DOI:10.19476/j.ysxb.1004.0609.2017.11.08

过共晶Al-Si合金P吸收率的影响因素

胡恺琪1,蒋 伟1,朱向镇1,张 茜1,孙谦谦2,刘相法1

(1. 山东大学 材料液固结构演变与加工教育部重点实验室,济南 250061;

2. 山东大学 山东吕美熔体技术有限公司,济南 250061)

摘 要:采用含P中间合金细化过共晶铝硅合金时,P吸收率是影响合金最终P残留量和Si细化效果的关键因素。研究P吸收率与中间合金种类、熔炼工艺参数以及耦合添加外来微米粒子的相关性,并分析其与AlP相在熔体中演变行为的内在联系。结果表明:熔炼工艺相同时,5种中间合金的吸收率有一定差异,杆状Al-3P的P吸收率最高,可达80%;而Cu-14P的最低,仅为13%。随着熔体温度升高,P吸收率显著提高;随着保温时间延长,P吸收率呈现先增加后减小的趋势;保温90 min时,P吸收率达到极大值;随着加入量增加,P吸收率呈现不断下降趋势。此外,在铝合金熔体中引入与AlP有结构匹配关系的TiB2、TiC等微米粒子,可与未溶解之AlP耦合在一起,起到固定AlP粒子的作用,显著提高P吸收率。

关键词:Al-Si合金;初晶Si;P吸收率;工艺参数;晶粒细化

文章编号:1004-0609(2017)-11-2242-09 中图分类号:TG244.1 文献标志码:A

过共晶Al-Si系多元合金因具有铸造性能好、密度低、热膨胀系数小、体积稳定性和耐磨性好等优点[1-4],近年来已大规模用于汽缸、活塞等发动机配件的制造。但普通凝固条件下,初晶Si相往往长成粗大的板条、五瓣星[5-6]等形貌,具有锐利的棱角,容易割裂基体,导致合金力学性能下降[7],从而限制了其应用范围。因此,必须对初晶Si相进行细化处理。目前,含P中间合金以其便捷、高效和环保的优势被广泛使用[8-9]。工厂实践[10]发现,Al-Si合金熔体处理前后的P吸收率与细化效果之间存在正相关性,即在P加入量相同的条件下,合金中最终的P残留量越多,表明熔体对其吸收越充分,可发挥形核衬底作用的AlP数目越多,细化效果越好。然而实际生产中,由于受到复杂熔体环境及具体操作的影响,如保温过程中温度的大幅度波动,使得各炉次之间P吸收率起伏较大,不利于工艺参数和细化效果的稳定化调控。因此,研究过共晶Al-Si系合金中P吸收率的影响因素及其规律对指导工业生产具有重要意义。

合金中最终的P残留量主要包括熔体中溶解的P以及发挥形核作用的AlP相中的P元素。若中间合金本身溶解较慢,或处理工艺不当影响其溶解过程而使熔体中存在较大尺寸的AlP颗粒时,AlP颗粒倾向于吸附在氧化铝薄膜[11]或固态夹渣上,精炼过程中容易被带出熔体,使得P吸收率降低。目前,过共晶Al-Si合金细化处理工艺方面的研究[12-14]主要集中于对初晶Si的影响,还未建立诸因素与P吸收率之间的相关性,因此炉前处理工艺缺乏理论和技术的支持,还不很完善。常用的含P中间合金包括Al-P系和Cu-P系合金,彼此之间P吸收率差异的研究也鲜有报道。此外,根据YU等[15]的研究,TiB2、TiC等与AlP晶体的晶格错配度较小,当与Al-P中间合金共同加入熔体时,会在凝固过程中与AlP相耦合析出,促进其发挥细化作用。本文作者研究含P中间合金种类和工艺参数对P吸收率的影响规律,在此基础上提出通过外加微米粒子改善P吸收率的新工艺。

1 实验

1.1 实验原料

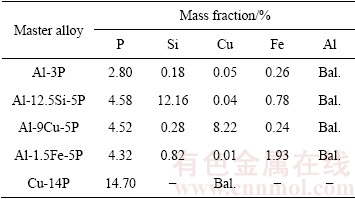

用纯度为99.85%(质量分数)的工业纯铝、99.99%的结晶硅配制Al-18Si(质量分数,%)合金,试验所需杆状Al-3P,锭状Al-12.5Si-5P、Al-9Cu-5P、Al-1.5Fe-5P(质量分数,%),块状Cu-14P中间合金均由山东吕美熔体技术有限公司提供,其化学成分如表1所示。

表1 不同中间合金的化学成分

Table 1 Chemical compositions of different master alloys

1.2 实验过程及方法

1) 研究中间合金种类对P吸收率的影响:在中频炉中熔化Al-18Si合金,780 ℃时以不同种类含P中间合金的形式加入1.5×10-4 P(质量分数),搅拌均匀,并调整功率使其在780 ℃(温度波动为±5 ℃)下保温20 min,之后分别浇注到KBI环模中。

