文章编号:1004-0609(2010)03-0435-07

双级时效对6061铝合金拉伸性能和晶间腐蚀性能的影响

潘道召1,王芝秀1, 2,李 海1,郑子樵2

(1. 江苏工业学院 材料科学与工程学院,常州 213164;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用拉伸试验、晶间腐蚀试验、金相及透射电镜观察,研究双级时效对6061铝合金拉伸性能和晶间腐蚀性能的影响。结果表明:6061铝合金经(180 ℃, 8 h)的T6峰值时效,抗拉强度和屈服强度分别为356 MPa和331.6 MPa,伸长率为13.7%,但出现严重的晶间腐蚀,腐蚀深度约为270 mm。在T6峰值时效的基础上进一步升高温度和延长时间进行二级时效,合金强度总体上呈逐渐降低趋势,电导率逐渐上升,腐蚀类型也由晶间腐蚀逐渐转变为点蚀,腐蚀深度明显变浅。对于6061铝合金,最佳双级时效工艺为(180 ℃, 8 h)+(210 ℃, 2 h),抗拉强度为348.4 MPa,屈服强度为320.3 MPa,伸长率为11.3%,腐蚀类型为轻微点蚀,腐蚀深度约为50 mm。

关键词:6061铝合金;双级时效;晶间腐蚀;微观组织

中图分类号:TG292 文献标识码:A

Effects of two-step ageing treatment on tensile properties and intergranular corrosion of 6061 aluminum alloy

PAN Dao-zhao1, WANG Zhi-xiu1, 2, LI Hai1, ZHENG Zi-qiao2

(1. School of Materials Science and Engineering, Jiangsu Polytechnic University, Changzhou 213164, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Effects of two-step ageing treatment on tensile properties and intergranular corrosion(IGC)of 6061 aluminum alloy were investigated by tensile test, intergranular corrosion test, optical microscopy and TEM observation. The experimental results show that ultimate tensile strength, yield strength and elongation of 6061 alloy in T6 temper are 348.4 MPa, 320.3 MPa and 13.7%, respectively. However, the serious intergranular corrosion occurs with corrosion depth of about 270 mm. As a result of two-step ageing treatment, the strength decreases and the conductivity increases with the increase of two-step ageing temperature and time, but the mode of corrosion changes from intergranular corrosion to pitting corrosion (PC) while the corrosion depth decreases. Under the optimum two-step ageing treatment of (180 ℃, 8 h)+(210 ℃, 2 h), the ultimate strength, yield strength and elongation are 348.4 MPa, 320.3 MPa and 11.3%, respectively. The mode of corrosion is slight pitting with corrosion depth of 50 mm.

Key words: 6061 aluminum alloy; two-step ageing; intergranular corrosion; microstructure

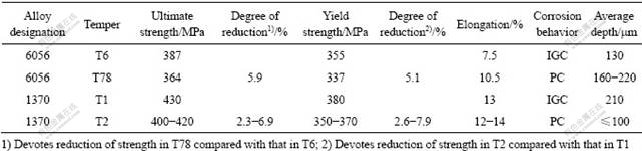

6000系铝合金属于可热处理强化的变形铝合金,具有中等强度、良好的焊接性和耐蚀性等,被广泛应用于航天航空、交通运输和建筑等行业[1?2]。Pechiney公司为了降低生产成本和减轻飞机质量,采用耐蚀性和焊接性等更好的6000系铝合金来部分代替目前飞机上大量使用的2000系铝合金,开发了6056铝合金[3]。然而,6000系铝合金虽具有良好的耐蚀性,但不适当的热处理方式[4?6]、Cu含量[7?8]及Mg与Si的质量比[9]等因素会增加合金的晶间腐蚀倾向。例如,在T6(180 ℃, 8 h)峰值时效状态下,合金具有较强的晶间腐蚀倾向,限制该类合金的进一步使用。为此,Pechiney公司又开发出具有专利保护性质的T78时效工艺。采用该热处理工艺,在轻微降低强度的前提下,显著改善6056铝合金抗晶间腐蚀性能,并在A380客机上得到应用[10?12]。由于6056-T78合金具有良好的拉伸性能和抗晶间腐蚀性能,俄罗斯也开发出与6056铝合金类似的1370铝合金,以及与T78类似的T2时效工艺。这2种铝合金在不同状态下的拉伸性能和晶间腐蚀性能如表1所列[13?14]。

