文章编号:1004-0609(2007)06-0897-06

TiAlN涂层的热残余应力分析

黄自谦1,贺跃辉1,蔡海涛2,肖逸锋1, 3,黄伯云1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 数学科学与计算技术学院,长沙 410083;

3. 湘潭大学 机械工程学院,湘潭 411105)

摘 要:采用有限元方法分析氮铝钛涂层的残余热应力,研究不同的基体及过渡层对残余热应力分布的影响。结果表明:当基体为硬质合金时,涂层内以拉应力为主,而基体为不锈钢时,涂层内以压应力为主;增加过渡层可以使涂层内的残余应力减少40%以上;硬质合金基体中涂层的拉应力随基体钴含量和涂层厚度的增加而减少;无过渡层时,不锈钢基体存在明显的塑性约束区,有过渡层时,随着界面应力的减少,塑性约束区明显减小或消失。因此,通过不同的涂层和基体搭配可以改善应力场,同时增加过渡层可以缓和界面应力和增强界面结合力。

关键词:TiAlN涂层;有限元方法;残余应力;过渡层

中图分类号:TF 124.5 文献标识码:A

Thermal residual stress analysis of TiAlN coating

HUANG Zi-qian1, HE Yue-hui1, CAI Hai-tao2, XIAO Yi-feng1, HUANG Bai-yun1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Mathematical Science and Computing Technology, Central South University, Changsha 410083, China;

3. College of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China)

Abstract: Thermal residual stresses in TiAlN coatings were calculated using the finite element method. Effects of different substrates and interlayer bonding on residual stress field were investigated. The results show that the high tensile stress occurs in TiAlN coating as the substrate is cemented carbide and the high compressive stress occurs as the substrate is stainless steel. The composites show a decrease of 40% in interface shear stress when the composites has a interlayer. The tensile stress in coating layer decreases with increasing coating thickness and cobalt content of cemented carbide substrate. Without interlayer, plastic constraint zone develops distinctly in stainless steel substrate, but the plastic constraint zone decreases greatly even disappears when there is a transition layer. Residual stress distribution can be improved by varying the coating thickness or selecting different substrates.

Key words: TiAlN coating; finite element method; thermal residual stresses; interlayer

硬质涂层技术的出现被认为是切削和耐磨工具的一次革命,经过几十年的发展,硬质涂层的研究仍然是方兴未艾,而且新的技术和方法不断产生[1?3]。就耐磨损涂层而言,初期开发了TiN涂层,然后开发出TiC和TiCN涂层[4?6],近来出现的TiAlN涂层引起了研究者更大的兴趣[7?8]。相对于TiN涂层,TiAlN涂层具有更高的硬度、更好的耐磨性和高温抗氧化性能,有取代TiN涂层的趋势。涂层技术的一个重要问题就是基体和涂层的结合强度,产生这个问题的主要原因是基体和涂层热膨胀系数的差异。材料由热处理温度下降到室温时,不均匀的热收缩导致了界面剪切残余热应力的产生。涂层中压缩残余应力的存在,在一定程度上对改善材料的性能有利,如增加断裂强度和抗磨损性能,从而提高材料的疲劳寿命。然而,材料中的拉伸残余应力却极具破坏性,常常导致涂层中裂纹的产生甚至引起材料的失效。因此,降低基体与涂层间的热应力,提高结合强度是涂层技术的一个主要问题。

为了降低界面剪切应力和提高涂层与基体的结合强度,主要方法有采用过渡层、复合涂层或梯度涂层技术 [9?11]。本文作者研究了硬质合金和不锈钢两种基体TiAlN涂层的热残余应力分布,同时引进TiAl和AlN过渡层,比较了不同基体应力场的分布和有无过渡层时应力分布。

残余应力的分析方法很多,一般来说,可分为有损测量和无损测量两类。有损测量是指采用打孔、挖块,剥层方法测量应变,再计算应力;无损测量是指采用X射线衍射和中子衍射等方法[12?15],测量晶格常数的变化,再计算应变和应力。对硬质合金来说,由于其高硬度和高强度,有损测量基本不可行。X射线衍射方法比较可行,但是由于X射线衍射深度的限制,只能得到表面的应力分布。中子衍射方法虽然可以得到不同深度的应力分布,但是其精度和误差得不到保证,制约了其应用。