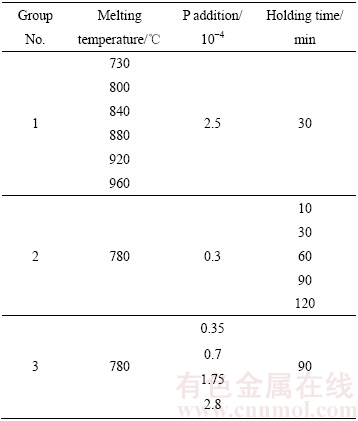

2) 选取P吸收率最高的一种中间合金,研究细化工艺参数对P吸收率的影响:在中频炉中熔化Al-18Si合金,待其过热至800 ℃后转移至电阻炉中进行细化处理,分别改变熔体温度、P加入量和保温时间等工艺参数(具体工艺参数见表2),最后分别浇注到KBI环模中。

3) 研究添加微米粒子对P吸收率的影响:在中频炉中熔化Al-18Si合金,待其过热至800 ℃后转移至电阻炉中在780 ℃进行保温,当温度稳定后,加入0.5%的杆状Al-3P中间合金进行细化处理,保温25 min后分别加入0.4% Al-5Ti-1B、0.5%Al-5Ti-0.8B- 0.2C和0.2%Al-5Ti-0.3C-0.2B中间合金,继续保温至30 min和60 min,最后分别浇注到KBI环模中。

对以上所有浇注在KBI环模中的试样进行车削处理,使其表面平整、光洁,利用SPECTROMAXx光电直读光谱仪测定细化前后试样中的P元素含量,根据式(1)计算P吸收率:

(1)

(1)

