文章编号: 1004-0609(2006)05-0894-05

Ni76Cr19AlTi合金的高温氧化行为

滕 浩, 尹志民, 朱远志, 黄继武, 张保胜

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 采用静态恒温氧化增质法研究Ni76Cr19AlTi合金在600~800℃范围内的高温氧化动力学规律, 采用场发射扫描电镜对氧化产物进行表面和横断面形貌观察, 用X射线衍射仪分析氧化膜层的物相组成。 结果表明, 合金在600~800℃范围内氧化增质与氧化时间的关系遵从抛物线规律, 氧化速率常数Kp随温度的升高而增大; 在800℃下氧化200h, 平均氧化速率为0.00215mg·cm-2·h-1, 合金属于完全抗氧化级; 氧化过程中, 氧化膜主要受控于Cr2O3的生长, 经过长时间氧化后, 表层为比较疏松的TiO2和Cr2O3, 内层为起保护作用的Cr2O3和Al2O3, 氧化膜的组成以Cr2O3为主。

关键词: Ni76Cr19AlTi合金; 镍基合金; 高温氧化; 氧化动力学 中图分类号: TG132.3

文献标识码: A

High temperature oxidation behavior of Ni76Cr19AlTi superalloy

TENG Hao, YIN Zhi-min, ZHU Yuan-zhi, HUANG Ji-wu, ZHANG Bao-sheng

(School of Material Science and Engineering, Central South University,Changsha 410083, China)

Abstract: The oxidation kinetics of Ni76Cr19AlTi superalloy in air from 600℃ to 800℃ was studied by using TGA method. The composition, phase structure and morphologies of oxides formed under different conditions were observed and analyzed. The results show that the oxidization kinetics of the alloy follows the parabolic rate law in the range of 600-800℃, the oxidization rate constant Kp increases as temperature elevating. The average oxidization rate at 800℃ for 200h is 0.00215mg·cm-2·h-1, showing the oxidization resistance of the alloy is the first grade. During oxidation, the oxidation film mainly consists of Cr2O3 and the growth of the oxidation film is mainly controlled by Cr2O3. After oxidizing for a long time, the oxidation film becomes loose, in which the upper layer consists of TiO2 and Cr2O3, but internal protective layer consists of Cr2O3 and Al2O3.

Key words: Ni76Cr19AlTi superalloy; nickel-based superalloy; high temperature oxidation; oxidation kinetics

镍基高温合金具有耐腐蚀、 抗高温蠕变、 屈服强度和断裂韧性高等特点, 被广泛用作航空发动机、 发电厂的燃气轮机以及船用柴油机高温部件[1-4]。 近年来, 国外有将某些牌号的镍基高温合金用作重型发动机排气门的报道[5, 6], 但国内还没有见到相关报道。 气门在高温高压及燃气腐蚀环境下工作, 气门表面的氧化腐蚀直接影响到气门—气门座的密封性能, 从而影响到发动机的动力特性和燃油的经济性以至导致气门失效, 因此研究排气门用镍基合金在高温下的氧化行为有实际意义。

镍基高温合金组成元素较多, 其高温环境下的氧化行为比较复杂, 人们通常用氧化动力学和氧化膜的特性来表征这类合金的抗氧化能力[7, 8]。 Seal等[9]对IN-738LC超合金在850~950℃的氧化行为进行了研究, 指出氧化过程主要受Cr离子在氧化层中的扩散控制。 楼翰一等[10]对K17F镍基铸造高温合金溅射微晶层的高温氧化行为进行研究后指出, 溅射微晶层后合金表面生成单一的α-Al2O3, 其抗循环氧化性能比铸态合金的好得多。 本研究是某工程气门/气门座研究的一部分, 目的是要研制一种新型的发动机排气门材料。 本文作者要考察这种合金在600~800℃工况温度范围内的氧化特性, 旨在为新型镍基合金排气门的设计和制造提供理论和实验的依据。

1 实验

1.1 材料与试样制备

研究合金的化学成分(质量分数, %)为: C 0.04, Mn 0.10, P 0.005, S 0.002, Si 0.12, Cr 19.36, Al 1.49, Ti 2.11, Fe 0.64, Ni余量。 合金经中频熔铸成锭, 之后热轧成棒材。 棒材在1080℃固溶, 经850℃, 24h时效, 之后将棒材线切割成d11mm×10mm的抗氧化试样, 试样经800目砂纸打光, 再用丙酮超声波清洗、 干燥, 氧化实验前称量质量。

1.2 实验方法

氧化实验在箱式电炉(精度±2℃)内进行, 实验温度分别为600、 650、 700、 750和800℃, 氧化时间分别为10min、 30min、 1h、 10h、 50h、 100h、 200h。 不同状态氧化后, 在感量为0.1mg的DT-100光电分析天平上称量, 每个试样称量3次, 试样氧化后质量取3次称量的平均值。 采用带能谱的Sirion200场发射扫描电镜对氧化产物进行表面形貌观察和横断面观察, 用D/max-2500/PCX射线衍射仪分析氧化膜层的物相组成。

