文章编号:1004-0609(2011)11-2799-06

Mg-Y-Ce 阻燃镁合金表面膜的阻燃机理

樊建锋1, 2

( 1. 太原理工大学 材料科学与工程学院,太原 030024;

2. 新材料界面科学与工程教育部重点实验室,太原 030024)

摘 要:通过同时加入Y和Ce获得了阻燃效果优异的Mg-Y-Ce阻燃镁合金,实现了镁合金在大气条件下的无保护熔炼,Mg-Y-Ce合金由工业纯Mg(99.9%,质量分数)、Mg-25%Y(质量分数)中间合金和纯Ce(99.5%,质量分数)在电阻炉中于保护性气氛(CO2+0.5%SF6)下熔配而成。AES(PHI550 ESCA/SAM)和XRD(X’Pert Pro MPD)表面分析结果表明:当Mg-3Y-4.5Ce阻燃镁合金在高温下暴露于大气中时,其表面膜为双层膜,外层主要由Y2O3组成,而内层Y和Ce含量极低,以Mg和MgO为主。基于高温氧化热力学分析,建立了Mg-Y合金在高温下的选择性氧化模型,获得了Mg-Y合金能够发生选择性氧化的Y浓度阈值(约为7%,质量分数)。分析了Ce在Mg-Y合金选择性氧化中的第三元素效应,Ce起到了“吸气剂”的作用,可以抑制氧向合金内部扩散,从而抑制Y元素的内氧化。

关键词:阻燃镁合金;氧化膜;选择性氧化;第三元素效应

中图分类号:TG 146.4 文献标志码:A

Ignition-proof mechanics of surface film of Mg-Y-Ce alloy system

FAN Jian-feng1, 2

(1. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. Key laboratory of Interface Science and Engineering in Advanced Materials, of Ministry of Education,

Taiyuan University of Technology, Taiyuan 030024, China)

Abstract: By adding Y and Ce high ignition-point temperature was realized in Mg-Y-Ce magnesium alloy, which can be melted in air without any protection. All the alloys, i.e., Mg-Y and Mg-Y-Ce alloys were prepared by adding commercial purity Mg (99.9%, mass fraction), Mg-25%Y (mass fraction) master alloy and pure Ce (99.5%, mass fraction) in a steel crucible under a cover gas mixture of CO2 and 0.5%SF6. AES (PHI550 ESCA/SAM) and XRD (X’Pert Pro MPD) analysis of the oxide scale reveals that, when the ignition-proof Mg-3Y-45Ce alloy is exposed in air at high temperature the oxidation film includes two layers. The outer layer consists of Y2O3, and the inner layer consists of Mg and MgO with a little Y and Ce. Based on the analysis of the high temperature oxidation thermodynamics, the model of the selective oxidation for Mg-Y alloys at high temperature was established, and the critical content of Y for the selective oxidation of Mg-Y alloys was obtained to be about 7% (mass fraction). The third element effect of Ce in the selective oxidation of Mg-Y alloys was analyzed. Ce plays a role of “getter” which inhibits the diffusion of O to internal alloy, so as to inhibit the inner oxidation of Y.

Key words: ignition-proof magnesium alloy; oxidation film; selective oxidation; the third element effect

近年来,镁合金在汽车、电子和航天航空等领域中受到了极大关注[1-5]。然而,镁合金在熔炼和成形过程中极易发生氧化、燃烧、甚至爆炸,这不仅会给零件的成形与性能造成危害,还很容易伤害人体和污染环境,因此,镁合金研究的一个重要课题是如何阻止镁合金在高温下的燃烧氧化。目前,常用的阻燃方法是熔剂保护法与气体保护法。但是,这两种方法的使用都因其存在难以避免的缺陷而受到限制,如易产生有毒气体污染环境和造成熔剂夹杂而损害合金性能,熔炼、浇注设备和工艺复杂而增加了成本等[6-9]。因此,自20世纪50年代以来,研究者就提出了阻燃镁合金的概念,以从根本上解决镁合金的高温氧化与燃烧问题。

Be和Ca是最早发现的具有良好阻燃效果的合金元素。但含Be和Ca的阻燃镁合金一直处于实验室阶段,这主要是因为难以解决阻燃效果与力学性能之间的矛盾。要达到一定的阻燃效果,合金元素含量必须高于一定的阈值,而过量的Be和Ca又会严重损害镁合金的力学性能[5, 10]。另外,Be或Be的化合物具有很强的毒性,危害人体健康和污染环境。因此,开发新的阻燃元素、深入研究各阻燃元素对镁合金的阻燃机制和进一步强化其阻燃效果是阻燃镁合金研究的重要突破口。