式中:AP表示熔体处理前后P元素的吸收率;wPF表示最终合金锭中P元素的质量分数;wPI表示初始熔体中P元素的质量分数;wPA表示添加的P元素的质量分数。

表2 细化处理工艺参数

Table 2 Refinement process parameters

2 结果与分析

2.1 中间合金种类的影响

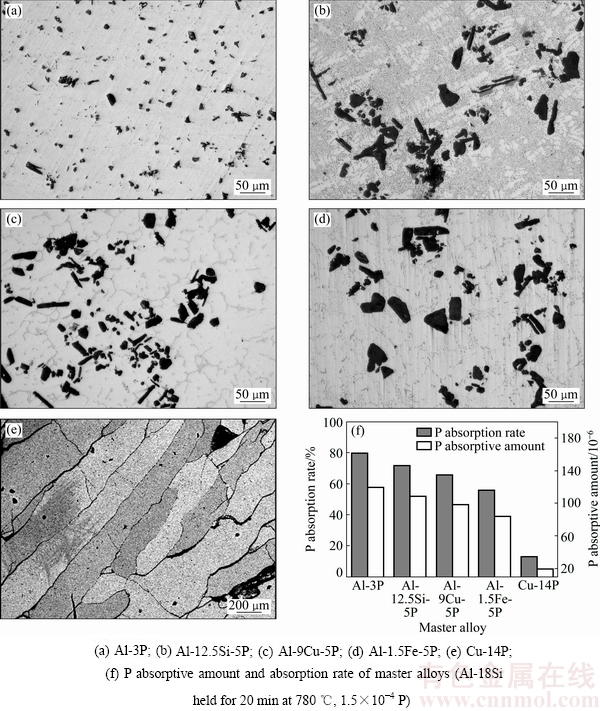

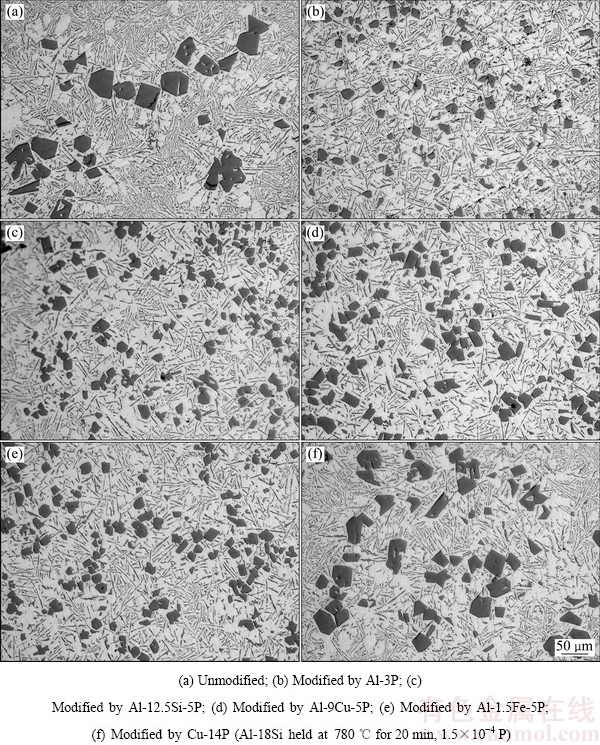

图1(a)~(e)所示依次为Al-3P、Al-12.5Si-5P、Al-9Cu-5P、Al-1.5Fe-5P及Cu-14P中间合金的金相组织。从图1(a)~(d)可以看出,Al-P系中间合金的组织特征为铝基体上分布着不同形貌和尺寸的AlP相,其中,Al-3P中AlP相呈现颗粒状,平均尺寸最小,约10 μm,而且分布较为弥散;Al-12.5Si-5P、Al-9Cu-5P和Al-1.5Fe-5P合金组织中包括α(Al)基体、共晶组织和AlP相,其中AlP相皆呈现为短棒状和块状,平均尺寸为40~50 μm,有轻微的聚集现象,分别如图1(b)~(d)所示;而Cu-14P合金组织则由单一的Cu3P相组成,如图1(e)所示。图1(f)所示为采用不同中间合金细化Al-18Si合金时P的吸收量和吸收率,P的加入量均为1.5×10-4。对比各组数值可以看出,P的添加量一定时,Al-3P中间合金的P元素被熔体吸收的含量最大,故吸收率也最高,达80%,Al-12.5Si-5P的次之,为72%,其次是Al-9Cu-5P和Al-1.5Fe-5P,而Cu-14P的P吸收率最低,仅13%。

Al-P系中间合金加入Al-Si熔体中后,其中的AlP相直接发生破碎、溶解,其反应式如下:

AlP(s)→Al(l)+[P] (2)

在熔体中,以AlP颗粒(特别是颗粒团)形式存在时,随时可能被型壁或夹杂物等外来界面吸附而脱离Al-Si熔体;溶解态的P则可认为是被熔体完全“吸收”,并在随后的凝固过程中以AlP晶体的形式析出并发挥其对初晶Si的形核与细化作用[16]。

中间合金组织中AlP相的形貌、尺寸和分布对其在铝熔体中的溶解行为起着至关重要的作用,故对吸收率影响较大。结合图1(a)~(e)中的金相组织分析可知,Al-3P合金中AlP相细小而弥散,在熔体中容易分散得较均匀,溶解速度快,偏聚成大颗粒被氧化夹杂带出去的可能性小,故吸收率数值最高。Al-12.5Si-5P、Al-9Cu-5P和Al-1.5Fe-5P合金中AlP相尺寸均较粗大,且有轻微聚集,在熔体中溶解反应不完全,因而吸收率低于Al-3P合金的。其中,由于Al-12.5Si-5P中间合金与Al-Si熔体局部的润湿状况优于Al-9Cu-5P和Al-1.5Fe-5P合金的,故吸收率稍高于后两者的。而Cu-14P组织中是Cu3P单相,其加入熔体及在随后的凝固过程中,先发生如下反应:

Cu3P(s)+Al(l)→3[Cu]+AlP(s) (3)

生成的AlP相在凝固时作为初晶Si的异质形核衬底发挥细化作用。而该反应的发生需要满足一定的热力学和动力学条件,即需要较高的温度和较长的保温时间方能进行到底[17-19]。此外,由于Cu-14P合金本身密度大,加入后容易偏析在熔体底部,再加上P的部分烧损,使其吸收率较低。

图1 含P中间合金的金相组织及相应的P吸收量和吸收率

Fig. 1 Microstructures of master alloys ((a)~(e)) and P absorptive amount and absorption rate of master alloys (f)

图2 含P中间合金细化后Al-18Si合金的金相组织

Fig. 2 Microstructures of Al-18Si alloys after modified by master alloys containing P

图2(a)~(f)所示依次为未细化和分别以Al-3P、Al-12.5Si-5P、Al-9Cu-5P、Al-1.5Fe-5P及Cu-14P中间合金的形式加入1.5×10-4 P细化处理后的Al-18Si合金的金相组织。对比图2(a)中未细化组织可以明显看出,采用含P中间合金细化后,各组的初晶Si平均尺寸均有所下降,通过Image Pro Plus软件统计发现,其数值从83.9 μm分别降低至33.8、37.3、39.5、43.0和49.1 μm。显然 Al-3P的细化效果最好,基体上初晶Si相细小而弥散分布,如图1(b)所示,Al-12.5Si-5P、Al-9Cu-5P和Al-1.5Fe-5P中间合金的细化效果次之,初晶Si相尺寸显著减小,但出现轻微偏聚现象,如图1(c)~(e)所示;而Cu-14P的细化效果较差,不仅Si相平均尺寸较大,形貌仍不规则,而且偏聚明显,如图1(f)所示,杨子润等[20]也发现同样的现象,这与Cu-14P合金加入Al-18Si合金熔体后原位反应生成的AlP相无法快速弥散均匀有紧密的联系。这一规律与上述不同种类中间合金P吸收率数值的变化趋势一致,充分证明了细化效果与P吸收率之间存在正相关关系。

