文章编号:1004-0609(2010)S1-s0083-04

Ti2448合金在不同应变速率下的高温变形机制

田宇兴, 李述军, 郝玉琳, 杨 锐

(中国科学院 金属研究所, 沈阳 110016)

摘 要:通过对亚稳β-Ti2448合金进行Gleeble热模拟压缩实验,研究其在单相β区的高温变形机制。结果表明:Ti2448合金的高温变形机制与应变速率有关,在较低应变速率(10-3~10-1 s-1)范围内,合金表现出初始应力峰值,随后逐渐软化直到达到稳态流变;其变形机制主要是形核和新晶粒长大的不连续动态再结晶(DDRX)。在较高的应变速率(1~63 s-1)范围内,合金首先表现出明显的硬化,随后略有软化,最后达到稳态;其变形机制主要是位错滑移主导的塑性变形,位错与晶界以及亚晶界之间的相互作用促使小角度晶界向高角度晶界的转变,表明变形机制为连续动态再结晶(CDRX)。

关键词:亚稳β-Ti2448合金;动态再结晶(DRX);位错结构

中图分类号:TG 146.2 文献标志码:A

Elevated temperature deformation mechanism of Ti2448 alloy at different strain rates

TIAN Yu-xing, LI Shu-jun, HAO Yu-lin, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The deformation mechanism of metastable β-Ti2448 alloy at elevated temperature was investigated by compression tests using Gleeble 3800 isothermal thermal simulator. The result shows that the deformation mechanism of Ti2448 at elevated temperature is associated with strain rate. In the lower strain rate range (10-3-10-1 s-1), the alloy exhibits stress peak in the initial stage and gradually softens subsequently until steady-flow. The primary mechanism of Ti2448 alloy at lower strain rate is discontinuous dynamic recrystallization (DDRX), with the characteristic of nucleation and new grain growth. In the higher strain rate range of 1~63 s-1, the alloy presents obvious hardening firstly, then slight softening and steady-state finally. The leading mechanism of Ti2448 alloy at higher strain rate is plastic deformation dominated by dislocation slipping. The interaction between dislocations and grain or sub-grain boundaries induces the transformation of low angle boundaries into high angle boundaries, which indicates continuous dynamic recrystallization (CDRX).

Key words: metastable β-Ti2448 alloy; dynamic recrystallization (DRX); dislocation structure

对合金进行高温塑性变形和随后的热处理可以控制合金的微观组织和力学性能。热塑性变形过程中通常伴随着动态再结晶的发生,这也是有希望获得细晶和超细晶组织的可行的方法[1-4]。然而,根据变形参数的不同,动态再结晶在组织演变中表现出不同的特 点[5-8],一般有连续动态再结晶、不连续动态再结晶和几何动态再结晶。金属及合金的高温变形过程受应变速率、变形温度、变形量和加载模式等变形参数的控制。因此,变形参数也控制着金属或合金的变形机制的转变。

实验选用亚稳β-Ti2448合金,研究其在单β相区的高温变形机制。通过对变形参数(温度和应变速率)的控制,研究不同应变速率下变形机制的差异。

1 实验

利用真空自耗熔炼炉3次熔炼获得直径为140 mm的Ti-24Nb-4Zr-8Sn(Ti2448)合金铸锭,其化学成分的为(质量分数):24.2%Nb,3.9%Zr,7.9%Sn,0.11%O,0.008%N,余量为Ti。合金铸锭在850 ℃锻造成15 mm厚的板材。从板材厚度方向上切取压缩试样,表面打磨后得到尺寸为d8 mm ×12 mm的圆柱体。热模拟压缩试验在Gleeble3800试验机上进行:试验温度为750 ℃,应变速率范围为10-3~63 s-1,所有圆柱试样的轴向压缩量为75%(压缩方向为板材的厚度方向)。试验过程中温度由焊在试样侧面中部的铂铑热电偶实时测控,以保证压缩变形过程中的恒温条件。压缩到预定的应变量后,试样立即水冷,以保留变形组织。压缩后的饼状试样沿纵向中心剖开,切取小片制作透射样品。经过机械减薄和电解双喷获得的透射样品在Philips EM42透射电镜上进行观察,操作电压为100 kV。金相组织在100 ℃的40%HCl水溶液中蚀刻得到。

