Al含量对TiAlN涂层热稳定性能的影响

张雨萌1,朱丽慧1,倪旺阳2,刘一雄2

(1.上海大学 材料科学与工程学院,上海,200072;

2. Kennametal Inc., Latrobe, PA 15650, USA)

摘要:采用阴极电弧蒸镀在WC-Co硬质合金基体上沉积Ti1-xAlxN涂层(x=0.5、0.55和0.6),并对涂层试样在900℃下真空退火0.5~4h。采用X线衍射仪(XRD)和显微维氏硬度计分析比较退火前后TiAlN涂层物相及硬度,研究Al含量对涂层结构、硬度和热稳定性能的影响。研究结果表明:Ti0.5Al0.5N和Ti0.45Al0.55N为单相面心立方结构,Ti0.4Al0.6N为面心立方(fcc)TiAlN和密排六方(hcp)AlN双相结构。涂层退火时发生分解,先析出介稳相fcc-AlN,再转变为稳定相hcp-AlN和fcc-TiN,硬度逐渐下降。Ti0.45Al0.55N涂层高温下能保持较长时间的稳定,退火后仍具有最高的硬度,表现出优异的热稳定性;而Ti0.4Al0.6N涂层中因存在hcp-AlN硬度略低,分解最早,热稳定性最差。当x=0.55时为最佳涂层成分。

关键词:TiAlN涂层;阴极电弧蒸镀;热稳定性;相结构;硬度

中图分类号:TB43 文献标志码:A 文章编号:1672-7207(2013)07-2696-06

Effect of Al content on thermal stability of TiAlN coatings

ZHANG Yumeng1, ZHU Lihui1, NI Wangyang2, LIU Yixiong2

(1. School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China;

2. Kennametal Inc., Latrobe, PA 15650, USA)

Abstract: Ti1-xAlxN coatings (x=0.5, 0.55 and 0.6) were deposited on WC-Co cemented carbides by cathode arc evaporation and then annealed at 900℃ in vacuum for 0.5-4h. X-ray diffraction (XRD) and Vickers hardness tester were used to study the effect of Al content on the structure, hardness and thermal stability of TiAlN coatings. The results show Ti0.5Al0.5N and Ti0.45Al0.55N exhibit single-phase face-centered cubic structure, while Ti0.4Al0.6N is composed of face-centered cubic (fcc) TiAlN and close-packed hexagonal (hcp) AlN. During the annealing, TiAlN coatings undergo the phase transformation as follows: fcc-TiAlN→fcc-AlN+fcc-TiN→hcp-AlN+fcc-TiN, and the hardness decreases gradually. Ti0.45Al0.55N coating exhibits excellent thermal stability, since it keeps stable after annealed for relatively long time, and possesses the highest hardness. In contrast, the existence of hcp-AlN in Ti0.4Al0.6N coating results in slightly lower hardness, earlier decomposition and the worst thermal stability. The optimal composition of TiAlN coating is x=0.55.

Key words: TiAlN coatings; cathode arc evaporation; thermal stability; phase structure; hardness

TiAlN拥有高的硬度、耐磨性和优异的抗高温氧化性能,现已逐步替代TiN成为高速干式切削领域广泛使用的刀具涂层之一[1-3]。Ti1-xAlxN涂层结构和性能很大程度上取决于Al含量。当Al含量较小时,涂层为单相NaCl型面心立方结构(fcc)。随Al含量增加,涂层晶粒细化,硬度和抗氧化性都有一定提高;但超过某一临界值后,密排六方(hcp)AlN的出现使其力学性能开始下降[4-10]。因此,为提高TiAlN涂层性能,应在避免出现hcp-AlN相的条件下尽可能增加Al含量。临界Al含量大致在x=0.5~0.67,确切的范围因涂层制备方法和工艺参数的不同而有所差异[5, 7-8, 10]。涂层热稳定性是影响刀具切削性能和使用寿命的关键因素之一。陈利等人对TiAlN涂层热稳定性的研究结果表明,涂层在高温下退火将发生调幅分解:先析出介稳态fcc-AlN,而后fcc-AlN逐渐转变为稳定的hcp-AlN[11-15]。Escudeiro Santana等[9, 14]则针对阴极电弧蒸镀制备的不同Al含量Ti1-xAlxN涂层开展了研究。通过分析x=0.4的fcc-TiAlN单相和x=0.6的fcc-TiAlN+ fcc-AlN双相涂层[9],x=0.5,0.66的fcc-TiAlN单相涂层[14]高温退火时结构和硬度的变化,他们发现涂层分解后形成的hcp-AlN将导致TiAlN涂层硬度较快下降。本文作者采用阴极电弧蒸镀工艺在硬质合金表面制备了x=0.5,0.55和0.6 Ti1-xAlxN涂层,分析比较原始态涂层的相结构和硬度,确定性能最优时涂层的Al含量;并通过高温退火实验,研究此范围内Al含量对TiAlN涂层热稳定性能的影响。