2.2 工艺参数的影响

本文作者选取上述5种中间合金中P吸收率最高的杆状Al-3P中间合金进行试验,每次只改变单个工艺因素,保持其余处理条件均相同,观察P吸收率的变化规律。

1) 熔体温度

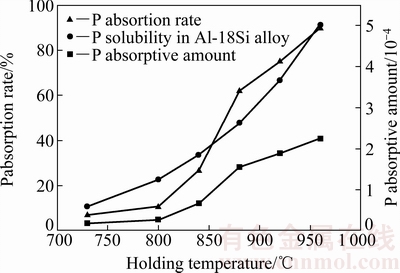

图3中3条折线分别显示了加入2.5×10-4 P,保温30 min时,P吸收量、吸收率及P在Al-18Si熔体中的平衡溶解度随熔体温度的变化曲线。从图3中可以看出,随着温度的升高,P吸收量和吸收率呈明显上升趋势。

图3 P吸收量、吸收率及P在Al-18Si熔体中的平衡溶解度随熔体温度的变化曲线

Fig. 3 Change curves of P absorptive amount, P absorption rate and P equilibrium solubility in Al-18Si melt under different holding temperatures

根据LESCUYER等[21]利用控温过滤仪器研究的Al-Si熔体中P的溶解度随温度变化的曲线,可以看出,P在Al-Si熔体中的溶解度十分有限,为10-5数量级。其溶解度的数学表达式如下:

(4)

(4)

式中:xp为溶解P的摩尔分数;T为Al-Si熔体的温度(K)。由上式计算可得对应试验温度下P的平衡溶解度,如图3中红色线条所示。可以看出,P的平衡溶解度随着温度升高而逐渐升高,与P吸收率随熔体温度的变化表现出一致的规律。

当Al-P系中间合金加入Al-Si熔体后,组织中的AlP相在化学势的驱动下,会持续进行破碎、溶解反应,形成Al-P团簇[11],当P在Al-Si熔体中的溶解度到达该熔体温度下的极限值时,又会以AlP的形式原位析出,从而保持溶解析出动力学平衡。当温度上升时,P溶解度迅速增大;同时温度升高,使得AlP粒子的溶解反应加快,更多的P原子被熔体“吸收”。因此,升高温度能够大幅度提高P吸收率。如图3中紫色线条所示,730 ℃时的P吸收率仅为7%,960 ℃时P吸收率可高达90%。

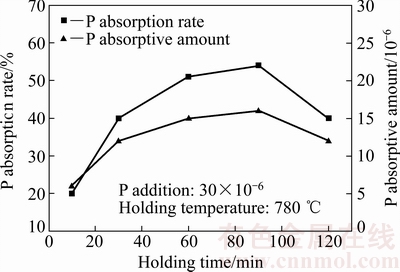

2) 保温时间

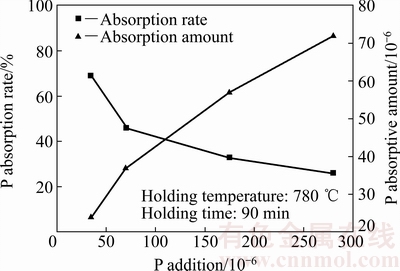

图4所示为熔体温度为780 ℃、P的加入量为0.3×10-4时,P吸收率随保温时间的变化曲线。由图4可以看出,随着保温时间的延长,P吸收率呈现先增加后减小的趋势,保温90 min时达到极大值。这是由于AlP相的溶解反应在一定保温时间内不断进行,使得P溶解量逐渐增加,而超过临界保温时间90 min后,P 的烧损增加,使得熔体中的P元素减少,吸收率下降,ZHU[9]和龚啟良[12]在保温过程中实时测定的P含量的变化规律也充分论证了这一观点。

图4 P吸收量和吸收率随保温时间的变化曲线

Fig. 4 Change curves of P absorptive amount and absorption rate under different holding time

3) 加入量

图5所示为在780 ℃下保温90 min时P吸收量和吸收率随P加入量的变化曲线。由图5可以看出,随着加入量的增加,熔体对P的吸收量逐渐增加,P吸收率则呈不断下降趋势。这是由于熔体温度和保温时间一定时,熔体中可溶解的P量是一定的,加入量越大,未溶解的固态AlP颗粒越多。凝固过程中重新析出的AlP倾向于以此类颗粒为衬底,形成较大尺寸的AlP相,而AlP粒子本身具有强的吸附性[11],容易吸附在氧化膜上,精炼时被带出熔体,使得熔体损失的P含量增加,故当P加入量超出其在Al-Si熔体中的溶解度极限时,加入量越大,P吸收率越低。

