文章编号:1004-0609(2010)S1-s0631-03

退火温度对Ti80合金挤压管材组织与性能的影响

王巧莉,代 春,成小丽

(宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:研究Ti80合金挤压管材在800~1 020 ℃范围内不同温度退火处理对挤压管材组织与性能的影响。研究发现:随着退火温度从800 ℃升高到1 020 ℃,Rm从910 MPa提高到935 MPa,A从15%升至17%再降至12%,抗拉强度变化不大,但塑性变化较明显。在800~900 ℃退火可消除管材内应力并发生部分再结晶。温度升高到950 ℃时,再结晶进行得较充分,组织得到细化和球化,管材的室温力学性能良好。退火温度继续升至1 020 ℃时,获得魏氏组织,导致塑性降低。

关键词:Ti80钛合金管材;组织;性能

中图分类号:TG 146.2 文献标志码:A

Effect of annealing temperature on microstructure and properties of Ti80 alloy extrusion tube

WANG Qiao-li, DAI Chun, CHENG Xiao-li

(Baoji Titanium Industry Co., Ltd., Baoji 721014, China)

Abstract: The effect of annealing process on microstructure and properties of Ti80 alloy extruded tube at 800-1 020 ℃ was studied. The results show that the Rm of Ti80 tube increases from 910 MPa to 935 MPa when the annealing temperature rises from 800 ℃ to 1 020 ℃, meanwhile the elongation increases from 15% to 17% and then goes down to 12%. Tensile strengh is nealy the same, but the ductility change is obvious. The annealing between 800 ℃ and 900 ℃ can remove the internal stress and creat the partial recrystallization. When the temperature goes up to 950 ℃, the recrystalization is sufficient, the microstructure is refined and spheroidized, and the mechanical properties of the tube are improved. When the annealing temperature continously goes up to 1 020 ℃, the microstructure changes to Widmanstaten structure and the ductility decreases.

Key words: Ti80 alloy tube; microstructure; properties

Ti80合金的名义成分为Ti-6Al-3Nb-2Zr-1Mo,是一种铝含量较高(5.5%~6.5%,质量分数)并含有β稳定元素Nb、Mo和中性元素Zr的近α型钛合金。Ti80合金具有高的比强度、强的抗腐蚀性及良好的焊接 性[1],可制成板材、棒材、锻件、小型材等多种规格产品,被广泛应用于潜艇和水中兵器的受力构件、螺栓、轴以及耐腐蚀壳体等。由于该合金的强度高,其管材加工存在很大的困难,目前,很少见到热挤压管材方面的相关报道。根据目前设计需求,Ti80合金挤压管材通常在退火状态下使用,针对这一情况,本文作者研究不同退火温度对挤压管材组织与性能的影响,为热挤压管材制备工艺的制定提供理论基础和依据。

1 实验

1.1 坯料制备

采用真空自耗三次熔炼的铸锭,其化学成分见表1。铸锭在β区锻造开坯,两相区精锻成为棒坯;经扒皮、钻孔、镗孔等工序制成挤压用的锭坯。在3 150 t

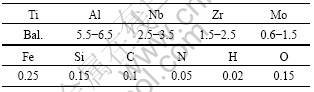

表1 Ti80合金的化学成分

Table 1 Chemical composition of Ti80 alloy (mass fraction, %)

卧式水压机上将锭坯加热至两相区后进行挤压,挤压时采用普通润滑剂润滑,挤压后的管材尺寸为d 140 mm×13.5 mm。本研究所取的挤压试样靠近挤压管头部,因为挤压时头部的变形与其它部位相比不均匀,组织与性能也相对较差。

