文章编号:1004-0609(2014)08-2050-07

包套设计对典型粉末钛合金拉伸性能的影响

郭瑞鹏1, 2,徐 磊1,柏春光1,吴 杰1,王清江1,杨 锐1

(1. 中国科学院 金属研究所,沈阳 110016;

2. 东北大学 材料与冶金学院,沈阳 110819)

摘 要:采用热等静压工艺制备Ti-6Al-4V和Ti-60两种预合金粉末钛合金,研究两种不同包套形式对粉末合金拉伸性能的影响,采用SEM观察粉末合金的拉伸断口形貌,并利用MSC.Marc有限元分析软件对两种包套在热等静压过程中包套各部位的尺寸收缩进行模拟预测。结果表明:包套结构设计不合理时,焊缝在热等静压过程中存在泄漏的风险,进而会严重恶化粉末合金的性能;有限元模拟仿真可以辅助包套设计,提高效率,对制备粉末冶金近净成型构件有较为重要的工程应用意义。

关键词:Ti-6Al-4V;Ti-60;包套设计;粉末冶金;拉伸性能

中图分类号:TG146.2 文献标志码:A

Effects of can design on tensile properties of typical powder metallurgy titanium alloys

GUO Rui-peng1, 2, XU Lei1, BAI Chun-guang1, WU Jie1, WANG Qing-jiang1, YANG Rui1

(1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China)

Abstract: Pre-alloyed powders of Ti-6Al-4V and Ti-60 were prepared through hot isostatic pressing (HIP) route. The tensile properties of two typical powder metallurgy (PM) titanium alloys HIPped from two different kinds of cans were tested, and the fracture surface morphology was studied by SEM. The simulation, using MSC.Marc software of capsule/powder shrinkage during HIPping for two different can designs was presented. The numerical simulations of Hipping experiments indicate that improper can design shows great probability of capsule failures, which is in accordance with the experimental data. Capsule failure will deteriorate the mechanical properties of the PM alloys, and finite element method is a useful tool for can design, especially for manufacturing near-net-shape components.

Key words: Ti-6Al-4V; Ti-60; can design; powder metallurgy; tensile property

钛合金具有比强度高、高温性能好、抗腐蚀性能优异等优点,因而在航空航天、海洋开发等领域有着越来越广泛的用途[1]。钛合金构件的常用加工方法有精密铸造和锻造。然而,对于大型薄壁和复杂结构的钛合金构件,铸造工艺方法存在难以彻底解决的疏 松、成分偏析等铸造缺陷,会严重恶化铸件性能。锻造钛合金虽然性能优良,但对于复杂结构件,其热机械加工工艺复杂,加工时存在回弹现象,周期长,材料利用率极低等缺点[2-3]。而粉末冶金工艺材料利用率高,后续加工量小,并且快速凝固制粉工艺能够提高低溶解度合金元素的过饱和固溶度,在很大程度上解决了成分偏析和偏聚[4-5]。近年来,随着制粉技术的进步和粉末冶金近净成型技术的成熟,美欧等发达国家已经采用粉末冶金工艺制备了许多结构复杂的钛合金构件,并获得了初步应用。粉末冶金近净成型工艺设计灵活,能够制备大型和复杂结构钛合金构件,已经成为国内外研究的热点领域[6-9]。随着计算机技术的发展,3D CAD和Solidworks等三维造型软件以及MARC/ABSQUS等有限元仿真软件功能的日益提升和完善,计算机辅助包套设计在粉末冶金钛合金近净成型工艺中的应用也越来越普遍。然而,国际上大多数研究工作主要集中在粉末冶金钛合金热等静压过程中的致密化行为[10]或者粉末冶金构件最终尺寸的预测[9]上,但由于包套设计引起的结构变化对粉末冶金合金力学性能的影响报道较少。本文作者设计了两种不同形式的包套,并利用热等静压工艺制备了两种典型的近α型钛合金Ti-6Al-4V和Ti-60,从实验和有限元预测两个方面研究了包套设计对Ti-6Al-4V和Ti-60粉末合金拉伸性能的影响。

1 实验

1.1 实验材料

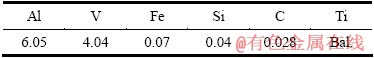

本实验中,采用无坩埚感应熔炼超声气体雾化法制备Ti-6Al-4V和Ti-60两种预合金粉末,其化学成分如表1和表2所示。预合金粉末粒度主要分布在60~250 μm之间,且呈高斯分布。