图5 P吸收量和吸收率随P添加量的变化曲线

Fig. 5 Change curves of P absorptive amount and absorption rate at different P additions

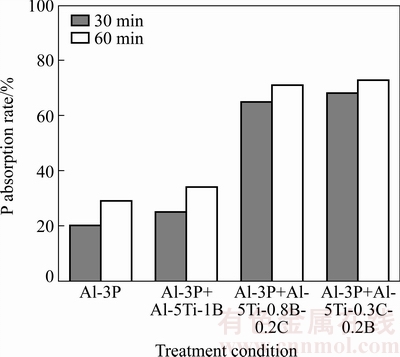

2.3 外来微米粒子的影响

实际生产中由于成本和效率的制约,只能通过工艺条件的优化来最大限度地提高P在合金熔体中的残留量。课题组前期的研究[15, 22]发现,TiB2、TiC等与AlP相的晶体结构有良好的匹配性,当与Al-P中间合金共同加入熔体时,能够在最终凝固组织中观察到AlP包裹着TiB2或TiC,作为该微米粒子的过渡相,分布于初晶Si核心的现象。本研究即通过TiB2和TiC等微米粒子与AlP相的耦合作用起到固定AlP颗粒的作用,从而促进熔体对P的吸收。

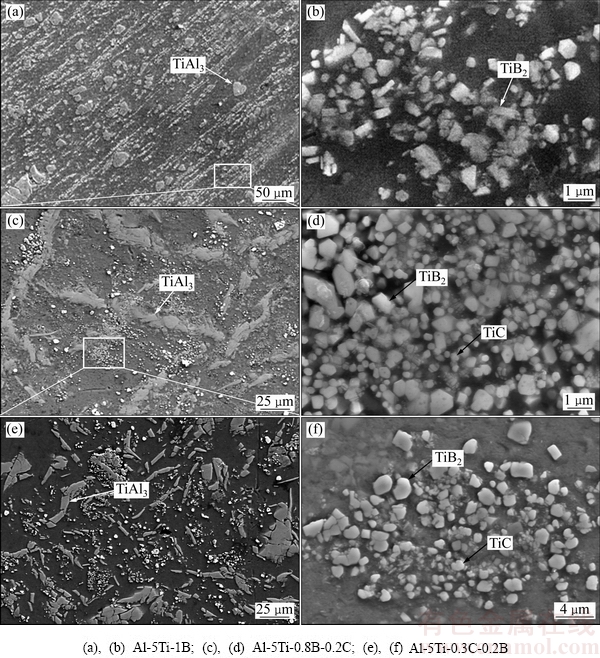

图6(a)和(b)所示分别为Al-5Ti-1B中间合金的SEM像。从低倍组织中可以发现,块状的TiAl3相及大量的颗粒状TiB2相分布在α(Al)基体上,高倍组织观察可以发现TiB2粒子平均尺寸在1 μm左右。图6(c)、(d)、(e)和(f)所示分别为Al-5Ti-0.8B-0.2C和Al-5Ti-0.3C-0.2B中间合金的SEM像,其中,从低倍组织中可以看到板条状TiA13相和尺寸不一的掺杂型TiC和TiB2粒子,并且Al-5Ti-0.8B-0.2C合金中粒子数目多于Al-5Ti-0.3C-0.2B合金。高倍组织中呈较规则板片状的是TiB2相,尺寸在1~3 μm之间,形貌较为圆整的为TiC相,尺寸在0.1~1 μm之间。

图7所示为单独加入0.5%Al-3P中间合金和复合加入0.5%Al-3P与不同种中间合金后的吸收率。对比各组数据可以看出,复合加入两种中间合金使得P吸收率显著提升,其中,单独加入TiB2粒子时,提升幅度较小,约5%;而同时加入TiB2和TiC两种粒子时,P吸收率提升幅度较大,达45%以上。可见这两种外来粒子的协同耦合作用能够极大地促进P被Al-Si熔体吸收。但由于在此种情况下,耦合粒子的数目均为过量的,故Al-5Ti-0.8B-0.2C和Al-5Ti-0.3C-0.2B这两种中间合金的复合加入对P吸收率的影响差异较小。

图6 含不同粒子的中间合金的SEM像

Fig. 6 SEM images of master alloys containing different particles

图7 复合加入0.5%杆状Al-3P和不同种外来粒子分别保温30 min和60 min时的P吸收率

Fig. 7 P absorption rate (Al-18Si, 780 ℃) of Al-18Si melt by combining adding 0.5%Al-3P ingot and external particles held for 30 and 60 min, respectively

