactive products should be intermetallic compound Al3Ti. The residual Ti wires can be found and are surrounded by Al3Ti particles in Al matrix, but these particles have agglomerated and are not dispersible.

Fig. 5 SEM images of composite coating heated at 10 min (a) and micro-zone (b)

With increasing the holding time to 20 min, microstructure of the composite coating has extremely changed, it is hardly acknowledged to the original distribution rule of Ti wires, and Ti wires are consumed completely and converted into a large number of white, which are uniformly distributed in the matrix shown in Fig. 6(a). To better explain the reaction, the chemical compositions of white particles (Fig. 6(b)) were analyzed by EDS to be 75.23%Al-24.77% Ti (mole fraction). It can be concluded that the particles are Al3Ti, which agrees with the analysis of XRD. However, Ti content of the matrix region between particles is 3.50% (mole fraction) and exceeds the solubility limit of Ti in Al which is about 2.0% (mole fraction). We can confirm the formation of the Al and Ti surpersaturated solid solution without the presence of Al3Ti particle, which is benefit to improve the microhardness of the matrix. It can be also deserved that the interface bonding between particles and matrix is metallurgical bonding. This kind of good cohesion interface can be explained by advantages of the in-situ method and the small lattice parameter mismatch between the Al3Ti particle and matrix [13].

Fig. 6 SEM images of in-situ Al3Ti composite coating heated at 890 ℃ for 20 min (a, b), and cross section of composite coating (c)

Figure 6(c) shows the cross-section microstructure of the composite coating at 890 ℃ for 20 min, and the thickness of the composite coating is about 1.5 mm. The micro-hardnesses of both matrix Al and reinforcement are HV0.1123 and HV0.1562, respectively. The microhardness of the latter is about 4.5 times that of the former, which is very beneficial to improve the wear resistance of the composite coating.

3.3 Friction and wear

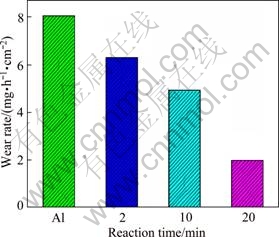

Friction coefficients for different specimens tested under 10 N are shown in Fig. 7 as a function of wear time. Through eliminating the initial sliding values, i.e. by ignoring the running in period, the average values for friction coefficients are calculated in the wide range of 0.4-1.1, and the lowest friction coefficient corresponds to the sample with 20 min. Wear rates for different samples are shown in Fig. 8, indicating that the wear rates decrease with increasing the reaction time. The wear resistance of the composite coating at 890 ℃ for 20 min is the best among all the tested specimens and is 4 times that of the matrix compared with sample.

Fig. 7 Friction coefficient of specimens heated at 890 ℃ for different time vs wear time under 10 N

Fig. 8 Wear rates of different specimens under 10 N

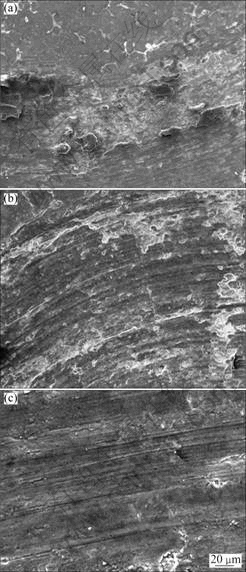

Figure 9(a) shows the worn morphology of the unreinforced Al matrix at 10 N, with many lamella spallings taking on the main recognizable features of the mass loss. Due to the fact that two contacted wear surfaces relatively move, and the points of contact coming from adherence and cold welding are clipped, the material transfers from one surface to another, causing the large mass loss. Therefore, the adhesive wear is the main mechanism for the unreinforced Al matrix. In terms of the composite coating heated at 890 ℃ for 20 min (Fig. 9(b)), the degree of lamella spallings decreases and some grooves can be observed, indicating that abrasive wear is formed and coexists with the adhesive wear. During the wear tests, due to the weak interface bonding between particles and matrix, a small amount of reinforced particles are pulled out from the composite coating and abrasive particles occur between two contacted surfaces, and micro-cutting to matrix arises. As far as the composite coating heated at 890 ℃ for 20 min, a large number of Al3Ti particles embedded homogeneously into Al matrix, as well as good metallurgical bonded with matrix. These particles can effectively act as load supporting elements and allow the less soft Al matrix to be involved in the wear process [13]. Therefore, the mass loss is low and the worn morphology (see Fig. 9(c)) is free of spallings and no delaminating. However, a few shallow, narrow ploughing grooves and squeezing traces are also presented in Fig. 9(c). The reason is that during dry sliding wear tests, Al matrix is displaced to both sides of the wear grooves, forming pile-ups which subsequent passes by the hard wear abrasion. The abrasive wear comes from two sources: parts of the Al3Ti particles detached from the alloy and the hard asperities on the surface of the counterpart steel [14]. Therefore, the abrasive wear plays a signification role in the material removement. In conclusion, the wear rates of the composite coatings decrease with increasing the reaction time, and their wear mechanisms change from the adhesive wear to abrasive wear [15].

Fig. 9 Worn morphologies of Al matrix at 10 N (a), and coatings heated at 890 ℃ for 10 min (b) and 20 min (c)

4 Conclusions

1) With the help of the differential thermal analysis (DTA) curve, the temperature of in-situ reaction between Ti wires and Al ingot is determined at 890 ℃.

2) Increasing the holding time at 890 ℃, the reaction amount of Ti wires and in-situ particles increase. When the holding time is 20 min, the titanium wires react completely and transform into Al3Ti particles, which present blocky and strip-like states.