基于以上方法的不足,有限元方法表现出明显的优势,恰当的模型可预测其宏观残余应力的大小和分布,分析其产生裂纹和失效的原因,从而有效地防止热裂纹的产生和优化材料的结构,以便设计出性能更优的材料。本文作者采用有限元方法对 TiAlN涂层由于热失配引起的宏观残余应力进行模拟计算,并研究不同的基体及过渡层对残余热应力分布的影响。

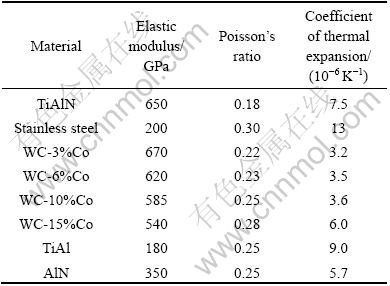

1 数值模型

采用有限元软件MSC.Marc2005进行计算分析,样品采用了轴对称几何模型(如图1所示)。因为实际涂层的厚度相对于基体很小,所以模型里不能直接把整个基体和涂层放在一起考虑,而是考虑一部分基体和涂层结合时的应力分布。实际上,热残余应力主要分布在明锐界面附近,远离明锐界面的残余应力非常小,可以不加考虑。考虑的尺度主要是微米级的,例如,TiAlN涂层的厚度一般为5~10 μm左右,过渡层一般是1~3 μm, 当接近1 mm时可以把基体涂层整体考虑。若涂层是纳米级时就不在考虑的范围内,不能用连续介质力学方法,只能用分子动力学方法。圆柱体中基体的高度用H表示,涂层的厚度用h1表示,过渡层的厚度用h2来表示。这样可以调节h1和h2的大小来分析涂层厚度对热残余应力的影响。由于化学汽相沉积要求温度很高,为了降低残余应力,一般采用热处理温度相对较低的物理汽相沉积,沉积温度为500 ℃左右[16]。模型中采用均匀温度场,不考虑温度梯度,冷却时温度下降是整体一致的。不考虑温度变化对材料物性参数的影响,均为常数。考虑了硬质合金基体钴含量从3%~15%范围内的应力分布情况。硬质合金基体和氮铝钛涂层的物性参数列于表1[16?20]。基体和涂层均假定为各向同性的且是完美粘结在一起的,并假定硬质合金基体和氮铝钛涂层是完全弹性的,不锈钢基体是弹塑性的。在确定塑性变形本构关系时,采用率无关各向同性硬化的材料性质,屈服应力为400 MPa[20]。

图1 轴对称二维实体模型示意图

Fig.1 Schematic diagram of axisymmetric 2D solid model

表1 模型中各材料的物性参数[16?20]

Table 1 Material properties for calculated model

对单一涂层且直径无限大的圆柱体,可采用双轴应力解析模型直接估算界面应力大小[21],其表达式为

这里同样没有考虑材料性质随温度的变化,计算时取均匀的温度场。制备温度td设为500 ℃,t0为20 ℃。由式(1)计算得出硬质合金基体时涂层中的张应力为1 856 MPa,不锈钢基体时涂层中压应力为 2 552 MPa。由此可见,当涂层非常薄时(如纳米级时),残余应力很大;对于有限几何体中的复合或梯度涂层,式(1)不适用。另外,式(1)也没考虑温度对膨胀系数的影响,而数值模型计算可以更深入考虑上述因素,计算结果更准确。

2 结果分析

2.1 无过渡层时应力大小及分布

计算采用均匀温度场,且假设材料从初始无应力状态的500 ℃时开始下降到室温。计算结果是材料的宏观应力分布,该应力是由温度下降时不均匀的热收缩引起的。图2所示为无过渡层时径向应力分布的云图。由图可见,当基体为硬质合金时,基体内以压应力为主,最大的径向压应力达727 MPa, TiAlN涂层内以拉应力为主,最大径向拉应力为869 MPa,如此大的拉应力极有可能导致裂纹产生;当基体为不锈钢时,出现了相反的应力分布,基体内以拉应力为主,最大的径向拉应力为526 MPa,涂层内以压应力为主,最大径向压应力为727 MPa。此时,涂层压应力对提高材料的硬度和疲劳寿命有利。

