文章编号:1004-0609(2013)S1-s0086-06

高强钛合金挤压管材的组织及性能

赵 彬,赵恒章,郭荻子,戚运莲,杨英丽

(西北有色金属研究院,西安 710016)

摘 要:对亚稳β高强钛合金Ti-1300管材挤压成形进行了研究,分析并测试了挤压管材在不同热处理制度下的组织及力学性能,并采用扫描电镜对拉伸试样断口形貌特征进行了观察。研究结果表明,Ti-1300亚稳β钛合金通过选择合适的挤压工艺参数可以制备出高质量管材,挤压态管材经860 ℃固溶处理后组织为完全β相单相组织,断口布满韧窝,具有较高的塑性,有利于进一步冷轧变形;560 ℃时效后为等轴β晶粒内弥散分布针状α相,断口为韧脆混合断口,强度可达1 310 MPa,伸长率为8%。

关键词:Ti-1300钛合金;挤压管材;显微组织;拉伸性能;热处理

中图分类号:TG 146.4 文献标志码:A

Microstructure and mechanical properties of high strength titanium alloy extruded tube

ZHAO Bin, ZHAO Heng-zhang, GUO Di-zi, QI Yun-lian, YANG Ying-li

(Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: The extrusion forming of metastable β high strength titanium alloy Ti-1300 tube was studied. The room-temperature tensile properties were tested and the microstructures of specimens were characterized. The fractographs of tensile specimens were observed by SEM. The results show that, the high quality extruded tubes of high strength titanium alloy Ti-1300 are manufactured with suitable parameters. The extruded tube after ST 860 ℃ consists of only β phases and has plastic dimple fracture surface. The ductility of raw extruded and solution state tubes is excellent, which is advantageous to deep deformation process. The extruded tubes of Ti-1300 alloy after aging treatment are composed of diffusion acicular α phase and β matrix and have plastic and brittle mixed fracture surface. Their strength reaches 1 310 MPa and the elongation is 8%.

Key words: Ti-1300 alloy; extruded tube; microstructure; tensile properties; heat treatment

钛合金材料的研制不断向高性能化、功能化、低成本化方向发展,与此相适应, 国内外钛合金管材制造的发展趋势一方面是降低原材料的成本, 即开发不含或少含贵金属元素, 取而代之添加铁、氧、氮等廉价元素的合金;另一方面是通过各种工艺降低钛合金管材的加工、制造成本, 如开发低加工成本的可冷变形的钛合金管材[1-7]。

Ti-1300钛合金是西北院自行研制的高强、高塑、亚稳定型β钛合金,该合金的β稳定系数Kβ=1.25,钼当量[Mo]=13.5,在固溶状态下具有优异的冷成形性能和良好的焊接性能,在航空航天领域如发动机管路、耐压容器、舰船通海管路及核电设备具有广泛的应用前景[8-9]。高强度钛合金管材一直是我国钛合金研究领域的弱项,还处于起步阶段,而欧美等发达国家目前已经能够批量生产中、高强钛合金管材,满足航空、航天及民用领域的需求。本文作者结合实际课题的需要,主要研究了挤压工艺及热处理对Ti-1300高强钛合金管坯组织及性能的影响,为高强钛合金管材批量生产提供一定的指导。

1 实验

实验用料为二次真空自耗电弧熔炼的d 560 mm吨级Ti-1300合金铸锭,合金相变点为840 ℃。铸锭经β区开坯锻造,α+β两相区精锻为d 105 mm棒材。管坯采用钻孔挤压工艺制备,挤压温度830~930 ℃,在2 500 t卧式挤压机上制备出管材规格为d 65 mm×5 mm,并对内、外表面缺陷进行了修理。

从挤压管材上截取试样进行力学性能测试和显微组织分析。对挤压管材试样采取在单相区和两相区温度分别固溶, 继而进行不同温度时效处理, 然后进行室温拉伸试验和金相组织观察, 并对部分试样断口通过扫描电镜进行观察。室温拉伸是在INSTRON-1185拉伸实验机上进行,拉伸试样按ASTN E8的规定制备, 工作部分宽12.5 mm,标距长50 mm;并利用光学显微镜观察组织;在SUPRATM55型扫描电子显微镜下进行断口形貌观察和分析。

