DOI: 10.11817/j.issn.1672-7207.2020.11.021

Zr和Cr掺杂TiAlN涂层结构、力学和高温性能研究

刘慧君1, 2,胡春1, 2,刘喆人1,陈利1, 2

(1. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

2. 株洲钻石切削刀具股份有限公司,湖南 株洲,412007)

摘要:采用阴极弧蒸发方法制备Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层,并借助配备X射线能量色散谱仪(EDX)的扫描电子显微镜(SEM)、X射线衍射仪(XRD)、差示扫描量热仪(DSC)和纳米压痕仪对比研究了Zr和Cr掺杂对TiAlN涂层结构、力学和高温性能的影响。研究结果表明:Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层均为单相面心立方结构,其硬度分别为(28.6±0.9) GPa、(31.9±0.9) GPa和(31.0±0.7) GPa;Zr的添加提高了TiAlN涂层的热稳定性,而Cr的添加降低了TiAlN涂层的热稳定性;在800 ℃氧化30 h,Zr降低了TiAlN涂层的抗氧化性能,Cr提高了TiAlN涂层的抗氧化性能;然而,在850 ℃氧化30 h,Ti0.45Al0.48Zr0.07N涂层却表现出最好的抗氧化性能。

关键词:TiAlN基涂层;硬度;热稳定性;抗氧化性能

中图分类号:TB32 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3178-09

Research on structure, mechanical and high-temperature properties of Zr and Cr doped TiAlN coatings

LIU Huijun1, 2, HU Chun1, 2, LIU Zheren1, CHEN Li1, 2

(1. State Key laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Zhuzhou Cemented Carbide Cutting Tools Co., Ltd., Zhuzhou 412007, China)

Abstract: The arc evaporated Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N, and Ti0.45Al0.49Cr0.06N coatings were characterized by scanning electron microscope(SEM) equipped with energy dispersive X-ray detector(EDX), X-ray diffraction(XRD), differential scanning calorimetry(DSC). The influence of Zr-addition and Cr-addition on structure, mechanical and high-temperature properties of TiAlN coatings was investigated by nanoindentation. The results show that all as-deposited coatings show a single-phase face-centered cubic structure. Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N, and Ti0.45Al0.49Cr0.06N coatings reveal hardness of (28.6±0.9) GPa, (31.9±0.9) GPa, and (31.0±0.7) GPa, respectively. Additionally, the addition of Zr improves the thermal stability of TiAlN coating whereas the addition of Cr gives rise to a contrary effect. Moreover, the results of 30 h isothermal oxidation at 800 ℃ reveal that the oxidation resistance of TiAlN coatings is weakened by Zr-addition while enhanced by Cr-addition. However, when the isothermal oxidation temperature is elevated to 850 ℃, Zr-doped coating presents the best oxidation resistance.

Key words: TiAlN based coatings; hardness; thermal stability; oxidation resistance

高速切削和干式切削由于可大幅度提高加工效率和加工质量,成为现代切削加工技术的重要发展趋势。刀具表面涂层技术的发展与应用对改善刀具性能和推动切削加工技术的进步具有十分关键的作用。涂层刀具结合了表面涂层高耐磨性、高热性能和基体高韧性、高强度的优点,有效解决了刀具材料的硬度和强度之间的矛盾,成为现代切削刀具发展的重要方向。TiAlN涂层具有高硬度、高熔点、时效硬化效应和高的热稳定性等优良性能,是目前应用最为普遍的切削刀具涂层材料之一。TiAlN涂层是由Al原子替换TiN中部分Ti原子形成的亚稳固溶体,其晶体结构和性能很大程度取决于Al含量[1-7]。当Al含量低于其在TiN中的固溶度时,涂层保持立方结构(c),力学和抗氧化性能随Al含量增加而提高;但当Al含量超过其在TiN中的固溶度,涂层由单相立方向立方和六方(w)的两相结构转变,性能下降。TiAlN涂层在高于800 ℃时发生调幅分解生成亚稳的富Ti立方相c-Ti(Al)N和富Al立方相c-Al(Ti)N而产生时效硬化现象,但高于1 000 ℃时上述亚稳相又会向其稳定相c-TiN和w-AlN转变,导致涂层力学性能下降。此外,TiAlN涂层的抗氧化温度较低,约为800 ℃[1]。随着高速干式切削加工技术的发展,刀具刃口的温度可能达到1 000 ℃以上,超过了TiAlN涂层的服役温度。