1 实验

1.1 涂层制备

实验用涂层试样由美国Kennametal公司提供,基体尺寸(长×宽×厚)为12mm×12mm×4mm的WC-Co硬质合金。采用阴极电弧蒸发工艺在Oerlikon Balzers Innova镀膜机上分别制备Ti0.5Al0.5N,Ti0.45Al0.55N和Ti0.4Al0.6N涂层。靶材采用热等静压及冷等静压粉末冶金工艺制得。涂层沉积前,对基体进行超声清洗及喷丸处理(氧化铝微珠)以提高涂层的结合力。处理后的基体试样安装在真空室的转架上,并将真空度抽至小于4mPa。随后将基体加热至450℃,通入氩气(0.2Pa),加-200V的脉冲偏压对基体进行等离子轰击20min,最后沉积涂层。

1.2 性能测试

采用入射线与试样表面近似平行的掠入射X线衍射法(PANalytical, Empyrean型衍射仪)分析涂层物相,实验参数为:Cu靶(0.154 184nm),掠入射角0.6°,电压40kV,电流40mA,扫描步长0.06(°)/s。采用JSM-6700F高分辨扫描电镜(HRSEM)观察涂层显微组织。采用MH-3型显微维氏硬度计测试涂层显微硬度,载荷为50g,测定8个点并取平均值。真空退火实验在SK2-1-12H型迴转式管式电阻炉中进行,退火温度900℃,保温时间0.5~4h,样品随炉冷却。对不同时间退火后的涂层进行物相分析和硬度测试。

2 实验结果

2.1 原始态涂层结构及硬度

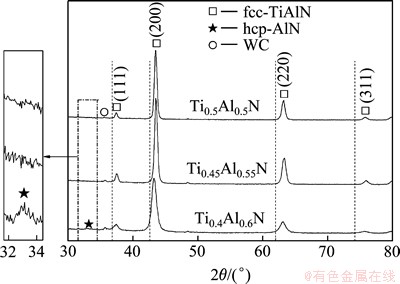

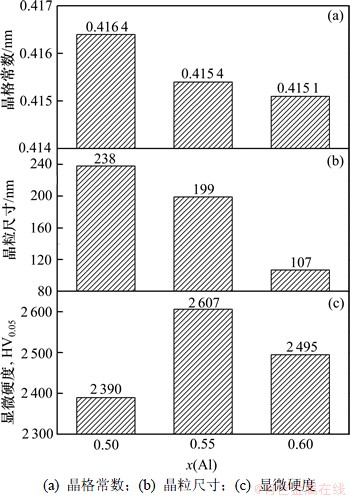

图1所示为Ti0.5Al0.5N,Ti0.45Al0.55N和Ti0.4Al0.6N涂层X线衍射图,虚垂线表示面心立方结构TiN (fcc-TiN)衍射峰峰位。从图1可知,Ti0.5Al0.5N和Ti0.45Al0.55N涂层为单相fcc-TiAlN,而Ti0.4Al0.6N涂层为fcc-TiAlN和少量hcp-AlN组成的双相结构。fcc-TiAlN为Al原子取代fcc-TiN晶格中部分Ti原子形成的固溶体,当Al含量较高,Al原子继续进入晶格所需的能量增大而高于hcp-AlN的形成能时,涂层中更易形成hcp-AlN[5, 16]。根据XRD图谱计算了Ti0.5Al0.5N,Ti0.45Al0.55N和Ti0.4Al0.6N的晶格常数和晶粒尺寸,结果如图2(a)和(b)所示。由于原子半径较小的Al的加入(Al和Ti的原子半径分别为0.182nm和0.200nm),fcc-TiN晶格发生收缩,使TiAlN涂层衍射峰位较标准fcc-TiN向高角度偏移,晶格常数变小(TiN的晶格常数为0.424 0nm)。当Al含量越高,晶格畸变程度越大,TiAlN晶格常数越小(图2(a))。

