文章编号:1004-0609(2013)S1-s0403-05

冷轧及退火工艺对TA18管材组织和性能影响

尉北玲1,张亚峰2,于振涛2,韩建业3,余 森2,刘春潮2,皇甫强3

(1. 西部金属材料股份有限公司,西安 710016;

2. 西北有色金属研究院,西安 710016;

3. 西安九洲生物材料有限公司,西安 710016)

摘 要:加工变形量ε和Q是管材冷轧变形的重要参数。通过三辊冷轧方式制备小规格TA18管材,并在不同温度下进行退火处理。研究不同加工变形量ε和Q对管材性能和表面质量的影响,分析不同退火温度下各管材的室温拉伸性能和显微组织,探索退火温度对TA18管材性能和组织的影响。结果表明:TA18管材具有较好的冷加工性能,变形量在12%~48%,且Q≤1.30时,管材表面质量较好,通过不同的退火温度(350~380℃,600~750℃),可获得满足不同强度级别要求的TA18管材。

关键词:TA18管材;变形量;退火温度;显微组织;力学性能

中图分类号:TG146.4 文献标志码:A

Effects of cold rolling and annealing process on microstructure and properties of TA18 tubes

WEI Bei-ling1, ZHANG Ya-feng2, YU Zhen-tao2, HAN Jian-ye3, YU Sen2, LIU Chun-chao2, HUANGFU Qiang3

(1. Western Metal Materials Co., Ltd, Xi’an 710016, China;

2. Northwest Institute For Non-ferrous Metal Research, Xi’an 710016, China;

3. Xi’an Jiuzhou Biological Material Co., Ltd., Xi’an 710016, China)

Abstract: Machining deformations ε and Q are important parameters for cold rolling of tubes. The small size tubes of TA18 were prepared by cold rolling through three-roll tube reducers. The effects of different machining deformations ε and Q values on the properties and surface quality of tubes were investigated, the tensile properties at room temperature and microstructures of tubes under different annealing temperatures were analyzed, and the effect of annealing temperature on the microstructure and properties of TA18 tubes was studied. The results show that TA18 tubes have good cold working properties, the surface quality of tubes is good when the deformation rates range from 12% to 48% and the Q value is not more than 1.30. The TA18 tubes have excellent properties to meet the requirements of different intensity levels after different annealing treatments (350-380 ℃, 600-750 ℃).

Key words: TA18 tubes; deformation rate; annealing temperature; microstructure; mechanical properties

TA18合金是从TC4合金演变而来的低合金化近α型钛合金,其名义成分为Ti-3Al-2.5V。该合金具有优良的力学性能和耐蚀性能,在室温和高温下其强度比纯钛高出20%~50%,焊接性能和冷、热加工性能均优于TC4合金,因此,该合金成为制作航空航天管路系统的首选材料[1-6]。TA18合金管材的力学性能按强度的级别分为2种:一种为中强度(620 MPa,再结晶态)级别的管材,主要用于发动机管路系统;另一种为高强度(862 MPa,去应力态)级别的管材,主要用于飞机液压等管路系统[6-7]。

20世纪70年代,美国率先将TA18合金应用在洛克希德C-5A“银河”大型军用运输机的管路系统,随后在F-14、F-15和波音747等飞机的液压、燃油管路系统中推广应用[5-7]。在我国,TA18合金管材还未获得广泛应用,通过冷轧技术生产高强度级别的TA18合金管材尚处于探索试制阶段。随着我国航空航天工业的不断发展,对高性能TA18合金管材的需求日益迫切。因此,开展TA18合金管材加工的相关研究具有重要意义。

1 实验

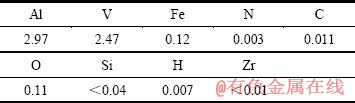

实验原料选用一级海绵钛、Al-V中间合金以及Al豆、Al箔等,经过3次真空自耗电弧炉熔炼制备成TA18合金铸锭,其化学成分如表1所列。

表1 TA18合金铸锭化学成分

Table 1 Chemical compositions of TA18 alloy ingot (mass fraction, %)