2 结果与讨论

2.1 热轧板材组织

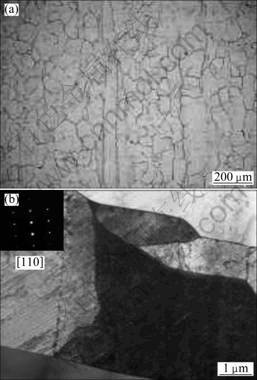

Ti2448热轧板材(厚15 mm)的纵向截面的显微组织见图1所示。由图1可看出,板材的原始组织主要由等轴晶组成,平均晶粒尺寸为40 μm。在部分等轴晶之间有少量的宽度约为80 μm的条状组织(见图1(a))。通过透射电镜观察,热轧板材的等轴晶粒由很多细小并不均一的亚晶粒组成,亚晶粒的平均尺寸为3 μm(见图1(b))。亚晶粒内有少量的位错,晶内表现出比较洁净的特征。选区电子衍射表明原始板材由单相β组成。

2.2 真应力—应变曲线

对Ti2448板材在750 ℃进行热模拟压缩试验。根据前人的研究[9],Ti2448合金的β转变温度为650~700 ℃,因此在750 ℃进行的压缩试验处在单β相区内。图2所示为由压缩试验得到的真应力—应变曲线。由图2可以看出,合金在应变速率10-3~63 s-1范围内表现出明显不同的应力响应特征。在较高应变速率下(1 s-1、10 s-1和63 s-1),合金表现出初始硬化,达到应力峰值后略有缓慢的软化,然后基本保持应力稳定,其应力水平在225~275 MPa。对于应变速率63 s-1,曲线在应变为0~0.6的范围内有明显的锯齿状波动,这是由于高速下材料内部局部变形失稳导致的。

在较低应变速率下(10-3~10-1 s-1),整体应力 在50~200 MPa的较宽范围内。图2中上部插图为 10-1、10-2和10-3 s-1应变速率下的曲线在小应变 (~0.2)范围的放大图。由图2可以看出,低应变速率下的合金在很小的应变内就达到单一的应力峰。随后,在较大应变范围内持续软化。当应变达到0.7时,应力水平达到最低值,而后合金表现出略微的硬化直到试验结束。

图1 Ti2448热轧板材的金相组织和透射电镜照片以及选区电子衍射花样

Fig.1 Optical metallograph of hot rolled Ti2448 billet (a) and TEM image and selected area electron diffraction pattern (b)

图2 Ti2448合金在750 ℃,应变速率为10-3~63 s-1下的真应力—应变曲线

Fig.2 True stress—strain curves of Ti2448 alloy at strain rate of 10-3-63 s-1and 750 ℃

通过合金的应力—应变曲线可以分析其组织演化和高温变形机制。大量的研究表明[1-2, 5],动态回复和动态再结晶是材料热加工过程中的主要变形机制。McQUEEN[10]指出,动态回复和动态再结晶在真应 力—应变曲线上表现出明显不同的趋势。动态再结晶主导的变形在真应力—应变曲线上表现出显著的初始应力峰,随后应力逐渐达到稳态。从图2可以看出,在较低应变速率下(10-3~10-1 s-1),真应力—应变曲线是典型的动态再结晶型曲线。而对于高应变速率(1~63 s-1),位错运动主导的动态回复是高速变形的主要机制。

2.3 高温变形动力学

金属的高温变形是热力学参数所支配的一个热激活过程。通常采用受热激活控制的动力学方程来分析温度和应变速率对流变应力的综合影响。本文中采用指数关系描述应变速率和流变应力之间的关系[3]:

(1)

(1)

式中: 为应变速率;σ为流变应力;A为系数;R为摩尔气体常数;T为绝对温度;n为应力指数;Q为变形激活能。需要指出的是,本研究中选用稳态阶段应变为0.7时的应力值为流变应力。对式(1)两边求导后得到lnσ和

为应变速率;σ为流变应力;A为系数;R为摩尔气体常数;T为绝对温度;n为应力指数;Q为变形激活能。需要指出的是,本研究中选用稳态阶段应变为0.7时的应力值为流变应力。对式(1)两边求导后得到lnσ和 的关系式,其数据关系表示在图3中。

