文章编号:1004-0609(2012)08-2174-07

人工时效对6005A铝合金晶间腐蚀性能的影响

盛晓菲1,杨文超1,汪明朴1, 2,李 周1,龚 静1,彭 诚1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 教育部有色金属材料科学与工程实验室,长沙 410083)

摘 要:采用硬度测试、晶间腐蚀试验、金相及透射电镜观察研究人工时效对6005A铝合金晶间腐蚀性能的影响。结果表明:6005A铝合金在固溶水淬后进行人工时效,晶间腐蚀敏感性随时效时间的延长而变化;时效初期,合金的晶间腐蚀敏感性很低,随时效时间的延长,晶间腐蚀敏感性增加;时效12 h时,合金硬度达峰值,同时晶间腐蚀敏感性也达最大,随后晶间腐蚀敏感性减弱,出现点蚀。6005A铝合金晶间腐蚀敏感性与晶界有关,点蚀的引入与晶内Q′相的析出长大有关。

关键词:6005A铝合金;人工时效;晶间腐蚀

中图分类号:TG 146.21 文献标志码:A

Effect of artificial ageing on intergranular corrosion of 6005A Al alloy

SHENG Xiao-fei1, YANG Wen-chao1, WANG Ming-pu1, 2, LI Zhou1, GONG Jing1, PENG Cheng1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The effect of artificial ageing on the corrosion performance of 6005A Al alloy was investigated by hardness test, intergranular corrosion test, optical microscopy and TEM observation. The results show that the intergranular corrosion susceptibility of 6005A Al alloy is related to the artificial ageing time. The accelerated corrosion test reveals that the intergranular corrosion(IGC) of 6005A Al alloy is low susceptible to in the beginning of the artificial ageing after water quenched. However, IGC susceptibility increases with the increase of aging time, and reaches the peak value after artificial ageing for 12 h, while the hardness is the highest. The overageing reduces the IGC susceptibility, however, the slight pitting is produced. The increased IGC susceptibility is related to the grain boundary. The pitting susceptibility by over ageing is evolved due to coarsening of the Q′-phase particles.

Key words: 6005A Al alloy; artificial ageing; intergranular corrosion

6000系铝合金(AlMgSi和AlMgSiCu合金)具有优异的比强度,易进行表面处理的加工特点及良好的抗腐蚀性能,在建筑、汽车和船舶行业[1]中得到了广泛的应用。然而,Cu元素的加入[2-8]、Si元素的过剩[9]以及不合适的热处理工艺[7, 10, 11-14]都会导致晶间腐蚀(IGC)倾向增加。通常晶间腐蚀最敏感的时候发生在峰值时效,而过时效能够降低晶间腐蚀的敏感性,但却会引入点蚀[16-18]。

Cu的加入和不适合的热处理能够增加含Cu的6000系铝合金的晶间腐蚀敏感性[15, 17-18],但是关于含Cu的6000系铝合金的晶间腐蚀的发生机理却还没有得到充分的研究。通常认为晶间腐蚀的发生是因为晶界上的AlCu相、CuSi相或者(Al)MgSiCu相与邻近的无沉淀析出带构成微电池,但是这些都没有确切的证据支持。然而,在焊接后的热影响区(AA6005)和热处理后(AA6061、AA6056、AA6013)的合金中[20-21],已经证实Al5Cu2Mg8Si6(Q相)在晶界上存在,并与晶间腐蚀有关。

本文作者采用晶间腐蚀试验、透射电镜 (TEM)等研究固溶水淬后人工时效处理对6005A晶间腐蚀性能的影响,以便为6005A铝合金抗晶间腐蚀性能的变化研究提供理论依据。

1 实验

采用半连续铸造工艺制备了6005A铝合金,在线挤压淬火成厚度为3 mm的型材,其成分(质量分数)为Mg 0.65、Si 0.73、Cu 0.13、Mn 0.31、Cr 0.16、Ti≤0.10、Zn≤0.10、Al余量。

实验用样品尺寸为3 cm×3 cm×0.3 cm,取样在厢式电阻炉中经550 ℃、1 h固溶,水淬到室温,为了减小自然时效的影响,在15 s内对试样进行175 ℃等温油浴时效。因为本文作者所采用的6005A铝合金在热加工后于室温存储了很长的时间,已经自然时效至基本稳定状态,为了消除自然时效的影响,对合金进行了重新固溶处理。