3) The thickness of the composite coating is about 1.5 mm. The micro-hardness of reinforcement is HV0.1562, which is about 4.5 times that of matrix.

4) Compared with the unreinforced Al specimen, the composite coating prepared at 890 ℃ for 20 min offers a unique wear resistance behavior, and its wear mechanism is the coexistence of the adhesive and abrasive wear.

References

[1] CHEN Deng-bin, ZHAO Yu-tao, LI Gui-rong, ZHENG Meng, CHEN Gang. Effects of high intensity ultrasonic on microstructure and mechanism of in-situ Al3Ti/6070 composites [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1956-1961. (in Chinese)

[2] FERREIRA S C, SEQUEIRA P D, WATANABE Y, ARIZA E, ROCHA L A. Microstructural characterization and tribocorrosion behaviour of Al/Al3Ti and Al/Al3Zr FGMs [J]. Wear, 2011, 270: 806-814.

[3] HSU C J, KAO P W, HO N J. Intermetallic-reinforced aluminum matrix composites produced in situ by friction stir processing [J]. Mater Lett, 2007, 61: 1315-1318.

[4] TORRES B, LIEBLICH M, IBANEZ J, GARCLA ESCORIAL A. Mechanical properties of some PM aluminide and silicide reinforced 2124 aluminium matrix composites [J]. Scripta Mater, 2002, 47: 45-49.

[5] ALBITER A, CONTRERAS A, BEDOLLA E, PEREZ R. Structural and chemical characterization of precipitates in Al-2024/TiC composites [J].Composites A, 2003, 34: 17-24.

[6] NAYAKA S S, PABIA S K, MURTY B S. Al-(L12) Al3Ti nanocomposites prepared by mechanical alloying: Synthesis and mechanical properties [J]. Journal of Alloys and Compounds, 2010, 492: 128-133.

[7] KARABI D, NARNAWARE L K. A study of microstructure and tribological behaviour of Al–4.5% Cu/Al3Ti composites [J]. Materials Characterization, 2009, 60: 808-816.

[8] WATANABE Y, YAMANAKA N, FUKUI Y. Wear behavior of Al–Al3Ti composite manufactured by a centrifugal method [J]. Metall Mater Trans A, 1999, 30: 3253-3261.

[9] WATANABE Y, ERYU H, FUKUI Y. Anisotropy of wear resistance in Al–Al3Ti FGMs fabricated by a centrifugal method [J]. Ceramic Trans, 2001, 114: 675-682.

[10] PENG L M, LI Z, LI H, WANG J H, GONG M. Microstructural characterization and mechanical properties of TiAl–Al2Ti4C2–Al2O3– TiC in situ composites by hotpress-aided reaction synthesis [J]. Journal of Alloys and Compounds, 2006, 414: 100-106.

[11] PENG L M, WANG J H, LI H, ZHAO J H, HE L H. Synthesis and microstructural characterization of Ti-Al3Ti metal–intermetallic laminate (MIL) composites [J]. Scripta Materialia, 2005, 52: 243-248.

[12] FENG C F, FROYEN L. Formation of Al3Ti and Al2O3 from an Al-TiO2 system for preparing in situ aluminium matrix composites [J]. Composites A, 2000, 31: 385-390.

[13] SRINIVASAN S, DESCH P B, SCHWARZ R B. Metastable phases in the Al3X (X D Ti, Zr and Hf) intermetallic system [J]. Scripta Materialia, 1991, 25: 2513-2517.

[14] ALPAS A T, ZHANG J. Effect of microstructure (particle size and volume fraction) and counter face material on the sliding wear resistance of particulate reinforced aluminum matrix composite [J]. Met Mater Trans A, 1994, 25: 969-981.

[15] WU J M, LI Z Z. Contributions of the particulate reinforcement to dry sliding wear resistance of rapidly solidified Al-Ti alloys [J]. Wear, 2000, 244: 147-153.

原位合成Al3Ti颗粒增强铝基复合涂层

牛立斌,张菊梅, 杨小兰

西安科技大学 材料科学与工程学院,西安 710055

摘 要:以直径200 μm、纯度99.5%的钛丝丝网为反应源,通过熔渗-原位反应法制备一种Al3Ti金属间化合物颗粒增强铝基表面复合涂层。差热分析结果表明,在890 ℃下,Ti丝和Al熔体间发生反应。采用XRD、SEM以及显微硬度和磨损测试对所得到的复合涂层进行表征。结果表明:当保温时间为20 min时,钛丝反应完全,原位合成为块状和条状的Al3Ti颗粒; 颗粒的显微硬度大约为基体显微硬度的4.5倍;在载荷10 N的干滑动磨损条件下,与没有增强的Al基体相比较,保温20 min所制备的复合涂层表现出较好的耐磨性,其磨损机制为粘着磨损和磨粒磨损共存。

关键词:金属间化合物;原位反应;复合涂层;耐磨性

(Edited by LI Xiang-qun)

Foundation item: Project (11JK0799) supported by Scientific Research Program Funded by Shaanxi Provincial Education Department, China; Project (KTCQ1-17) supported by Scientific and Technological Innovation and Co-ordination Funded by Science and Technology Department of Shaanxi Province, China

Corresponding author: NIU Li-bin; Tel: +86-29-85587373; E-mail: libinniu1123@yahoo.com.cn

DOI: 10.1016/S1003-6326(11)61330-7