2 结果与分析

2.1 氧化动力学曲线

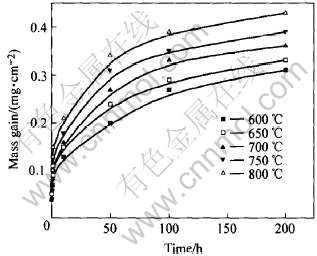

合金在不同温度下氧化时氧化增质与氧化时间的关系如图1所示。 图1的结果表明, 第一, 在给定温度下, 氧化初期(0~10h)氧化速度较快, 氧化约10h之后, 氧化速率开始减慢; 第二, 合金的氧化速度随着温度的升高而加快, 800℃氧化速度最快, 该温度下氧化200h的平均氧化速率为0.00215mg·cm-2·h-1。 根据HB5258-83《钢及合金抗氧化性的测定方法》, 研究合金在800℃及以下氧化属于完全抗氧化级。

图1 合金在不同温度下的氧化动力学曲线

Fig.1 Kinetics of isothermal oxidation of

studied alloy at different temperatures

从图1还可以看出, 氧化增质与氧化时间的关系遵循抛物线规律, 可以表示为

式中 Δ为氧化增质, mg; S为试样的表面积, cm2; Kp为氧化速率常数, mg2·cm-4·s-1; t为时间, s; C为常数。 根据图1所示实验数据, 利用最小二乘法可以拟合抛物线方程中的参数, 得到不同温度下的抛物线方程:

600℃, (Δ/S)2=1.46×10-7t+0.007

650℃, (Δ/S)2=1.69×10-7t+0.011

700℃, (Δ/S)2=2.13×10-7t+0.012

750℃, (Δ/S)2=2.48×10-7t+0.016

800℃, (Δ/S)2=2.94×10-7t+0.023

从上面所列出的各温度下的氧化动力学方程可看出, 氧化速率常数Kp值随着加热温度的提高而增大, 合金在800℃时的氧化速率常数Kp为2.94×10-7mg2·cm-4·s-1, 接近于Cr2O3的800℃生长速度常数(5×10-7mg2·cm-4·s-1)[11], 说明合金氧化膜主要受控于O和Cr3+离子的扩散过程。

2.2 合金的氧化膜特性

2.2.1 X射线衍射物相分析

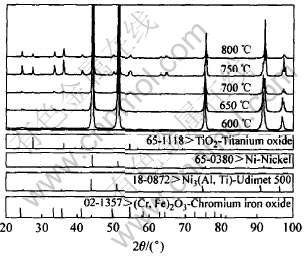

不同温度下氧化50h后试样表面的X射线衍射图谱如图2所示。 由图可见, 在600~700℃下氧化时, 氧化产物衍射图谱中有镍基固溶体和γ′(Ni3(Al, Ti))相的衍射峰, 氧化物衍射峰的强度比较微弱。 这个结果说明氧化层厚度较小, X射线穿透了样品表面氧化薄层, 把薄层下基体的物相信息激发了出来; 当温度达到750℃以上时, 氧化物的衍射峰明显增强, 物相分析结果为(Cr, Fe)2O3和TiO2相, 由于合金成分中Fe含量很少, (Cr, Fe)2O3相中应当以Cr2O3为主; 当温度达到800℃时, γ′相的衍射峰不明显, 一方面可能是氧化层厚度的增加, 另一方面可能是内氧化层(氧化层靠近基体的部分)形成Al2O3, 消耗了基体中的Al原子, 致使基体表层以下一定厚度区域贫Al, 导致γ′相消失[12]。

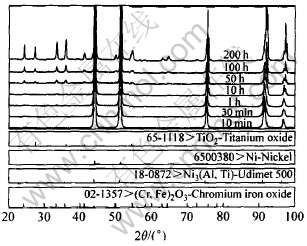

在700℃氧化不同时间后试样表面的X射线衍射谱如图3所示。

图2 不同温度下氧化50h后试样表面的X射线衍射谱

Fig.2 XRD patterns of surface of samples

oxidized at different temperatures for 50h

图3 700℃氧化不同时间后试样表面的X射线衍射谱

Fig.3 XRD patterns of surface of samples

oxidized at 700℃ for different time

从图3可以看出, 在700℃氧化时, 在10min~1h内, X射线衍射图谱中, 除镍基固溶体外, 没有出现明显的氧化产物的衍射峰, 表明氧化产物含量极少。 随着时间的增加, 氧化产物(Cr, Fe)2O3和TiO2的衍射峰逐渐显现, 衍射线强度逐渐增强。