TA18合金铸锭经过锻造、机械加工后制成挤压坯,在1 000 t卧式挤压机上挤压成管坯,经过LG30两辊开坯轧制和LD15三辊多道次冷轧和表面处理,制备出实验用管材。在LD8三辊轧机上选择不同工艺冷轧成外径为d4~5.5 mm管材,选择规格为d5.0 mm×0.50 mm管材进行了7种不同温度的热处理,冷却方式为炉冷。

管材试样室温拉伸性能在INSTRON1185 万能材料实验机上按照GB/T 228—2002《金属材料室温拉伸试验方法》测定。试样的截面经过磨制、抛光后,使用腐蚀剂(1~3 mL HF+2~6 mL HNO3+100 mL H2O)进行腐蚀,侵蚀时间为10~20 s。使用Olympus MPG3光学显微镜观察管材试样的显微组织。

2 结果与讨论

2.1 变形量对管材性能和表面质量的影响

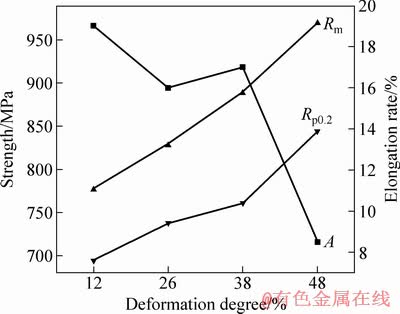

选择规格为d6.0 mm×0.65 mm退火态管材为研究对象,分别经过12%、26%、38%和48% 4种不同变形量的轧制,随后对其进行室温拉伸性能测试,以研究变形量对TA18管材性能和表面质量的影响。

图1所示为变形量对TA18管材力学性能的影响。由图1可见:当变形量在12%~26%时,管材的强度均随着变形量的增大而逐渐增大,伸长率随着变形量的增大而降低。当变形量在26%~38%时,管材的强度、伸长率均随着变形量的增大而逐渐增大,这与经过一定变形量加工后,管材内部的晶粒各向异性减少,晶粒取向趋于一致,从而有利于塑性变形。当变形量在38%~48%时,管材的强度急剧升高,伸长率下降趋势明显,这主要是由于管材经过大变形后,内部产生大量位错和缺陷,同时还产生很大的残余应力,导致加工硬化比较明显。对4种不同变形量的管材表面质量进行观察(如表2所列)可以看出,冷轧变形量在12%~48%时,可获得不同强度且表面质量较好的TA18管材。

图1 变形量ε对管材力学性能的影响

Fig. 1 Effect of ε value on mechanical properties of tubes

表2 变形量ε对TA18管材表面质量的影响

Table 2 Effect of ε value on surface quality of TA18 tubes

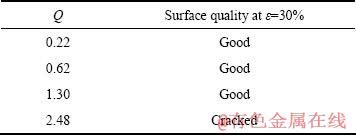

2.2 Q对管材性能和表面质量的影响

变形量Q是管材冷轧变形的另一个重要参数。同样选择规格为d6.0 mm×0.65 mm退火态管材为研究对象,分别经过0.22、0.62、1.30、2.48这4种不同Q的轧制,随后对其进行室温拉伸性能测试,以研究Q对TA18管材性能和表面质量的影响。

图2所示为Q对TA18管材力学性能的影响。由图2可见:当Q在0.22~0.62时,管材的强度随着Q的增大而增大,伸长率随着Q的增大而降低;当Q=0.62~1.30时,管材的强度仍呈上升趋势,但伸长率逐渐趋于一致,在这一区间轧制时,通过塑性变形,管材内部晶粒出现择优取向形成以径向织构为主。当Q=1.30~2.48时,管材的强度和伸长率均随着Q的增大而降低,这说明随着Q的增大,径向织构减少,这也与小规格管材的尺寸效应有关。同时,对4种不同Q的管材表面质量进行了观察,结果如表3所列。通过分析可以看出,TA18合金管材不宜在Q>1.30的条件下冷轧。