本文作者通过同时加入Y和Ce获得了阻燃效果优异的Mg-Y-Ce阻燃镁合金,实现了镁合金在大气条件下的无保护熔炼。利用多种表面分析手段研究合金元素对镁合金高温氧化膜形貌和结构的影响,探索新型阻燃镁合金的高温氧化机制。

1 实验

本研究中所有合金都由工业纯Mg(99.9%,质量分数),Mg-25%Y(质量分数)中间合金和纯Ce(99.5%,质量分数)在电阻炉中于保护性气氛(CO2+0.5%SF6)下熔配而成。对高温下液态合金表面膜结构进行原位观察非常困难,因此,研究所指高温氧化膜形貌均为在给定温度下于大气中保温一定时间后空冷至室温的试样表面组织形貌。对样品进行表面分析后再将其横向剖切,取其中一半进行镶嵌和打磨,以便观察氧化膜横截面组织和形貌以及氧化膜与基体之间的界面结合情况。用X’Pert Pro MPD 型X 射线薄膜衍射法测定氧化膜的相成分,衍射所用靶材为Cu Kα靶;微观组织形貌分析在带有能谱仪的JEM-200CX 型扫描电镜(SEM & EDS)上进行;试样表面成分采用美国PE公司制造的PHI550 ESCA/SAM多功能电子能谱测定。

2 结果与分析

2.1 合金元素对镁合金燃点的影响

大气条件下含Y和Ce镁合金的静态燃点测试结果如表1所列。表1中,“No ignition”表示在1 173 K的高温下保温0.5 h而不燃烧。结果表明,单独加入稀土元素Ce后镁合金的燃点提高了15~30 K,且随Ce含量的继续增加没有明显的提高。另一方面,Y元素的加入对镁合金燃点的影响存在一个阈值,约为7%(质量分数),当Y含量低于7%(质量分数)时,镁合金的燃点提高了30~50 K,且随Y含量的继续增加燃点变化不大。然而,当Y含量高于7%(质量分数)时,Mg-Y合金的燃点快速增加约200 K,且当Y含量继续增加至10%(质量分数)以上时,Mg-Y合金能在 1 173 K下保温0.5 h而不燃烧。 虽然单独加入Y能使镁合金获得良好的阻燃效果,但因其所需的含量很高,而大量的合金元素不仅会使镁合金成本增加,更严重的是较高的Y含量将严重损害镁合金的力学性能。研究显示[11]:随着Y含量的增加,Mg-Y合金的延展性遵循高-中-脆性演变规律,当Y含量高于8%(质量分数)时,Mg-Y合金就会产生严重的脆性而不能使用。而二元Mg-Y阻燃合金中Y的含量须高于10%(质量分数),显然是不实用的。因此,要使含Y阻燃镁合金获得实际应用,就必须寻求新的方法以降低合金元素的临界含量。实验表明,第三元素Ce的加入能大幅降低Y的阈值含量, Mg-Y-Ce三元合金具有很好的阻燃效果,在阻燃元素Y含量明显降低的同时,合金燃点却大幅上升。

表1 不同成分镁合金的燃点

Table 1 Ignition points of magnesium alloys with different compositions

2.2 保护性氧化膜的微观形貌及相组成

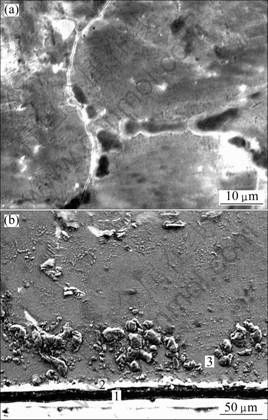

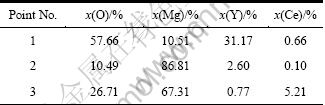

图1所示为Mg-3Y-4.5Ce合金在1 173 K保温0.5 h所得到的氧化膜表面及横截面形貌。由图1可见,其微观形貌由大尺寸的粒状晶组成。从横截面看,表面膜比较平整。从图1(b)可以观察到Mg-3Y-4.5Ce合金的表面膜分为两层。结合EDS成分分析(见表2)和XRD薄膜衍射分析(见图2)结果可知,Mg-3Y-4.5Ce合金表面膜的外层主要由Y2O3组成,而内层以Mg和MgO为主,Y和Ce含量极低。

