文章编号: 1004-0609(2005)06-0860-05

切削-挤压复合成形技术

袁启龙, 李 言, 肖继明, 朱江新, 李鹏阳

(西安理工大学 机械与精密仪器工程学院, 西安 710048)

摘 要: 提出了一种新的翅片管无屑切削-挤压复合成形方法。 对成形原理及切削、 挤压翻转、 弯曲成形3个阶段的特点进行了研究, 建立了翅片几何尺寸的理论计算公式, 分析了适合这种加工的刀具结构特点, 给出了刀具的设计原则, 通过实验获得了主偏角、 切削深度、 进给量等工艺参数对翅片几何尺寸的影响规律。 理论和实验研究表明: 在紫铜材料的成形中, 切削深度小于2mm、 进给量0.5~3mm、 刀具主偏角20°~50°范围内, 可以稳定地形成翅高1.5~3.0mm、 翅厚0.3~1.8mm的翅片。 因此, 合理地选择刀具结构及切削用量参数是获得理想翅片形状和尺寸的关键因素。

关键词: 切削-挤压复合成形; 翅片; 工艺参数; 刀具结构

中图分类号: TG506.9 文献标识码: A

Cutting-press compound shaping technique

YUAN Qi-long, LI Yan, XIAO Ji-ming, ZHU Jiang-xin, LI Peng-yang

(Department of Mechanical Engineering and Precision Instrument,

Xian University of Technology, Xian 710048, China)

Abstract: A new non-chip cutting-press compound shaping technique of fin tube was presented. The mechanism of cutting-press shaping was studied, and the shaping process properties about the cutting, the overturning with proper press and the bend shaping were analyzed. The theoretical calculating formulas of fin geometry dimension were set up. The structure characteristics of the cutting-press tool were analyzed, and the tool design rules were presented. Laws of the fin geometry dimension influenced by process parameters such as tool side cutting edge angle, depth of cutting, feed, etc. were obtained through experiments. Theoretical analysis and experimental results show that in shaping of copper fin, when the depth of cut is less than 2mm, the feed is ranged from 0.5 to 3mm, and side cutting edge angle is ranged from 20° to 50°, fin with height from 1.5 to 3mm and thickness from 0.3 to 1.8mm can be steadily formed. Therefore, appropriate tool structure and cutting parameters are key facts in the fin shaping with ideal shape and size.

Key words: cutting-press compound shaping technique; fin; process parameters; tool structure

翅片管作为强化传热的核心元件已广泛应用于各工业领域, 其质量的优劣直接影响强化传热的性能[1-4]。 翅片管一般有内翅片管和外翅片管两种, 外翅片管一般是用机械的方法在光管外表面形成一定片距、 一定高度、 一定厚度的翅片, 与光管相比, 在金属消耗量相同的情况下具有更大的传热面积并可以改善流体的流动状态, 因而传热效率更高[5]。 翅片管按照制造方法的不同可分为整体翅片管、 焊接翅片管和机械连接翅片管, 其中整体式翅片管是由基管材料直接加工形成的, 翅片和基管之间无接触热阻[6, 7], 因此受到了国内外学者的广泛重视, 已开发出了各种结构形式的高效传热翅片管[8-12]。

目前整体式外翅片管大多是采用专用滚压设备轧制而成, 其基管材料以铜或铝为主[13, 14]。 汤和夏等[15, 16]采用挤压-犁削、 劈切-挤压的机械加工方法加工高效整体翅片管, 已获了实际应用, 取得了很好的效果。 本文作者提出了一种新的外翅片管的切削-挤压成形方法, 该方法利用普通机床, 专用刀具, 把切削加工与塑性挤压成形有机地结合起来, 使传统机械加工中的切屑直接变成翅片, 是一种具有广泛应用前景的绿色工艺技术。