近年来,在TiAlN涂层中添加合金元素以改善其性能成为刀具涂层的重点研究方向之一。如添加Ta[8-11],Nb[12-13],Zr[14-17]和Hf[18]提高了TiAlN涂层的硬度、热稳定性和高温抗氧化性能;添加Cr改善了TiAlN涂层的抗氧化性能[19-20];TiAlMoN[21]和TiAlVN[22-23]涂层在高温时会形成氧化物润滑相而表现出自润滑效应。同时,研究者尝试添加多组元协同提升TiAlN涂层性能。如ASANUMA等[24]研究表明:La和B的加入可以显著提升TiAlN涂层的硬度和高温性能。在TiAlTaN涂层中添加Cr和Ce可提升其热稳定性和抗氧化性能[25]。其中,Zr和Cr掺杂的TiAlN涂层因其优异性能而受到较多关注,并逐渐在切削刀具上得到应用。然而,TiAlZrN和TiAlCrN涂层的力学和高温性能优劣尚缺乏深入认识。

在此,本文作者采用阴极弧蒸发方法制备Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层,对比研究Zr和Cr掺杂对TiAlN涂层结构、力学和高温性能的影响。

1 实验方法

1.1 涂层制备

采用Balzers公司生产的型号为INNOVA的阴极弧蒸发设备制备TiAlN,TiAlZrN和TiAlCrN涂层,对应的靶材分别为Ti0.50Al0.50,Ti0.40Al0.55Zr0.05和Ti0.40Al0.55Cr0.05。根据不同的检测需求选用多种基体材料:抛光的硬质合金片用于涂层的表面和断口形貌及成分分析,低合金钢箔片用于涂层沉积态、退火和氧化后的相结构分析,抛光的W片用于涂层沉积态和退火后的硬度分析,多晶Al2O3片用于涂层的抗氧化性能分析。涂层制备沉积参数如下:沉积温度为500 ℃、靶材电流为180 A、N2压强为3.2 Pa、基体偏压为-40 V。

1.2 热处理

将沉积涂层的低合金钢箔片置于10%(体积分数)的稀硝酸溶液中腐蚀基体材料,然后将过滤得到的涂层材料研磨获得涂层粉末样品。采用差示扫描量热仪(DSC,Netzsch STA409C)对涂层粉末样品进行退火和氧化处理:分别于Ar气(20 mL/min,纯度为99.99%)或合成空气(20 mL/min,79% N2和21% O2(体积分数))气氛中以10 K/min的升温速率升到目标温度,随后以50 K/min的冷却速率降至室温。将涂层后的刚玉片置于DSC设备中,于合成空气中以10 K/min的升温速率分别升温至800 ℃和850 ℃保温30 h,随后以50 K/min的冷却速率降至室温。

将沉积涂层的钨片置于真空炉(COD533R,真空度≤0.1 mPa)进行退火处理:以5 K/min的速率升温至目标温度(800,900,1 000,1 100和1 200 ℃)后保温30 min,然后随炉冷却至室温。

1.3 结构及性能表征

采用X射线衍射仪(XRD,Bruker D8 Advance)分析沉积态、退火后和氧化后粉末样品的相结构;采用配有X射线能量色散谱仪(EDX)的扫描电镜(SEM,Zeiss Supra 55)分析涂层沉积态和氧化后的涂层成分及断口截面形貌;采用纳米压痕仪(NHT2,CSM)测量涂层沉积态和退火后的硬度和模量。

2 结果与分析

2.1 涂层结构与力学性能

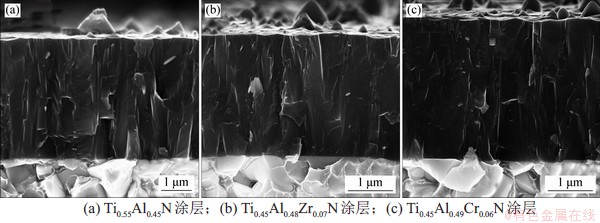

EDX测得3种涂层的成分分别为Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N,其中金属元素和氮元素的原子比约为1:1。涂层在沉积过程中,各原子的离化率、散射程度和再溅射程度不同,导致涂层成分与对应的靶材成分略有差异[26]。图1所示为Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层粉末样品的XRD图谱和点阵常数。可见,3种涂层均为单相面心立方结构,表明Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层为Zr和Cr原子取代TiAlN涂层的Ti或Al原子形成的置换固溶体。因此,Ti,Zr,Cr和Al原子半径的差异引起涂层点阵常数的变化,Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的点阵常数分别为(4.181±0.004)×10-10,(4.201±0.004)×10-10和(4.167±0.003)×10-10 m。图2所示为Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的断口截面形貌,可见:3种涂层均呈现结晶状况良好的柱状晶形貌。