分析是由于Al-5Ti-1B中TiB2的(112)晶面与AlP的(442)晶面的错配度较小,TiB2粒子能够作为AlP形核的良好衬底[15]。当熔体温度降低时,溶解的AlP容易向TiB2粒子偏聚,并发生类包晶耦合反应,形成耦合粒子TiB2·AlP,即TiB2粒子周围形成一层富AlP薄层,该耦合粒子再对初晶Si起到形核衬底的作用。随着耦合粒子的不断形成,铝熔体中溶解的P原子减少,促使之前未溶解的AlP相继续溶解。同时,TiB2粒子尺寸小,数量多,起到固定AlP粒子的作用,阻止部分AlP从熔体中游离出去,而使其更多地保留在熔体中,从而提高了P吸收率,改善了细化效果。ZHOU等[22]在采用该耦合粒子细化Al-45Si时也取得了明显的提升效果。TiC粒子有相似的作用,可与AlP相形成耦合粒子[23],促进其在熔体中的分散,从而在提升P吸收率的同时,显著地提高形核效率。

3 讨论

上述试验结果表明,P吸收率与AlP相在熔体中的演变行为密切相关。当含P中间合金加入到Al-Si熔体中后,从热力学方面考虑,由于其与熔体之间存在P元素的浓度梯度,故首先由表及里发生AlP相破碎和溶解的反应[24],形成Al-P团簇,根据LESCUYER等[21]的测量结果,对应不同的熔体温度,P元素有不同的极限溶解度;此外,从动力学方面考虑,物相的溶解过程不是瞬间完成的,其内在机制是由扩散因素和界面反应共同作用的结果,需要足够的弛豫时间才能使熔体温度和结构达到均匀[25],最终达到溶解平衡。在凝固过程中,随着温度的降低,P在铝熔体中的溶解度迅速降低[21, 26],使得溶解态的P重新以AlP晶体形式析出,而AlP与Si具有良好的界面匹配关系,故AlP相可作为初晶Si的有效形核衬底。P能否被Al-Si熔体“吸收”取决于溶解反应进行的程度和AlP相的尺寸及其在熔体中的界面行为,这两者分别为影响P吸收率的热力学和动力学因素。

选用含有更细小弥散分布的AlP相的中间合金、提高熔体温度、适当延长保温时间以及控制加入量在熔体温度对应的溶解度极限内均能在热力学上促进P元素最大限度地被熔体溶解,从而提高P吸收率,如图1及图3~5中结果所示。反之,熔体处理过程中,如果熔体温度较低或加入量过多,未溶解的AlP颗粒较多,亦或是温度波动范围较大,极易使已经进入熔体的P 原子以AlP粒子形式析出,使之易于游离出铝熔体而造成P的损失,造成P吸收率和初晶Si细化效果下降。

为了促进以颗粒形式存在的AlP相被熔体吸收,需添加TiB2、TiC等与AlP相晶体结构有良好匹配性的微米粒子。一方面,这些外来微米相可吸附AlP颗粒,形成尺寸较小的耦合粒子在熔体中弥散分布,防止AlP相在保温和精炼过程中聚集成颗粒团游离出熔体,起到固定的作用,从而使P吸收率明显提升;另一方面,在凝固过程中,该类耦合粒子的存在降低了体系自由能,优化AlP衬底的界面结构[22],使其作为初晶Si更加有效的形核衬底,显著提高P吸收率,改善细化效果。

4 结论

1) 采用不同含P中间合金细化处理Al-18Si合金,工艺条件相同时(中频炉中780 ℃保温20 min,加入1.5×10-4 P),杆状Al-3P合金的P吸收率最高,达80%;Cu-14P吸收率最低,仅有13%。

2) P吸收率与AlP相在铝熔体中的演变行为密切相关。细化工艺参数影响AlP相的溶解过程,进而影响P吸收率。随着熔体温度升高,P吸收率显著提高;随着保温时间延长,P吸收率呈现先增加后减小的趋势,保温90 min时达到极大值;随着加入量增加,P吸收率呈现不断下降趋势。

3) 复合加入Al-3P中间合金及TiB2与TiC微米粒子可有效提高P吸收率,提升幅度达45%~50%。

REFERENCES

[1] KASPRZAK W, KURITA H, BIRSAN G, AMIRKHIZ B S. Hardness control of Al-Si HPDC casting alloy via microstructure refinement and tempering parameters[J]. Materials & Design, 2016, 103: 365-376.

[2] JAVIDANI M, LAROUCHE D. Application of cast Al-Si alloys in internal combustion engine components[J]. International Materials Reviews, 2014, 59(3): 132-158.

[3] XIE Huan-jun, CHENG Ying-liang, LI Shao-xian, CAO Jin-hui, CAO Li. Wear and corrosion resistant coatings on surface of cast A356 aluminum alloy by plasma electrolytic oxidation in moderately concentrated aluminate electrolytes[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 336-351.