2.3 保护性氧化膜的成分分析

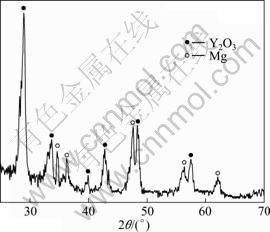

对在1 173 K下保温0.5 h后的Mg-3Y-4.5Ce合金氧化膜进行AES深度分析(见图3)。由图3可见,氧化表面由O、 Mg、Y和Ce 等4种元素组成,且在1 173 K保温0.5 h时生成的Mg-3Y-4.5Ce合金表面膜的元素分布遵循如下规律。

图1 在1 173 K保温0.5 h后Mg-2.9Y-4.5Ce合金氧化表面及横截面形貌

Fig.1 Morphologies of oxidation surface (a) and cross-sectional (b) of Mg-2.9Y-4.5Ce alloy oxidized at 1 173 K for 0.5 h

表2 图1中指定点的化学成分能谱分析结果

Table 2 EDS results of compositions of appointed areas in Fig.1

图2 Mg-3Y-4.5Ce镁合金在空气中于1 173 K保温0.5 h后表面氧化膜的XRD谱

Fig.2 XRD pattern of oxide film formed on Mg-3Y-4.5Ce alloys oxidized at 1 173 K for 0.5 h in air

1) 可将其元素的摩尔分数随深度的变化分为孕育层、稳定层和过渡层3个深度:所有元素的浓度都有一个相对稳定层;稳定层出现前,元素含量的变化有一个从试样表面成分到稳定层成分的过渡阶段,称为孕育层;稳定层以下,元素含量的变化又有一个从稳定层成分向合金基体成分的过渡深度,称为过渡层,且稳定层的厚度远大于其余两层的厚度。

2) 孕育层内Mg和Ce元素含量较高,且呈下降趋势,而O元素和Y元素浓度呈上升趋势;稳定层内Y和O元素的摩尔分数高于95%,只有极少量的Mg与Ce。

图3 1 173 K下保温0.5 h后Mg-3Y-4.5Ce合金氧化膜的AES成分分析

Fig.3 AES surface analysis of oxide films on Mg-3Y-4.5Ce alloy formed at 1 173 K for 0.5 h

3) 过渡层中Mg元素的浓度急剧上升,O元素的浓度快速下降,Ce元素的浓度增加。

由上述分析可知,高温下Mg-3Y-4.5Ce合金表面生成了一层Y2O3膜,所以,显著提高了镁合金的高温抗氧化和燃烧性能。

2.4 保护性氧化膜的形成机理

2.4.1 Mg-Y合金中的选择性氧化

Mg-3Y-4.5Ce合金液面可能发生如下化学反应:

(s) (1)

(s) (1)

(s) (2)

(s) (2)

(s) (3)

(s) (3)

(4)

(4)

(5)

(5)

(6)

(6)

镁合金的熔体处理温度通常为973~1 073 K,所以,把研究重点放在这一温度范围,选择1 033 K为理论计算温度。将热力学参数[12-13]代入式(1)~(6),得

<0 (7)

<0 (7)

×

× (8)

(8)

<0 (9)

<0 (9)

×

× (10)

(10)

J/mol<0 (11)

J/mol<0 (11)

×

× (12)

(12)

J/mol<0 (13)

J/mol<0 (13)

J/mol<0 (14)

J/mol<0 (14)

J/mol<0 (15)

J/mol<0 (15)

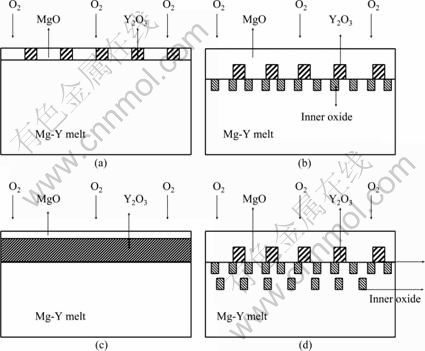

从上述的热力学计算可知,在本研究条件下Mg和Y 都可以氧化,所以,在氧化的初始阶段,氧化按照合金组成进行,即MgO与Y2O3的比例几乎与合金中金属的配比一样,如图4(a)所示。接着,由于MgO中Mg2+的扩散速度比Y2O3中Y3+的扩散速度快,所以,MgO生长也较快,形成了如图4(b)所示的形貌,MgO完全被基体和Y2O3覆盖。此时,由于表面氧化物的阻滞,MgO/基体界面上的氧分压降低至与MgO分解压相同的水平,但仍然高于Y2O3的分解压,所以,在氧化物/合金界面发生Y与MgO的置换反应生 成Y2O3。此外,接近界面的合金内部固溶氧的析出使Y在合金内部氧化,如图4(b)所示。如果内氧化生成的Y2O3和置换反应生成的Y2O3形成连续的膜层,如图4(c)所示,那么在合金内侧,氧压降低到接近 Y2O3的分解压后,停止内氧化,此时Mg元素稳定存在,不会以Mg2+的形式进入氧化膜,因此,以后的氧化将只是Y2O3膜层的增厚。由于Y2O3膜的阻滞作用,氧化速度明显下降,这就是选择性氧化。但如果氧化物/基体界面上Y浓度不高,则内部不能形成连续的Y2O3膜,如图4(d)所示,氧化物/基体界面的氧压增大,内氧化继续进行,不能阻碍Mg2+经过MgO膜及其中的裂缝扩散和蒸发,灾难性氧化仍不可避免。