有限的文献资料表明[3],T78时效属于一种轻微的双级过时效处理。在此,本文作者以6061铝合金为实验材料,在T6峰值时效的基础上再在较高温度 (>180 ℃)下进行二级时效,通过改变二级时效温度和时间,在轻微降低拉伸性能的前提下改善其抗晶间腐蚀性能。

1 实验

实验材料为2 mm左右厚的6061铝合金冷轧薄板,其化学成分为0.8~1.2Mg,0.4~0.8Si,0.15~0.4Cu,0.15Mn,0.7Fe,0.04-0.35Cr,0.25Zn,余量为Al(质量分数,%)。沿板材纵向加工拉伸试样和晶间腐蚀试样,经(550 ℃, 1 h)固溶处理及室温水淬后,首先,进行(180 ℃, 8 h)峰值时效(即T6峰值时效);然后,在190~240 ℃再进行二级时效0.5~8 h。

将时效处理好的拉伸试样在WDT?030型电子试验机上进行拉伸性能测试,拉伸速率为2 mm/min。 另外截取拉伸试样夹持端,利用7501型涡流电导仪测量其电导率,然后,进一步制备成透射电镜薄膜试样,在Tecnai G20透射电镜上观察显微组织。

晶间腐蚀按GB7998─87标准进行。将试样清洗出光,浸入3%NaCl+10 mL/L HCl晶间腐蚀溶液中,在35 ℃放置24 h。实验结束后,将试样沿横向切开进行抛光,用XJG?05型金相显微镜观察腐蚀形貌并测量腐蚀深度。

2 结果与分析

2.1 双级时效对6061铝合金的拉伸性能的影响

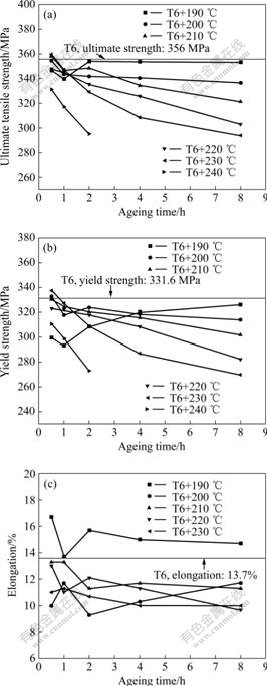

图1所示为6061铝合金在T6态及双级时效条件下的拉伸性能,其中直线表示T6态下合金的拉伸 性能。由图1可以看出,T6态合金的强度较高,抗拉强度和屈服强度分别为356 MPa和331.6 MPa,伸长率为13.7%。

从图1(a)和(b)可以看出,在T6态基础上进一步在190 ℃和200 ℃时效,经短时间时效(2 h),合金强度均经历一个下降阶段,之后随时效时间的延长,在T6+190 ℃条件下,合金强度逐渐升高,并在较长时间内保持稳定;而在T6+200 ℃条件下,合金的强度呈现先升高后下降的趋势。当二级时效温度从210 ℃升高到240 ℃时,合金的强度随温度的升高和时间的延长而逐渐降低,且下降程度随二级时效温度的升高而增大。在T6+(210 ℃, 2 h)的条件下,其抗拉强度和屈服强度分别为348.4 MPa和320.3 MPa,与T6态相比,分别下降7.8 MPa和11.3 MPa,下降程度分别为2.2%和3.1%。由此可见,通过这种二级时效处理,能很好地保持合金的强度。与表1中的数据相比,强度保持效果要优于6056-T78,而与1370-T2的最佳值相当。