图2 Q对TA18管材力学性能的影响

Fig. 2 Effect of Q on mechanical properties of TA18 tubes

表3 Q对TA18管材表面质量的影响

Table 3 Effect of Q value on surface quality of TA18 tubes

2.3 退火温度对管材性能和组织的影响

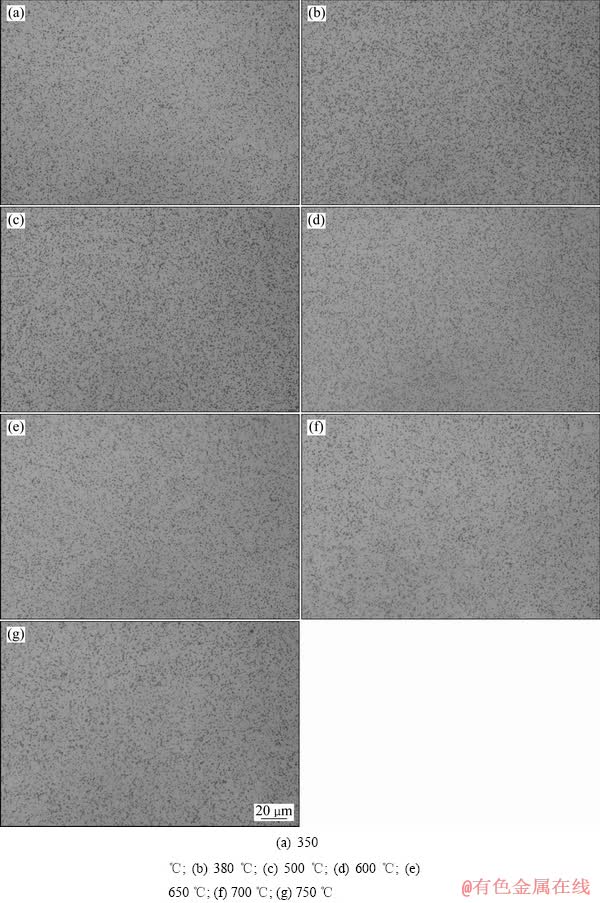

选择规格为d5.0 mm×0.50 mm冷轧态管材为研究对象,分别经过350 ℃、1 h,380 ℃、1 h,500 ℃、1 h,600 ℃、1 h,650 ℃、1 h,700 ℃、1 h,750 ℃、1 h等7种不同温度的热处理,随后对其进行室温拉伸性能测试和显微组织分析,以研究退火温度对TA18管材显微组织和性能的影响。

图3所示为不同退火温度对TA18管材力学性能的影响。由图3可见,管材经过冷轧变形产生大量的残余应力,使得管材强度较高,伸长率较小。退火温度在350~380 ℃时,管材的强度降低,塑性得到提高;退火温度在380~600 ℃时,管材的强度和塑性变化比较明显;退火温度在600~750 ℃时,管材的强度和塑性均呈现下降趋势。在700~750 ℃时,由于发生了完全再结晶,加工硬化已完全消除,管材的强度和塑性基本趋于一致。

图3 退火温度对TA18管材力学性能的影响

Fig. 3 Effect of annealing temperature on mechanical properties of TA18 tubes

图4 不同温度退火后的金相组织(横向)

Fig. 4 Microstructure of tubes after annealing at different temperatures

图4所示为不同热处理温度对TA18管材组织的影响。由图4可见,在500 ℃以下退火时,管材的显微组织未发生明显变化。600 ℃退火后组织中出现极少量的再结晶晶粒。当退火温度升到650 ℃时,管材的再结晶晶粒的数量明显增加。退火温度为700 ℃时,管材的组织发生了明显再结晶。750 ℃退火时的完全再结晶组织形貌与700 ℃的非常相似,只是晶粒尺寸不同程度地变大。