[4] YU Wen-zhou, MA Wen-hui, ZHENG Zhong, JIANG Wei-yan, LI Jie, TIAN Mao-hong. Effects of melt viscosity on enrichment and separation of primary silicon from Al-Si melt[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 467-474.

[5] 何克准, 于福晓, 赵大志, 左 良. 磷变质对 Al-17.5Si-4.5Cu-1Zn-0.7Mg-0.5Ni 变形合金初晶硅形貌与室温拉伸性能的影响[J]. 中国有色金属学报, 2010, 20(11): 2081-2087.

HE Ke-zhun, YU Fu-xiao, ZHAO Da-zhi, ZUO Liang. Effects of phosphorus modification on morphology of primary silicon particles and mechanical properties of wrought Al-17.5Si-4.5Cu-1Zn-0.7Mg-0.5Ni alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2081-2087.

[6] 胡慧芳. Al-25% Si合金Si相形态, 变质及性能研究[D].重庆:重庆大学, 2010: 1-2.

HU Hui-fang. Study on the Si phase, modification and properties of Al-25%Si alloy[D]. Chongqing: Chongqing University, 2010: 1-2.

[7] 蒋 伟, 胡恺琪, 朱向镇,武玉英,刘相法. Al-Si合金力学行为对Si相形貌敏感性的差异[J]. 中国有色金属学报, 2017, 27(1): 15-23.

JIANG Wei, HU Kai-qi, ZHU Xiang-zhen, WU Yu-ying, LIU Xiang-fa. Difference in sensitivity of mechanical behaviors for Al-Si alloys to Si phase morphologies[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 15-23.

[8] FARAHANY S, OURDJINI A, BAKHSHESHI-RAD H R. Microstructure, mechanical properties and corrosion behavior of Al-Si-Cu-Zn-X (X=Bi, Sb, Sr) die cast alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 28-38.

[9] 牟俊东, 高晓波, 冯增建, 王建强, 李占军, 韩永贞. 温度对近共晶 Al-Si 多元合金中 P 含量的影响[J]. 铸造技术, 2012, 4: 21.

MOU Jun-dong, GAO Xiao-bo, FENG Zeng-jian, WANG Jian-qiang, LI Zhan-jun, HAN Yong-zhen. Effect of temperature on P content in near-eutectic Al-Si alloy[J]. Foundry Technology, 2012, 4: 21.

[10] LI J H, HAGE F S, LIU X F, RAMASSE Q, SCHUMACHER P. Revealing heterogeneous nucleation of primary Si and eutectic Si by AlP in hypereutectic Al-Si alloys[J]. Scientific Reports, 2016, 6.

[11] ZHU X Z, WU Y Y, LI C, LI P T QIAO H, LIU X F. The dispersive orientated-precipitation of AlP on alumina film and its effect on the primary Si gathering behavior in the Al-Si alloy surface layer[J]. Cryst Eng Comm, 2014, 16(25): 5583-5590.

[12] 龚啟良. A390 铝合金之初晶矽细化[M]. 台湾: 大同大学, 2010.

GONG Qi-liang. Refinement of Primary Silicon in an A390 Al alloy[M].Taiwan: Datong university, 2010.

[13] GAO T, ZHU X Z, QIAO H, LIU X F. A new Al-Fe-P master alloy designed for application in low pressure casting and its refinement performance on primary Si in A390 alloy at low temperature[J]. Journal of Alloys and Compounds, 2014, 607: 11-15.

[14] 龚啟良, 杨智富, 陈亮宇. 不同之含磷细化剂对过共晶铝硅合金之初晶硅细化效果比较[J]. 铸造工程学刊, 2011, 37(2): 1-10.

GONG Qi-liang, YANG Zhi-fu, CHEN Liang-yu. Comparison on the refinement of primary silicon in a hypereutectic Al-Si alloy by different types of P-bearing refiners[J].Journal of Taiwan Foundry Society, 2011, 37(2): 1-10.

[15] YU L N, LIU X F, DING H M, BIAN X F. A new nucleation mechanism of primary Si by peritectic-like coupling of AlP and TiB2 in near eutectic Al-Si alloy[J]. Journal of Alloys and Compounds, 2007, 432(1): 156-162.

[16] HO C R, CANTOR B. Heterogeneous nucleation of solidification of Si in Al-Si and Al-Si-P alloys[J]. Acta Metallurgica et Materialia, 1995, 43(8): 3231-3246.

[17] ZHANG H H, DUAN H L, SHAO G J, XU L P. Microstructure and mechanical properties of hypereutectic Al-Si alloy modified with Cu-P[J]. Rare Metals, 2008, 27(1): 59-63.

