DOI: 10.11817/j.ysxb.1004.0609.2020-35727

高铬含量Fe-Cr合金800 ℃的循环和恒温高温氧化行为

徐勋虎1,张 涛2,王 玲1,张洪华1,门丹丹1,向军淮1,安江山1

(1. 江西科技师范大学 江西省材料表面工程重点实验室,南昌 330013;

2. 中国科学院固体物理研究所,合肥 230031)

摘 要:研究了高铬含量的Fe-20Cr、Fe-30Cr和Fe-40Cr三种合金在800 ℃,空气中的循环氧化行为和0.1 MPa纯氧气中的恒温氧化行为。三种合金在循环氧化条件下的氧化动力学均不规则,随着Cr含量的增加,其抗氧化性能逐渐增强。24 h氧化后,Fe-20Cr单位面积增质最大,其值为2. 21×10-2 mg/(cm2·h),Fe-40Cr单位面积增质最小,其值为1. 45×10-2 mg/(cm2·h)。结果表明:三种合金的恒温氧化动力学曲线均可分为暂态氧化和稳态氧化两个阶段,每个阶段都能较好地符合抛物线规律。总体上来说,恒温条件下三种合金都具有优异的抗高温氧化性能,其24 h单位面积氧化增质比循环氧化下降了将近一个数量级。但随着Cr含量的增加,三种合金抗氧化性能逐渐下降,Fe-20Cr反而具有最佳的抗氧化性能。在循环和恒温氧化条件下,三种Fe-Cr合金均生成了单一的保护性Cr2O3外氧化膜。

关键词:Fe-Cr;高温氧化;高铬含量

文章编号:1004-0609(2020)-03-0580-07 中图分类号:TG141 文献标志码:A

随着科学技术的飞速发展,对材料的综合性能要求越来越高。高温合金广泛应用于航空航天等重要领域,其氧化机制非常复杂,近年来合金高温氧化的机理研究越来越受到人们关注[1-6]。Fe-Cr合金价格低廉、具有优良的抗高温氧化性能,应用非常广泛[7-8]。王建明等[9]研究了Fe-5Cr和Fe-10Cr合金在1000 ℃的空气中的氧化行为,结果表明,相比于Fe-5Cr合金,Fe-10Cr合金表现出更好的抗氧化性能。梁艳等[10]研究了Fe-15Cr和Fe-20Cr合金在900 ℃和1000 ℃的空气中的氧化行为,结果表明,随着Cr含量的增加,Fe-Cr合金的抗氧化性能越来越好。RIFAI等[11]研究表明,用强塑性变形(SPD)制备的二元Fe-Cr合金可以获得超细晶结构,因此显著提高了其耐蚀性。褚冉[12]研究了添加Al元素的Fe-Cr合金,由于在高温下形成致密的Al2O3保护膜,使用温度可达1300 ℃,扩大了Fe-Al合金的应用范围。MOON等[13]研究了2Si对于不同Cr含量的三种合金(Fe-12Cr,Fe-16Cr,Fe-20Cr)的氧化行为的影响。结果表明,由于Fe-12Cr-2Si和Fe-16Cr-2Si两个合金表面均只形成了多孔且不完全的多层氧化物(主要由混合的Fe/Cr/Si尖晶石组成),故其抗氧化性能非常差。相反,由于Fe-20Cr-2Si合金在界面处形成了连续的无定形SiO2层和几乎完全致密的Cr2O3保护层,因此其显示出更佳优异的抗氧化性。低铬含量的Fe-Cr合金高温氧化行为已有较多研究,且集中于其恒温氧化行为。高铬含量的Fe-Cr合金高温氧化行为未见系统研究。本文选择Fe-20Cr、Fe-30Cr和Fe-40Cr三种高铬含量二元模型合金,分别研究其循环氧化及恒温氧化行为,以获得对高铬含量Fe-Cr合金氧化机制的新认识,进一步拓展Fe-Cr合金的应用范围。