图2 温度从500 ℃下降到20 ℃时径向应力的分布云图

Fig.2 Contour plots of radial stress after decrease of temperature from 500 ℃ to 20 ℃: (a) WC-6%Co substrate; (b) Stainless steel substrate

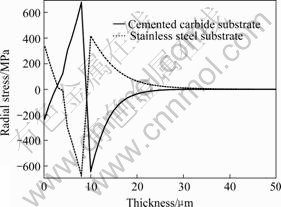

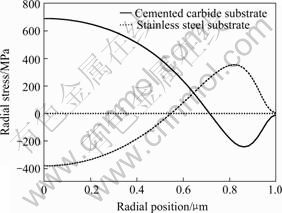

温度下降时在明锐界面出现的剪切应力奇异场如图3所示。由图可见,最大剪切应力为333 MPa, 应力奇异点出现在明锐界面靠近自由边界处,由此可知,裂纹及界面脱粘首先在此产生。TiAlN涂层不同基体径向应力沿厚度方向的分布如图4所示。由图可知,两种基体出现了相反的应力分布规律,硬质合金基体的涂层中以拉应力为主,而不锈钢基体中是压应力为主。在界面附近都存在大的温度梯度。径向应力在涂层表面由中心到边缘的分布如图5所示。由图可见,应力分布极不均匀,由中心到边缘应力性质和大小均发生变化。

图3 温度从500 ℃下降到20 ℃时明锐界面出现的剪切应力奇异场

Fig.3 Singularity field of shear stress in sharp interface after decrease of temperature from 500 ℃ to 20 ℃

图4 不同基体中径向应力由表及里沿厚度方向的分布

Fig.4 Distributions of radial stress at axial direction in different substrates

图5 径向应力在涂层表面由中心到边缘的分布

Fig.5 Distributions of radial stress from core to edge in coating surface

2.2 涂层厚度和基体参数对残余应力的影响

图6所示为残余热应力与涂层厚度的关系。由图可知,径向应力随涂层厚度的增加而减小,而剪切应力先减小随后又趋于平稳。因此,适当增加涂层厚度可以减少残余应力。然而,涂层厚度的增加又导致材料的强度和韧性的降低,这是一对矛盾。

图6 残余应力随涂层厚度的变化

Fig.6 Residual stress variations with coating thickness (h1/H is ratio of thickness from coating to cemented carbide substrate)

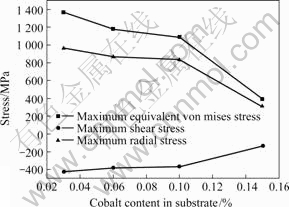

基体材料不同,其界面响应也不同。硬质合金基体中,研究了钴含量由3%到15%时界面应力的变化。图7所示为不同钴含量残余热应力的分布。由图可知,等效Mises应力和径向应力均随钴含量的增加而减小,而剪切应力略有增加。当钴含量由3%上升到15%时,表面拉应力下降了50%以上。因此,通过增加基体的钴含量可以减小涂层中的拉应力,同时可以增加材料的强度和韧性。

图7 硬质合金基体中钴含量对热残余应力的影响

Fig.7 Effects of cobalt content on thermal residual stress in cemented carbide substrate

2.3 过渡层对热应力的缓和作用

为提高涂层的结合强度及减小界面剪切应力,一般采用过渡层的方法。在硬质合金基体与TiAlN涂层之间采用AlN涂层,在不锈钢基体与TiAlN涂层之间采用TiAl涂层。过渡层是根据热膨胀系数的过渡和材料的结合性能来确定。图8(a)所示为硬质合金基体中增加AlN过渡层时对应力的缓和作用,涂层内的最大拉应力从678 MPa减小到389 MPa,减少了40%; 而基体内最大压应力从641 MPa减小到415 MPa,减少了35%。图8(b)所示为不锈钢基体中增加TiAl过渡层时对应力的缓和作用,涂层内最大压应力从676 MPa减少到396 MPa,减少了40%;不锈钢基体内的拉应力从417 MPa减小到303 MPa,减少了27%。由此可见,添加过渡层对界面应力的缓和作用非常明显,界面应力缓和后,界面结合强度明显提高。