1.2 实验方法

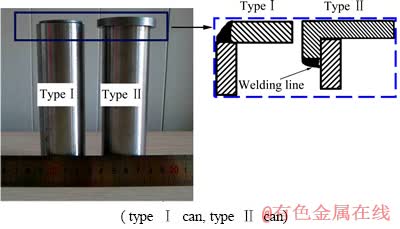

将预合金粉末填充到洁净的低碳钢圆柱形包套(包套尺寸为d 40 mm×120 mm,壁厚3 mm)中,保证预合金粉末的填充密度在68%左右。包套体经真空除气、封焊,然后在930 ℃、130 MPa、3 h条件下进行热等静压处理,得到全致密的Ti-6Al-4V和Ti-60粉末合金[11-12]。实验中用到两种不同形式的包套,包套实物图如图1所示。对于Ⅰ型包套和Ⅱ型包套,包套端盖设计的不同导致包套焊缝位置的改变:Ⅰ型包套的端盖的外形尺寸为d 40 mm×3 mm,Ⅱ型包套端盖尺寸为d 46 mm×6 mm。本实验中,由Ⅰ型包套体和Ⅱ型包套体经热等静压成型得到的粉末合金分别称为Ⅰ型合金和Ⅱ型合金。利用有限元模拟软件对两种包套在热等静压过程中各部位的尺寸收缩进行了数值模拟。

表1 Ti-6Al-4V预合金粉末的化学成分

Table 1 Chemical composition of Ti-6Al-4V pre-alloyed powders (mass fraction, %)

表2 Ti-60预合金粉末的化学成分

Table 2 Chemical composition of Ti-60 pre-alloyed powders (mass fraction, %)

采用TCH 600 氧、氮和氢分析仪测量两种粉末合金中间隙元素氧、氮和氢的含量;采用PMA-1000 质谱气体分析仪测量了粉末合金中的氩气含量。粉末合金的室温拉伸和高温拉伸性能测试在德国Zick Z050 型电子拉伸试验机完成。采用日本岛津生产SSX-350 型扫描电子显微镜对拉伸断口进行观察。

2 结果与讨论

2.1 包套结构对粉末热等静压成型的影响

EISEN等[13]研究认为,如果焊缝位置存在剪切应力,会大大增加包套在热等静压过程中发生泄漏的倾向,从而影响粉末合金的冶金质量。实验研究过程中通常可以根据包套外观尺寸收缩情况、致密度测试以及焊缝荧光检测等结果,判断包套体是否顺利地进行了热等静压成型。本实验中选用两种不同形式的包套进行热等静压试验,初步判断了相应的热等静压成型的成功率,结果表明:Ⅰ型包套的成功率约为75%,Ⅱ型包套的成功率在95%以上;Ⅱ型包套的设计明显优于Ⅰ型包套的设计。

图1 两种形式包套实物图

Fig. 1 Pictures of two different cans

包套泄漏分为微泄漏和严重泄漏,严重泄漏的包套可以从外观尺寸变化分辨出来,而微泄漏较难辨别,对材料性能影响也最大。其原因如下:热等静压是一个动态升温升压的过程,如果焊缝位置存在冶金缺陷并且包套在热等静压升温升压阶段从焊缝缺陷处渗入一定量的氩气,当达到设定的温度和压力时,缺陷在高温高压的作用下可能会闭合从而形成良好的冶金结合,此时包套内部就会存留一定压力的氩气。焊缝产生缺陷的原因可能如下:1) 焊缝融合区存在焊丝氧化形成的非金属夹杂缺陷;2) 焊缝处混入了填充的钛合金粉末;3) 熔焊区气体保护不良导致焊缝冶金质量差。当热等静压结束,降温降压过程中,包套内部压力大于外界压力,严重时可能会造成包套膨胀(严重泄漏),也可能在热处理过程中造成包套内部封闭气体的膨胀(微泄漏),这种情况会在后续讨论中详细说明。

2.2 有限元仿真辅助包套设计

本实验中选择了低碳钢圆柱形包套(包套尺寸为d 40 mm×120 mm,壁厚3 mm),粉末的振实密度达到理论密度的68%左右。粉末体在热等静压过程中的体积收缩超过30%,如此大的收缩量会给包套设计带来很大考验,包套不仅需要顺利容纳粉末热等静压致密化导致的体积收缩,而且要确保收缩均匀,特别是保证局部发生大变形的部位不会发生撕裂引起热等静压失败。为此,本实验中引入有限元仿真辅助包套设计,力求通过合理的包套设计降低热等静压失效的风险。