1 实验

二元Fe-20Cr,Fe-30Cr和Fe-40Cr(摩尔分数,%)合金是由纯度大于99.9%的Fe和Cr金属单质为原料,在氩气保护下于非自耗真空电弧熔炼炉中反复熔炼而成。将熔炼好的合金锭置于真空管式退火炉中,在900 ℃的条件下真空退火24 h,其作用是去除内应力,使合金成分均匀化。通过数控线切割技术将合金锭切割成10 mm×10 mm×1 mm大小的式样。然后分别用180#、600#、1000#、2000#的防水砂纸打磨样品表面,磨好后再抛光。最后,用蒸馏水、丙酮和乙醇超声清洗后置于干燥器中备用。样品的连续质量变化测量是在Setaram Setsys Evo 热分析仪中进行的,氧化条件为800 ℃,空气中循环氧化24 h和0.1 MPa纯氧气中恒温氧化24 h。采用场发射扫描电子显微镜(FESEM)结合能谱分析仪(EDS)对氧化膜和组成进行表征,X射线衍射仪(XRD)分析样品氧化膜的物相组成。

2 实验结果

2.1 氧化动力学

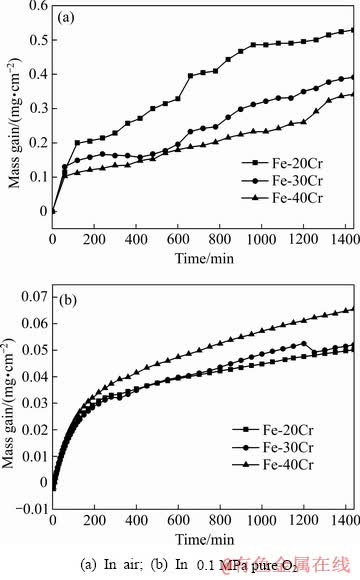

Fe-20Cr、Fe-30Cr和Fe-40Cr合金在800 ℃,空气中循环氧化24 h和0.1 MPa纯氧气中恒温氧化24 h的氧化动力学曲线如图1所示。

图1 Fe-20Cr、Fe-30Cr和Fe-40Cr合金在800 ℃循环与恒温氧化24 h的动力学曲线

Fig. 1 Oxidation kinetics of Fe-20Cr, Fe-30Cr and Fe-40Cr alloys after oxidation at 800 ℃ for 24 h

Fe-20Cr、Fe-30Cr和Fe-40Cr合金在800 ℃,空气中循环氧化24 h后的氧化动力学曲线均不太规则,但大致符合抛物线规律。Fe-20Cr经过24 h氧化后的增质最大,其Dm值为2.21×10-2 mg/(cm2·h),而Fe-40Cr的增质小得多,其Dm值为1.45×10-2 mg/(cm2·h)。在三种合金中,Fe-40Cr表现出最佳的抗氧化性能。

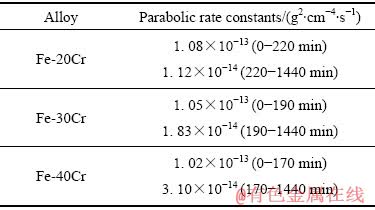

在0.1 MPa纯氧气中恒温氧化24 h后,Fe-20Cr和Fe-30Cr合金Dm值非常接近,其Dm值均小于Fe-40Cr合金的。Fe-20Cr、Fe-30Cr和Fe-40Cr合金800 ℃恒温氧化的抛物线速率常数列于表1,三种合金从暂态氧化到稳态氧化,其抛物线速率下降明显。与循环氧化比较,三种合金中,Cr含量最低的Fe-20Cr抗高温氧化性反而最好。

表1 Fe-20Cr、Fe-30Cr和Fe-40Cr合金在800 ℃恒温氧化24 h的近似抛物线速率常数

Table 1 Approximate parabolic rate constants of Fe-20Cr, Fe-30Cr and Fe-40Cr alloys after isothermal oxidation at 800 ℃ for 24 h