硬度测试使用HV-5型小负荷维氏硬度计,载荷19.6 N,加载时间15 s,所记录的硬度数据都是经7次测量后,去除最大值和最小值的平均值,误差范围为±HV3。

晶间腐蚀实验按GB/T7998—2005要求进行,将试样打磨、抛光,先用有机溶剂(依次用石油醚、丙酮、乙醇)清洗试样表面油污,然后将其浸入氢氧化钠溶液(10%,质量分数)5~15 min,取出试样,用水洗净,再浸入硝酸溶液(30%,体积分数)中,直至表面光洁。取出试样,用水洗净,用3%NaCl(质量分数)+10 mL/L HCl溶液在35 ℃浸泡24 h,然后将腐蚀试样沿横向切开并抛光,用Leica DM ILM HC光学显微镜观察腐蚀形貌并测量腐蚀深度。

TEM样品在MTP-1双喷电解减薄仪上双喷减薄、穿孔。电解液为硝酸和甲醇的混合液,两者体积比为3:7,温度为-30~-20 ℃,电压为12~15 V,电流为80~100 mA。在JEOLF-2100型TEM上观察,加速电压为200 kV。

2 结果与分析

2.1 晶间腐蚀结果

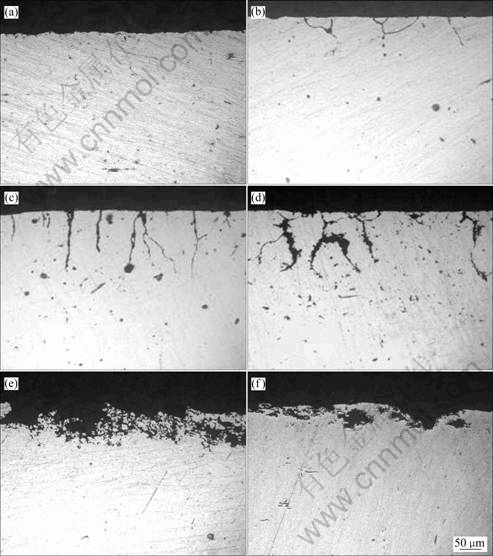

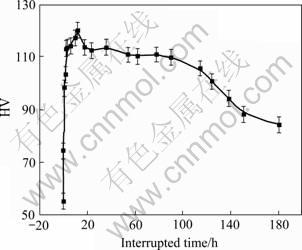

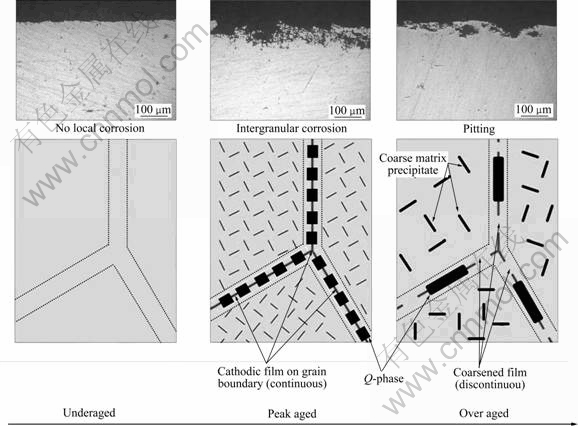

不同的时效时间导致不同的腐蚀敏感度和腐蚀类型。图1所示为6005A铝合金经175 ℃时效后的晶间腐蚀形貌。腐蚀结果如表1所列。图2所示为6005A铝合金在175 ℃时效后的硬度曲线。

从图1、2和表1中可以发现,在时效初期,晶间腐蚀敏感性最低,基本没有发生晶间腐蚀,腐蚀形貌如图1(a)所示。当时效至5 h时,出现了轻微的局部晶间腐蚀,晶间腐蚀最深的深度约为50 μm,如图1(b)所示。时效至6 h时,晶间腐蚀深度加深,最深的深度约为100 μm,虽然此时晶间腐蚀在深度上比较严重,但是出现腐蚀的间隔比较远,与5 h状态的间隔差不多,如图1(c)所示。当达到11 h时,晶间腐蚀深度进一步加深,最深的深度达到120 μm,腐蚀间隔并没有太大的变化,但是出现了晶界的刀口状连续腐蚀,如图1(d)所示。晶间腐蚀最严重的情况在时效12 h时出现,此时正好是时效曲线达峰值状态,如图2所示,其腐蚀形貌如图1(e)所示,此时,出现局部严重晶间腐蚀倾向,部分表层晶粒相互脱离,甚至脱落,发生晶间腐蚀区域腐蚀最深深度约为100 μm,最深深度较11 h时的有所下降。而时效24 h后,最深的腐蚀深度下降至80 μm,以点蚀为主,如图1(f)所示。