由于选用的两种包套均为轴对称结构,建模时只对对称面的二分之一进行分析考虑。包套轴向尺寸收缩的计算结果如图2所示。从图2(a)可以看出,Ⅰ型包套端盖处的尺寸收缩从中心到焊缝位置轴向位移差别很大,Ⅱ型包套端盖处的收缩比较均匀,从中心到焊缝位置轴向位移并无明显差异(见图2(b))。将包套端盖中心到边缘进行等距离剖分,对应节点位置的轴向位移如图3所示。从图3可以看出,Ⅰ型包套端盖中心的轴向位移为7.3 mm,而焊缝位置的轴向位移仅为2.2 mm左右,而Ⅱ型包套端盖处的轴向位移均在4.9~5.4 mm之间。

图2 Ⅰ型和Ⅱ型包套位移云图

Fig. 2 Displacement distribution in y-axis of two typical cans

图3 包套端盖纵向位移与位置的关系

Fig. 3 Displacement in y-axis at different positions for two typical cans

图4 包套端盖部位的受力分析图

Fig. 4 HIPping pressure analysis of two typical caps

图4所示为Ⅰ型和Ⅱ型包套端盖部位的受力分析图。从图4可以看出,Ⅰ型包套的焊缝位置存在切应力,Ⅱ型包套由于端盖的保护作用,有效地降低了焊缝位置的剪切作用。包套焊缝位置可以认为是刚性连接,结合有限元模拟的计算结果(见图2和图3),剪切应力使得Ⅰ型包套焊缝附近至端盖中心发生较大且不均匀的塑性变形,增加了包套焊缝泄漏的可能性,从而降低Ⅰ型包套热等静压成型的成功率。Ⅱ型包套端盖的设计等效为增加了焊缝区域包套的壁厚,能够有效地削弱焊缝位置的剪切力,提高Ⅱ型包套热等静压成型的成功率。包套壁厚的增加会导致粉末体热等静压致密化过程中包套屏蔽效应的增加,然而,程文祥[14]通过对不同包套壁厚对Ti-5Al-2.5Sn ELI预合金粉末致密化行为的研究表明,在较高的保压压力下,包套壁厚引起的屏蔽效应会导致相应区域致密化进程的差异,但对最终的致密度无明显影响。Ti-5Al-2.5Sn ELI、Ti-6Al-4V和Ti-60均属典型的近α型钛合金,因此,可以认为本实验中包套设计对粉末合金的致密度无明显影响,但会显著降低包套焊缝发生微泄漏的风险。