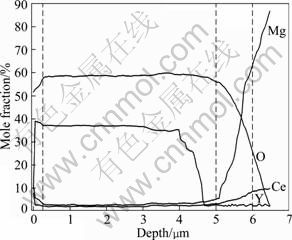

图4 Mg-Y合金氧化过程示意图

Fig.4 Schematic diagram of oxidation process for Mg-Y alloy: (a) Original oxidation; (b) Inner oxidation; (c) Selective oxidation; (d) Disastrous oxidation

可见,形成选择性氧化的关键在于能否形成连续的内氧化膜,这主要取决于氧化膜/基体界面合金元素的浓度,浓度越高,越容易形成连续氧化膜。WAGNER[14]提出了内氧化向外氧化转变的理论模型,并给出了临界浓度判据:

≥

≥ (16)

(16)

式中: 为形成选择性氧化所需的临界熔质溶度;Vox为氧化物的体积;Vall为参加氧化的金属的体积;Kp为氧化动力学速度常数;

为形成选择性氧化所需的临界熔质溶度;Vox为氧化物的体积;Vall为参加氧化的金属的体积;Kp为氧化动力学速度常数; 为互扩散系数。

为互扩散系数。

对于Mg-Y合金,当合金中Y含量低于约7%(质量分数)时,Y对镁合金的燃点无显著影响,与纯Mg的燃点相比仅提高了40~50 K。但是,随着Y含量的继续增加,合金的燃点开始明显上升;当Y含量高于10%(质量分数)时,合金可以在1 173 K的高温下保持0.5 h而不燃烧(见表1)。可见,对于Mg-Y合金,能够发生选择性氧化的Y浓度阈值约为7%(质量分数)。

2.4.2 Ce在Mg-Y合金中的第三元素效应

根据表1,加入微量Ce元素后,提高Mg-Y合金燃点所需的Y含量将大幅下降。测试结果表明,其表面仍然形成了Y2O3膜,从选择性氧化方面考虑,Ce的加入降低了从内氧化向外氧化转变的临界浓度 。WAGNER[14]对此类氧化行为进行了解释,认为第三元素起到了“吸气剂”的作用,可以抑制氧向合金内部扩散,从而抑制Y元素的内氧化。例如,在Mg-Y-Ce合金中,氧化初期,3种合金元素都参加了氧化反应,同时生成MgO、Ce2O3和Y2O3,且MgO的生长速度仍然最快,覆盖了Ce2O3、Y2O3和基体。但是,如果合金表面存在足够的Ce,就会与MgO发生置换反应,生成较致密的Ce2O3膜,因此,降低了氧化膜/基体界面的氧分压,使合金在Y含量较低的情况下也可形成连续的Y2O3膜。WAGNER[14]认为,第三元素氧化的Gibbs自由能变化应小于基体金属氧化的Gibbs自由能变化,而大于选择性氧化物的Gibbs自由能变化。从热力学计算结果可知,0>?G0(MgO)>?G0(Ce2O3)>?G0(Y2O3),Ce完全满足第三元素的热力学条件。

。WAGNER[14]对此类氧化行为进行了解释,认为第三元素起到了“吸气剂”的作用,可以抑制氧向合金内部扩散,从而抑制Y元素的内氧化。例如,在Mg-Y-Ce合金中,氧化初期,3种合金元素都参加了氧化反应,同时生成MgO、Ce2O3和Y2O3,且MgO的生长速度仍然最快,覆盖了Ce2O3、Y2O3和基体。但是,如果合金表面存在足够的Ce,就会与MgO发生置换反应,生成较致密的Ce2O3膜,因此,降低了氧化膜/基体界面的氧分压,使合金在Y含量较低的情况下也可形成连续的Y2O3膜。WAGNER[14]认为,第三元素氧化的Gibbs自由能变化应小于基体金属氧化的Gibbs自由能变化,而大于选择性氧化物的Gibbs自由能变化。从热力学计算结果可知,0>?G0(MgO)>?G0(Ce2O3)>?G0(Y2O3),Ce完全满足第三元素的热力学条件。