的关系式,其数据关系表示在图3中。

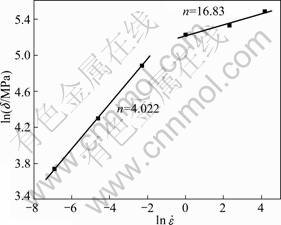

从图3可以看出, 应力—应变双对数曲线在两个不同的应变速率范围内分别较好地满足线性关系,即在10-3~10-1 s-1和1~63 s-1 2个应变速率范围内表现出双线性关系,其应力指数分别为4.022和16.83。

图3 Ti2448合金 —

— 曲线

曲线

Fig.3  —

— curves of Ti2448 alloy

curves of Ti2448 alloy

有研究[11]表明:基于不同相区不同的温度,在单相区及两相区热变形的应力对温度的敏感值可划分为不同的区间。而基于温度的变化而引起的变形机制的不同也将在动力学分析曲线上表现出不同的特征[12]。本文中lnσ和 的关系在2个不同的应变速率范围表现出不同的应力指数,反映了合金在不同应变速率下的机制的转变[13]。

的关系在2个不同的应变速率范围表现出不同的应力指数,反映了合金在不同应变速率下的机制的转变[13]。

2.4 组织演变和高温变形机制

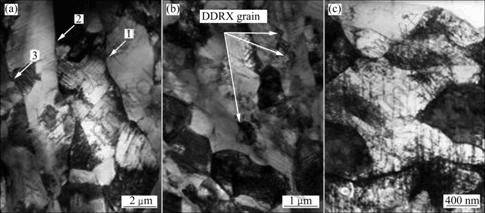

图4所示为Ti2448合金在10-2 s-1和10 s-1应变速率条件下变形量为75%的微观组织的演变。从图4(a)可以看出,在应变速率10-2 s-1下,晶粒在压缩方向上被压扁,但原始的大角度晶界在变形后的组织中依然存在(白色箭头1、2和3所指)。在晶界或者三角晶界处有很细小的新晶粒(见图4(b)中白色箭头所示),其尺寸为400~800 nm,远小于原始组织中亚晶粒的尺寸。经过分析,这些细小的内部洁净的新晶粒为动态再结晶晶粒;在低速变形过程中,新晶粒会继续长大。传统的动态再结晶是指合金在热变形过程中重新发生形核和新晶粒长大,即不连续动态再结晶[14]。由于结构的满足和成分扩散,不连续再结晶的形核一般都出现在晶界或者三角晶界处[15]。图4(c)所示为应变速率为10 s-1条件下微观组织的TEM像。从图4(c)可以看出,在高速变形后原始等轴晶粒内布满高密度的位错结构,且一些位错穿过晶界扩展到相邻的晶粒,或者在晶粒内部形成位错胞状结构。位错在高应变速率变形中起着重要作用,位错的运动以及形成的位错结构是发生动态回复的主要特征。另外,高速变形下位错与原始小角度晶界相互作用转变为大角度晶界,在图4(c)中显示出衬度分明的组织特征。

根据合金的真应力—应变曲线特征、动力学参数特点和组织演变的不同,Ti2448合金热轧板材在不同应变速率下表现出明显不同的变形机制。在低应变速率下,缓慢压缩使得材料有充足的时间发生高温扩散,且经过协调变形很容易在三角晶界处满足结构起伏,为形核提供了可能的条件[15]。随后,再结晶新晶粒在充足的时间内长大,而且新晶粒的长大同时伴随着其他位置的形核的发生。不连续动态再结晶导致应力随着应变的增加而持续下降,直到再结晶过程的完成。此外,变形合金中也出现稀疏的位错结构。但是,高应变速率下变形后的合金表现出更高密度的位错结构。位错从原始晶界激发,在外加应力条件下向晶内扩展,直到在晶界处塞积,并且扩展穿过相邻晶界。因此,在真应力—应变曲线上表现出持续较高的应力水平。另外,位错也会塞积在亚晶界或者变形前原始位错墙,使得小角度晶界向大角度晶界转变,发生所谓的连续动态再结晶。

图4 应变速率为10-2 s-1和10 s-1条件下Ti2488合金的TEM像

Fig.4 TEM images of Ti2488 alloy at strain rates of 10-2 s-1 (a, b) and 10 s-1 (c)