1 切削-挤压加工原理

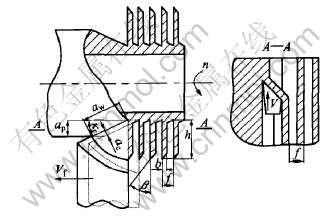

传统的切削过程追求的是金属切除率以及加工后零件表面的质量, 不重视切屑的形状和尺寸; 而切削-挤压复合成形方法考虑的重点是如何使无用的切屑不脱离基体, 形成有用的结构形式。 图1所示为在普通机床上采用切削-挤压复合成形方法加工翅片管的两个剖面的原理图。 专用刀具固定在刀架上, 实现横向和纵向移动, 主轴带动工件旋转, 在工件和刀具之间的相对运动中, 让刀具主切削刃切开表层金属, 通过对刀具参数和运动参数的合理控制, 使切开的金属层在流动的过程中逐渐翻转直立起来, 形成螺旋形式的外翅片管。

图1 切削-挤压成形原理

Fig.1 Principle of cutting-press shaping

实际上, 翅片的成形是在刀具的主切削刃和副切削刃围成的前刀面上的扇形区域内完成的, 按照加工成形的特点可将成形过程分为以下3个阶段。

1) 切削阶段。 同普通切削一样, 刀具主切削刃首先按切削深度ap切入工件表面层, 刀具相对工件沿轴向每移动一个进给量f之后, 形成具有一定厚度ac和宽度aw的切削层, 该层金属发生剪切滑移塑性变形, 形成和基体在根部相连的“切屑”, 顺着前刀面流出。

2) 挤压翻转阶段。 随着切削运动的进行, 被切开的金属层沿刀具前刀面的扇形区流动时, 由于不同位置的流动速度不同, 外部金属流动最快, 因此, 在前刀面进一步的挤压和摩擦的作用下, 使之逐渐地翻转直立起来。

3) 弯曲成形阶段。 在刀具前刀面上翻转直立起来的那层金属, 最终受到副切削刃的挤压, 发生塑性折弯而形成翅片, 从而使光管表面逐渐地形成螺旋式的外翅片。

2 翅片几何尺寸的理论计算

翅片的形成过程实质上是主切削刃切开的那层金属, 在刀具的挤压作用下发生塑性弯曲而形成的, 因此切削层的形状和尺寸将决定最终形成翅片的几何结构和尺寸。 从图1可以看出, 在主切削速度(v), 进给速度(vf)的情况下加工翅片时, 切削厚度(ac)主要影响翅片厚度(b), 而切削宽度(aw)主要影响翅片高度(h)。 由于加工过程中变形的存在, 翅片厚度(b)必然要大于切削厚度(ac), 引入翅片厚度变形系数(ξ)进行修正, 即:

则翅片厚度(b)可表示为

式中 κr为主偏角。

假设翅片外圈尖角部分的金属是由切削层外圈的金属形成的, 可以推出翅端尖角(β)为

根据金属塑性变形的体积不变原理, 推出翅片高度h为

从上述理论公式可以看出, 影响翅片几何尺寸的主要因素是刀具结构、 切削用量以及材料特性等因素。 翅片高度和厚度之间合理的比值是影响传热效率和流动阻力的决定因素[17, 18], 因此在实际加工时, 通过主偏角(κr)、 切削深度(ap)和进给量(f)的合理匹配, 就可形成理想的翅片结构形式。 变形系数(ξ)主要受刀具几何参数和加工材料的影响, 可以通过实验很容易获得, 如采用κr=30°的刀具加工紫铜时, 变形系数(ξ)约为1.2。

3 切削-挤压成形实验

3.1 实验条件

切削-挤压复合成形方法加工翅片管的实验是在CA6140机床上进行, 加工刀具采用W18Cr4V高速钢材料, 试件为外径d22mm、 壁厚2mm的紫铜管。

3.2 刀具几何参数的影响

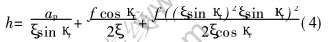

切削-挤压复合成形的刀具是用普通车削刀具刃磨而成, 其合理几何参数的选取对能否形成翅片以及对形成翅片的结构尺寸起着关键的作用。 图2所示为在相同切削用量的条件下, 采用主偏角κr分别为10°, 30°和60°的刀具加工时获得的翅片剖面照片。 可以看出, 主偏角(κr)的改变, 对翅片结构有较大的影响。 κr较小时, 形成的翅片薄而高, 但这种情况下, 翅片尖部易弯曲而形成翻边(图2(a)), 同时也容易造成翅片的脱落; 过大的κr容易使切削层金属挤出刀具而堆积在工件表面上, 形成尖角形的低翅片(图2(c))。 选择合理的主偏角(κr)可以获得理想的翅片结构, 其中图2(b)所示为传热性能较优的一种翅片结构。