图8 过渡涂层对热残余应力分布的影响

Fig.8 Effects of interlayer on thermal residual stress distribution: (a) Cemented carbide substrate with AlN interlayer; (b) Stainless steel substrate with TiAl interlayer

2.4 塑性屈服对应力分布的影响

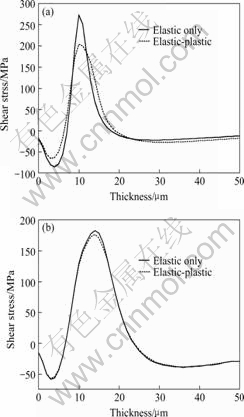

不锈钢是弹塑性的,TiAlN涂层和过渡层可看作是完全弹性的。当界面剪切应力较大时,在界面附近基体一侧有塑性屈服的现象发生。此时,基体的屈服应力为400 MPa[20], 采用率无关各向同性硬化的塑性本构关系。图9(a)所示为无过渡层时TiAlN涂层不锈钢基体的塑性变形对应力的缓和作用。由图可见,塑性变形使界面剪切应力从275 MPa减小到200 MPa,下降了27%。图9(b)所示为有TiAl过渡层时TiAlN涂层不锈钢基体的塑性变形对应力分布的影响。由图可见,由于过渡层的影响,塑性变形很小,两条曲线几乎重合。因此,增加过渡层不仅增加了界面结合强度,而且保持了基体的韧性,减小了塑性硬化的可能性。

图9 不锈钢基体的塑性变形对应力的缓和作用

Fig.9 Relaxation effects on plastic deformation of stainless steel: (a) Without interlayer; (b) With interlayer

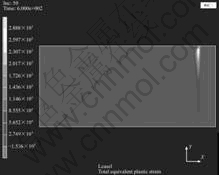

应力奇异场引起的塑性约束区如图10所示。由图可见塑性变形的最大处正是在界面应力奇异点附近。计算表明,无过渡层时的塑性约束区的范围远大于有过渡层时的,其中没有过渡层时最大的等效塑性应变为0.002 8,有过渡层时,塑性应变由0.002 8减小到0.000 7,减少了75%。

图10 无过渡层不锈钢基体中明锐界面处出现的塑性约束区

Fig.10 Plastic constraint zone in sharp interface of stainless steel substrate without interlayer

3 结论

1) 硬质合金金基体TiAlN涂层在制备过程中,从制备温度下降到室温时出现了较大的残余应力;当基体内钴含量为10%以内,考虑弹性变形时,涂层内径向拉应力有1 000 MPa以上,这时表面极有可能产生微裂纹。当为基体不锈钢时,涂层内以压应力为主,径向压应力的最大值也在1 000 MPa以上。在明锐界面与靠近自由表面处出现了应力奇异点,由此产生剪切应力奇异场。

2) 涂层应力随涂层厚度的增加而减小,硬质合金基体中随基体钴含量的增加而减小。通过增加涂层的厚度和基体中的钴含量可以减小涂层应力以阻止裂纹的产生。

3) 增加过渡层时可以使界面剪切应力减小40%以上,这样既缓和了应力集中,又增加了界面结合强度。另外,过渡层可以减小塑性流动,保持基体的韧性。

REFERENCES

[1] Narasimhan K, Boppana P S, Deepak G. Development of a graded TiCN coating for cemented carbide cutting tools—a design approach[J]. Wear, 1995, 188: 123?129.

[2] Su Y L, Yao S H, Wei C S, Wu C T. Analysis and design of a WC milling cutter with TiCN coating[J]. Wear, 1998, 21: 559?566.

[3] Williamson R L, Rabin B H, Drake J T. Finite element analysis of thermal residual stresses at graded ceramic-metal interfaces. Part Ⅱ. Interface optimization for residual stress reduction[J]. J appl Phys, 1993, 74: 1321?1326.

[4] Bromark M, Larsson M, Hedenqvist P, Hogmark S. Wear of PVD Ti/TiN multilayer coatings[J]. Surf Coat Technol, 1997, 90: 217?223.

[5] Dahan I, Admon U, Frage N, Sariel J, Dariel M P, Moore J J. The development of a functionally graded TiC-Ti multilayer hard coating[J]. Surf Coat Technol, 2001, 137: 111?115.