2 结果与分析

2.1 挤压对高强合金管材力学性能的影响

挤压加工具有许多突出的优点。可以降低原材料的消耗;提高零件的机械性能;在挤压变形后,金属材料的晶粒组织更加致密;可以获得较高的管材尺寸精度。同时,由于挤压可节省材料和加工工时,因此,必然降低生产成本[10]。

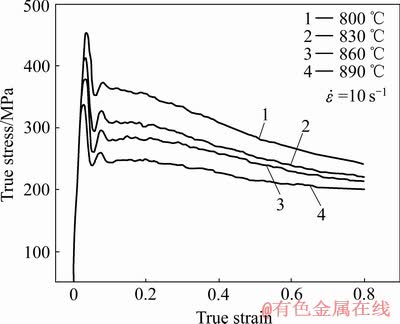

Ti-1300合金相变点较低,根据图1所示该合金在不同温度下热压缩应力—应变曲线可以看出,该合金在高应变速率下出现应力不连续屈服现象,而且随着温度的升高,这种现象更加明显。随着应变增加,流变应力趋向于一种相对稳定的状态。这主要是由于加工硬化和动态软化共同作用达到平衡的结果[8]。合金在830 ℃以下流变应力较高,不适宜进行大变形量加工,因此,在挤压比为8的条件下,选择了830、870和930 ℃ 3种挤压温度,研究了不同挤压温度对管材组织和性能的影响。管材挤压时工艺参数见表1。

图1 Ti-1300合金在不同温度时的应力—应变曲线

Fig. 1 Stress—strain curves of Ti-1300 alloy at different temperatures

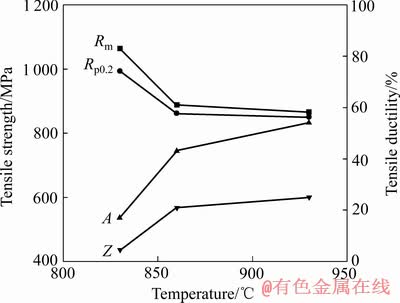

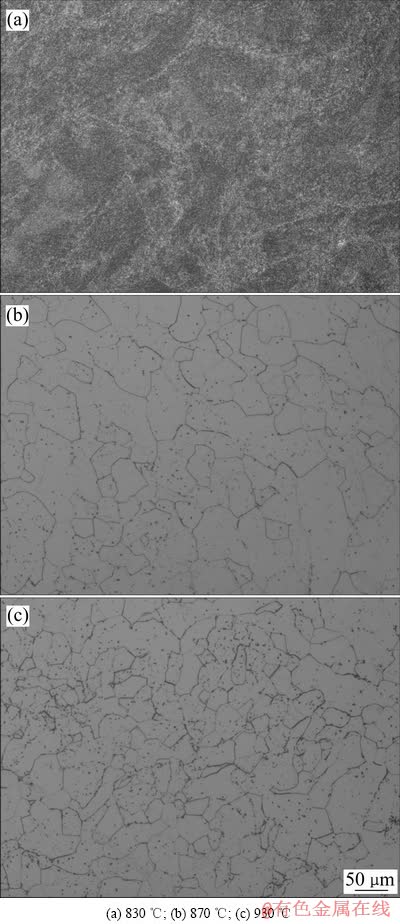

图2所示为不同挤压温度下Ti-1300合金挤压管材的力学性能。可以看出,低于相变点挤压管材的断裂强度和屈服强度都很高,分别为1 080 MPa和1 000 MPa,但管材塑性很差,基本为脆断。将挤压温度提高到相变点以上,管材的力学性能变化不大,趋于稳定。这主要与合金的显微组织有关,从图3中所示显微组织可以发现,挤压态Ti-1300合金的显微组织与挤压温度密切关联。当挤压温度高于合金的相变温度(840 ℃)时,合金在变形过程中发生了充分的再结晶,主要由等轴的β相晶粒组成;当挤压温度低于合金的相变温度时,合金的组织主要由α相和β相组成,在等轴的β相基体界面处分布着未溶解的球状α相。因此,挤压温度对Ti-1300合金显微组织的影响主要表现在对α相形态和含量的控制上,即α相随挤压温度的升高逐渐溶解于β相基体中,当挤压温度超过合金的相变温度时,合金的组织主要由β相晶粒组成。