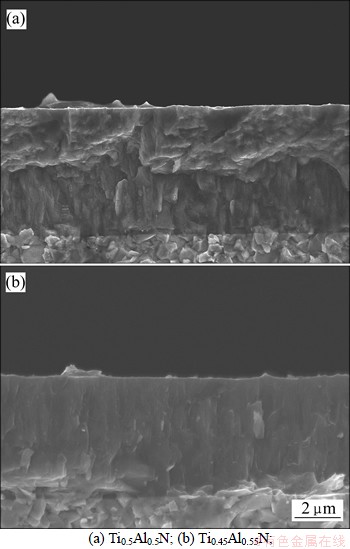

涂层衍射峰随Al含量增加略有变宽,表明涂层晶粒发生细化,这与前人的研究结果[5, 10, 13]相一致。通过扫描电镜观察也发现,随Al含量增加,涂层截面的柱状结构特征逐渐减弱,晶粒逐渐变小。图3所示为Ti0.5Al0.5N和Ti0.45Al0.55N涂层截面形貌。与Ti0.5Al0.5N涂层相比,Ti0.45Al0.55N涂层结构的柱状特征不明显,晶粒较为细小。这是由于不断加入的Al原子抑制了Ti和N原子的扩散;另外,Al含量较高的涂层中出现的hcp-AlN相倾向于在晶界析出,抑制了晶粒长大[5, 7],从而减小了晶粒尺寸(图2(b))。

图1 原始态TiAlN涂层的X线衍射谱

Fig.1 XRD patterns of as-deposited TiAlN coatings

图2 TiAlN的晶格常数、晶粒尺寸及显微硬度

Fig.2 Lattice parameter, grain size and microhardness of TiAlN

图3 原始态Ti0.5Al0.5N和Ti0.45Al0.55N涂层截面形貌

Fig.3 Fracture cross-section morphology of as-deposited Ti0.5Al0.5N and Ti0.45Al0.55N coatings

图2(c)所示为各涂层的显微硬度。硬度从高到低依次为Ti0.45Al0.55N涂层、Ti0.4Al0.6N涂层、Ti0.5Al0.5N涂层。当Al含量增加,涂层晶粒细化;同时晶格畸变程度增大,所引起的固溶强化效应增强,使硬度有所提高。然而Ti0.4Al0.6N涂层中存在的hcp-AlN硬度低且倾向于在晶界析出[7],导致Ti0.4Al0.6N涂层硬度比Ti0.45Al0.55N涂层稍有下降。