从图1(c)可以看出,伸长率受二级时效温度的影响较大,而时效时间对其影响较小。在190 ℃二级时效时,合金具有较高的伸长率;而在200~240 ℃的范围内进行二级时效时,合金的伸长率较低,但总体上伸长率不低于8%。

表1 不同热处理制度下6056和1370铝合金的力学性能和腐蚀性能[12?13]

Table 1 Mechanical and corrosion properties of 6056 and 1370 alloys after different ageing treatments[12?13]

图1 双级时效处理的6061铝合金的拉伸性能

Fig.1 Tensile properties of 6061 aluminum alloys after two-step ageing treatment: (a) Ultimate strength; (b) Yield strength; (c) Elongation

2.2 双级时效对6061铝合金电导率的影响

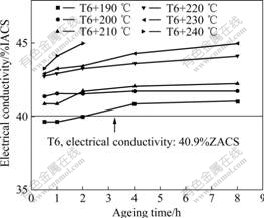

图2所示为6061铝合金在T6态及双级时效条件下的电导率,其中直线表示T6态下的电导率为40.9%IACS。由图2可以看出,合金的电导率基本上随二级时效温度的升高和时间的延长逐渐升高。与T6态相比,在190 ℃二级时效2 h,电导率略低于T6态的电导率;其他时效条件下的电导率均比T6态的电导率高,在T6+(210 ℃, 2 h)的条件下,电导率为41.7% IACS,比T6态高出0.8%IACS。通常认为,铝合金的耐蚀性优劣可用电导率来表征[15]。一般情况,电导率越大,其耐蚀性也越好,因而,对于大多数经过双级时效的合金来说,其耐蚀性应优于T6态的。

图2 双级时效处理的6061铝合金的电导率变化

Fig.2 Electrical conductivities of 6061 aluminum alloys after two-step ageing treatment

2.3 双级时效对6061铝合金晶间腐蚀性能的影响

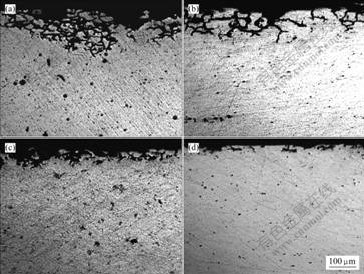

图3所示为6061铝合金T6态及部分双级时效状态的晶间腐蚀形貌。从图3(a)可以看出,T6态合金的 表层晶粒之间相互脱离,甚至出现部分晶粒从表面 脱落的现象,出现严重的晶间腐蚀倾向,腐蚀深度约为270 mm。

图3 不同热处理下6061铝合金的晶间腐蚀形貌

Fig.3 Intergranular corrosion micrographs of 6061 alloy after different heat treatments: (a) T6; (b) T6+(190 ℃, 2 h); (c) T6+(210 ℃, 2 h); (d) T6+(230 ℃, 2 h)

由图3可以看出,尽管腐蚀深度变浅,但仍有较强的晶间腐蚀敏感性。而经T6+(210 ℃, 2 h)时效后,晶间腐蚀敏感性大幅度降低,腐蚀形貌呈现轻微点蚀(图3(c)),腐蚀深度约为50 mm,大大低于表1所列的6056-T78和1370-T2的腐蚀深度(见图3(c))。图3(d)所示为T6 +(230 ℃, 2 h)时效的合金的腐蚀形貌,腐蚀深度进一步降低。由以上实验结果可知,随着二级时效温度的升高,6061合金的抗晶间腐蚀能力逐渐 增强。各种时效条件下的腐蚀类型和腐蚀深度如表2 所列。

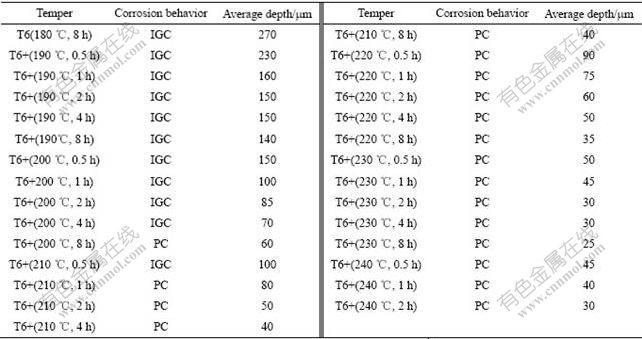

表2 6061合金在不同热处理条件下的晶间腐蚀行为

Table 2 Intergranular corrosion behaviors of 6061 alloy after different heat treatments