2.2 氧化膜形貌和组成

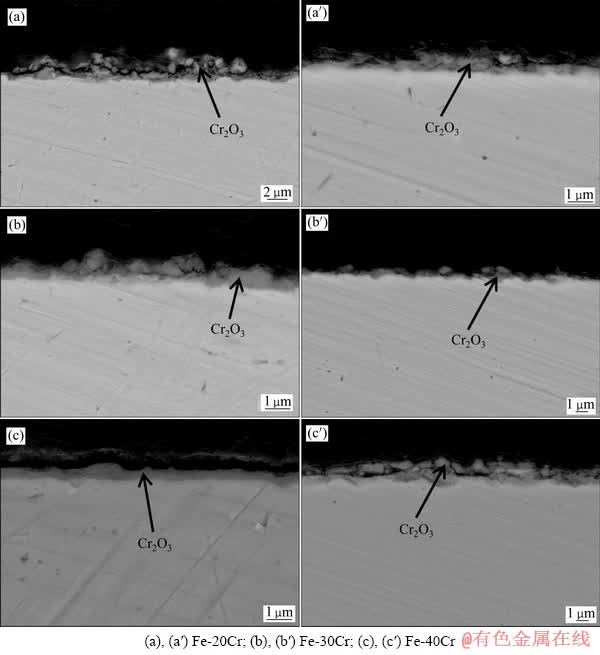

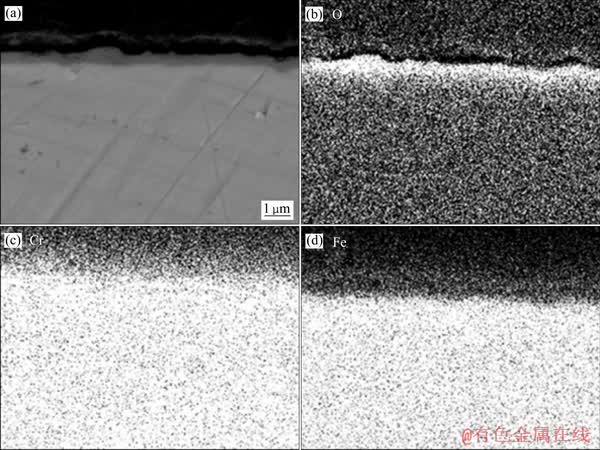

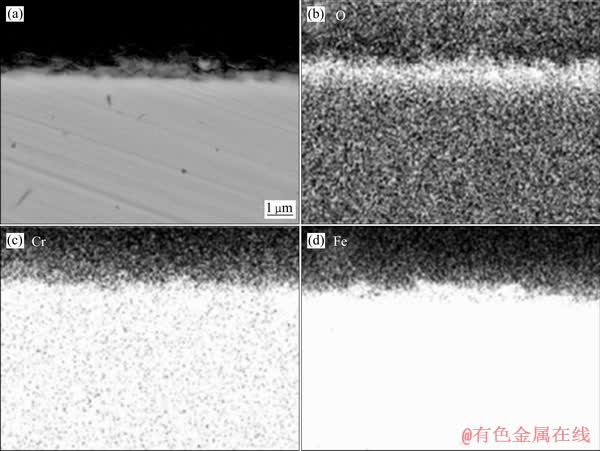

Fe-20Cr、Fe-30Cr和Fe-40Cr合金在800 ℃循环和恒温氧化24 h后的截面形貌如图2所示。三种合金在循环与恒温氧化中均只形成了单一的保护性Cr2O3膜。在循环氧化中,Fe-20Cr, Fe-30Cr合金的氧化膜并不平整,形如锯齿,且厚度明显大于Fe-40Cr。然而,由于此时氧化膜中存在较大的应力,导致其容易因为破裂而剥落。如图1(a)所示,Fe-30Cr合金在200 min后由于氧化膜的剥落导致出现了短暂的失重,但是由于合金中Cr含量较高,剥落的氧化膜能快速愈合,Fe-30Cr合金在400 min后开始出现增质。图3所示为Fe-40Cr合金800 ℃循环氧化24 h后的截面形貌及对应的元素分布图,致密的保护性Cr2O3膜阻止了合金被进一步氧化。