[18] DONG T S, CUI C X, LIU S J, YANG L J, SUN J B. Influence of rapid solidification of Cu-P intermediate alloy on wear resistance of Al-Si alloy[J]. Rare Metal Materials and Engineering, 2008, 37(4): 686-689.

[19] 王季明, 张庆昕, 扬 帆, 崔春翔, 孙继兵, 董天顺. 快速凝固Al-Ti-B和Cu-P对Al-13.5Si-xCu-yNi合金组织和性能的影响[J]. 天津冶金, 2009, 5: 30-33.

WANG Ji-ming, ZHANG Qing-xin, YANG Fan, CUI Chun-xiang, SUN Ji-bing, DONG Tian-shun. Effect of rapid solidified Al-Ti-B and Cu-P on Al-13.5Si-xCu-yNi alloy structure and properties[J].Tianjin Metallurgy, 2009, 5: 30-33.

[20] 杨子润, 庞绍平, 孙 瑜, 宋 娟. 变质及合金化对过共晶 Al-20% Si合金组织及磨损性能的影响[J]. 中国有色金属学报, 2013, 23(5): 1217-1225.

YANG Zi-run, PANG Shao-ping, SUN Yu, SONG Juan. Effect of modification and alloying on microstructure and wear properties of hypereutectic Al-20%Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1217-1225.

[21] LESCUYER H, ALLIBERT M, LASLAZ G. Solubility and precipitation of AlP in Al-Si melts studied with a temperature controlled filtration technique[J]. Journal of Alloys and Compounds, 1998, 279(2): 237-244.

[22] ZHOU X L, WU Y Y, LI Y F, WU L, Gao T, LI H, LIU X F. Absorbing formation mechanism of AlP on TiB2 substrate and their application as high-efficiency nucleating agent in Al-45Si alloy[J]. Journal of Alloys and Compounds, 2017, 693: 853-858.

[23] 戴洪尚. 超高硅铝合金中硅相的细化与界面性质研究[D]. 济南: 山东大学, 2009: 1-2.

DAI Hong-shang. Study on the grain refinement of Si phase and the interfacial characteristics in Si-high Al alloys[D]. Jinan: Shandong University, 2009: 1-2.

[24] ZHANG Q, LIU X F, DAI H S. Re-formation of AlP compound in Al-Si melt[J]. Journal of Alloys and Compounds, 2009, 480(2): 376-381.

[25] 张 蓉, 赵志龙, 刘汉武, 刘 林. 初生硅在熔体中的溶解动力学[J]. 金属学报, 2002, 38(4): 397-399.

ZHANG Rong, ZHAO Zhi-long, LIU Han-wu, LIU Lin. Dissolution kinetics of primary silicon in the melt[J]. Acta Metallurgica Sinica, 2002, 38(4): 397-399.

[26] LIANG S M, SCHMID-FETZER R. Phosphorus in Al-Si cast alloys: Thermodynamic prediction of the AlP and eutectic (Si) solidification sequence validated by microstructure and nucleation undercooling data[J]. Acta Materialia, 2014, 72: 41-56.

Affecting factors of P absorption rate of hypereutectic Al-Si alloys

HU Kai-qi1, JIANG Wei1, ZHU Xiang-zhen1, ZHANG Qian1, SUN Qian-qian2, LIU Xiang-fa1

(1. Key Laboratory of Liquid-Solid Structural Evolution and Processing of Materials, Ministry of Education, Shandong University, Jinan 250061, China;

2. Shandong Al and Mg Melt Technology Company Limited, Shandong University, Jinan 250061, China)

Abstract: The phosphorous absorption rate is an important parameter for the refining process of hypereutectic Al-Si alloys, which not only influences final P content, but also reflects the evolution of AlP phase in the melt. The changing rules of P absorption rate were studied as kinds of master alloys, the processing parameters, coupling relationship of added solid particles varied. The experimental results show that Al-3P rod alloy appears the highest absorption rate (80%), while Cu-14P appears the lowest absorption rate (13%) under the same melting condition. The higher holding temperature contributes to superior P absorption rate while the more addition results in the lower. As holding time extends, P absorption rate first increases then decreases when achieving the maximum level at 90 min. Moreover, adding proper solid particles, such as TiB2 and TiC, which have a good structural matching relationship with AlP crystal, can dramatically increase P absorption rate.

Key words: Al-Si alloys; primary silicon; P absorption rate; processing parameters; grain refinement

Foundation item: Project(51571133) supported by the National Natural Science Foundation of China

Received date: 2016-09-02; Accepted date: 2017-06-27

Corresponding author: LIU Xiang-fa; Tel: +86-531-88392006; E-mail: xfliu@sdu.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51571133)

收稿日期:2016-09-02;修订日期:2017-06-27

通信作者:刘相法,教授,博士;电话:0531-88392006;E-mail:xfliu@sdu.edu.cn