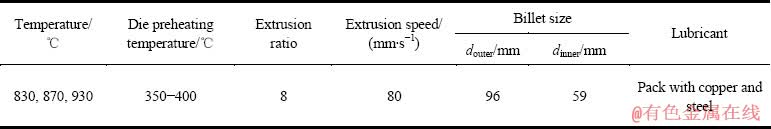

表1 Ti-1300高强钛合金管材挤压工艺参数范围

Table 1 Processing parameters of high strength titanium alloy Ti-1300 extruded tube

图2 Ti-1300管材在不同挤压温度时的力学性能

Fig. 2 Tensile properties of Ti-1300 alloy tube after extrusion at different temperatures

图3 不同挤压温度时管材的显微组织

Fig. 3 Microstructures of specimens after extrusion at different temperatures

2.2 热处理对高强合金管材组织的影响

2.2.1 固溶态Ti-1300合金管材的显微组织

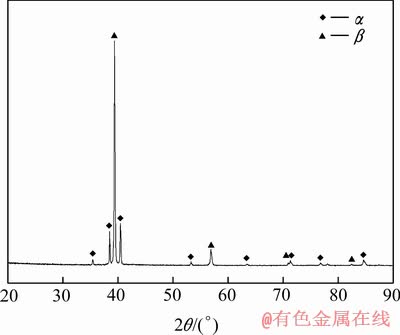

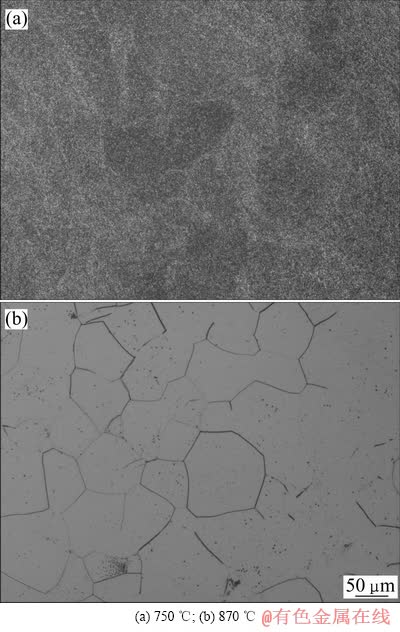

根据Ti-1300合金的相转变温度,确定了分别采用β单相区和α+β两相区的固溶处理温度,实验选用的试样为830 ℃挤压管材。图4所示为两相区固溶态Ti-1300合金的XRD衍射谱,固溶态Ti-1300合金主要由α相和β相组成。图5所示为不同相区固溶态Ti-1300合金的组织,可以发现,α+β两相区固溶条件下合金的相组成与图4所示XRD衍射谱分析结果相一致,主要由大量的球状或拉长的α相以及残留的亚稳定β相组成(图5(a));随着固溶温度的升高,α相逐渐溶解于亚稳定β基体中,当固溶温度高于合金的相转变温度时,β单相区固溶的合金组织主要由等轴的β相晶粒组成(图5(b)),平均晶粒尺寸为80 μm。

图4 750 ℃固溶态Ti-1300合金的XRD谱

Fig. 4 XRD pattern of Ti-1300 alloy solution treated at 750 ℃

图5 不同固溶温度下Ti-1300合金挤压管材的显微组织

Fig. 5 Microstructures of Ti-1300 alloy solution treated at different temperatures

