复压复烧对预合金钢粉烧结材料性能的影响

高翔1,袁勇2,张德金2,李威1,蔺瑞冬1,崔建民2,罗丰华1, 2

(1. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

2. 莱芜钢铁集团粉末冶金有限公司,山东 莱芜,271105)

摘要:通过在预合金钢粉中加入C等元素,采用模压-烧结和复压复烧2种方法制备粉末冶金低合金钢,并对其密度、显微组织、力学性能和断口形貌进行分析。研究结果表明:对于添加质量分数为0.8% C的合金粉末,用普通压制-烧结法制备的样品密度最高为7.15 g/cm3,抗拉强度为406 MPa;而用复压复烧法制得的样品密度可达7.53 g/cm3,抗拉强度为611 MPa,伸长率也有很大提升;复压复烧法制得的样品孔隙较少且圆滑平直化,断口分布有大量的韧窝,因此,合金的强度和塑性均较高。

关键词:粉末冶金;预合金钢粉;复压复烧;拉伸性能

中图分类号:TF125.1+2,TF124 文献标志码:A 文章编号:1672-7207(2011)09-2628-07

Influence of double press/double sinter processing on sintered alloys made from pre-alloyed steel powder

GAO Xiang1, YUAN Yong2, ZHANG De-jin2, LI Wei1, LIN Rui-dong1, CUI Jian-min2, LUO Feng-hua1, 2

(1. State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China;

2. Laiwu Iron & Steel Group Powder Metallurgy Co. Ltd, Laiwu 271105, China)

Abstract: PM low alloy steel samples were prepared by die-wall pressing-sintering and double press/double sinter (DP/DS) processing. The density, mechanical properties, microstructure and fractography were analyzed. The results indicate that the density of the sintered alloys with 0.8% graphite addition prepared by die-wall pressing-sintering is the maximum 7.15 g/cm3, and the ultimate tensile strength is 406 MPa; when prepared by DP/DS processing, the density can achieve 7.53 g/cm3, the ultimate tensile strength is 611 MPa, and the elongation is increased, too. The samples prepared by DP/DS processing has fewer pores and the pores are more rounded, and there are lots of dimples distributed in fracture surface, thereby the strength and plasticity of the alloys are better.

Key words: powder metallurgy; pre-alloyed steel powder; double press/double sinter; tensile properties

近年来,粉末冶金零件的生产和应用得到了广泛的关注,这与新的合金钢粉末的开发是分不开的[1-2]。用雾化法生产的预合金粉末中的合金元素分布均 匀,且用其生产的烧结材料具有均匀的显微结构[3],因此,预合金化粉末冶金低合金钢粉得到了广泛的应用。Ni,Mn,Cr和Mo等合金元素是常用的低合金钢粉的预合金化元素,这些合金元素的加入可以增加钢的力学性能和淬透性[4-6]。但大量合金元素的加入会降低铁粉的压缩性[7],从而使烧结后的合金难以达到高密度水平,因此,需要在尽可能少地加入合金化元素的前提下,使粉末冶金钢具有较高的力学性能。通常,粉末冶金铁基零件的力学性能主要受密度、合金元素含量及组织特征等3个方面的影响,在其他条件不变的情况下,密度是一个关键因素。可以提高粉末冶金零件密度的方法有:复压复烧、温压成形、粉末锻造、高速压制以及渗铜等[8-9]。复压复烧即将铁基粉末在400~500 MPa压力下进行压制,于780~850 ℃预烧,然后在600~900 MPa压力下进行复压,根据材料的成分及性能要求选择在1 100~1 200 ℃烧结[10-12]。可以看出复压复烧不需要增添新的设备,技术难度不大,工艺过程比较容易控制,且质量比较稳定,适合于大批量生产。这种方法的主要缺点是工序增加导致成本增加。但是,可以在预烧结后进行机械加工,略降低加工成本[13-15]。LAP100.29A2粉是莱芜钢铁集团粉末冶金有限公司开发出来的含Ni,Mn,Cr和Mo等合金元素的低合金钢粉。由于其加入的合金元素总量较少,对合金钢力学性能的提高作用不大,并且压缩性也不高,因此,有必要提高其密度来增加其力学性能。为此,本文作者研究复压复烧工艺和C含量对该粉末冶金制品组织和力学性能的影响。