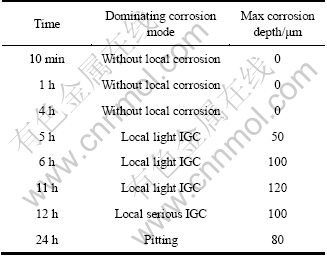

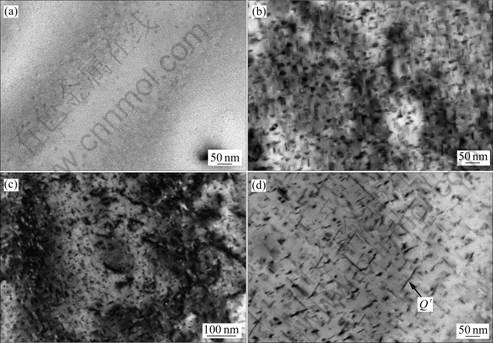

2.2 TEM组织观察

为了进一步研究微观结构对腐蚀性能的影响,对6005A铝合金进行了TEM观察。图3所示为不同时效时间下6005A铝合金的晶界TEM像。在时效初期,即175 ℃、10 min时,晶界上没有发现明显的析出相,如图3(a)所示。当时效至5 h时,晶界上可以看到存在析出相,其数量和尺寸都很小,无沉淀析出带的宽度约为25 nm,如图3(b)所示。而时效至12 h时,晶界出现了呈不连续分布的析出相,尺寸较小,相互之间间隔比较近,数量较时效5 h状态大幅上升,尺寸没有发生明显变化,无沉淀析出带的宽度约为25 nm,如图3(c)所示。随着时效时间的延长,析出相的尺寸越来越大,相互之间的间隔也越来越大,图3(d)所示为时效24 h后晶界的TEM像,无沉淀析出带的宽度约为25 nm。从5 h到24 h,晶界上的无沉淀析出带没有发现明显的变化。

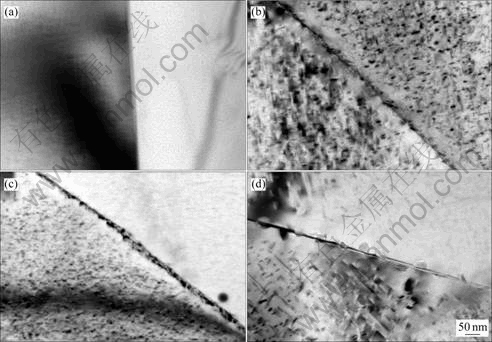

图4所示为不同时效时间下晶内TEM像。由图4(a)可以看出,在时效初期,即10 min时,晶内基本没有明显的析出相。时效至5 h时(图4(b)),晶内已经大量析出与基体共格的针状β″相,尺寸约为15 nm。当达到峰时效状态(图4(c)),即时效到12 h时,合金中仍以共格的针状β″相为主,平均尺寸约为20 nm。而时效至24 h时(图4(d)),晶内已经出现了板状的Q′相,尺寸约为60 nm,同时还能观察到针状β″相的存在,尺寸约为25 nm。

图1 6005A铝合金经175 ℃时效后的腐蚀形貌

Fig. 1 Corrosion micrographs of 6005A Al alloy after artificial aging time at 175 ℃: (a) 10 min; (b) 5 h; (c) 6 h; (d) 11 h; (e) 12 h; (f) 24 h

图2 6005A铝合金在175 ℃时效的硬度曲线

Fig. 2 Hardness curve of 6005A Al alloy after artificial aging time at 175 ℃

表1 6005A铝合金的晶间腐蚀结果

Table 1 Intergranular corrosion results of 6005A Al alloy

图3 不同时效时间下6005A铝合金的晶界TEM像

Fig. 3 TEM images of grain boundaries of 6005A Al alloy after different heat treatment times: (a) 175 ℃, 10 min; (b) 175 ℃, 5 h; (c) 175 ℃, 12 h; (d) 175 ℃, 24 h