图1 Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的XRD图谱和点阵常数

Fig. 1 XRD patterns and lattice constant of Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N, and Ti0.45Al0.49Cr0.06N coatings

图2 沉积态Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的横断面SEM形貌

Fig. 2 Fractured cross-section SEM images of as-deposited Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N and Ti0.45Al0.49Cr0.06N coatings

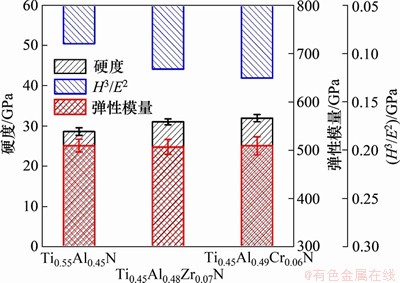

图3所示为沉积态Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的硬度H、弹性模量E及H3/E2。Ti0.55Al0.45N涂层的硬度为(28.6±0.9) GPa,Zr和Cr掺杂引起的固溶强化使Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的硬度分别增加至(31.9±0.9) GPa和(31.0±0.7) GPa。Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的弹性模量没有明显差异,分别为(509.2±13.2) GPa,(506.5±15.4) GPa和(508.8±18.7) GPa。H3/E2与材料的屈服应力成正比,可用来评价材料抵抗塑性变形能力[27]。Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的H3/E2分别为0.091,0.152和0.126 GPa,表明Zr和Cr的添加提高了涂层的抗塑性变形能力,即Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层具有更高的断裂韧性。

图3 沉积态Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N的硬度、弹性模量和H3/E2

Fig. 3 Hardness, elastic modulus and H3/E2 of as-deposited Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N, and Ti0.45Al0.49Cr0.06N coatings

2.2 涂层热稳定性

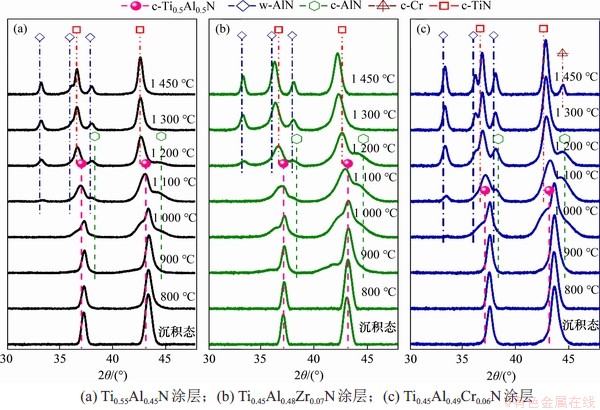

图4所示为Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层粉末样品在Ar保护气氛下经不同温度(800~1 450 ℃)退火后的XRD图谱。由图4(a)可见:Ti0.55Al0.45N在800 ℃退火后仅发生回复过程,涂层的衍射峰略微向高角度偏移。退火温度升高至900 ℃和1 000 ℃,涂层发生调幅分解生成富Ti和富Al立方亚稳相,分别对应于衍射峰左、右肩峰。退火温度升至1 100 ℃和1 200 ℃,调幅分解继续进行;此外,调幅分解产物富Al立方相向其稳定相w-AlN转变。退火温度上升至1 300 ℃和1 450 ℃时,涂层完全转变为其对应的稳定相c-TiN和w-AlN。由图4(b)可见,Ti0.45Al0.48Zr0.07N涂层的热分解趋势与Ti0.55Al0.45N涂层相似。在900~ 1 200 ℃温度区间退火,涂层发生调幅分解;但Zr掺杂抑制了调幅分解生成的亚稳相向其稳定相转变,在1 200 ℃退火后才观察到w-AlN的生成。在1 300 ℃和1 450 ℃退火后,涂层完全转变为其稳定相,未观察到Zr及含Zr化合物的生成。特别是在1 450 ℃退火后,涂层的立方相分解产物的衍射峰较标准c-TiN向低角度方向偏移,表明Zr以固溶形式存在于TiN中,Ti0.45Al0.48Zr0.07N涂层的最终分解产物为c-Ti(Zr)N和w-AlN。Ti0.45Al0.49Cr0.06N涂层在900~1 200 ℃温度区间退火后同样发生调幅分解(图4(c))。但Ti0.45Al0.49Cr0.06N涂层在1 000 ℃退火后,便可在2θ=33.5°处观察到微弱的w-AlN衍射峰,表明Cr的添加促进了调幅分解生成的亚稳相产物向其稳定相转变。在1 300 ℃退火后,调幅分解结束,分解产物为c-Ti(Cr)N及w-AlN。继续增加退火温度至1 450 ℃,c-Ti(Cr)N中不稳定的Cr—N键断裂生成bcc-Cr和N2;此时,立方相的衍射峰较标准c-TiN向高角度方向偏移,表明仍有部分Cr原子以固溶形式存在于TiN中,涂层的分解产物为c-Ti(Cr)N,w-AlN和bcc-Cr。