1 试验材料及方法

基础粉末LAP100.29A2(简称为A2)预合金钢粉的化学组成(质量分数)为:C,≤0.01%;Si,≤0.05%;Mn,0.29%;P,≤0.02%;S,≤0.015%;Cr,0.18%;Ni,0.51%;Mo,0.51%;Co,0.31%;Cu,0.24%;其余为铁。该粉末的物理性能见表1。

配制了3种不同C含量的铁基合金粉末,即:A2+ 0.8%石蜡+0.6%硬脂酸锌;A2+0.8%石蜡+0.6%硬脂酸锌+0.4% C和A2+0.8%石蜡+0.6%硬脂酸锌+0.8% C,其中C元素时以石墨的形式加入的,其灰分和挥发分分别为1.0%和1.5%。将混合粉末在滚筒式混料机中混合6 h,再分别采用普通压制-烧结法和复压复烧法制备烧结合金。具体做法为:(1) 普通压制-烧结法:将混合粉末在不同压力下经模压成形后,在钼丝炉中氢气气氛下烧结:压制压力分别为400,600和800 MPa,烧结温度为1 120 ℃,保温30 min后推入水冷区冷却25 min出炉。(2) 复压复烧法:将混合粉末在400,600和800 MPa 3种压力下压制成形,在800 ℃氢气气氛下预烧30 min后推入水冷区冷却20 min出炉,然后,将预烧坯分别在400,600和800 MPa 3种压力下复压,在1 120 ℃氢气气氛下烧结30 min后推入水冷区冷却25 min出炉。在这2种工艺中,推舟速度都较慢,以使样品中添加的石蜡和硬脂酸锌等成形剂能缓慢脱除,烧结时样品埋在氧化铝填料中并在其上覆盖一层木炭,因此,烧结后样品并没有明显的脱碳,添加0.4%和0.8%石墨的样品化合碳含量分别为0.37%和0.78%。

采用排水法测量烧结坯的密度。在CTM4000电子万能试验机上进行拉伸试验,拉伸速率为1 mm/min,拉伸试样为经线切割加工出的非比例板状试样,试样的平行长度部分(即横截面)为3 mm×3 mm,用细墨线标记20 mm原始标距,头部与平行长度部分以半径20 mm的过渡弧连接。用MeF3A金相显微镜观察显微组织,金相样品浸蚀液为3%硝酸-酒精溶液。用JSM-6360LV扫描电子显微镜观察拉伸样品的断口 形貌。

2 试验结果及分析

2.1 合金的密度

图1所示为以A2为基体粉末,添加3种不同C含量的合金粉末经普通压制-烧结制备的样品压坯和烧结坯的密度与压制压力的关系。

从图1可以看出:经过模压成形后,所得压坯的密度都较低,在6.45~6.85 g/cm3范围内。3种压制压力下,含0.4% C的压坯密度最高,而含0.8% C的压坯密度比不添加C时的还要低。这是因为在基体粉末中添加适量的石墨可以起到润滑作用,有利于减少压制过程中压力的损失,从而可以提高压坯密度;但由于石墨的密度比铁的密度低得多,过多的石墨会使混合粉末理论密度降低,因而会降低压坯的密度。故随着石墨添加量的增多,合金粉末的压坯密度先增加后降低。

表1 LAP100.29A2预合金钢粉的物理性能

Table 1 Physical properties of LAP100.29A2 pre-alloyed steel powder

图1 普通压制-烧结工艺制备样品的密度与压制压力的关系

Fig.1 Density versus compaction pressure for samples prepared by single press/single sinter processing (SP/SS)

经1 120 ℃烧结30 min后样品的密度有所提升;随着石墨添加量的增多,烧结坯的密度有降低的趋势;随着压制压力的提升,烧结坯的密度增加,但密度增加的量是有限的,而且过大的压制压力容易引起模具的急剧损坏和增加操作的危险性。因此,单纯通过提高压制压力的方法来增加合金的致密度是不可取的。