图4 6005A铝合金的晶内TEM像

Fig. 4 TEM images of grains of 6005A Al alloy: (a) 175 ℃, 10 min; (b) 175 ℃, 5 h; (c) 175 ℃, 12 h; (d) 175 ℃, 24 h

3 讨论

晶界腐蚀是肉眼观察不到的,几乎不引起材料的质量损失,但它破坏晶界和晶粒之间的结合力,引起力学性能降低,所以它是结构铝合金中危险性最大的腐蚀破坏形式之一。传统理论认为晶间腐蚀的原动力是晶界与相邻晶粒之间的电位差[22]。

因为晶界上的沉淀相较Al基体或者更活泼,或者电位更高,从而形成了微电池,导致晶间腐蚀。对于含Cu的6000系铝合金,若含有过量的Si会加速Q相形成[10],可能引起IGC。Si的消耗加剧了Al基体中无沉淀析出带的形成,沿着晶界两边分布,性质活泼,引发微电池效应,导致腐蚀。Q相电化学性质活泼,特别是Q相形成时消耗了大量溶质原子,导致更多的无沉淀析出带的形成,从而使微电流效应更加明显,增加了晶间腐蚀的危险性。

在时效初期,晶界上基本没有发现有析出相(见图3(a)),而此时基体主要以过饱和固溶体形式存在(见图4(a)),电位均一,且和晶界的电位差很小,故此时合金的抗晶界腐蚀性能很强,晶间腐蚀测试显示基本没有出现晶间腐蚀(见图1(a))。

时效至5 h时,从晶间腐蚀结果来看,出现了轻微的局部晶间腐蚀,晶间腐蚀最深的深度约为50 μm,如图1(b)所示,但是从图3(b)上可以看到,此时合金的晶界上依然没有出现大量明显的析出相,只有零星的一些细小析出相,说明此时发生的晶间腐蚀并不是由晶界上连续的析出相和晶界上的无沉淀析出带构成的微电池效应所导致的。随着时效时间的延长,晶间腐蚀加剧,如图1(c)和(d)所示。

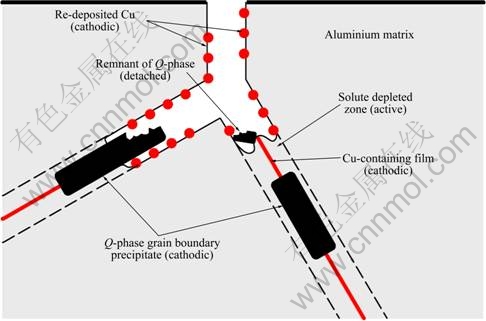

晶间腐蚀最严重的时候发生在时效12 h时,此时正好是6005A铝合金硬度最高的时候,所以此时出现严重的晶间腐蚀对6005A铝合金的实际应用是非常不利的。晶间腐蚀最严重时出现局部严重晶间腐蚀倾向,部分表层晶粒相互脱离、甚至脱落,发生晶间腐蚀区域腐蚀最深深度约为100 μm,同时,晶界TEM像显示在晶界上已经析出了大量平衡相Q相[10],尺寸比较小,呈不连续分布。但是,在晶界上不连续析出的Q相无法解释峰时效状态的严重的晶间腐蚀倾向。SVENNINGSEN等[10]认为在晶界上存在着纳米尺度的连续的Cu富集带,基于热力学的计算[15],此时,Cu无法以单质形式存在,也不会以AlCu相(Al2Cu)的形式存在,因此,这些Cu富集带极有可能是Q相的先驱。这些分布在晶界上的Q相,还有连续的Cu富集带形成了连续的阴极活性通道,而在晶界附近的无析出带则作为阳极,相互之间形成微电池,导致晶界优先连续的溶解,产生严重的晶间腐蚀。然而,来自Cu富集带和Q相中的Cu能够在酸性的氯化物溶液中溶解然后再沉淀在暴露的晶粒边缘[19-20],继续充当阴极,这就有可能就是导致图1(d)中出现的刀口状的腐蚀的原因。图5所示为晶间腐蚀机制的示意图[10]。