2.2.2 时效态Ti-1300合金管材的显微组织

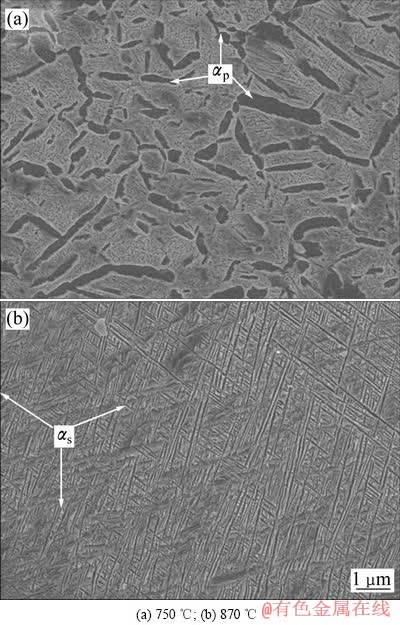

时效处理可以显著提高β钛合金强度。Ti-1300合金挤压管材经固溶处理后主要形成大量的亚稳定β相,在随后的时效过程中亚稳定β相开始分解,等轴和拉长的初生α相在合金的β基体以及β晶界上析出,而在β晶界内也形成大量的密集的次生α相,呈点状和针状分布在β基体上。由于初生α相和次生α相都有一定的强化效应(弥散强化和细晶强化),因此,可以通过控制析出相的尺寸、分布以及含量使合金的强度、韧性以及塑性等性能得到匹配,从而获得理想的高强钛合金管材。

图6 不同固溶温度下时效态Ti-1300合金的显微组织

Fig. 6 Microstructures of Ti-1300 alloy after extrusion at different temperatures

图6所示为不同相区时效态Ti-1300合金的显微组织。可以发现,α+β两相区时效态合金的组织主要由球状或拉长的初生α相、针状次生α相以及β相基体组成(图6(a));随着固溶温度的升高,时效态合金中初生α相逐渐溶解于β基体中,当固溶温度高于合金的相转变温度时,β单相区固溶的合金组织主要由密排交错的针状次生α相和β相基体组成(图6(b))。从图6中还可以发现,随着固溶温度的升高,Ti-1300合金显微组织中初生α相的尺度(长度和宽度方向)随固溶温度的升高而减小,但次生α相在宽度方向上的减小趋势比长度方向更加显著,这与次生α相生长取向有关,从而影响合金的力学性能。

2.3 挤压管材热处理后的力学性能

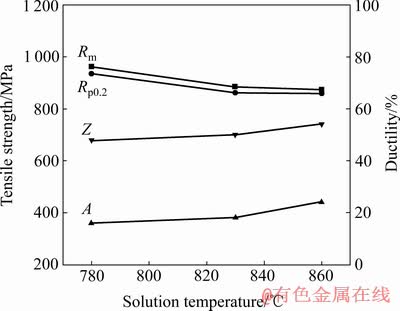

β钛合金虽然具有良好的冷成形能力,但相比于纯钛,其变形抗力要高得多,这就对管材加工设备提出了更高的要求,而且变形抗力随着变形程度的提高而增加。从后续的管材冷轧加工的角度考虑,我们总是希望β钛合金固溶处理后具有较低的变形抗力。图7所示为Ti-1300合金挤压管材在不同温度保温30 min空冷后的拉伸性能。可以看出,随着固溶温度的升高,拉伸强度呈下降趋势,相变点以下固溶后的强度明显比相变点上固溶强度要高,其差值接近100 MPa,当然,进一步降低固溶温度还可以使强度继续升高,而拉伸塑性则基本呈相反的变化趋势,但是总的差异并不明显。考虑到β钛合金大的晶粒尺寸容易使时效后拉伸塑性急剧下降,因此,一般不采用过长的固溶时间及过高的固溶温度。从图7中的曲线还可以看出,在所选择的各个温度固溶后,合金均未出现低屈服强度现象,也就是说合金固溶处理后是稳定的。