有研究表明[13], 高温合金中加入15%Cr后, 合金表面在氧化过程中就能形成以Cr2O3为主并含有NiCr2O4、 TiO2等复合氧化物薄膜。 该氧化膜致密且与基体结合比较牢固, 可以阻止金属进一步氧化。 由图3可见, 合金在700℃氧化10h后, 氧化膜中Cr2O3物相的衍射峰比较明显, 说明Cr2O3氧化层已形成。 这个结果与图1氧化动力学数据相吻合, 说明氧化初期(0~10h)的氧化由表面化学反应(生成Cr2O3)控制, 而氧化后期(10~200h)的氧化可能主要由Cr3+离子在氧化层中的扩散控制。 应当指出, 氧化产物中未见到NiCr2O4尖晶石的存在, 可能是NiCr2O4氧化物的数量少且不能形成连续的氧化膜[14]。

2.2.2 氧化膜表面形貌

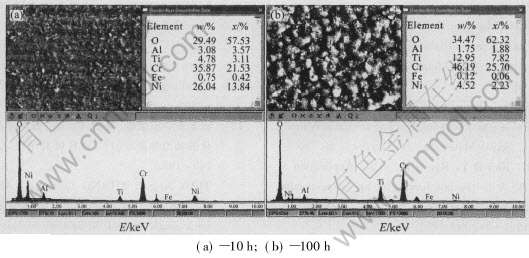

合金在700℃氧化不同时间, 氧化后试样表面的形貌及氧化产物成分如图4所示。

从图4(a)可以看出, 在700℃氧化10h后试样表面出现了颗粒状和短棒状的氧化物, 而且氧化膜比较致密。 EDAX分析出有26.04%的Ni和35.87%的Cr, 还含有4.78%的Ti和3.08%的Al和微量的Fe。 与合金基体成分相比(19%Cr、 76%Ni、 2.11%Ti和1.49%Al), 试样表面成分中Cr、 Ti和Al的比例远高出它们在基体中的比例。 这个结果表明, Cr、 Ti和Al在氧化物中是富集的, 因此氧化产物主要应为Cr的氧化物和TiO2、 Al2O3等。 XRD未能分析出含Ni的氧化物物相, 说明试样表面成分中的Ni主要来自氧化膜下面的基体, 这是因为X射线有一定的穿透深度。 图4(b)所示为700℃、 100h氧化后试样的表面形貌。 从图中可以看出, 在700℃氧化100h后试样表面的氧化物长成了团簇状, 短棒状的氧化物颗粒减少了, 而且样品表面氧化物比较疏松。 从氧化产物的能谱分析结果可知, Cr、 Ti的含量分别由10h时的35.87%、 4.78%上升到了46.19%、 12.95%, 反映在XRD谱上为(Cr, Fe)2O3和TiO2的衍射峰已经大大增强, Ti含量增加说明Ti离子在Cr2O3层中有较高的迁移率[15]。 此外, Ni的含量大大降低, 说明氧化膜生长变厚了, 由氧化膜下面的基体激发出来的Ni减少了。

一般认为, Cr2O3膜的生长主要是由基体内的Cr原子通过氧化膜向外扩散进行的, 空气中的O通过氧化膜向内扩散进行的, 而Al2O3主要是在氧化膜靠近基体的地方生成。 综合图4(a)和(b)可以得出, 氧化初期, 基体中的Cr原子和Al原子直接与O发生反应生成Cr2O3和Al2O3氧化膜; 随着氧化时间的延长, Cr、 Ti明显向氧化膜表层富集, Cr和Ti的质量分数增大, Cr2O3层增厚且表层的氧化物颗粒长大聚集成团簇状, 形成疏松的TiO2和Cr2O3混合层; 而Al因氧化而贫乏, 难以维持其外氧化层, 长时间氧化的试样表面局部的Al2O3外氧化膜消失了, 但是O通过氧化膜仍可以与内部的Al发生氧化反应, 因此氧化膜内层仍应含有Al2O3层。

图4 在700℃氧化不同时间后试样表面形貌的SEM照片和EDAX谱

Fig.4 SEM morphologies and EDAX patterns of oxidized sample surfaces at 700℃ for different time

2.2.3 氧化膜的截面形貌

图5所示为在不同温度下氧化50h后氧化膜的截面形貌。 由图可见, 氧化膜连续地覆盖在试样的表面, 氧化膜的厚度随氧化温度的提高而增加。 600℃时只形成约2μm厚的氧化膜(白亮区), 氧化膜与基体之间的深色部分为缝隙, 可能是制样时应力导致开裂; 700℃时氧化膜厚度增加到5μm左右, 中间的深色区域为氧化物脱落的部分, 可能是制样时应力导致氧化物脱落。 从图5还可以看出, 氧化膜内层比较致密, 对基体有保护作用。