2.3 包套缺陷对粉末合金冶金质量的影响

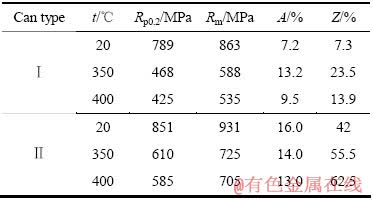

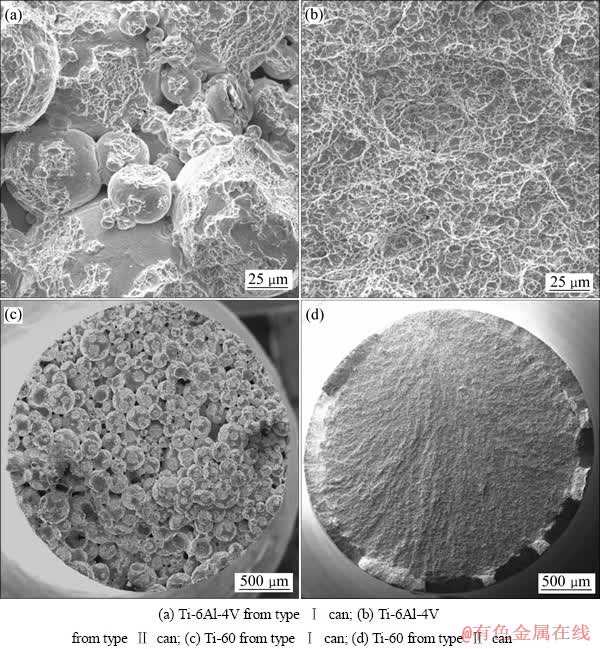

选择初步判定热等静压成功的两种包套体,切取样品进行力学性能测试和组织分析。表3和表4所列分别为Ⅰ型包套和Ⅱ型包套体热等静压后Ti-6Al-4V和Ti-60两种粉末合金的拉伸性能。两种粉末合金对应的拉伸断口形貌如图5所示。从表3可以看出,通过Ⅰ型包套体热等静压成型得到的Ti-6Al-4V合金(Ⅰ型合金)的拉伸性能明显低于通过Ⅱ型包套体获得的粉末合金(Ⅱ型合金)的。室温抗拉强度降低70 MPa左右,室温伸长率降低超过50%;高温条件下,Ⅰ型Ti-6Al-4V合金的伸长率较Ⅱ型合金的伸长率没有明显降低,然而抗拉强度恶化程度显著,350 ℃下抗拉强度降低约140 MPa,400 ℃下抗拉强度降低约170 MPa。从图5(a)可以看出,Ⅰ型Ti-6Al-4V粉末合金的断口虽然有一部分韧窝,但原始颗粒边界和大量的微观孔洞清晰可见;而Ⅱ型粉末合金的断口(见图5(b))由丰富的韧窝组成,无明显的孔洞。

表3 两种不同包套中制备的热等静压态Ti-6Al-4V的拉伸性能

Table 3 Tensile properties of HIPped Ti-6Al-4V prepared in two typical cans

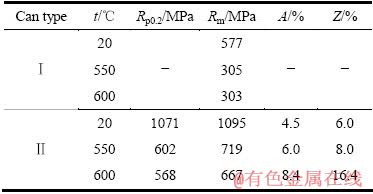

表4 两种不同包套中制备热等静压态Ti-60的拉伸性能

Table 4 Tensile properties of HIPped Ti-60 prepared in two typical cans

从表4可以看出,Ⅰ型Ti-60粉末合金未到屈服点全部发生脆断,而Ⅱ型Ti-60粉末合金的拉伸性能明显优于Ⅰ型Ti-60合金的。Ⅱ型Ti-60合金拉伸性能能够达到铸造Ti-60合金的水平[15-16]。从Ⅰ型Ti-60合金的拉伸断口(图5(c))可以看出,粉末合金未完全致密化,粉末颗粒之间的结合力较弱,在受到轴向载荷时,颗粒之间发生脱粘,从而使粉末合金未达屈服点而发生断裂。图5(d)所示为Ⅱ型Ti-60粉末合金的室温拉伸断口形貌,可以看出,断口表面并无明显的孔洞,粉末合金的致密化程度较高;断口存在剪切唇,表明Ⅱ型Ti-60合金具有一定的室温塑性。结合图5(a)和(c)可以判断出,造成Ⅰ型Ti-6Al-4V和Ti-60粉末合金拉伸性能降低的原因是粉末在热等静压致密化的过程中,包套发生了微泄漏。

图5 Ti-6Al-4V和Ti-60粉末合金的室温拉伸断口形貌

Fig. 5 Tensile fracture surfaces of P/M Ti-6Al-4V and Ti-60 at room temperature

对Ti-6Al-4V和Ti-60两种经热等静压成型后的粉末包套体(初判合格)进行典型的固溶时效热处理,结果发现:Ⅱ型包套体无异常,而Ⅰ型Ti-60粉末包套体经热处理后发生鼓包现象如图6所示。该现象说明Ⅰ型Ti-60粉末包套体中存在气体,同时也进一步佐证了Ⅰ型Ti-60粉末包套在热等静压过程中确实发生了微泄漏。