在切削-挤压成形过程中, 刀具的主切削刃参与切削, 而前刀面和副切削刃承担着挤压和弯曲的 任务, 因此刀具是影响翅片形成的关键环节。 理论和实验研究表明, 有利于翅片形成的刀具设计原则应为: 1) 切削过程应使金属层的变形尽可能小, 其流动趋向工件基体, 刀具主切削刃要锋利; 2) 切开的金属层在前刀面上流动时, 受到的阻力要小, 因此前刀面应平整光滑; 3) 切开的金属层在弯曲成形时不能脱落, 副切削刃最好磨成带圆弧的钝刃。

图2 不同主偏角κr下的翅片剖面照片

Fig.2 Fin section photos with different κr

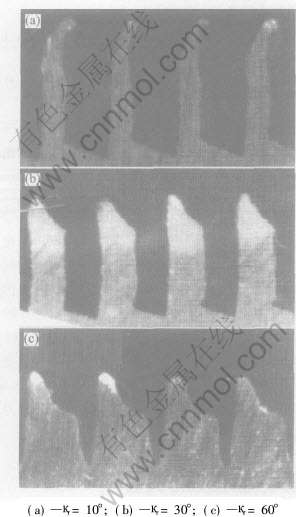

根据上述的刀具设计原则, 通过对刀具的前角、 后角、 刃倾角、 主偏角、 副偏角等角度的合理选择与刃磨, 并正确地安装, 就可以实现翅片管的加工。 一般而言, 较大的前角和后角, 会使切削刃锋利, 加工过程的摩擦阻力减小, 有利于翅片的形成, 但过大的前角和后角会导致刀具切削部分的强度降低, 影响刀具寿命; 刃倾角主要控制切削层金属的流向, 为使切削层金属流动时趋向工件, 应选择负刃倾角; 副偏角的大小主要控制翅片的直立程度, 为形成直翅结构, 副偏角一般取90°。 在这些角度中, 主偏角对翅片的形状和几何尺寸影响最大。 图3所示为在切削用量参数ap为1.2mm, f为0.81mm/r, v为50m/min加工时, 翅片高度和厚度随主偏角的变化。 从图中可以看出, 随着κr的增加, 翅高(h)降低, 而翅厚(b)变大, 趋势逐渐平缓; 这是由于κr增加, 切削厚度(ac)增加, 而切削宽度(aw)减小, 使刀具的挤压作用增强, 变形程度相应增加而引起的, 这和理论分析是一致的。