以A2为基体粉末,添加3种不同C含量的合金粉末经复压复烧工艺制得的烧结坯的密度见表2。

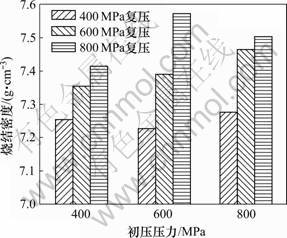

从表2可知:相比于普通压制-烧结法制备的样品,复压复烧制得的样品密度都有了较大的提高,例如:添加0.4%C的合金粉末经普通压制-烧结法制备的烧结坯样品密度最大为7.16 g/cm3,而经复压复烧制备的烧结坯样品的密度最小值就可达到7.23 g/cm3,最大为7.57 g/cm3。且在同一复压压力下,初始压制压力的提升有助于最终烧结坯密度的提升。但也有例外,例如添加0.4% C的合金的密度在初始压制压力为600 MPa;当复压压力为800 MPa时,出现最大值。如图2所示。

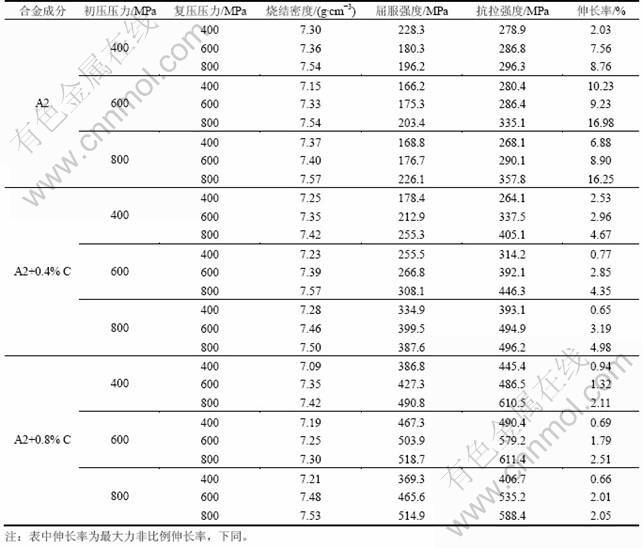

表2 复压复烧法制得样品的密度及拉伸性能

Table 2 Density and tensile properties of samples prepared by double press/ double sinter processing (DP/DS)

图2 复压复烧法制得样品的密度与压制压力的关系(添加0.4% C)

Fig.2 Density versus compaction pressure for samples with 0.4% graphite added prepared by DP/DS

由图2可见:LAP100.29A2预合金钢粉的压缩性不佳,在添加了石蜡、硬脂酸锌及石墨后合金的压坯密度不高,在6.45~6.85 g/cm3范围内。烧结坯密度在7.05~7.22 g/cm3之间;经复压复烧制备的烧结态样品的密度在7.2~7.6 g/cm3之间,达到了高密度铁基粉末冶金制品(>7.5 g/cm3)的要求[16]。因此,可以通过复压复烧工艺来制备高密度粉末冶金铁基合金。

2.2 合金的拉伸力学性能

采用普通压制-烧结法制备的以A2为基体粉末的3种铁基烧结合金的屈服强度、抗拉强度以及伸长率,如表3所示。

由表3可知:由普通压制-烧结法制得的样品强度都比较低,添加C元素的合金伸长率都很低,即使在不添加C的情况下,伸长率最高也只有2.29%,若以5%作为塑-脆断裂的标准,则样品都为脆性断裂;随着C含量的增多,合金的屈服强度和抗拉强度都有所提升,而伸长率下降,这也反映了C元素增加使低合金钢强度上升而塑性下降的规律。

由复压复烧工艺制备的3种合金的拉伸力学性能数据如表2所示。由表2可以看出:

(1) 经复压复烧后,材料的强度和伸长率大幅度提高,特别是伸长率,不加C时伸长率最高可达16.98%,为延性断裂;即使是添加0.8% C,合金的伸长率也比普通压制-烧结合金的高。