图4 Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在不同温度下退火后的XRD图谱

Fig. 4 XRD patterns of Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N and Ti0.45Al0.49Cr0.06N coatings after annealing at given temperatures

一般以力学性能较差的w-AlN出现时的温度来衡量TiAlN基涂层的热稳定性。基于上述退火XRD图谱可知:Zr的添加使w-AlN的形成温度由Ti0.55Al0.45N涂层的1 100 ℃上升到Ti0.45Al0.48Zr0.07N涂层的1 200 ℃,提高了TiAlN涂层的热稳定性;而Cr的添加使w-AlN的形成温度降低至1 000 ℃,降低了TiAlN涂层的热稳定性。

图5所示为沉积在W片上的Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在800~ 1 200 ℃于真空退火后的硬度变化曲线。在800 ℃退火后,涂层发生调幅分解,生成的富Ti、富Al立方相与涂层之间形成大量的共格界面,界面间存在错配应力场阻碍了位错运动,从而使Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的硬度分别上升至(32.4±0.9) GPa,(33.5±1.1) GPa和(33.2±0.8) GPa。在900 ℃退火后,Ti0.55Al0.45N和Ti0.45Al0.48Zr0.07N涂层的硬度继续增加至(32.8±1.0) GPa和(34.0±1.0) GPa;而热稳定性较低的Ti0.45Al0.49Cr0.06N涂层的硬度降低至(32.6±0.9) GPa。在1 000 ℃退火后,Ti0.55Al0.45N涂层的硬度也开始降低,为(31.0±0.7) GPa,而热稳定性最好的Ti0.45Al0.48Zr0.07N涂层的硬度持续升高至(34.2±0.6) GPa。退火温度上升至1 100 ℃后,Ti0.45Al0.48Zr0.07N涂层开始下降至(31.2±0.3) GPa,Ti0.55Al0.45N和Ti0.45Al0.49Cr0.06N涂层的硬度分别降至(30.6±0.9) GPa和(30.8±1.1) GPa。最终在1 200 ℃退火后,Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层的硬度分别为(27.7±0.7) GPa,(31.0±0.7) GPa和(26.9±0.9) GPa,其中,Ti0.45Al0.49Cr0.06N涂层由于Cr—N键断裂生成bcc-Cr,其硬度降幅最大。

图5 Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在不同温度下退火后的硬度

Fig. 5 Hardness of Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N, and Ti0.45Al0.49Cr0.06N coatings after annealing at different temperatures