图3 主偏角κr对翅片尺寸的影响

Fig.3 Effects of κr on fin dimension

3.3 切削用量的影响

理论和实验研究表明, 除刀具参数外, 切削用量参数也是影响翅片结构和尺寸的重要因素, 因此合理地选择切削用量参数对切削-挤压成形工艺的实现有重要的意义。

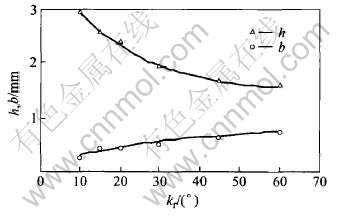

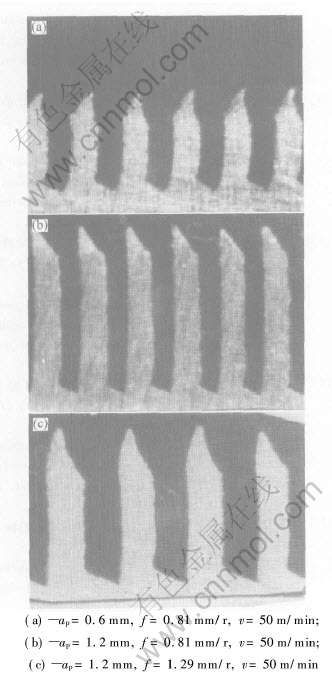

一般切削速度v主要受被加工材料的性能和刀具耐用度的制约, 在铝及铝合金的成形中, 低速会使翅片脱落; 加工紫铜时, 由于材料的塑性好, 切削速度(v)对能否形成翅片并不敏感, 但在低速时, 翅片表面较粗糙, 翅尖有毛刺和裂纹, 刀尖易粘切屑, 容易出现断翅现象, 因此在刀具耐用度许可的情况下, 为提高成形效率, 可适当提高切削速度。 而切削深度(ap)和进给量(f)是影响翅片形状和几何尺寸的主要参数。 图4所示为在主偏角(κr)为20°, 不同的切削深度和进给量情况下, 采用切削-挤压成形时获得的翅片剖面照片。 可以看出, 在不同的切削深度(ap)和进给量(f)条件下, 翅片形状和几何尺寸有较大的差异, 为了获取ap和f对翅片的影响规律, 实验中进行了ap和f的单因素实验。

图4 不同ap和f时的翅片剖面照片

Fig.4 Fin section photos with different ap and f

3.3.1 切削深度

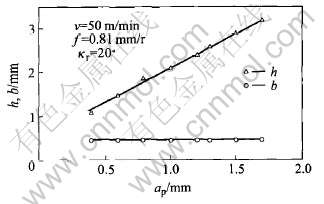

图5所示为在κr为20°, f为0.81mm/r, v为50m/min的条件下, 翅片几何尺寸随切削深度的变化。 可以看出, 随着ap的增加, 翅高h呈线性增加趋势, 而翅厚b几乎不变。 这是因为ap的变化只影响切削宽度的改变, 而对切削厚度和加工中的金属厚度的变形程度影响很小。 但实际加工中, ap过大时, 刀具作用在翅片上的力显著增加, 容易造成翅片脱落, 同时会使翅片外缘产生周向裂纹和较大的毛刺; 考虑到刀具强度及工件刚度等条件的限制, 切削深度ap一般不超过2mm。

图5 切削深度ap对翅片尺寸的影响

Fig.5 Effects of ap on fin dimension

3.3.2 进给量

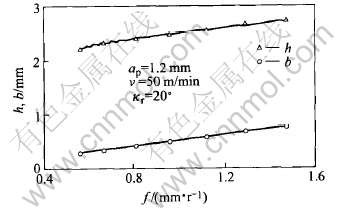

图6所示为在κr为20°, ap为1.2mm, v为50m/min的条件下, 翅片几何尺寸随进给量的变化。 进给量(f)主要影响翅厚(b)与翅片的疏密程度, f对翅高(h)的影响要比ap的影响小。 这是因为从理论上而言, 进给量(f)只影响切削厚度, 对切削宽度没有影响, 但由于切削-挤压成形的翅片顶端为尖角结构, 当f增加时, 金属层受刀具的挤压作用加剧, 翅端尖角高度相应增加, 使得翅高(h)略有增加。 根据材料特性及翅片管的技术要求, 进给量(f)一般在0.5~3mm/r范围内选取。

图6 进给量f对翅片尺寸的影响

Fig.6 Effects of f on fin dimension

REFERENCES

[1]Bergles A E. Enhanced heat transfer: endless frontier, or mature and routine[J]. Journal of Enhanced Heat Transfer, 1999, 6(2): 79-88.

[2]Seiichi I, Kotaro N, Shunroku S. Heat transfer and pressure drop during evaporation and condensation of HCFC22 in horizontal copper tubes with many inner fins[J]. Journal of Enhanced Heat Transfer, 2002, 9(1): 17-23.

[3]Prochorov A M, Apollonov V V, Zubkov N. Prospects of the development of cooled mirrors for high power technological lasers[A]. Experimental Heat Transfer, Fluid Mechanics and Thermodynamics, Proc of the First World Conference[C]. Yugoslavia, Dubrovnik, 1988. 882-892.

[4]Choi S H, Cho W H, Kim J W, et al. A study on the development of the wire woven heat exchanger using small diameter tubes[J]. Experimental Thermal and Fluid Science, 2004, 28(2): 153-158.

[5]王必武, 杨子谦, 施广森. 高效节能翅片管的加工、 应用及发展趋势[J]. 水利电力机械, 2002, 24(1): 16-18.

WANG Bi-wu, YANG Zi-qian, SHI Guang-sen. Machining and application and development tendency of high efficiency wing pipe in energy saving[J]. Water Conservancy & Electric Power Machinery, 2002, 24(1): 16-18.