图5 在不同温度下氧化50h后氧化膜的截面形貌

Fig.5 Section morphologies of oxidation film at different temperatures for 50h

3 结论

1) 镍基高温合金在600~800℃的氧化动力学服从抛物线规律, 氧化速率常数Kp随温度的升高而增大, 800℃以下氧化时, 表面氧化膜无剥落, 属于完全抗氧化级。

2) 镍基高温合金在700℃氧化时, 氧化初期形成比较致密的氧化层, 氧化由表面化学反应(生成Cr2O3)控制, 长时间氧化后, 表面氧化物颗粒长大成团簇状, 性质比较疏松, 氧化物组成为Cr2O3和TiO2。 内层为起保护作用的Cr2O3和Al2O3层, 氧化后期主要由Cr3+离子在氧化层中的扩散控制。

REFERENCES

[1]Srinivasan N, Prasad Y V R K. Hot working characteristics of nimonic 75, 80A and 90 superalloys: a comparison using processing maps[J]. Journal of Materials Processing Technology, 1995, 51(1-4): 171-192.

[2]Choudhury I A, El-Baradie M A. Machinability of nickel-base super alloys: a general review[J]. Journal of Materials Processing Technology, 1998, 77(1-3): 278-284.

[3]Gabrisch H, Mukherji D. Character of dislocations at the γ/γ′ interfaces and internal stresses in nickel-base superalloys[J]. Acta Metall Mater, 2000, 48(12): 3157-3167.

[4]TIAN Bao-hui, Paris O, Zickler G A, et al. SANS investigation of phase separation in hot-deformed Nimonic 80a[J]. Scipta Materialia, 2002, 47(1): 25-30.

[5]Kim D K, Kim D Y, Ryu S H, et al. Application of nimonic 80A to the hot forging of an exhaust valve head[J]. Journal of Materials Processing Technology, 2001, 113(1-3): 148-152.

[6]Jeong H S, Cho J R, Park H C. Microstructure prediction of Nimonic 80A for large exhaust valve during hot closed die forging[J]. Journal of Materials Processing Technology, 2005, 162-163: 504-511.

[7]Smialek J L, Meier G H. Insuperalloys Ⅱ[M]. New York: John Wiley and Sons, 1987. 187.

[8]黄乾尧, 李汉康. 高温合金[M]. 北京: 冶金工业出版社, 2000. 100.

HUANG Qian-yao, LI Han-kang. Superalloy[M]. Beijing: Metallurgical Industry Press, 2000. 100.

[9]Seal S, Kuiry S C, Leyda A. Studies on the surface chemistry of oxide films formed on IN-738LC superalloy at elevated temperatures in dry air[J]. Oxidation of Metals, 2001, 56(5/6): 583-603.

[10]楼翰一, 唐幼军, 孙晓峰, 等. K17F高温合金溅射微晶层的抗循环氧化行为[J]. 中国有色金属学报, 1995, 5(4): 87-92.

LOU Han-yi, TANG You-jun, SUN Xiao-feng, et al. Cycle oxidization resistance of the layer of sprayed K17F superalloy[J]. The Chinese Journal of Nonferrous Metals, 1995, 5(4): 87-92.

[11]Giggins C S, Pettit F S. Oxidation of Ni-Cr alloys between 800℃ and 1200℃[J]. Transactions of the Metallurgical Society of AIME, 1969, 245(12): 2495-2507.

[12]田素贵, 张禄廷, 杨洪才, 等. 镍基单晶合金高温氧化的动力学特征[J]. 材料研究学报, 2002, 16(2): 183-187.

TIAN Su-gui, ZHANG Lu-ting, YANG Hong-cai, et al. Kinetic features of high temperature oxidization for a single crystal Ni-base superalloy[J]. Chinese Journal of Materials Research, 2002,16(2):183-187.

[13]Ledjeff K, Rahmel A, Schorr M. Influence of metal grain growth on the oxidation behavior of a 25Cr-20Ni steel[J]. Oxidation of Metals, 1981, 15(5-6): 485-493.

[14]李美栓. 金属的高温腐蚀[M]. 北京: 冶金工业出版社, 2001. 5.

Li Mei-quan. High Temperature Corrosion of Metals[M]. Beijing: Metallurgical Industry Press, 2001. 5.

[15]Abe F, Araki H, Yoshida H, et al. Role of aluminum and titanium on the oxidation process of a nickel-base superalloy in steam at 800℃[J]. Oxidation of Metals, 1987, 27(1-2): 21-36.

收稿日期: 2005-08-19; 修订日期: 2005-11-23

通讯作者: 尹志民, 教授; 电话: 0731-8830262; 传真: 0731-8830262; E-mail: yin-grp@mail.csu.edu.cn

(编辑何学锋)