2.3 涂层抗氧化性能

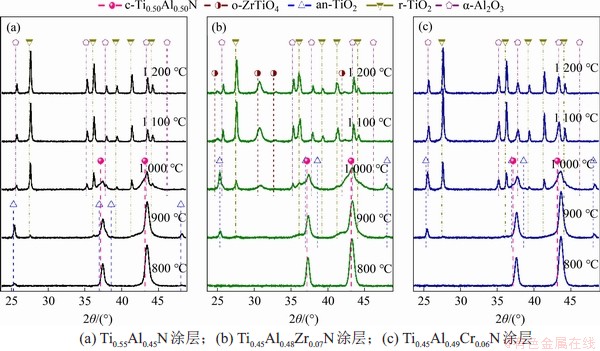

图6所示为Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层粉末在合成空气气氛中于800,900,1 000,1 100和1 200 ℃氧化后的XRD图谱。由图6(a)可见,Ti0.55Al0.45N涂层在800 ℃已开始氧化,生成亚稳相的锐钛矿an-TiO2。氧化温度上升至900 ℃,an-TiO2的衍射峰的强度增加,且生成的亚稳相an-TiO2开始向其稳定相金红石型r-TiO2转变。在1 000 ℃氧化后,an-TiO2的衍射峰消失,r-TiO2衍射峰的强度增加,表明an-TiO2已完全转变为r-TiO2;同时,涂层中的Al开始氧化生成刚玉型α-Al2O3。氧化温度上升至1 100 ℃和 1 200 ℃,涂层完全氧化成r-TiO2和α-Al2O3。由图6(b)可见,Ti0.45Al0.48Zr0.07N在900 ℃才开始氧化生成an-TiO2和r-TiO2。在1 000 ℃氧化后,Ti0.45Al0.48Zr0.07N仍可观察到an-TiO2,表明Zr的添加抑制了亚稳相an-TiO2向其稳定相r-TiO2转变;除了氧化物an-TiO2,r-TiO2和α-Al2O3外,还可观察到ZrTiO4的生成。氧化温度上升至1 100 ℃和1 200 ℃,an-TiO2转变为r-TiO2,涂层完全氧化为r-TiO2,α-Al2O3和ZrTiO4。与Ti0.45Al0.48Zr0.07N涂层相似,Ti0.45Al0.49Cr0.06N涂层在900 ℃才开始氧化生成an-TiO2和r-TiO2 (图6(c))。Cr的添加也抑制了an-TiO2向r-TiO2转变,在1 000 ℃氧化后仍可观察到an-TiO2,但其抑制效果不如Zr元素,Ti0.45Al0.49Cr0.06N中r-TiO2的含量明显比Ti0.45Al0.48Zr0.07N涂层的多;此时,生成的氧化物为an-TiO2,r-TiO2和α-Al2O3。同样,在1 100 ℃和 1 200 ℃氧化后,涂层完全氧化为r-TiO2和α-Al2O3。与Ti0.45Al0.48Zr0.07N涂层不同,在Ti0.45Al0.49Cr0.06N涂层的整个氧化阶段,观察不到含Cr氧化物的生成。基于以上分析,Ti0.55Al0.45N在800 ℃已开始氧化,而Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N在900 ℃才开始氧化,表明Zr和Cr的添加改善了TiAlN涂层的抗氧化性能;另外,Zr和Cr掺杂抑制了氧化过程中亚稳相an-TiO2向其稳定相r-TiO2转变,相较而言,Zr的抑制效果优于Cr的抑制效果,但Zr在氧化早期会形成氧化物ZrTiO4。

图6 Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层粉末不同温度氧化后的XRD图谱

Fig. 6 XRD patterns of Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N and Ti0.45Al0.49Cr0.06N coatings after oxidation at different temperatures