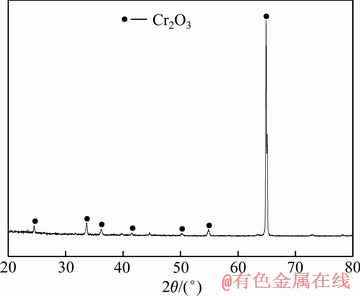

在恒温氧化条件下,只有Fe-20Cr合金在氧化后形成了一层致密且连续的Cr2O3层。Fe-30Cr合金的氧化膜厚度比Fe-20Cr合金厚,但是其氧化膜并不平整,形如锯齿,且在其氧化膜中发现少部分因应力而破裂的颗粒状氧化物。Fe-40Cr合金氧化膜比前两种合金厚,其氧化膜全部破裂成颗粒状,图4所示为Fe-20Cr合金800 ℃恒温氧化24 h的截面形貌及对应的元素分布图,Fe-20Cr所形成的Cr2O3氧化膜比较薄,连续且致密,表现出最佳的抗高温氧化性能。XRD谱显示三个合金在循环和恒温氧化下的检测结果基本一致,氧化膜中均只有Cr2O3的存在,这也对应于截面形貌,因此本文中只放了Fe-20Cr合金在800 ℃循环氧化24 h后氧化膜的XRD谱(见图5)。

图2 Fe-20Cr、Fe-30Cr和Fe-40Cr合金在800 ℃循环氧化和恒温氧化24 h后的截面形貌

Fig. 2 SEM images of cross sections of Fe-xCr(x=20, 30, 40) alloys after cyclic oxidation in air((a), (b), (c),) and isothermal oxidation in 0.1 MPa pure O2((a′), (b′), (c′),) at 800 ℃ for 24 h

3 讨论

本实验结果表明,所有合金在循环和恒温氧化条件下均只形成了单一的保护性Cr2O3膜。Fe-Cr合金的氧化与Ni-Cr合金比较类似,研究表明[14],当Ni-Cr合金中Cr含量较低时,掺杂的Cr3+增加了NiO中的缺陷浓度,合金氧化严重;当Cr含量为5%~15%时,合金氧化膜主要分为3层,外层为NiO,次外层为NiCr2O4,内层为不连续的Cr2O3;当Cr含量大于15%时,合金形成了单一的保护性Cr2O3膜,合金氧化速率大幅降低;当Cr含量达到20%,局部因应力破裂而脱落的Cr2O3氧化膜可以通过Cr3+向外扩散修复。高铬含量的Fe-20Cr、Fe-30Cr和Fe-40Cr在循环与恒温氧化条件下与高铬含量的Ni-Cr合金氧化形成的氧化膜基本一致,均只形成了单一的Cr2O3保护膜。

图3 Fe-40Cr合金800 ℃循环氧化24 h的截面形貌及对应的元素分布图

Fig. 3 SEM-cross section image(a) and corresponding EDS elemental maps((b), (c), (d),) of Fe-40Cr alloy after cyclic oxidation in air for 24 h at 800 ℃

图4 Fe-20Cr合金800 ℃恒温氧化24 h的截面形貌及对应的元素分布图

Fig. 4 SEM-cross section image(a) and corresponding EDS elemental maps((b), (c), (d),) of Fe-20Cr alloy after isothermal oxidation in 0.1 MPa pure O2 for 24 h at 800 ℃

图5 Fe-20Cr合金在800 ℃循环氧化24 h后氧化膜的XRD谱

Fig. 5 X-ray diffraction patterns of Fe-20Cr alloy after cyclic oxidation at 800 ℃ for 24 h

研究表明[15],当Cr含量较高时,在氧化初期,一方面,基体表面的大量Cr质点作为Cr2O3的形核中心,缩短了Cr2O3核间的距离,使得Cr2O3的形核数量大大增加;另一方面,当Cr含量较高时,合金中晶界体积分数很大,导致Cr向外扩散加快,补充“Cr”源,促使Cr2O3快速形核。对于Fe-20Cr、Fe-30Cr和Fe-40Cr合金的氧化过程来说,Cr原子可以不断地通过高密度晶界向外扩散,促使Cr2O3氧化物迅速横向生长,在很短的暂态氧化过程中形成连续的保护性Cr2O3保护膜,导致合金表面Fe2O3的形核和生长受到限制。氧化膜最外层只形成少许Fe2O3和FeCr2O4。由于Cr2O3的标准形成自由能比Fe2O3的标准形成自由能更负,因此合金元素Cr可以把Fe2O3还原为Fe而生成Cr2O3:

2Cr+Fe2O3→Cr2O3+2Fe (1)

Fe2O3被还原,导致Fe2O3含量降低,此时FeCr2O4开始分解成Fe2O3和Cr2O3以补充Fe2O3,直到形成单一Cr2O3保护膜。

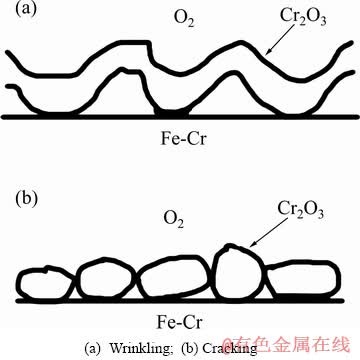

在循环氧化过程中,Fe-40Cr比Fe-20Cr和Fe-30Cr表现出更好的抗氧化性能,Fe-20Cr、Fe-30Cr氧化膜并不平整,形如锯齿,只有Fe-40Cr形成连续且致密的Cr2O3保护膜。在高温氧化过程中,氧化膜中存在应力作用,这时氧化膜容易起皱和破裂[16-18],由于氧化膜中应力较大,且无法通过塑性变形释放,氧化膜将会起皱、甚至破裂。但是,应力的释放也有迹可循。当应力很大时,氧化膜就会起皱,如图6(a)所示,氧化膜与合金基体的接触面积减小,且呈弯曲状,此时可以去除部分应力。如果氧化膜的应力通过塑性变形也无法得到完全释放,氧化膜就会破裂,破裂后的氧化膜呈颗粒状,如图6(b)所示,此时氧化膜不具备保护性能,合金氧化加速进行。循环氧化过程中,由于频繁的温度骤变,相对于生长应力,此时热应力起主要作用。但是二者共同作用时产生了较大的综合应力,导致氧化膜易破裂,此时氧化膜的修复快慢成为主要矛盾。Fe-40Cr中Cr含量充足,剥落的氧化膜可以通过获得充足的“Cr”源快速愈合。因此只有Fe-40Cr形成连续且致密的Cr2O3保护膜,且表现出最佳的抗氧化性能。

与循环氧化相比,恒温氧化条件下氧化膜生长过程中并不存在由于温度骤变而引起的热应力,综合应力仅仅由生长应力提供,其值明显降低,氧化膜因为应力的作用而破裂的可能性大大减小,氧化增质几乎下降了一个数量级,此时氧化膜的修复已经不再是主要矛盾。与Fe-30Cr和Fe-40Cr合金相比,Fe-20Cr合金恒温氧化过程中形成的氧化膜应力比较小,不容易破裂,故其抗氧化性能最佳。

图6 氧化膜破裂机制图

Fig. 6 Fracture mechanism of oxide layer

4 结论

1) Fe-20C、Fe-30Cr和Fe-40Cr合金在800 ℃,空气中循环氧化24 h和0.1 MPa纯氧气中恒温氧化24 h后表面均形成了单一的保护性Cr2O3膜,且其氧化动力学曲线大致符合抛物线规律。

2) 在循环氧化条件下,由于氧化膜中应力较大,导致氧化膜容易破裂,此时氧化膜的修复快慢程度成为主要矛盾。Fe-40Cr合金中Cr的含量充足,剥落的氧化膜可以通过获得充足的“Cr”源快速愈合。在这三种合金中,Fe-40Cr合金表现出最佳的抗氧化性能。

3) 在恒温氧化条件下,氧化膜中应力较小,氧化膜不易破裂,此时的主要矛盾不再是氧化膜的修复快慢程度,而是氧化膜中的应力大小。与Fe-30Cr和Fe-40Cr合金相比,Fe-20Cr合金恒温氧化过程中形成的氧化膜应力比较小,不容易破裂,故其抗氧化性能最佳。

REFERENCES

[1] SHI Z, LI J, LIU S. Isothermal oxidation behavior of single crystal superalloy DD6[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 534-538.