[6] Bull S J, Bhat D G, Staia M H. Properties and performance of commercial TiCN coatings. Part 1: coating architecture and hardness modeling[J]. Surf Coat Technol, 2003, 163/164: 499?506.

[7] Casas B, Lousa A, Calderon J, Anglada M, Esteve J, Llanes L. Mechanical strength improvement of electrical discharge machined cemented carbides through PVD (TiN, TiAlN) coatings[J]. Thin Solid Films, 2004, 447/448: 258?263.

[8] Castanho J M, Vieira M T. Effect of ductile layers in mechanical behavior of TiAlN thin coatings[J]. J Mater Process Tech, 2003, 143/144: 352?357.

[9] LI D F, HUANG J L, LIN M H. The effect of TiAl interlayer on PVD TiAlN films[J]. Surf Coat Technol, 1998, 99: 197?202.

[10] Morant C, Prieto P, Forn A, Picas J A, Elizalde E, Sanz J M. Hardness enhancement by CN/TiCN/TiN multilayer films[J]. Surf Coat Technol, 2004, 180/181: 512?518.

[11] Manaila R, Devengi A, Biro D, David L, Barna P B, Kovacs A. Multilayer TiAlN coatings with composition gradient[J]. Surf Coat Technol, 2002, 151/152: 21?25.

[12] Lengauer W, Dreyer K. Functionally graded hardmetals[J]. J Alloy Compd, 2002, 338: 194?212.

[13] Paggett J W, Drake E F, Krawitz A D, Winholtz R A, Griffin N D. Residual stress and stress gradients in polycrystalline diamond compacts[J]. Int J Refract Met H, 2002, 20: 187?194.

[14] Bull S J, Bhat D G, Staia M H. Properties and performance of commercial TiCN coating. Part I: coating architecture and hardness modeling[J]. Surf Coat Technol, 2003, 163/164: 499?506.

[15] Gunnars J, Alahelisten A. Thermal stresses in diamond coatings and their influence on coating wear and failure[J]. Surf Coat Technol, 1996, 80: 303?312.

[16] Bielawski M. Residual stress control in TiN/Si coatings deposited by unbalanced magnetron sputtering[J]. Surf Coat Technol, 2006, 200: 3987?3995.

[17] Cawalho N J M, Zoestbergen E, Kooi B J, Hosson De. Stress analysis and microstructure of PVD monolayer TiN and multilayer TiN/(Ti, Al)N coating[J]. Thin Solid Films, 2003, 429: 179?189.

[18] 劳技军,胡晓萍,虞晓江,李戈扬,顾明元. AlN在AlN/VN纳米多层膜中的相转变及其薄膜力学性能的影响[J]. 物理学报,2003, 52(9): 2259?2263.

LAO Ji-jun, HU Xiao-ping, YU Xiao-jiang, LI Ge-yang, GU Ming-yuan. Phase transformation of AlN in AlN/VN nanomultilayers and its effect on the mechanical properties of films[J]. Acta Physica Sinica, 2003, 52(9): 2259?2263.

[19] 毛延发,唐为国,刘金良, 韩培刚. TiAlN纳米复合涂层的技术进展[J]. 工具技术,2006, 40(4): 20?24.

MAO Yan-fa, TANG Wei-guo, LIU Jin-liang, HAN Pei-gang. Technology development of TiAlN nano-composite coatings[J]. Tool Engineering, 2006 40(4): 20?24.

[20] 基费尔R, 施华尔茨柯普弗P. 硬质合金[M]. 北京:中国工业出版社,1963: 337.

Kieffer R, Schwarzkopf P. Hardmetals[M]. Beijing: China Industry Press, 1963: 337.

[21] 章德铭,陈贵清,韩杰才,孟松鹤. γ-TiAl基高温结构材料研究评述[M]. 中国稀土学报,2005, 23: 163?167.

ZHANG De-ming, CHEN Gui-qing, HAN Jie-cai, MENG Song-he. Review on studies of gamma TiAl-based high-temperature structural materials[J]. Journal of the Chinese Rare Earth Society, 2005, 23: 163?167.

基金项目:国家自然科学基金资助项目(50323008)

收稿日期:2006-10-26;修订日期:2007-01-29

通讯作者:贺跃辉,教授;电话:0731-8877391;E-mail:yuehui@mail.csu.edu.cn

(编辑 陈爱华)