(2) 随着C含量的增加,复压复烧制得样品的强度增加,而伸长率下降。

(3) 初压压力相同时,合金的强度和伸长率都随着复压压力的增加而增加。

以添加0.8% C的合金为例,压制压力为400 MPa时,相比于普通压制-烧结制备的样品,复压复烧制得的样品的屈服强度、抗拉强度以及伸长率分别增加了37.7%,35.2%和84.4%,如图3所示。

2.3 合金的组织和断口形貌

从试验结果可知:添加C元素的合金虽然烧结后密度有所下降,但其抗拉强度明显高于不添加C元素的合金。这可以通过合金显微组织中珠光体量的变化来解释,用复压复烧法(即试样经600 MPa初压,800 MPa复压)制得样品的显微组织如图4所示。

由图4可以看到合金中组织随C添加量的变化。当合金中添加的C含量由0变化到0.4%再到0.8%时,合金的显微组织也由铁素体变化到铁素体+珠光体再到基本完全为珠光体。组织中珠光体的量越多,合金的抗拉强度也越高,相应的塑性会降低。因此,随着C添加量的增加,合金的屈服强度和抗拉强度提升,而伸长率下降。可以看出:在合金显微组织中还有一些未溶解的石墨,这说明在1 120 ℃烧结30 min并不能使C完全扩散到Fe晶格的间隙中与之形成间隙固溶体。

表3 普通压制-烧结法制得样品的拉伸性能

Table 3 Tensile properties of samples prepared by SP/SS

图3 普通压制-烧结和复压复烧法(初始压制压力为400 MPa)制备的添加0.8%C的样品的拉伸性能

Fig.3 Tensile properties of samples with 0.8% graphite addition prepared by SP/SS and DP/DS

相比于普通压制-烧结方法制备的样品,用复压复烧法制备的样品在具有较高强度的同时还具有优良的塑性。这可以通过合金中的孔隙对粉末冶金材料性能的影响来解释。图5所示为普通压制-烧结和复压复烧法制备样品的孔隙形貌及拉伸断口形貌。

从图5(a)和图5(b)可以看出:用普通压制-烧结法制备的样品,其光学显微组织中还有较多的孔隙,孔隙大多为不规则的形状且倾向于聚集在一起而形成孔隙群;而用复压复烧法制备的样品中虽然也有孔隙,但孔隙较少且比较圆滑并弥散分布在基体中。铁基粉末冶金材料的强度和塑性会随着孔隙度的增加而降低,这是因为在由铁等塑性金属制取的粉末冶金材料中,孔隙的存在不会引起大的应力集中,但会削弱试样承载的有效断面,导致应力沿烧结材料的显微体积分布不均匀。而粉末冶金材料的伸长率不仅受孔隙度的强烈影响,还对孔隙的形状很敏感。复压复烧工艺不仅可以降低试样的孔隙度,从而提升合金的拉伸强度和伸长率,而且可以改变孔隙的形状。在复压过程中,试样中的孔隙会变小且形状也会发生变化,在复烧过程中会导致孔壁的圆滑平直化和球化,这使得材料在拉伸过程中的变形更加均匀且可减少应力集中,从而使对孔隙结构敏感的伸长率得到提高[17]。因此,用普通压制-烧结法制备样品的强度和塑性都较低,对应于断口形貌中韧窝的尺寸都比较小且较浅;而用复压复烧法制备样品的强度和塑性有了大幅提升,断口表面分布有大量韧窝,韧窝的尺寸较大而且比较深。

图4 复压复烧制备的不同成分合金的光学显微组织(浸蚀)

Fig.4 Microstructural phases in sintered alloys with different amounts of graphite added prepared by DP/DS

图5 由不同工艺制备的添加0.8% C的合金的孔隙金相(未浸蚀)及拉伸断口形貌

Fig.5 Pore morphology and tensile fracture of sintered alloys with 0.8% graphite added prepared by different processings

3 结论

(1) LAP100.29A2预合金钢粉在普通压制-烧结工艺中可以通过提高压制压力来提升密度,但制备的烧结坯密度最高只有7.22 g/cm3;通过复压复烧工艺制备的烧结坯密度最高为7.57 g/cm3。