[2] LIU L, WU S, CHEN Y, LU S. Oxidation behavior of RE-modified nickel-based superalloy between 950 ℃ and 1150 ℃ in air[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(4): 1163-1169.

[3] YAN W, YONG L, TANG H, LI W, HAN C. Oxidation behavior and mechanism of porous nickel-based alloy between 850 and 1000 ℃[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1558-1568.

[4] WANG X, SZPUNAR J A. Effects of grain sizes on the oxidation behavior of Ni-based alloy 230 and N[J]. Journal of Alloys & Compounds, 2018, 752: 40-52.

[5] 肖逸锋, 刘 艳, 汤 智, 吴 靓, 许艳飞, 钱锦文, 贺跃辉. Ni-Cr-Fe多孔材料的制备及抗氧化性能[J]. 中国有色金属学报, 2017, 27(2): 295-304.

XIAO Yi-feng, LIU Yan, TANG Zhi, WU Liang, XU Yan-fei, QIAN Jin-wen, HE Yue-hui. Fabrication and high temperature oxidation resistance of porous Ni-Cr-Fe alloys[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 295-304.

[6] 曹中秋, 孙 玥, 贾中秋. 纳米晶块体 Fe-60Ni-15Cr 合金的高温氧化行为[J]. 中国有色金属学报, 2015, 25(10): 2790-2797.

CAO Zhong-qiu, SUN Yue, JIA Zhong-qiu. High temperature oxidation behavior of nanocrystalline bulk Fe-60Ni-15Cr alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2790-2797.

[7] GARZA-MONTES-DE-OCA N F, RAMIREZ-RAMIREZ J H, ALVAREZ-ELCORO I, RAINFORTH W M, COLAS R. Oxide structures formed during the high temperature oxidation of hot mill work rolls[J]. Oxidation of Metals, 2013, 80(1): 191-203.

[8] MONTEIRO M J, SAUNDERS S R, RIZZO F C. The effect of water vapour on the oxidation of high speed steel, kinetics and scale adhesion[J]. Oxidation of Metals, 2011, 75(1): 57-76.

[9] 王建明, 高 炜, 孙 彬. Fe-Cr合金钢在1000 ℃空气条件下的氧化行为[J]. 沈阳大学学报(自然科学版), 2018, 30(4): 259-262.

WANG Jian-ming, GAO Wei, SUN Bin. Oxidation behavior of Fe-Cr alloy steel at 1000 ℃ in air[J]. Journal of Shenyang University (Natural Science), 2018, 30(4): 259-262.

[10] 梁 艳, 龙媛媛, 付广艳. Fe-Cr合金在1000 ℃空气中的高温腐蚀行为[J]. 辽宁化工, 2004(5): 263-266.

LIANG Yan, LONG Yuan-yuan, FU Guang-yan. Study on high temperature oxidation of Fe-Cr alloys[J]. Liaoning Chemical Industry, 2004(5): 263-266.

[11] RIFAI M, YUASA M, MIYAMOTO H. Enhanced corrosion resistance of ultrafine-grained Fe-Cr alloys with subcritical Cr contents for passivity[J]. Metals-Open Access Metallurgy Journal, 2018, 8(3): 149.

[12] 褚 冉. Fe-Cr-Al 合金高温氧化及影响机理研究[D]. 沈阳: 沈阳师范大学, 2013.

CHU Ran. Studies on high-temperature oxidation and its influence mechanism of Fe-Cr-Al alloy[D]. Shenyang: Shenyang Normal University, 2013.

[13] MOON J, KIM S, PARK W D, KIM T Y, MCALPINE S W, SHORT M, KIM H J, BAHN C B. Initial oxidation behavior of Fe-Cr-Si alloys in 1200 ℃ steam[J]. Journal of Nuclear Materials, 2019, 513: 297-308.