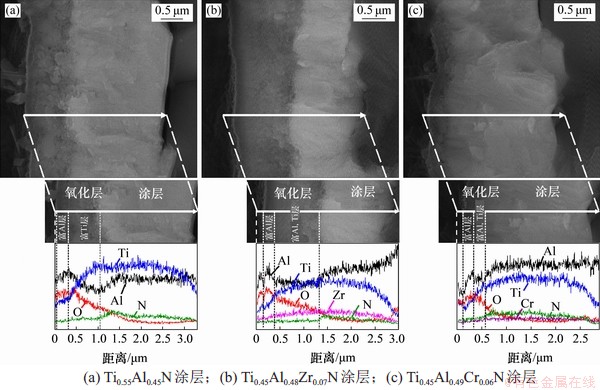

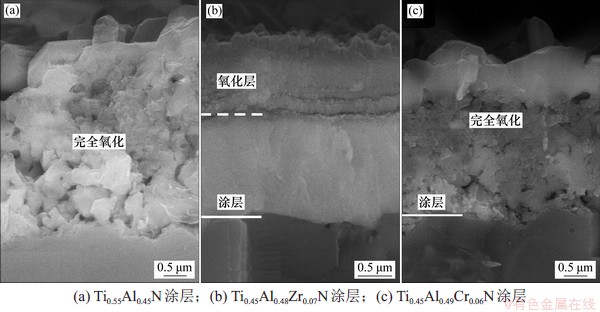

TiAlN涂层的氧化过程分为3个阶段[25,28]:首先,与O原子亲和性更好的Al原子向外扩散,在涂层表面形成致密的富Al氧化层,阻止氧化扩散过程的进一步进行而保护涂层;其次,O原子向涂层内部扩散与Ti反应形成富Ti氧化层,氧化层转变为致密的富Al氧化外层和富Ti氧化内层的双层结构;最后,氧化过程加剧,富Ti氧化内层生长、尤其是an-TiO2向其稳定相r-TiO2转变引起体积膨胀[29],破坏表面富Al氧化保护层。图7所示为沉积于多晶Al2O3基体上的Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在合成空气气氛中于800 ℃氧化30 h后的断口截面形貌和能谱线扫描数据。由图7(a)可见,Ti0.55Al0.45N涂层在800 ℃氧化30 h后进入了氧化过程的第二阶段,形成了表面富Al致密层和内部富Ti疏松层的双层氧化层,厚度约1.01 μm。同样,Ti0.45Al0.48Zr0.07N涂层的氧化层也为表面富Al和内部富Ti的双层结构(图7(b))。由于Zr的添加抑制了an-TiO2向r-TiO2转变,降低了因此而产生的体积膨胀,Ti0.45Al0.48Zr0.07N涂层中的富Ti氧化内层的结构较Ti0.55Al0.45N涂层更为致密。然而,在该温度下,Ti0.45Al0.48Zr0.07N涂层的氧化层厚度反而增加至约1.26 μm,这可能是因为ZrTiO4氧化物的生成加剧了氧化过程。由图7(c)可见,Ti0.45Al0.49Cr0.06N涂层具有最好的抗氧化性能,氧化层的厚度仅0.33 μm左右,其结构为表面富Al和内部富Ti的双层结构。图8所示为沉积于多晶Al2O3基体上的Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在合成空气气氛中于850 ℃氧化30 h后的断口截面形貌。由图8可见,Ti0.55Al0.45N和Ti0.45Al0.49Cr0.06N已完全氧化;而Ti0.45Al0.48Zr0.07N涂层尚未完全氧化,反而呈现最好的抗氧化性能。

图7 Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在800 °C等温下氧化30 h后的横断面SEM形貌和EDX

Fig. 7 Fractured cross-section SEM images and EDX of Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N and Ti0.45Al0.49Cr0.06N coatings after isothermal oxidation at 800 °C for 30 h

图8 Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在850 °C等温氧化30 h后的横断面SEM形貌

Fig. 8 Fractured cross-section SEM images of Ti0.55Al0.45N, Ti0.45Al0.48Zr0.07N, and Ti0.45Al0.49Cr0.06N coatings after isothermal oxidation at 850 °C for 30 h

从以上分析可知,Cr添加提高了TiAlN涂层的起始氧化温度且抑制了氧化过程中an-TiO2向r-TiO2转变,从而改善其抗氧化性能,并在800 ℃氧化后呈现最好的抗氧化性能。同样,Zr添加也通过提高起始氧化温度和抑制an-TiO2向r-TiO2转变而有益于TiAlN涂层的抗氧化性能,但氧化物ZrTiO4的形成却会降低其抗氧化性能;因此,Zr对TiAlN涂层抗氧化性能的影响是上述2个因素综合作用的结果。Ti0.45Al0.48Zr0.07N涂层在800 ℃氧化后,因氧化物ZrTiO4的形成作用较强,其抗氧化性变差;而在850 ℃氧化后,前者占优,其抗氧化性能得到改善。另外,与Cr相比,Zr抑制an-TiO2向r-TiO2转变作用更优,Ti0.45Al0.48Zr0.07N涂层在850 ℃的抗氧化性能反而比Ti0.45Al0.49Cr0.06N涂层的更优。

3 结论

1) Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层均为面心立方结构,其硬度分别为(28.6±0.9) GPa,(31.9±0.9) GPa和(31.0±0.7) GPa;Zr和Cr的添加提高了涂层的断裂韧性。