3 结论

1) Mg-3Y-4.5Ce合金能在大气中于1 173 K保温0.5 h而不燃烧,实现了镁合金在大气条件下的无保护熔炼。

2) Mg-3Y-4.5Ce合金宏观表面平坦,颜色较黑且有光泽。从横截面观察氧化膜分为3层,微观组织由大尺寸的粒状晶组成。X射线衍射结果表明,Mg-3Y-4.5Ce合金表面膜的外层主要由Y2O3组成,而内层以Mg为主,Y和Ce含量极低,中间为过渡层。

3) AES深度分析结果显示,Mg-3Y-4.5Ce合金在1 173 K下保温0.5 h时生成的氧化膜表面由O、Mg、Y和Ce 4种元素组成。各元素在膜深度方向的浓度分布可分为孕育层、相对稳定层和过渡层3个阶段。

4) 选择性氧化与第三元素效应共同决定了Mg-3Y-4.5Ce合金表面可生成以Y2O3为主的致密保 护膜。

REFERENCES

[1] 吕宜振, 翟春泉, 王渠东, 曾晓勤. 压铸镁合金的应用现状及发展趋势[J]. 铸造, 1998, 12: 50-53.

L? Yi-zhen, ZHAI Chun-quan, WANG Qu-dong, ZENG Xiao-qin. Application and developing tendency of die casting magnesium alloys[J]. Casting, 1998, 12: 50-53.

[2] BROWN R. Magnesium automotive meeting[J]. Light Metal Age, 1992, 50(5/6): 18-29.

[3] 曾小勤, 阻燃镁合金及其阻燃性能研究[D]. 上海: 上海交通大学, 2000.

ZENG Xiao-qin. Study on ignition proof magnesium alloy and its ignition proof principles[J]. Shanghai: Shanghai Jiao Tong University, 2000.

[4] MAGERS D. Global review of magnesium parts in automobiles[J]. Light Metal Age, 1997, 55(7): 60-62.

[5] CZERWINSKI F, ZIELINSKA-LIPIEC A, PINET P J, OVERBEEKE J. Correlating the microstructure and tensile properties of a thixomolded AZ91D magnesium alloy[J]. Acta Matter, 1994, 49: 1225-1235.

[6] LUO A, PEKGULERYUZ M O. Review of cast magnesium alloy for elevated temperature applications[J]. Journal of Materials Science, 1994, 29: 5259-5271.

[7] FAN J F, YANG G C, CHENG S L, XIE H, HAO W X, WANG M, ZHOU Y H. Surface oxidation behavior of Mg-Y-Ce alloys at high temperature[J]. Metallurgical and Materials transactions A, 2005, 36(1): 235-239.

[8] 黄晓锋, 周 宏, 何镇明. 阻燃镁合金研究进展[J]. 中国有色金属学报, 2000, 10(2): 271-274.

HUANG Xiao-feng, ZHOU Hong, HE Zhen-ming. Research and development on ignition proof magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(2): 271-274.

[9] HUDDLE R A U, LAING J, JESSUP A C, EMLEY E F. An Mg-base alloy resistant to the effect of air or oxidizing gases: UK 776649[P]. 1953-07-25.

[10] PEKGULERYUZ M O, AVDESIAN M M. Effects of element from No.IV or V on the mechanics properties of magnesium alloys[J]. Light Metals, 1992, 42(12): 679-686.

[11] CZERWINSKI F. The oxidation behavior of an AZ91D magnesium alloy at high temperatures[J]. Acta Materialia, 2002, 50: 2639-2654.

[12] 陆家和. 表面分析技术[M]. 北京: 电子工业出版社, 1987: 132.

LU Jia-he. Surface analysis technology[M]. Beijing: Electron Industry Press, 1987: 132.

[13] 樊建锋. 镁合金的高温氧化及阻燃理论研究[D]. 西安: 西北工业大学, 2005.

FAN Jian-feng. Research on oxidation and ignition-proof principles of magnesium alloys at high temperatures[D]. Xi’an: Northwestern Polytechnical University, 2005.

[14] WAGNER C. On the theory of scaling reactions[J]. Phys Chem B, 1933, 21: 25-42.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(50901048);山西省高等学校优秀青年学术带头人支持计划;山西省基础研究计划项目(2010021022-5);西北工业大学凝固技术国家重点实验室开放基金资助项目(SKLSP201003)

收稿日期:2010-10-22;修订日期:2011-04-30

通信作者:樊建锋,副教授,博士;电话:0351-6014852;E-mail: fanjianfeng77@sina.com