[14] 李铁藩. 金属高温氧化和热腐蚀[M]. 北京: 化学化工出版社, 2003, 202-203.

LI Tie-fan. High temperature oxidation and hot corrosion of metals[M]. Beijing: Chemical Industry Press, 2003, 202-203.

[15] 李 墨. 不同Cr含量的Ni基合金腐蚀行为[D]. 沈阳: 沈阳工业大学, 2009.

LI Mo. Corrosion behavoir of nickel-based alloys with different chromium contents[D]. Shenyang: Shenyang University of Technology, 2009.

[16] 李美栓. 金属高温腐蚀[M]. 北京: 冶金工业出版社, 2001: 200.

LI Mei-shuan. High temperature corrosion of metals[M]. Beijing: Metallurgical Industry Press, 2001: 200.

[17] WU H, LI C, FANG K, XUE F, ZHANG G, LUO K, WANG L. Effect of machining on the stress corrosion cracking behavior in boiling magnesium chloride solution of austenitic stainless steel[J]. Materials & Corrosion, 2018, 69(4): 519-526.

[18] KIM Y S, KIM W C, KIM J G. Influence of ultrasonic nanocrystal surface modification on the corrosion and stress corrosion cracking behavior of low carbon steel (ASTM A139) welded joint in the simulated district heating environment[J]. Corrosion, 2018, 74(1): 112-122.

Oxidation behavior of Fe-Cr alloys with high Cr content at 800 ℃

XU Xun-hu1, ZHANG Tao2, WANG Ling1, ZHANG Hong-hua1, MEN Dan-dan1, XIANG Jun-huai1, AN Jiang-shan1

(1. Jiangxi Key Laboratory of Surface Engineering, Jiangxi Science and Technology Normal University, Nanchang 330013, China;

2. Institute of Solid State Physics, Chinese Academy of Sciences, Hefei 230031, China)

Abstract: The cyclic oxidation in air and isothermal oxidation in 0.1 MPa pure oxygen at 800 ℃ for Fe-20Cr, Fe-30Cr and Fe-40Cr alloys with a high Cr content were investigated. The results show that the three alloys exhibit irregular oxidation kinetics under the cyclic oxidation condition. With the increase of Cr content, the oxidation resistance of the alloy is improved. After 24 h oxidation, Fe-20Cr obtains the highest mass gain per unit area with the value of 2.21×10-2 mg/(cm2·h), while Fe-40Cr obtains the lowest value of 1.45×10-2 mg/(cm2·h). The isothermal oxidation kinetics of the three alloys can be divided into two stages as transient and steady oxidation. At each stage the kinetics obeys the parabolic law quite well. On the whole, the three alloys show excellent oxidation resistance. Compared with the case of cyclic oxidation, the mass gain per unit area after 24 h oxidation of the three alloys decreases by almost an order of magnitude. On the contrary, with the increase of Cr content, the oxidation resistance of the three alloys decreases gradually and Fe-20Cr presents the best performance. Under all conditions, an exclusive and protective Cr2O3 layer forms on the surfaces of the three Fe-Cr alloys.

Key words: Fe-Cr; high temperature oxidation; high Cr content

Foundation item: Project(51701054) supported by the National Natural Science Foundation of China; Project (GJJ160770) supported by the Science and Technology Research Program of Jiangxi Provincial Education Department, China; Project(YC2018-X01) supported by the Graduate Innovation Fund of Jiangxi Science and Technology Normal University, China; Project(20181203058) supported by the College Student Innovation Fund of Jiangxi Science and Technology Normal University, China

Received date: 2019-04-01; Accepted date: 2019-09-09

Corresponding author: XIANG Jun-huai; Tel: +86-13870805075; E-mail: xiangjunhuai@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51701054);江西省教育厅科技项目(GJJ160770);江西科技师范大学研究生创新基金(YC2018-X01);江西科技师范大学大学生创新基金(20181203058)

收稿日期:2019-04-01;修订日期:2019-09-09

通信作者:向军淮,教授,博士;电话:13870805075;E-mail:xiangjunhuai@163.com