[6]Joshi H M, Thomas R M, Wanni A S, et al. A petrochemical industry perspective on professor webbs contribution to heat transfer enhancement[J]. Journal of Enhanced Heat Transfer, 1999, 6(5): 251-262.

[7]朱聘冠. 换热器原理及计算[M]. 北京: 清华大学出版社, 1987. 169-172.

ZHU Pin-guan. Principles and Calculation of Heat Transfer Enhancement[M]. Beijing: Tsinghua University Press, 1987. 169-172.

[8]赵晓曦, 邓先和, 陆恩锡. 菱形翅片管的强化传热特性[J]. 化工进展, 2002, 10(5): 1-3.

ZHAO Xiao-xi, DENG Xian-he, LU En-xi. Heat transfer enhancement performance lozenge fin tube[J]. Science & Technology in Chemical Industry, 2002, 10(5): 1-3.

[9]庄礼贤, 陆应生, 李伟立, 等. 机械加工表面多孔管(E管)蒸发器与低肋管蒸发器的整机实验研究[J]. 制冷学报, 1987, 32(2): 1-9.

ZHUANG Li-xian, LU Ying-sheng, LI Wei-li, et al. Experimental test of mechanically fabricated porous surface tube evaporator and low finned tube evaporator[J]. Journal of Refrigeration, 1987, 32(2): 1-9.

[10]Rabas T J, Taborek J. Performance, fouling and cost considerations of enhanced tubes in power plant condensers[J]. Journal of Enhanced Heat Transfer, 1999, 6(6): 289-315.

[11]Lendezma G, Morega A M, Bejan A. Optimal spacing between pin fins with impinging flow[J]. Journal of Heat Transfer, 1996, 118(3): 570-577.

[12]Lin C N, Jang J Y. A two-dimensional fin efficiency analysis of combined heat and mass transfer in elliptic fins[J]. International Journal of Heat and Mass Transfer, 2002, 45(20): 3839-3847.

[13]严珩志. 翅片管轧制工艺润滑剂性能特征与配方模式[J]. 中国有色金属学报, 1999, 9(1): 197-200.

YANG Hang-zhi. Feature properties and prescription model of technology lubricant for fin-tube rolling[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 197-200.

[14]赵起, 崔保元, 尹清华, 等. 换热器传热强化单管筛选试验研究[J]. 核动力工程, 1996, 17(1): 23-29.

ZHAO Qi, CUI Bao-yuan, YIN Qing-hua, et al. Single tube sieve test for heat transfer enhancement in heat exchanger[J]. Nuclear Power Engineering, 1996, 17(1): 23-29.

[15]汤勇, 张发英, 陈澄洲, 等. 挤压-犁削外翅片铜管加工机理的研究[J]. 工具技术, 1997, 31(1): 7-10.

TANG Yong, ZHANG Fa-ying, CHEN Deng-zhou, et al. Study on the mechanism of extrusion-ploughing during manufacturing copper outside fin tube[J]. Tool Engineering, 1997, 31(1): 7-10.

[16]夏伟, 吴斌, 汤勇, 等. 整体翅片管的劈切-挤压加工[J]. 中国有色金属学报, 2001, 11(1): 27-30.

XIA Wei, WU Bin, TANG Yong, et al. Chopping-extrusion technique for making integral-fin tubes[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 27-30.

[17]林宗虎. 强化传热及其工程应用[M]. 北京: 机械工业出版社, 1987. 189-193.

LIN Zong-hu. Enhanced Heat Transfer and Application in Engineering[M]. Beijing: China Machine Press, 1987. 189-193.

[18]Roques J F, Thome J R. Falling film transitions between droplet, column, and sheet flow modes on a vertical array of horizontal 19 FPI and 40 FPI low-finned tubes[J]. Heat Transfer Engineering, 2003, 24(6): 40-45.

(编辑陈爱华)

基金项目: 国家自然科学基金资助项目(50475039)

收稿日期: 2004-11-11; 修订日期: 2005-03-04

作者简介: 袁启龙(1970-), 男, 讲师, 博士研究生.

通讯作者: 李 言, 教授; 电话: 029-82312820; E-mail: jyxy-ly@xaut.edu.cn