2.2 涂层热稳定性能

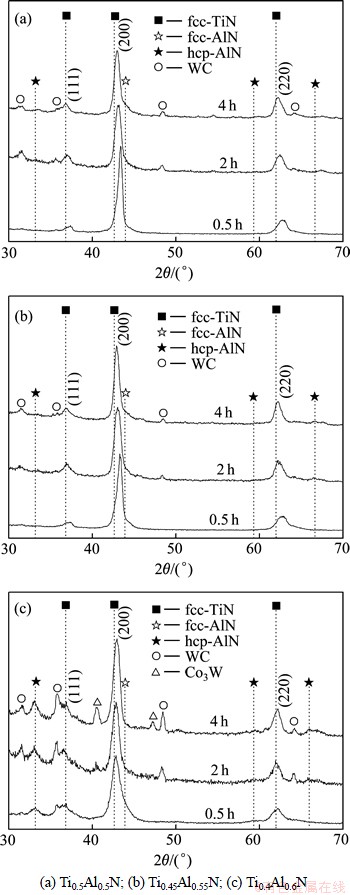

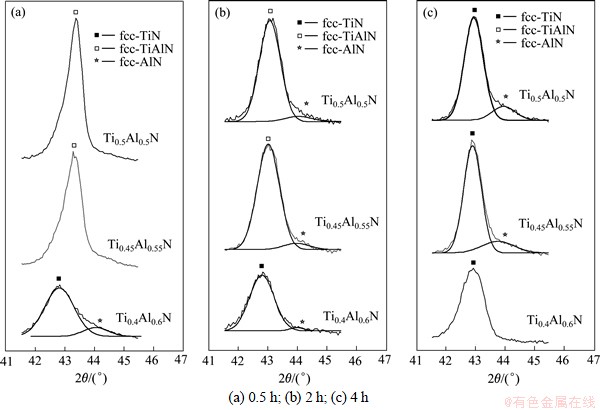

图4所示为Ti0.5Al0.5N,Ti0.45Al0.55N和Ti0.4Al0.6N涂层在900℃分别退火0.5h,2h和4h时的XRD图谱。为进一步分析涂层退火时物相变化,对图4中各图谱的(200)衍射峰进行分峰处理,结果如图5所示。由图4和图5可知,退火0.5h时,Ti0.5Al0.5N涂层物相无明显变化。退火2h后,其(200)衍射峰右侧出现一弱峰,为fcc-AlN。退火4h时,涂层中fcc-AlN有所增多并出现少量hcp-AlN。随退火时间的延长,各衍射峰逐渐向低角度移动。这应与Al原子不断从TiAlN晶格中析出有关,同时残余应力的释放也将引起衍射峰位的左移[9]。Ti0.45Al0.55N涂层退火时XRD图谱变化与Ti0.5Al0.5N涂层相似。

图4 TiAlN涂层在900℃退火后的XRD图谱

Fig.4 XRD patterns of TiAlN coatings after annealing at 900℃

图5 退火后TiAlN涂层的局部XRD图谱

Fig.5 Details of XRD patterns of annealed TiAlN coatings

然而,Ti0.4Al0.6N涂层与前两者略有不同。当退火0.5h时,涂层中已出现一定量的fcc-AlN。与原始态相比,hcp-AlN明显增多,fcc-TiAlN涂层衍射峰向低角度移动。随退火时间的延长,fcc-AlN逐渐减少,hcp-AlN继续增多,但衍射峰峰位无明显变化。退火4h时,涂层中fcc-AlN基本消失,hcp-AlN的含量明显高于其他2个涂层(图4(c))。

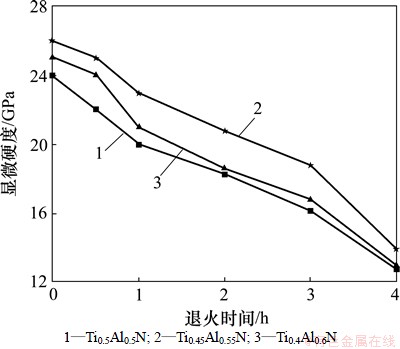

图6所示为Ti0.5Al0.5N、Ti0.45Al0.55N和Ti0.4Al0.6N涂层在900℃退火过程中的硬度变化。从图6可以看出,各涂层硬度随退火时间的延长逐渐下降。这主要是由于软相hcp-AlN的出现及增多造成的。此外,涂层残余应力的释放也是其硬度下降的原因之一[9]。退火至4h时,Ti0.45Al0.55N涂层仍具有最高的硬度,Al含量最高的Ti0.4Al0.6N涂层硬度下降程度最大。

图6 TiAlN涂层900℃退火后的硬度

Fig.6 Microhardness of TiAlN coatings during annealing at 900℃

3 结果分析与讨论

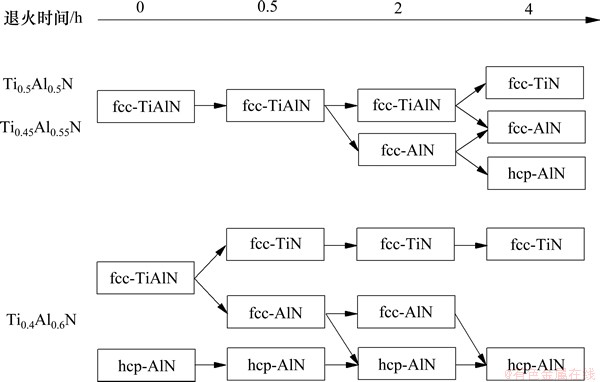

图7所示为Ti0.5Al0.5N、Ti0.45Al0.55N和Ti0.4Al0.6N涂层900℃下退火的相变示意图。涂层在高温下发生如下分解:

fcc-TiAlN→fcc-AlN+fcc-TiN→hcp-AlN+fcc-TiN

fcc-AlN和hcp-AlN为2种不同结构的AlN,前者为介稳态,后者为稳定态。由于hcp-AlN原子体积较大且与fcc-TiN间存在不连续的相界面,直接形核时能垒较高[13-14],因此TiAlN涂层在分解形成稳定相时,先析出介稳相fcc-AlN作为过渡。