图6 Ti-60热处理后包套膨胀照片

Fig. 6 Photos of Ti60 after typical heat treatment

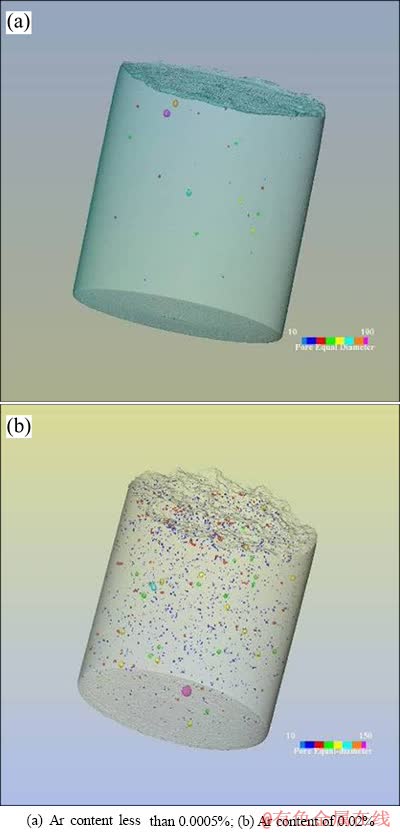

为了判断包套中封存气体的种类,分别测试了Ⅰ型Ti-6Al-4V和Ti-60粉末合金的间隙元素和氩含量,测试结果列于表5中。可以看出,Ti-6Al-4V合金的氧含量较高,但LEE等[17]的研究结果表明,粉末Ti-6Al-4V合金对氧元素的包容能力很强,氧含量在0.2%(质量分数)以下波动并不会对合金的静力学性能产生显著的影响;Ti-60合金中氮含量较高,但也属于合金设计的范围之内。粉末合金残存氩含量测试结果表明:Ti-6Al-4V合金的氩含量低于0.0005%(质量分数),而Ti-60合金中氩含量达到了0.0035%(质量分数)。氩在钛合金中的固溶度极低,说明氩气的存在源自包套发生微泄露;在粉末热等静压致密化过程中,氩气的存在会降低粉末颗粒之间的结合作用,并在粉末颗粒边界形成孔洞,影响粉末合金的致密化程度,进而严重恶化粉末合金的力学性能。

表5 Ⅰ型粉末合金中的间隙元素及Ar含量

Table 5 Interstitial elements and Ar contents in as-HIPped Ti-6Al-4V and Ti-60 alloys (mass fraction, %)

本文作者在研究Ti-Al系粉末合金致密化行为时也遇到类似的现象。在测试力学性能时发现同批次样品性能差异明显,对样品进行气体含量分析,结果显示H、O和N含量均未见异常。

拉断试样本体的Micro-CT扫描结果显示,性能正常的样品(图7(a))中,气孔较少,而性能严重下降的样品(图7(b))中,气孔较多。二次离子质谱仪检测结果表明,气孔中封存气体为氩气(尚未发表的工作),从另一个角度证明了包套确实存在泄露氩气的现象。

图7 TiAl系粉末合金Micro-CT照片

Fig. 7 Micro-CT photos of TiAl alloys

3 结论

1) Ⅰ型包套设计不合理,在热等静压过程中包套体在焊缝位置发生微泄漏的概率在20%以上;包套发生微泄漏将显著降低粉末合金的冶金质量和粉末合金力学性能的稳定性。

2) 包套泄漏渗入氩气将显著降低粉末合金的致密度,恶化粉末合金的力学性能。

3) 通过焊缝位置有限元模拟,本研究中选用的Ⅱ型包套的设计明显优于Ⅰ型包套的。有限元模拟可辅助包套设计,对制备粉末合金和构件具有一定的工程应用意义。

REFERENCES

[1] LEYENS C, PETERS M. 钛与钛合金[M]. 陈振华, 等, 译. 北京: 化学工业出版社, 2005: 1-3.

LEYENS C, PETERS M. Titanium and titanium alloy[M]. CHEN Zhen-hua, et al, transl. Beijing: Chemical Industry Press, 2005: 1-3.

[2] BOYER R R. An overview on the use of titanium in the aerospace industry[J]. Materials Science and Engineering A, 1996, 213(1): 103-114.

[3] 邬 军. Ti-5Al-2.5Sn ELI预合金粉末热等静压致密化行为研究[D]. 沈阳: 中国科学院, 2011: 7-8.

WU Jun. Densification behavior of Ti-5Al-2.5Sn ELI pre-alloyed powders under hot isostatic pressing[D]. Shenyang: Chinese Academy of Sciences, 2011: 7-8.

[4] 李少强, 刘建荣, 闫 伟, 李玉兰, 杨 锐. 高温钛合金Ti-60粉末的制备和表征[J]. 材料研究学报, 2010, 24(1): 10-16.

LI Shao-qiang, LIU Jian-rong, WANG Qing-jiang, LI Yu-lan, YANG Rui. Preparation and characterization of high temperature titanium alloy Ti-60 powder[J]. Chinese Journal of Materials Research, 2010, 24(1): 10-16.

[5] 李月珠. 快速凝固技术和材料[M]. 北京: 国防工业出版社, 1991: 6-8.