图7 Ti-1300合金挤压管材在不同温度保温30 min空冷后的拉伸性能

Fig. 7 Tensile properties of Ti-1300 alloy tube after solution treatment at different temperatures for 30 min and air cooling

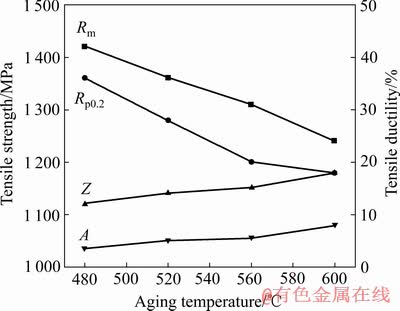

图8所示为Ti-1300合金挤压管材860 ℃空冷后拉伸性能随时效温度的变化。可以看出,随着时效温度的升高,拉伸强度的降低非常明显,断面收缩率则呈相反的变化趋势。值得注意的是,伸长率随时效温度升高的变化很小,这可能是由于高温时效时,晶界上容易形成连续的α片层所致。总体来看,选择560 ℃时效4 h,Ti-1300管材具有较优的综合力学性能。

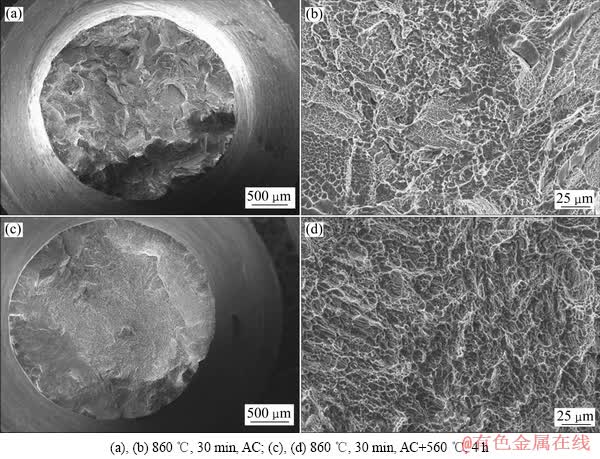

Ti-1300挤压管材热处理后拉伸断口形貌如图9所示,图9(a)和(b)所示为挤压管坯经860 ℃,30 min,AC固溶处理拉伸试样断口形貌,断口表面布满韧窝,呈典型的韧窝状,这与测试的其伸长率和断面收缩率较高相一致。图9(c)和(d)所示为时效后拉伸试样的断口形貌,860 ℃,30 min,AC+560 ℃,4 h处理后试样断口为韧脆混合断口。

图8 Ti-1300合金挤压管材860 ℃固溶空冷后拉伸性能随时效温度的变化

Fig. 8 Change of tensile properties of Ti-1300 alloy tube after 860 ℃ solution treatment with aging temperature

3 结论

1) Ti-1300合金挤压管材在两相区挤压后组织由等轴的β相和球状α相组成,而在β单相区挤压的Ti-1300管材主要由等轴的β相晶粒组成。管材时效后为α+β两相组织, 其中α相以弥散状态分布在等轴状β晶粒内。

2) Ti-1300合金挤压管材在两相区和相变点以上固溶处理其塑性均较高,尤其是860 ℃,30 min,AC固溶处理后,抗拉强度为863 MPa,伸长率达24%,断面收缩率更是高达54%,非常有利于进一步塑性加工;时效后抗拉强度最高达1 310 MPa,但伸长率较低,只有8%。

3) 固溶处理的挤压管材拉伸试样断口为布满韧窝的塑性断口, 时效试样断口为韧脆混合断口。

图9 Ti-1300合金挤压管材拉伸断口形貌

Fig. 9 SEM fractographs of Ti-1300 alloy tube

REFERENCES

[1] 江志强, 杨 合, 詹 梅, 许旭东, 李光俊. 钛合金管材研制及其在航空领域应用的现状与前景[J]. 塑性工程学报, 2009, 16(4): 44-50.