图7 TiAlN涂层900℃下退火相变示意图

Fig.7 Schematic diagram of phase transformation of TiAlN coatings during annealing at 900℃

在退火2 h时,Ti0.5Al0.5N和Ti0.45Al0.55N涂层分解析出fcc-AlN,在退火4h时,部分fcc-AlN转变为hcp-AlN。其中,Ti0.45Al0.55N涂层退火后仍具有最高的硬度,表现出优异的热稳定性。在退火0.5h时,Ti0.4Al0.6N涂层发生分解,析出的fcc-AlN于退火4h时转变完全,涂层硬度下降程度最大,热稳定性最差。这是由于当Al含量较高时,涂层相结构与AlN结构更为相近,高温下分解析出AlN所需能量较少[14],易于形核。

Kutschej等[7]对溅射沉积的TiAlN涂层研究表明,涂层高温退火分解形成hcp-AlN时,原始态下存在的hcp-AlN相易成为其形核核心,从而进一步加速涂层的分解。本实验结果表明,采用阴极电弧蒸镀制备的Ti0.4Al0.6N涂层因hcp-AlN的存在,也导致TiAlN涂层较快分解。结合图6和图7可知,当fcc-AlN向hcp-AlN转变时,涂层硬度出现较为明显的下降。Santana 等[9]采用阴极电弧蒸镀制备的Ti0.4Al0.6N涂层中不存在hcp-AlN相,其硬度于退火初期下降后,保持了一段时间的稳定。由此可见,阴极电弧蒸镀制备的TiAlN涂层中若存在hcp-AlN,不仅会降低涂层原始态下的硬度,也将导致高温下涂层分解加速,硬度下降加快,热稳定性能恶化,在涂层制备过程中应当尽量避免。

4 结论

(1) Ti0.5Al0.5N和Ti0.45Al0.55N 涂层为单相fcc-TiAlN,Ti0.4Al0.6N涂层为fcc-TiAlN+hcp-AlN双相结构。Ti0.45Al0.55N涂层晶粒较细小并具有最高的硬度(2 607 HV),而Ti0.4Al0.6N涂层因软相hcp-AlN的存在硬度略低。

(2) TiAlN涂层高温退火时发生如下分解:fcc-TiAlN→fcc-AlN+fcc-TiN→hcp-AlN+fcc-TiN。随退火时间延长,涂层硬度不断下降。Ti0.45Al0.55N涂层高温下能保持较长时间的稳定,退火后仍具有最高的硬度;而Ti0.4Al0.6N涂层分解最早,硬度降幅最大。

(3) Ti0.45Al0.55N 涂层硬度最高、热稳定性能最好。而当Al含量增加,Ti0.4Al0.6N涂层中出现的hcp-AlN不仅降低其硬度,还导致高温下涂层分解加速,热稳定性能恶化,应在涂层制备过程中尽量避免。

致谢:

荷兰PANalytical公司亚太区应用实验室对本实验中涂层的物相测试提供了很大的帮助,特此感谢。

参考文献:

[1] Man B Y, Guzman L, Miotello A, et al. Microstructure, oxidation and H2-permeation resistance of TiAlN films deposited by DC magnetron sputtering technique[J]. Surface and Coatings Technology, 2004, 180/181: 9-14.

[2] 陈利, 吴恩熙, 尹飞, 等. (Ti, Al)N涂层的微观组织和性能[J]. 中国有色金属学报, 2006, 16(2): 279-283.

CHEN Li, WU Enxi, YIN Fei, et al. Microstructure and properties of (Ti, Al)N coating[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 279-283.

[3] PalDey S, Deevi S C. Single layer and multilayer wear resistant coatings of (Ti, Al)N: A review[J]. Materials Science and Engineering A, 2003, 342(1/2): 58-79.