而时效至24 h时,起主导作用的是点蚀,腐蚀深度大约为80 μm,晶间腐蚀几近于消失,说明此时晶界上的Cu富集带发生了缩进,至少在局部发生了缩进,在晶界上形成不连续的Cu富集带,打破了原本连续的微电池,而且晶界上的Q相较T6峰时效状态有所长大,相互之间的间隔也有所扩大,Q相充当阴极产生的腐蚀效果进一步减弱。因为随着时效时间的延长,晶内析出相进一步长大,针状β″相的尺寸约为25 nm,同时析出了相当数量的Q′相,尺寸约为60 nm,如图4(d)所示,晶内针状β″相的长大以及Q′相的析出的进一步加剧了基体溶质原子的析出,基体进一步贫化,晶内析出相和基体之间的电位差增大,微电池效应加剧,此时腐蚀的不再只是晶界,而是整个晶粒,因此出现了严重的点蚀。同时,因为晶界上微电池效应的减弱,晶间腐蚀减弱,点蚀取代晶间腐蚀成为主要的腐蚀形式。图6所示为微观结构和腐蚀类型示意图。

图5 晶间腐蚀机制示意图[10]

Fig. 5 Conceptual sketch of IGC mechanism[10]

图6 微观结构和腐蚀类型示意图

Fig. 6 Conceptual sketch of microstructure and corrosion

4 结论

1) 所采用的6005A铝合金在时效初期晶间腐蚀敏感性很低,晶界上无明显析出相;随时效时间的延长,晶间腐蚀敏感性增加,时效5 h时,出现晶间腐蚀;时效12 h时,合金硬度达峰值,同时晶间腐蚀敏感性也达最大,晶界上的析出相呈不连续分布,尺寸较小;随后晶间腐蚀敏感性减弱,同时也引入点蚀,此时,晶界上析出相长大,相互之间的间隔也有所扩大。

2) 峰时效时晶间腐蚀的敏感性与由晶界上的化合物和无沉淀析出带构成的微电池效应有直接的关系。

3) 过时效后点蚀的引入主要是因为晶内大量析出长大的第二相(主要是Q′相)与贫化的基体形成的微电池效应。

REFERENCES

[1] MILLERA W S, ZHUANGA L, BOTTEMAA J, WITTEBROODA A J, SMETB P D, HASZLERC A, VIEREGGE A. Recent development in aluminium alloys for the automotive industry[J]. Materials Science and Engineering A, 2000, 28(1): 37-49.

[2] MONDOLFO L. Aluminium alloys: Structure and properties[M]. London: Britain, Butterworths & Co. Ltd, 1976: 336-357.

[3] MEISSNER H. Effect of copper on the corrosion behaviour of AlMgSi-alloy auto body sheet[J]. Aluminium, 1992, 68(12): 1077-1080.

[4] NISANCIOGLU K, STRANDMYR ?. Corrosion of AlMgSi alloys with Cu additions: The effect of Cu content up to 0.9 weight percent[R]. Trondheim, Norway, SINTEF, 1978.

[5] YAMAGUCHI K, TOHMA K. Effect of Zn addition on intergranular corrosion resistance of Al-Mg-Si-Cu[C]//SATO T, KUMAI S, KOBAYASHI T, MURAKAMI M. Proceedings of the 6th International Conference on Aluminium Alloys (ICAA6). Tokyo: Japan Institute of Light Metals, 1998: 1657-1662.

[6] YAMAGUCHI K, TOHMA K. The effect of Cu content on susceptibility to intergranular corrosion of Al-Mg-Si alloy[J]. Journal of Japan Institute of Light Metals, 1997, 47(5): 285-291.

[7] SVENNINGSEN G, LEIN J E, BJ?RGUM A, NORDLIEN J H, YU Y, NISANCIOGLU K. Effect of low copper content and heat treatment on intergranular corrosion of model AlMgSi alloys[J]. Corrosion Science, 2006, 48: 226-242.

[8] 何立子, 张晓博, 孙秋霞, 崔建忠. Cu及热处理制度对Al-Mg-Si系合金晶间腐蚀敏感性的影响[J]. 中国有色金属学报, 2001, 11(2): 231-235.

HE Li-zi, ZHANG Xiao-bo, SUN Qiu-xia, CUI Jian-zhong. Effects of Cu and age treatment on susceptibility to intergranular corrosion of Al-Mg-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 231-235.