2.4 透射电镜观察

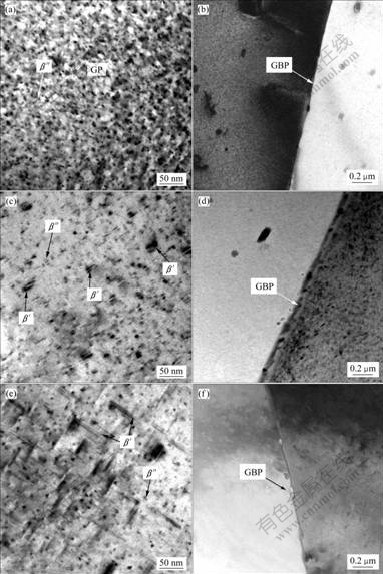

为了验证实验条件下6061铝合金的拉伸性能、晶间腐蚀和微观组织之间的内在联系,选取T6、T6+(210℃, 2 h)和T6+(230 ℃, 2 h)3种状态试样进行TEM观察,如图4所示。由图4可看出,经T6时效后,晶内析出相主要为球状的GP区和极少量的β?相(图4(a)),而晶界上则是呈连续分布的粗大条状β平衡相,(见图4(b))。

图4 不同热处理下6061铝合金的TEM像

Fig.4 TEM images of 6061 alloy after different heat treatments: (a), (b) T6; (c), (d) T6+(210 ℃, 2 h); (e), (f) T6+(230 ℃, 2 h)

在T6态基础上再升高时效温度进行二级时效,晶内和晶界析出相的形貌、数量及性质发生改变。经T6+(210 ℃, 2 h)时效的合金,晶内析出相主要是均匀分布的针状β?相和少量β?相,与T6态相比,晶内析出相的数量有所减少而尺寸增大(见图4(c));而晶界析出相形态也由T6态的条状连续分布转变为球状不连续分布,这表明晶界β相发生了一定程度的球化(见图4(d))。

图4(e)表明,进一步升高二级时效温度至230 ℃,晶内析出相数量继续减少而尺寸进一步变大,晶内析出相主要为β?相和较多的β?相;晶界β相球化过程进一步增强(见图4(f))。

3 讨论

时效硬化型铝合金的强度主要取决于晶内析出相的性质、形貌及数量,而晶间腐蚀性能主要取决于晶界析出特征。对于6061铝合金,广为接受的晶内析出序列为α过饱和固溶体→共格GP区(球状)→共格β?相(针状)→半共格β?相(棒状)→非共格β平衡相(条状);晶界析出序列是α过饱和固溶体→非共格β平衡相(条状)[16]。不同时效处理导致合金的晶内析出相性质、形貌及数量和晶界析出相的特征都有明显改变,从而拉伸性能和晶间腐蚀性能也有显著变化。

实验合金经T6峰值时效后,晶内析出相以球状GP区为主,还有极少量的β?相(图4(a))。由于共格的GP区数密度高,在基体中产生严重的共格畸变,从而使合金在T6状态下获得高强度。晶界由于具有高的界面能,成为短路扩散通道和择优形核位置,不仅在固溶处理时易形成元素偏析,而且在时效时晶界附近的溶质原子也易向晶界扩散。在晶界上优先析出连续分布的粗大条状的β平衡相(图3(b)),从而在晶界上形成连续的阳极活性通道,同时在晶界附近形成无析出带作为阴极,二者构成微电池。晶界上连续分布的b平衡相在晶间腐蚀溶液中优先溶解,导致严重的晶间腐蚀倾向(图3(a))[6, 17]。