3 结论

1) 通过研究亚稳β-Ti2448合金在单β相区高温变形机制发现:在相同的温度下,Ti2448合金的高温变形表现出明显不同的应力响应行为,其变形机制受应变速率影响。

2) 在较低应变速率(10-3~10-1 s-1)范围内,合金表现出初始应力峰值,随后逐渐软化直到达到稳态流变,其变形机制主要是形核和新晶粒长大为特征的不连续动态再结晶。

3) 在较高的应变速率(1~63 s-1)范围内,合金首先表现出明显的硬化,随后略有软化趋势,最后达到稳态;其变形机制主要是位错滑移主导的塑性变形,位错与晶界以及亚晶界之间的相互作用促使了小角度晶界向高角度晶界的转变,这表明其变形机制为连续动态再结晶。

REFERENCES

[1] McQUEEN H J, JONAS J J. Recent advances in hot working: Fundamental dynamic softening mechanisms[J]. Journal of Applied Metalworking, 1984, 3(3): 233-241.

[2] DUDOVA N, BELYAKOV A, SAKAI T, KAIBYSHEV R. Dynamic recrystallization mechanisms operating in a Ni-20%Cr alloy under hot-to-warm working[J]. Acta Materialia, 2010, 58(10): 3624-3632.

[3] BOURELL D L, McQUEEN H J. Thermomechanical processing of iron, titanium, and zirconium alloys in the bcc structure[J]. Journal of Materials Shaping Technology, 1987, 5: 53-73.

[4] CHEN Hui-qin, CAO Chun-xiao, GUO Ling, LIN Hai. Hot deformation mechanism and microstructure evolution of TC11 titanium alloy in β field[J]. Transaction of Nonferrous Metals Society of China, 2008, 18(5): 1021-1027.

[5] GOURDET S, MONTHEILLET F. An experimental study of the recrystallization mechanism during hot deformation of aluminium[J]. Materials Science and Engineering A, 2000, 283: 274-288.

[6] SAKAI T. Dynamic recrystallization microstructures under hot working conditions[J]. Journal of Materials Processing Technology, 1995, 53: 349-361.

[7] KUHLAANN-WILSDORF D, HANSEN N. Geometrically necessary, incidental and subgrain boundaries[J]. Scripta Metallurgica, 1991, 25: 1557-1562.

[8] McQUEEN H J. Development of dynamic recrystallization theory[J]. Materials Science and Engineering A, 2004, 387/389: 203-208.

[9] LI Shu-jun, ZHANG Yan-wei, SUN Bing-bing, HAO Yu-lin, YANG Rui. Thermal stability and mechanical properties of nanostructured Ti-24Nb-4Zr-7.9Sn alloy[J]. Materials Science and Engineering A, 2008, 480: 101-108.

[10] McQUEEN H J. Metallography and the mechanisms related to hot working of metals[J]. Microstructural Science, 1979, 7: 71-86.

[11] RAO K P, PREASAD Y V R K. High temperature deformation kinetics of A1-4Mg alloy[J]. Journal of Mechanical Working Technology, 1986, 13: 83.

[12] EGHBALI B. Effect of strain rate on the microstructural development through continuous dynamic recrystallization in a microalloyed steel[J]. Materials Science and Engineering A, 2010, 527: 3402-3406.

[13] SENKOV O N, JONAS J J. Effect of strain rate and temperature on the flow stress of β-phase titanium-hydrogen alloys[J]. Metallurgical and Materials Transaction A, 1996, 27(5): 1303-1312.

[14] YAMAGATA H. Dynamic recrystallization of single-crystalline aluminum during compression tests[J]. Scripta Metallurgica Materialia, 1992, 27(6): 727-732.

[15] MIURA H, SAKAI T, HAMAJI H, JONAS J J. Preferential nucleation of dynamic recrystallization at triple junctions[J]. Scripta Materialia, 2004, 50: 65-69.

(编辑 杨 华)

基金项目:国家自然科学基金资助项目(50631030,50901080);辽宁省自然科学基金资助项目(20092075)

通信作者:郝玉琳,研究员;电话:024-83978841;E-mail:ylhao@imr.ac.cn