2) Ti0.55Al0.45N,Ti0.45Al0.48Zr0.07N和Ti0.45Al0.49Cr0.06N涂层在退火过程中发生调幅分解而呈现时效硬化,Ti0.55Al0.45N在900 ℃达到峰值硬度(32.8±1.0) GPa;Zr的添加提高了TiAlN涂层的热稳定性,在1 000 ℃才达到峰值硬度(34.2±0.6) GPa;而Cr的添加降低了TiAlN涂层的热稳定性,在800 ℃便达到峰值硬度(33.2±0.8) GPa。

3) 在800 ℃氧化30 h后,Ti0.55Al0.45N和Ti0.45Al0.49Cr0.06N涂层的氧化层分别约为1.01 μm和0.33 μm,而Ti0.45Al0.48Zr0.07N涂层的抗氧化性能因氧化物ZrTiO4的形成而降低,氧化层的厚度约为1.26 μm;850 ℃氧化30 h后,Ti0.55Al0.45N和Ti0.45Al0.49Cr0.06N涂层均完全氧化,而Zr具有更强的抑制an-TiO2向r-TiO2转变作用,Ti0.45Al0.48Zr0.07N涂层反而呈现最好的抗氧化性能。

参考文献:

[1] CHEN Li, PAULITSCH J, DU Yong, et al. Thermal stability and oxidation resistance of Ti-Al-N coatings[J]. Surface and Coatings Technology, 2012, 206(11/12): 2954-2960.

[2] HORLING A, HULTMAN L, ODEN M, et al. Mechanical properties and machining performance of Ti1-xAlxN-coated cutting tools[J]. Surface and Coatings Technology, 2005, 191(2/3): 384-392.

[3] ZHOU Jingjing, ZHONG J, CHEN L, et al. Phase equilibria, thermodynamics and microstructure simulation of metastable spinodal decomposition in c-Ti1-xAlxN coatings[J]. Calphad, 2017, 56: 92-101.

[4] MCINTYRE D, GREENE J E, HAKANSSON G, et al. Oxidation of metastable single-phase polycrystalline Ti0.5Al0.5N films: Kinetics and mechanisms[J]. Journal of Applied Physics, 1990, 67(3): 1542-1553.

[5] MAYRHOFER P H, FISCHER F D, BOHM H J, et al. Energetic balance and kinetics for the decomposition of supersaturated Ti1-xAlxN[J]. Acta Materialia, 2007, 55(4): 1441-1446.

[6] MAYRHOFER P H, HORLING A, KARLSSON L, et al. Self-organized nanostructures in the Ti-Al-N system[J]. Applied Physics Letters, 2003, 83(10): 2049-2051.

[7] ELMKHAH H, ZHANG T F, ABDOLLAH-ZADEH A, et al. Surface characteristics for the TiAlN coatings deposited by high power impulse magnetron sputtering technique at the different bias voltages[J]. Journal of Alloys and Compounds, 2016, 688: 820-827.

[8] KOLLER C M, GLATZ S A, RIEDL H, et al. Structure and mechanical properties of architecturally designed Ti-Al-N and Ti-Al-Ta-N based multilayers[J]. Surface and Coatings Technology, 2020, 385: 125355.

[9] SEIDL W M, BARTOSIK M, KOLOZSVARI S, et al. Improved mechanical properties, thermal stabilities, and oxidation resistance of arc evaporated Ti-Al-N coatings through alloying with Ta[J]. Surface and Coatings Technology, 2018, 344: 244-249.

[10] YANG Y, XU Y X, CHEN L, et al. Improved Ti-Al-N coatings through Ta alloying and multilayer architecture[J]. Surface and Coatings Technology, 2017, 328: 428-435.

[11] RACHBAUER R, HOLEC D, MAYRHOFER P H. Increased thermal stability of Ti-Al-N thin films by Ta alloying[J]. Surface and Coatings Technology, 2012, 211: 98-103.

[12] MAYRHOFER P H, RACHBAUER R, HOLEC D. Influence of Nb on the phase stability of Ti-Al-N[J]. Scripta Materialia, 2010, 63(8): 807-810.

[13] 刘慧君, 吴明晶, 王社权. Nb添加对TiAlN涂层结构、力学和热性能的影响[J]. 硬质合金, 2019, 36(3): 184-191.

LIU Huijun, WU Mingjing, WANG Shequan. Effect of Nb-addition on the structure, mechanical and thermal properties of Ti-Al-N coating[J]. Cemented Carbide, 2019, 36(3): 184-191.