(2) 初始压制压力和复压压力的提升都有助于提高复压复烧工艺制品的密度,从而改善其力学性能。但并不是初压压力和复压压力越高越好。当初压压力为600 MPa,复压压力为800 MPa时,添加0.4% C合金的密度达到最大,为7.57 g/cm3。

(3) 复压复烧工艺可以减少烧结坯中的孔隙,并使孔隙圆滑平直化和球化,从而改善合金的力学性能。用复压复烧法制备的添加0.4% C合金的抗拉强度最高可达496 MPa,相应的伸长率为4.98%;而添加 0.8% C合金的抗拉强度最高可达611 MPa,相应的伸长率为2.51%。

参考文献:

[1] Engstr?m U. Evaluation of sinter hardening of different PM materials[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 2000: 147-157.

[2] Engstr?m U, Lindberg C, Tengzelius J. Powders and process for high performance PM steels[J]. Powder Metallurgy, 1992, 35(1): 67-72.

[3] Murphy T F, Baran M C. An investigation into the effect of copper and graphite additions to sinter-hardening steels[C]// Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 2004: 266-274.

[4] 郑朝旭, 郭瑞金. 烧结硬化钢高速高扭矩齿轮的开发[J]. 粉末冶金技术, 2003, 21(6): 334-337.

CHENG Chao-hsu, GUO Ray. Development of high speed and high torque gears by sinter hardening[J]. Powder Metallurgy Technology, 2003, 21(6): 334-337.

[5] Skena C, Prucher T, Czarnek R, et al. Hardenability characteristics of P/M alloy steels[J]. International Journal of Powder Metallurgy, 1997, 33(7): 25-35.

[6] Chagnon F, Trudel Y. Designing low alloy steel powders for sinter hardening applications[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 1996: 211-220.

[7] Trudel Y, Gagne M. Compaction behaviour of high compressibility low alloy steel powders[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 1989: 63-73.

[8] Hanejko F J. High-performance single-press/single-sinter processing[J]. International Journal of Powder Metallurgy, 2005, 41(5): 37-44.

[9] 叶途明, 易健宏, 彭元东, 等. 提高粉末冶金制品压坯密度的新技术[J]. 粉末冶金工业, 2003, 13(6): 32-36.

YE Tu-ming, YI Jian-hong, PENG Yuan-dong, et al. New technique of increasing the compact density of powder metallurgy parts[J]. Powder Metallurgy Industry, 2003, 13(6): 32-36.

[10] Mars O. High performance P/M steels[J]. Scandinavian Journal of Metallurgy, 1995, 24(4): 147-151.

[11] Rutz H G, Rawlings A J, Cimino T M. Advanced properties of high density ferrous powder metallurgy materials[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 1995: 97-115.

[12] German R M. Manipulation of strength during sintering as a basis for obtaining rapid densification without distortion[J]. Materials Transactions, 2001, 42(7): 1400-1410.

[13] Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 1994: 117-133.

[14] Hamill J A, Causation R J. High performance ferrous P/M materials utilizing high temperature sintering[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 1992: 193-213.

[15] Luk S H, Rutz H G, Lutz M A. Properties of high density ferrous PM materials-a study of various processes[C]//Advances in Powder Metallurgy and Particulate Materials. Princeton, NJ: MPIF, 1994: 135-154.

[16] 果世驹, 林涛, 李明怡. 铁粉温压压坯的烧结行为[J]. 粉末冶金技术, 1999, 17(2): 107-110.

GUO Shi-ju, LIN Tao, LI Ming-yi. Sintering behavior of warm-compacted green compacts[J]. Powder Metallurgy Technology, 1999, 17(2): 107-110.

[17] Chawla N, Deng X. Microstructure and mechanical behavior of porous sintered steels[J]. Material Science and Engineering A, 2005, 390: 98-112.

(编辑 杨幼平)

收稿日期:2010-08-09;修回日期:2010-11-13

基金项目:国家科技支撑计划项目(2009BAE74B02);湖南省博士后科学基金资助项目(2009RS3027);粉末冶金国家重点实验室创新基金资助项目(200902)

通信作者:罗丰华(1969-),男,湖南攸县人,教授,从事材料科学与工程研究;电话:0731-88830614;E-mail: fenghualuo@csu.edu.cn