[9] BOOTH F. Die korrosionsbest?ndigkeit von aluminium- magnesium-silizium-legierungen[J]. Aluminium, 1962, 38(4): 213-219.

[10] SVENNINGSEN G, LARSEN M H, NORDLIEN J H, NISANCIOGLU K. Effect of high temperature heat treatment on intergranular corrosion of AlMgSi(Cu) model alloy[J]. Corrosion Science, 2006, 48: 258-272.

[11] SPROWLS D O, BROWN R H. Stress corrosion mechanisms for aluminium alloys[C]//Proceedings of Fundamental Aspects of Stress Corrosion Cracking. Ohio: The Ohio State University, 1967: 466-506.

[12] DIF R, BECHET D, WARNER T, RIBES H. 6056 T78: A corrosion resistant copper-rich 6××× alloy for aerospace applications[C]//SATO T, KUMAI S, KOBAYASHI T, MURAKAMI M. Proceedings of the 6th International Conference on Aluminium Alloys (ICAA6). Tokyo: Japan Institute of Light Metals, 1998: 1991-1996.

[13] DIF R, BES B, EHRSTRO M, SIGLI C, WARNER J T, LASSINCE P, RIBES H. Understanding and modelling the mechanical and corrosion properties of 6056 for aerospace applications[J]. Mater Sci Forum, 2000, 331/337: 1613-1618.

[14] BHATTAMISHRA A K, LAL K. Influence of ageing on corrosion behaviour of Al-Mg-Si alloys in chloride and acid media[J]. Zeitschrift fuer Metallkunde/Materials Research and Advanced Techniques, 1998, 89(11): 793-796.

[15] BUCHHEIT R G, MARTINEZ M A, MONTES L P. Evidence for Cu ion formation by dissolution and dealloying the Al2CuMg intermetallic compound in rotating ring-disk collection experiments[J]. Am Ceramic Soc, 2000, 147(1): 119-135

[16] GUILLAUMIN V, MANKOWSKI G. Influence of overaging treatment on localized corrosion of Al 6056 aluminium alloy[C]//KELLY R G, FRANKEL G S. Proceedings of Critical Factors in Localized Corrosion Ⅲ. Pennington, New Jersey: The Electrochemical Society, 1999: 203-214.

[17] 李 海, 潘道召, 王芝秀, 郑子樵. T6I6时效对6061铝合金拉伸及晶间腐蚀性能的影响[J]. 金属学报, 2010, 46(4): 494-499.

LI Hai, PAN Dao-zhao, WANG Zhi-xiu, ZHENG Zi-qiao. Influence of T6I6 temper on tensile and intergranular corrosion properties of 6061 aluminum alloy[J]. Acta Metallurgica Sinica, 2010, 46(4): 494-499.

[18] BURLEIGH T D, LUDWICZAK E, PETRI R A. Intergranular corrosion of an aluminium-magnesium-silicon-copper alloy[J]. Corrosion, 1995, 51(1): 50-56.

[19] BUCHHEIT R G, MARTINEZ M A, MONTES L P. Evidence for Cu ion formation by dissolution and dealloying the Al sub 2 CuMg intermetallic compound in rotating ring-disk collection experiments[J]. Am Ceramic Soc, 2000, 147(1): 119-135.

[20] KOLICS A, BESING A S, WIECKOWSKI A. Interaction of chromate ions with surface intermetallics on aluminum alloy 2024-T3 in NaCl solutions[J]. Journal of the Electrochemical Society, 2001, 148(8): 428-439.

[21] GRABERG S, BRATLAND D H, GRONG ?, REISO O. Effect of local melting on the HAZ toughness of GMA welded AA6082 and AA6005 extrusions containing Cu[J]. Mater Sci Forum, 2002, 396/402: 1329-1334.

[22] 朱祖芳. 有色金属的耐腐蚀性及其应用[M]. 北京: 化学工业出版社, 2001: 11-12.

ZHU Zu-fang. Anticorrosion and applications of non-ferrous metals[M]. Beijing: Chemical Industry Press, 2001: 11-12.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2006AA03Z517);湖南省博士生科研创新项目(CX2010B044)

收稿日期:2011-08-01;修订日期:2011-10-27

通信作者:汪明朴,教授;电话:0731-88830264;E-mail: wangmp@csu.edu.cn