[14] ATTARI V, CRUZADO A, ARROYAVE R. Exploration of the microstructure space in Ti-Al-Zr-N ultra-hard nanostructured coatings[J]. Acta Materialia, 2019, 174: 459-476.

[15] GLATZ S A, HOLLERWEGER R, POLCIK P, et al. Thermal stability and mechanical properties of arc evaporated Ti-Al-Zr-N hard coatings[J]. Surface and Coatings Technology, 2015, 266: 1-9.

[16] YANG B, CHEN L, XU Y X, et al. Effect of Zr on structure and properties of Ti-Al-N coatings with varied bias[J]. International Journal of Refractory Metals and Hard Materials, 2013, 38: 81-86.

[17] CHEN L, HOLEC D, DU Y, et al. Influence of Zr on structure, mechanical and thermal properties of Ti-Al-N[J]. Thin Solid Films, 2011, 519(16): 5503-5510.

[18] FENG Changjie, ZHU Shenglong, LI Mingsheng, et al. Effects of incorporation of Si or Hf on the microstructure and mechanical properties of Ti-Al-N films prepared by arc ion plating(AIP)[J]. Surface and Coatings Technology, 2008, 202(14): 3257-3262.

[19] DANEK M, FERNANDES F, CAVALEIRO A, et al. Influence of Cr additions on the structure and oxidation resistance of multilayered Ti-Al-Cr-N films[J]. Surface and Coatings Technology, 2017, 313: 158-167.

[20] 程立军, 宋庆功. 磁控溅射制备TiAlCrN硬质薄膜及其抗腐蚀性能[J]. 材料保护, 2009, 42(9): 16-18, 84.

CHENG Lijun, SONG Qinggong. Preparation of Ti-Al-Cr-N hard coatings by reactive magnetron co-sputtering and their corrosion resistance[J]. Materials Protection, 2009, 42(9): 16-18, 84.

[21] GLATZ S A, KOLLER C M, BOLVARDI H, et al. Influence of Mo on the structure and the tribomechanical properties of arc evaporated Ti-Al-N[J]. Surface and Coatings Technology, 2017, 311: 330-336.

[22] XU Y X, CHEN L, PEI F, et al. Thermal stability and oxidation resistance of V-alloyed Ti-Al-N coatings[J]. Ceramics International, 2018, 44(2): 1705-1710.

[23] TILLMANN W, MOMENI S, HOFFMANN F. A study of mechanical and tribological properties of self-lubricating Ti-Al-V-N coatings at elevated temperatures[J]. Tribology International, 2013, 66: 324-329.

[24] ASANUMA H, KLIMASHIN F F, POLCIK P, et al. Impact of lanthanum and boron on the growth, thermomechanical properties and oxidation resistance of Ti-Al-N thin films[J]. Thin Solid Films, 2019, 688: 137239.

[25] PENG Bin, LI Haiqing, ZHANG Quan, et al. High-temperature thermal stability and oxidation resistance of Cr and Ta co-alloyed Ti-Al-N coatings deposited by cathodic arc evaporation[J]. Corrosion Science, 2020, 167: 108490.

[26] ERIKSSON A O, ZHU J Q, GHAFOOR N, et al. Layer formation by resputtering in Ti-Si-C hard coatings during large scale cathodic arc deposition[J]. Surface and Coatings Technology, 2011, 205(15): 3923-3930.

[27] CHEN Xinjie, DU Y, CHUNG Y W. Commentary on using H/E and H3/E2 as proxies for fracture toughness of hard coatings[J]. Thin Solid Films, 2019, 688: 137265.

[28] XU Y X, CHEN L, PEI F, et al. Influence of Hf on the structure, thermal stability and oxidation resistance of Ti-Al-N coatings[J]. Thin Solid Films, 2014, 565: 25-31.

[29] HOLLERWEGER R, RIEDL H, ARNDT M, et al. Guidelines for increasing the oxidation resistance of Ti-Al-N based coatings[J]. Thin Solid Films, 2019, 688: 137290.

(编辑 赵俊)

收稿日期: 2020 -09 -09; 修回日期: 2020 -09 -16

基金项目(Foundation item):国家自然科学基金资助项目(51775560) (Project(51775560) supported by the National Natural Science Foundation of China)

通信作者:陈利,博士,教授,从事物理气相沉积、硬质耐磨涂层研究;E-mail: chenli_927@126.com