在T6峰值时效基础上进一步升高二级时效温度,由于晶内和晶界析出相的性质、尺寸和形态将发生相应变化,进而引起性能上也发生改变。从图1(a)和(b)可以看出,在当二级时效温度为190 ℃和200 ℃时,经短时间时效(2 h以内)后,合金的强度下降,这主要是由于T6峰值时效形成的部分GP的区尺寸低于热稳定的临界值,发生回归重新形成溶质原子导致强化相数目减少的缘故[18]。在T6+190 ℃条件下,继续延长二级时效时间,早期回溶的溶质原子将以该时效温度下对应的析出序列β?相继续析出,以及那些超过临界尺寸的GP区也将继续转变成β?相,同时,β?相的强化效果要比GP区的更好,因而,合金的强度重新升高;而在T6+200 ℃时效的条件下延长时效时间,由于强化效果更好的β?相随二级温度的升高和时效时间的延长而长大粗化,导致合金的强度最后呈现下降趋势。随二级时效温度继续升高至210 ℃以上,在图1(a)和(b)中并没有发现强度先降低后升高的趋势,而是一直下降,这是因为二级时效温度升高,回溶时间缩短,而测量不在实验的时间点上,因而,未能在图1(a)和(b)中体现出强度先下降后上升再下降的特点。

随二级时效温度的升高,原子扩散速度加快,析出相越易长大,因而,析出相的尺寸较大而数密度较小。例如,在T6+(210 ℃, 2 h)条件下,晶内析出相主要由针状β?相和少量β?相组成,与T6态相比,析出相数量有所减少,如图3(c)所示。由于有少量的半共格b?相析出,合金的强度有所降低,但是,由于晶内此时以针状的b?相为主,另外,β?相比GP区的共格畸变程度更大、强化效果更高,使得T6+(210 ℃, 2 h)处理后的合金的强度与T6态相比并没有显著降低;晶界处的β平衡相,为了降低界面能而发生球化,呈现不连续分布,在一定程度上切断阳极连续腐蚀的通道,转变成不连续的腐蚀点,从而腐蚀形貌由T6状态的晶间腐蚀转变成局部点蚀,如图2(c)所示。

但是继续升高二级时效温度,原子扩散进一步加强,析出相的粗化速率也相应增加。例如,T6+(230 ℃, 2 h)时效,晶内析出相主要以粗大条状的β?相为主,还有少量的β?相,且析出相数量进一步减少,而晶界上的β平衡相的球化过程进一步加强(图3(e)和(f)), 从而导致强度大幅度降低和抗晶间腐蚀性能进一步 提高。

4 结论

1) 6061铝合金在T6峰值时效状态下,虽能获得较高的强度,但具有严重的晶间腐蚀倾向。

2) 在T6态基础上进行双级时效时,合金强度总体上随着二级时效温度的升高和时效时间的延长逐渐降低,但抗晶间腐蚀性能得到显著改善,并且腐蚀形貌由典型的晶间腐蚀转变为轻微点蚀。

3) 在T6+(210 ℃, 2 h)时效条件下,6061合金的强度和抗晶间腐蚀性能得到良好的配合,其抗拉强度和屈服强度分别为348.4 MPa和320.3 MPa,伸长率为11.3%;腐蚀类型为点蚀,腐蚀深度约为50 mm。

REFERENCES

[1] MILLER W S, ZHUANG L, BOTTEMA J, WITTEBROOD A J, DE SMET P, HASZLER A, VIEREGGE A. Recent development in aluminum alloys for the automotive industry[J]. Mater Sci Eng A, 2000, 280(3): 37?49.

[2] MASAMI S. A Japanese perspective on the use of aluminum alloys in the automotive sector[J]. Materials Science Forum, 2006, 519/521: 11?14.

[3] DIF R, BES B, WARNER T, LEQUEU P, RIBES H, LASSINCC P. Recent development in AA6056 aluminum alloy used for aerospace[J]. Advances in the Metallurgy of Aluminum Alloys, 2001: 390?397.