3 结论

1) TA18合金管材具有较好的冷加工性能,冷轧变形量在12%~48%时,管材表面质量较好。

2) 随着Q增大,管材塑性变差。Q=0.22~1.30时,在LD8三辊轧机上可顺利轧制出综合性能优异的管材。

3) 管材冷轧后,在350~380 ℃去应力退火时,管材性能满足高强度级别要求;在600~750 ℃退火时,管材性能满足中强度级别要求。

REFERENCES

[1] 谢群良, 汪建林. 工艺对Ti-3Al-2.5V 钛合金无缝的表面和性能的影响[J]. 上海钢研, 2002(2): 9-12.

XIE Qun-liang, WANG Jian-lin. The effect of process on the surfaces and property of Ti-3Al-2.5V seamless tube[J]. Journal of Shanghai Iron and Steel Research, 2002(2): 9-12.

[2] 南 莉, 杨亚社, 齐元昊, 罗登超, 杨永福, 曲恒磊, 杨建朝. 航空用高强TA18钛合金管材的轧制工艺[J]. 稀有金属材料与工程, 2013, 42(1): 166-170.

NAN Li, YANG Ya-she, QI Yuan-hao, LUO Deng-chao, YANG Yong-fu, QU Heng-lei, YANG Jian-chao. Rolling process of high-strength TA18 titanium alloy tubes for aviation[J]. Rare Metal Materials and Engineering, 2013, 42(1): 166-170.

[3] 罗登超, 南 莉, 杨亚社, 杨永福. 退火温度对TA18管材性能和组织的影响[J]. 材料热处理技术, 2012, 10: 206-208.

LUO Deng-chao, NAN Li, YANG Ya-she, YANG Yong-fu. Effect of annealing temperature on mechanical properties and microstructure of TA18 tubes[J]. Material & Heat Treatment, 2012, 10: 206-208.

[4] 齐元昊, 杨亚社, 南 莉, 杨永福. 高强Ti-3Al-2.5V合金管材的组织与性能[J]. 特种铸造及有色合金, 2011, 31(11): 1062-1065.

QI Yuan-hao, YANG Ya-she, NAN Li, YANG Yong-fu. Microstructure and properties of high strength Ti3Al-2.5V Ti alloy pipe[J]. Special Casting & Non-ferrous Alloys, 2011, 31(11): 1062-1065.

[5] 杨 磊, 惠松骁, 叶文君, 黄 亮. TA18钛合金管材织构的测试与EBSD分析[J]. 稀有金属, 2011, 35(6): 928-933.

YANG Lei, HUI Song-xiao, YE Wen-jun, HUANG Liang. Texture and EBSD of TA18 titanium alloy tubes[J]. Chinese Journal of Rare Metals, 2011, 35(6): 928-933.

[6] 张旺峰, 李 艳, 王玉会, 曹春晓. Ti-3Al-2.5V钛合金管材研究进展[J]. 材料导报, 2011, 25(12): 133-137.

ZHANG Wang-feng, LI Yan, WANG Yu-hui, CAO Chun-xiao. Research progress in Ti-3Al-2.5V alloy tube[J]. Materials Review, 2011, 25(12): 133-137.

[7] 杨亚社, 杨永福, 罗登超, 南 莉, 杨建朝. 航空用TA18管材加工工艺研究[J]. 稀有金属材料与工程, 2013, 42(3): 625-628.

YANG Ya-she, YANG Yong-fu, LUO Deng-chao, NAN Li, YANG Jian-chao. Study on processing technology of TA18 titanium tubes for aviation[J]. Rare Metal Materials and Engineering, 2013, 42(3): 625-628.

(编辑 邓履翔)

基金项目:国家科技支撑计划项目(2012BAI18B02);国家重点基础研究发展规划项目(2012CB619102);国家高技术研究发展计划资助项目(2011AA030101)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:尉北玲,高级工程师;电话:029-86231084;E-mail:swzx@c-nin.com