1.2 实验方法

挤压试样管在还原性气氛的箱式电阻炉内分别经800、850、900、950、980和1 020 ℃保温1.5 h退火处理,采用空冷形式冷却。

用CMT拉力试验机对合金试样进行室温力学性能测试,用ZiESS金相显微镜对合金组织进行观察和分析。

2 结果与分析

2.1 退火温度对显微组织的影响

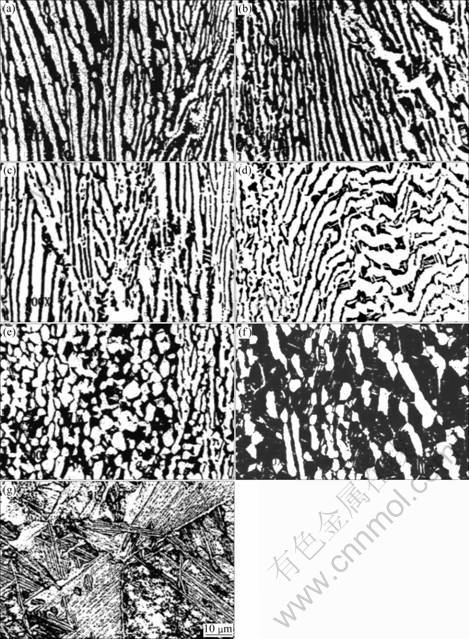

退火工艺对显微组织的影响见图1。

图1 Ti80合金经不同温度退火后的显微组织

Fig.1 Metallographs of Ti80 alloy tube at different annealing temperatures: (a) As- extruded; (b) 800 ℃; (c) 850 ℃; (d) 900 ℃; (e) 950 ℃; (f) 980 ℃; (g) 1 020 ℃

由图1可以看出:由于该合金挤压在α+β区温度范围内进行,挤压比较大,挤压过程中金属发生剧烈变形,使晶粒沿变形方向被压扁,沿金属的流动方向被拉长,形成了条状α+β组织(图1(a))。当退火温度为800 ℃时,其显微组织为条状的α+β(图1(b)),与挤压态组织形貌相似,组织无明显变化;当退火温度升高到850~900 ℃时,开始发生再结晶,条状α球化,并有转变β组织生成(见图1(c)和(d));当退火温度升高至950 ℃时,显微组织发生明显再结晶,球状初生α增多,形成等轴组织(见图1(e));当退火温度升高至980 ℃时,初生α减少,而片状β转变组织增多,形成了双态组织(见图1(f))。不难看出,随着退火温度由800 ℃升高到980 ℃,挤压管材的晶粒组织完成了从回复到再结晶整个过程;随着退火温度的继续升高,超过相变温度(1 000~1 010) ℃时,完成α+β向β相转变,并形成有β晶界的魏氏组织(见图1(g))[2]。

2.2 退火温度对力学性能的影响

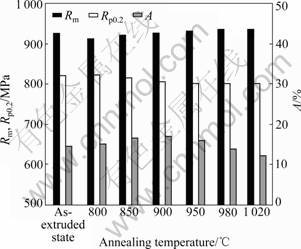

挤压态和经不同退火温度处理后的Ti80合金挤压管材的室温拉伸性能见图2。

图2 退火温度对室温力学性能的影响

Fig.2 Effect of annealing temperature on mechanical properties

从图2可以看出:挤压态合金的抗拉强度和塑性分别为Rm=925 MPa和A=14.5%。经800 ℃退火处理后,合金的抗拉强度略有降低(Rm=910 MPa),塑性略有提高(A=15%),这是因为在800 ℃退火时,挤压管中的残余应力得到一定程度的消除,使得材料抗拉强度降低、塑性提高,符合图1(a)和(b)的组织变化特点。在退火温度由850 ℃升高到900 ℃的过程中,随着退火温度的升高,Rm呈上升趋势,Rp0.2呈下降趋势,伸长率呈上升趋势,这是由于随着退火温度的升高,初生α相逐渐减少,β相转变组织逐渐增加,从而强度增加,塑性降低;但同时在高温下发生了再结晶,并且α相的再结晶超过β相的再结晶,使组织充分球化,有利于增加强度和塑性。在退火温度由900 ℃继续升高至1 000 ℃的过程中,Rm和Rp0.2变化平缓,而塑性则下降,这是由于初生α含量减少和晶粒长大所致。当退火温度升高至1 020 ℃时,发生α+β向β转变,形成魏氏组织,粗大的魏氏组织使材料的塑性降低。

3 结论

Ti80钛合金随着退火温度从800 ℃升高至980 ℃,挤压管材显微组织完成从恢复到再结晶整个过程,使组织得到改善,其最佳的退火温度范围为800~950 ℃,保温时间为1~2 h。

REFERENCES

[1] 徐希军, 何 刚, 卢 海. Ti80合金厚壁焊管冷压成形工艺[J]. 稀有金属材料与工程, 2008, 37(s): 247-249.

XU Xi-jun, HE Gang, LU Hai. Cold pressing formation process for Ti80 alloy thick wall welded pipe[J]. Rare Metal Materials and Engineering, 2008, 37(s): 247-249.

[2] 王金友, 葛志明, 周彦邦. 航空用钛合金[M]. 上海: 上海科技出版社, 1985: 208.

WANG Jin-you, GE Zhi-ming, ZHOU Yan-bang. Aviation titanium [M]. Shanghai: Shanghai Science and Technical Press, 1985: 208.

(编辑 杨 兵)

通信作者:王巧莉;电话:0917-3382444;E-mail: wang99003@yeah.net