LI Yue-zhu. Rapid solidification technology and materials[M]. Beijing: National Defense Industry Press, 1991: 6-8.

[6] WANG Liang, LANG Ze-bao, SHI Hong-pei. Properties and forming process of prealloyed powder metallurgy Ti-6Al-4V alloy[J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 639-643.

[7] FROES F H, MASHL S J. The technologies of titanium powder metallurgy [J]. JOM, 2004, 56(11): 46-48.

[8] ZHANG K, MEI J, WAIN N, WU X. Effect of hot-isostatic-pressing parameters on the microstructure and properties of powder Ti-6Al-4V hot-isostatically-pressed samples[J]. Metallurgical and Materials Transactions A, 2010, 41: 1033-1045.

[9] YUAN W X, MEI J, ARMROV V, SELIVERSTOV D, WU X. Computer modeling and tooling design for near net shaped components using hot isostatic pressing[J]. Journal of Materials Processing Technology, 2007, 182: 39-49.

[10] SANCHEZ L, OUEDRAOGO E, DELLI C, FEDERZONI L. Influence of container on numerical simulation of hot isostatic pressing: Final shape profile comparison[J]. Powder Metallurgy, 2004, 47(3): 253-260.

[11] 邬 军, 徐 磊, 雷家峰, 刘羽寅. 粉末冶金TA7 ELI 合金的制备及其界面反应层[J]. 中国有色金属学报, 2010, 20(1): 299-302.

WU Jun, XU Lei, LEI Jia-feng, LIU Yu-yin. Preparation of powder metallurgy TA7 ELI alloy and its interface reaction layer[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 299-302.

[12] 程文祥, 徐 磊, 雷家峰, 刘羽寅, 杨 锐. 粉末粒度偏析对Ti-5Al-2.5Sn ELI 粉末合金拉伸性能的影响[J]. 中国有色金属学报, 2013, 23(2): 362-369.

CHENG Wen-xiang, XU Lei, LEI Jia-feng, LIU Yu-yin, YANG Rui. Effects of powder size segregation on tensile properties of Ti-5Al-2.5Sn ELI alloy powder[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 362-369.

[13] EISEN W B, FERGUSON B L, GERMAN R M, IACOCCA R, LEE P W, MADAN D, MOYER K, SANDEROW H, TRUDEL Y. ASM Handbook Vol.7: Powder Metal Technologies and Applications[M]. Novelty: ASM International, 1998: 609-615.

[14] 程文祥. Ti-5Al-2.5Sn ELI 预合金粉末热等静压致密化行为与有限元模拟研究[D]. 沈阳: 中国科学院大学, 2013: 70-75.

CHENG Wen-xiang. Densification behavior and FEM simulation of Ti-5Al-2.5Sn ELI pre-alloyed powders under hot isostatic pressing[D]. Shenyang: University of Chinese Academy of Sciences, 2013: 70-75.

[15] 王宝善, 贾蔚菊, 渠维猛, 俞汉清, 周义刚, 曾卫东, 王青江. 锻造工艺对Ti60合金棒材组织和性能的影响[J]. 钛合金进展, 2011, 28(1): 8-11.

WANG Bao-shan, JIA Wei-ju, QU Wei-meng, YU Han-qing, ZHOU Yi-gang, ZENG Wei-dong, WANG Qing-jiang. Influence of forging processes on microstructure and mechanical properties of Ti60 alloy[J]. Titanium Industry Progress, 2011, 28(1): 8-11.

[16] 魏寿庸, 石卫民, 王鼎春, 王清江, 陈志勇, 刘建荣. 600 ℃时高温钛合金(Ti60)的组织与力学性能[J]. 中国有色金属学报, 2010, 20(1): 801-806.

WEI Shou-yong, SHI Wei-min, WANG Ding-chun, WANG Qing-jiang, CHEN Zhi-yong, LIU Jian-rong. Microstructure and mechanical properties of high temperature titannium alloy Ti60 at 600 ℃[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 801-806.

[17] LEE Y T, SCHURMANN H, GRUNDHOFF K J, PETERS M. Effect of degassing treatment on microstructure and mechanical properties of P/M Ti-6Al-4V[J]. International Journal of Powder Metallurgy, 1990, 22(1): 11-16.

(编辑 龙怀中)

收稿日期:2013-08-05;修订日期:2014-06-04

通信作者:杨 锐,研究员,博士; 电话;024-23971512;E-mail: ryang@imr.ac.cn