[4] Vaz F, Rebouta L, Andritschky M, et al. Thermal oxidation of Ti1-xAlxN coatings in air[J]. Journal of the European Ceramic Society, 1997, 17(15/16): 1971-1977.

[5] Jose F, Ramaseshan R, Dash S, et al. Significance of Al on the morphological and optical properties of Ti1-xAlxN thin film[J]. Materials Chemistry and Physics, 2011, 130(3): 1033-1037.

[6] H rling A, Hultman L, Odén M, et al. Mechanical properties and machining performance of Ti1-xAlxN-coated cutting tools[J]. Surface and Coatings Technology, 2005, 191(2/3): 384-392.

rling A, Hultman L, Odén M, et al. Mechanical properties and machining performance of Ti1-xAlxN-coated cutting tools[J]. Surface and Coatings Technology, 2005, 191(2/3): 384-392.

[7] Kutschej K, Mayrhofer P H, Kathrein M, et al. Structure, mechanical and tribological properties of sputtered Ti1-xAlxN coatings with 0.5≤x≤0.75[J]. Surface and Coatings Technology, 2005, 200(7): 2358-2365.

[8] Setsuhara Y, Suzuki T, Makino Y, et al. Phase variation and properties of (Ti, Al)N films prepared by ion beam assisted deposition[J]. Surface and Coatings Technology, 1997, 97(1/3): 254-258.

[9] Escudeiro Santana A, Karimi A, Derflinger V H, et al. The role of hcp-AlN on hardness behavior of Ti1-xAlxN nanocomposite during annealing[J]. Thin Solid Films, 2004, 469/470: 339-344.

[10] Wüstefeld C, Rafaja D, Klemm V, et al. Effect of the aluminium content and the bias voltage on the microstructure formation in Ti1-xAlxN protective coatings grown by cathodic arc evaporation[J]. Surface and Coatings Technology, 2010, 205(5): 1345-1349.

[11] 陈利. Ti-Al-N基硬质涂层的热稳定性、微结构及其力学、切削性能的研究[D]. 长沙: 中南大学粉末冶金研究所, 2009: 48-60.

CHEN Li. Investigation of thermal stability, microstructure as well as mechanical property and cutting performance of Ti-Al-N based hard coatings[D]. Changsha: Central South University. Powder Metallurgy Research Institute, 2009: 48-60.

[12] Rachbauer R, Stergar E, Massl S, et al. Three-dimensional atom probe investigations of Ti-Al-N thin films[J]. Scripta Materialia, 2009, 61(7): 725-728.

[13] H rling A, Hultman L, Odén M, et al. Thermal stability of arc evaporated high aluminum-content Ti1-xAlxN thin films[J] Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2002, 20(5): 1815-1823.

rling A, Hultman L, Odén M, et al. Thermal stability of arc evaporated high aluminum-content Ti1-xAlxN thin films[J] Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2002, 20(5): 1815-1823.

[14] Mayrhofer P H, H rling A, Karlsson L, et al. Self-organized nanostructures in the Ti-Al-N system[J]. Applied Physics Letters, 2003, 83(10): 2049-2051.

rling A, Karlsson L, et al. Self-organized nanostructures in the Ti-Al-N system[J]. Applied Physics Letters, 2003, 83(10): 2049-2051.

[15] CHEN Li, CHANG Keke, DU Yong, et al. A comparative research on magnetron sputtering and arc evaporation deposition of Ti-Al-N coatings[J]. Thin Solid Films, 2011, 519(11): 3762-3767.

[16] Hugosson H W, H gberg H, Algren M, et al. Theory of the effects of substitutions on the phase stabilities of Ti1-xAlxN[J].Journal of Applied Physics, 2003, 93(8): 4505-4511.

gberg H, Algren M, et al. Theory of the effects of substitutions on the phase stabilities of Ti1-xAlxN[J].Journal of Applied Physics, 2003, 93(8): 4505-4511.

(编辑 赵俊)

收稿日期:2012-07-18;修回日期:2012-11-04

基金项目:国家自然科学基金资助项目(51171097);美国Kennametal公司资助项目(2011)

通信作者:朱丽慧(1971-),女,浙江上虞人,博士,教授,从事硬质合金刀具涂层的研究;电话:021-56331462;E-mail: lhzhu@mail.shu.edu.cn