[4] GUILLAUMIN V, MANKOWSKI G. Influence of overageing treatment on localized corrosion of Al 6056[J]. Corrosion, 2000, 56(1): 12?23.

[5] SVENNINGSEN G, LARSEN M H, NORDLIEN J H, NISANCIOGLU K. Effect of high heat treatment on intergranular corrosion of AlMgSi(Cu) model alloy[J]. Corrosion Science, 2006, 48(1): 258?272.

[6] SVENNINGSEN G, LARSEN M H, WALMSLEY J C, NORDLIEN J H, NISANCIOGLU K. Effect of artificial aging on intergranular corrosion of AlMgSi model alloy with small Cu content[J]. Corrosion Science, 2006, 48(6): 1528?1543.

[7] SVENNINGSEN G, LEIN J E, BJORGUM A, NORDLIEN J H, YU Y, NISANCIOGLU K. Effect of low copper content and heat treatment on intergranular corrosion of AlMgSi(Cu) model alloy[J]. Corrosion Science, 2006, 48(1): 226?242.

[8] LARSEN M H, WALMSLEY J C, LUNDER O T, NISANCIOGLU K. Significance of low copper content on grain boundary nanostructure and intergranular corrosion of AlMgSi(Cu) model alloys[J]. Materials Science Forum, 2006, 519/521: 667?672.

[9] BHATTAMISHRA A K, LAL K. Influence of ageing on corrosion behavior of Al-Mg-Si alloys in chloride and acid media[J]. Z Metallkd, 1998, 89(11): 743?746.

[10] SVENNINGSEN G, LARSEN M H, LEIN J E, NORDLIEN J H, NISANCIOGLU K. Intergranular corrosion of extruded AA6000-series model alloys[C]// Proceedings of the 9th International Conference on Aluminum Alloys(ICAA9). Brisbane: Australia Institute of Materials Engineering, 2004: 818?823.

[11] DELMAS F, VIVAS M, LOURS P, CASANOVE M, COURET A, COUJOU A. Straining mechanisms in aluminum alloy 6056. In-situ investigation by transmission electron microscopy[J]. Mater Sci Eng A, 2003, 340(1/2): 286?291.

[12] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Material, 2003, 51: 5775?5799.

[13] KOLOBNEV N I, KHOKHLATOVA L B, SBITNEVA S V, TARARAEVA T I, POPOV V I. Heat treatment effect on properties of Al-Mg-Si-Cu 1370 alloy[J]. Materials Science Forum, 2006, 519/521: 519?524.

[14] DIF R, BECHET D, WARNER T, RIBES H. 6056 T78: A corrosion resistant copper-rich 6××× alloy for aerospace applications[C]// Proceedings of the 6th International Conference on Aluminum Alloys(ICAA6). Tokyo: Japan Institute of Light Metals, 1998: 1991?1996.

[15] LI H, ZHENG Z Q, WANG Z X. Effect of overageing and resolution and reageing treatment on microstructures and properties of 7055 Al alloy[J]. Transactions of Materials and Heat Treatment, 2004, 25(3): 57?61.

[16] BUHA J, LUMLEY R N, CROSKY A G. Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy[J]. Metallurgical and Materials Transactions, 2006, 10(37): 3119?3130.

[17] LIU Y, ZHOU X, THOMPSON E G, HASHIMOTO T, SCAMANS M G, AFSETH A. Precipitation in an AA6111 aluminium alloy and cosmetic corrosion[J]. Acta Materialia, 2007, 55: 353?360.

[18] WOO K D, LEE J S, KIM S W. Calorimetric investigation of precipitation kinetics in Al-Mg-Si-X(Cr, Be) alloys[J]. Metals and Materials, 1999, 5(4): 363?368.

基金项目:国家重点基础研究发展计划资助项目(2005CB623705)

收稿日期:2009-03-09;修订日期:2009-08-25

通信作者:王芝秀,讲师,硕士;电话:0519-86330099;E-mail: xiu_wzx@sohu.com

(编辑 杨 华)