JIANG Zhi-qiang, YANG He, ZHAN Mei, XU Xu-dong, LI Guang-jun. State of the arts and prospectives of manufacturing and application of titanium alloy tube in aviation industry[J]. Journal of Plasticity Engineering, 2009, 16(4): 44-50.

[2] 尚秀丽, 佟学文, 晏小兵, 冯红超, 张耀斌, 颜 苏, 徐忠普, 成小丽. TA15 钛合金管材热加工工艺[J]. 中国有色金属学报, 2010, 20(1): 765-769.

SHANG Xiu-li, TONG Xue-wen, YAN Xiao-bin, FENG Hong-chao, ZHANG Yao-bin, YAN Su, XU Zhong-pu, CHENG Xiao-li. Hot extrusion process of TA15 titanium alloy tube[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 765-769.

[3] 羊玉兰, 佟学文, 杨陇林. TC2钛合金管材挤压工艺[J]. 钛工业进展, 2005, 22(3): 22-24.

YANG Yu-lan, TONG Xue-wen, YANG Long-lin. Study on rolling process of TC2 titanium alloy tubes[J]. Titanium Industry Progress, 2005, 22(3): 22-24.

[4] 汶建宏, 杨冠军, 葛 鹏, 毛小南, 赵映辉. β钛合金的研究进展[J]. 钛工业进展, 2008, 25(1): 33-38.

WEN Jian-hong, YANG Guan-jun, GE Peng, MAO Xiao-nan, ZHAO Ying-hui. The research progress of β titanium alloys[J]. Titanium Industry Progress, 2008, 25(1): 33-38.

[5] 王鼎春. 高强钛合金的发展与应用[J]. 中国有色金属学报, 2010, 20(S1): s958-s963.

WANG Ding-chun. The development and application of high-strength titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s958-s963.

[6] 商国强, 朱知寿, 常 辉, 王新南, 寇宏超, 李金山. 超高强度钛合金研究进展[J]. 稀有金属, 2011, 359(2): 286-290.

SHANG Guo-qiang, ZHU Zhi-shou, CHANG Hui, WANG Xin-nan, KOU Hong-chao, LI Jin-shan. Development of ultra-high strength titanium alloy[J]. Chinese Journal of Rare Metals, 2011, 35(2): 286-290.

[7] 张 驰, 曾卫东, 李兴无, 沙爱学. 挤压参数对TC16 合金紧固件冷挤压过程的影响[J]. 材料工程, 2008, 8: 35-39.

ZHANG Chi, ZENG Wei-dong, LI Xing-wu, SHA Ai-xue. Effect of extrusion parameters on cold extrusion process of TC16 titanium alloy fastener[J]. Materials Engineering, 2008, 8: 35-39.

[8] 赵映辉, 葛 鹏, 赵永庆, 杨冠军, 汶建宏. Ti-1300合金的热变形行为研究[J]. 稀有金属材料与工程, 2009, 38(1): 46-49.

ZHAO Yin-hui, GE Peng, ZHAO Yong-qing, YANG Guan-jun, WEN Jian-hong. Hot deformation behavior of Ti-1300 alloy[J]. Rare Metal Materials and Engineering, 2009, 38(1): 46-49.

[9] 葛 鹏, 周 伟, 赵永庆. 热处理制度对Ti-1300合金组织和力学性能的影响[J]. 中国有色金属学报, 2010, 20(1): 1068-1072.

GE Peng, ZHOU Wei, ZHAO Yong-qing. Influence of heat treatment on microstructure and mechanical properties of Ti-1300 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 1068-1072.

[10] 贾如雷, 计 波, 维 洁, 王宗宝. 钛材热挤压成形技术的研究与发展[J]. 中国有色金属学报, 2010, 20(1): 897-901.

JIA Ru-lei, JI Bo, WEI Jie, WANG Zong-bao. Research and development of hot extrusion technology for titanium products[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 897-901.

(编辑 杨 兵)

基金项目:陕西省重点科技创新团队计划资助项目(2012KCT-23)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:赵 彬,高级工程师,硕士;电话:029-86231078;E-mail: zhaobin_51@126.com